CRE1 Amended

Diunggah oleh

Saints Burner ChristopherHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CRE1 Amended

Diunggah oleh

Saints Burner ChristopherHak Cipta:

Format Tersedia

Part 1 (a)

From the problem that facing by Dow Chemical Company, here are three main

possible reasons that cause the drop in conversion:

- The condition of Feed

- The troubles cause by the dent of CSTR

- !ista"e that cause error to the reactors and e#uipment$

%$ The condition of feed

The feed plays as a very important role in the reaction$ &hen there are slightly

differences or changes in the condition of feed, it will affect the whole reaction

including the resulting output$

%$% Feed Temperature

, ' ( ) -* C

The e#uation above is the reaction rate constant formula$ The rate constant +r, is then

converted into for plotting the graph of inverse of the reaction rate versus

conversion rate -$

.+T, is the reaction rate constant that depends on the temperature$ Thus, when the

temperature of feed is different it will affect the whole rate constant and thus gives an

impact to the graph$ Too low in feed temperature will cause the drop of rate constant

+",, where too high of Feed temperature will give a higher rate constant +",$

&e should chec" whether the heat e/changer of the feed is well function and also the

temperature sensor is giving a proper temperature reading or not$

%$0 Flow rate of feed to CSTR

&hen the flow rate of feed to CSTR is no longer optimi1ed, it will affect the

conversion rate$

's shown on the formula above, when the feed flow rate +F, is higher than optimi1ed,

the conversion +-, will drop, when the Feed flow rate +F, is lower than optimi1ed, the

conversion +-, will rise, which will give a totally different result by comparing the

graph$

&e should chec" the pump of the input feed whether it is giving a correct feed flow

rate and well function or not$

%$2 Feed concentration

)y referring bac" to the reaction rate constant formula, we can deduce that the

concentration of feed +let ' be the feed, 3'4 may affect the rate constant +r,$

&hen the feed concentration 3'4 is too low, it will decrease the reaction rate +r,$

&here too high of feed concentration may also increase the reaction rate +r,and cause

the changes in the graph$

&e should chec" the concentration of the feed properly to give an accurate result in

conversion$

0$ The trouble caused by the dent of CSTR$

's stated from the case, a dent was found in the CSTR that may have been caused by

something li"e a for"-lift, the dent may give some changes in the physical properties

of the reactor, such as the shape, volume and also the condition of the parts of CSTR

reactor such as agitator$

0$% The volume of CSTR

The appearance of the dent has already decrease the volume of CSTR, thus by

referring to the CSTR formula,

&hen the reactor volume +5, decreases, the conversion +-, will be decreased$

&e should clean the dent and chec" the current volume that the reactor is capable for

+after the formation of dent, if there is changes from the actual volume, we should fi/

it to the actual volume$

0$0 Dead 1ones

's the dent cause dead 1ones to the CSTR reactor, some composition of the feed and

the reactant may trapped inside the CSTR reactor and not flowing out to the 6FR

reactor$

Thus incomplete mi/ing occurs for the whole system, especially by the 6FR$

&e should chec" the concentration of the sample from various location of the CSTR

reactor +include and especially the dent location,

0$2 'gitator is bro"en

The dent is formed due to the CSTR reactor is hit by the for"-lift$ 7ence, we can also

assume that these collisions may cause an impact to the condition of the agitator of

the CSTR reactor, for e/ample the agitator is bro"en or loosen from the reactor$

)esides that, the 8woosh9 sound that cause by the CSTR reactor might also actually is

the noisy sound that caused by the bro"en agitator$

Chec" the CSTR agitator will be the only way to define the problem$

2$: 7uman mista"e that cause error to the reactors and e#uipment$

!ista"es such as wrongly e#uip or wrongly label of the conversion of 6FR or CSTR

+or both, may give false result$

&e should chec" well and double confirmed again the conversion of the 6FR and

CSTR reactor, before we start the reaction$

;f the problem still e/ist, it is force to ta"e a new or another set of the reactor to run

the reaction $

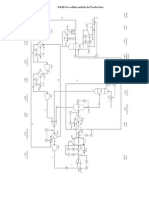

PART 1(b)

6FR -* CSTR

&here

Since we already "now the first conversion by the 6FR reactor, which is :$0%, thus we

can straight proceed to the calculation of CSTR$

)y using trial and error method, with referring to the graph of inversion of rate of

reaction versus conversion :

- < :$= ,

:$%0 < :$> +:$=-$:$0%,

<:$02? +@AT BCD'EF,

- < :$G,

:$%0 < :$%= +:$G-:$0%,

<:$:==0 +@AT BCD'EF,

Since :$%0 is between :$02? and :$:==0, we can deduce that the conversion value is

between :$G and :$=$

- < :$GH,

:$%0 < :$0H +:$GH-:$0%,

< :$%2H +@AT BCD'EF )ut the answer is getting closer,

&e can minimi1e the range of - into :$GI-I:$GH

- < :$G2,

:$%0 < :$00H +:$G2-:$0%,

< :$%%G

6roved, with -<:$G2$

Thus, the new conversion rate as shown in the graph form will be:

Anda mungkin juga menyukai

- Working Guide to Reservoir Rock Properties and Fluid FlowDari EverandWorking Guide to Reservoir Rock Properties and Fluid FlowPenilaian: 3 dari 5 bintang3/5 (1)

- Control of DC Motor Using Different Control StrategiesDari EverandControl of DC Motor Using Different Control StrategiesBelum ada peringkat

- 1999 Technical Inquiry ASME PTC 6A-1982 Section VIDokumen7 halaman1999 Technical Inquiry ASME PTC 6A-1982 Section VIag191182100% (1)

- Anleitung CVT B EnglischDokumen14 halamanAnleitung CVT B EnglischN193746Belum ada peringkat

- Constant Stirred Tank Reactor - Technical DefinitionDokumen6 halamanConstant Stirred Tank Reactor - Technical DefinitionAnthony RivasBelum ada peringkat

- HW 01 SolutionDokumen12 halamanHW 01 SolutionJuan Sebastian Suarez Ospina63% (8)

- CHEN3003 IndividualDokumen12 halamanCHEN3003 IndividualsadanakarunarathneBelum ada peringkat

- CRE Notes 14 Intro To CSTRsDokumen11 halamanCRE Notes 14 Intro To CSTRsYayan IndrayaniBelum ada peringkat

- Shrinkage FactorDokumen2 halamanShrinkage FactorRadovan JovicinBelum ada peringkat

- Vapor Lock in A Gasoline Fuel Supply SystemDokumen25 halamanVapor Lock in A Gasoline Fuel Supply SystemSusheel WankhedeBelum ada peringkat

- Distillation StartupDokumen4 halamanDistillation StartupsundharBelum ada peringkat

- Lab Report CSTR 40LDokumen26 halamanLab Report CSTR 40LAnonymous NyvKBW33% (3)

- Short Project On MBAlDokumen19 halamanShort Project On MBAlirene pafraBelum ada peringkat

- TEP4195 TURBOMACHINERY VALVE CONTROLLED SYSTEMSDokumen15 halamanTEP4195 TURBOMACHINERY VALVE CONTROLLED SYSTEMSCatalin PruncuBelum ada peringkat

- Modes of Plant OperationDokumen4 halamanModes of Plant Operationsachin_vjtiBelum ada peringkat

- Production Method For Violent TCB Jet Plasma From CavityDokumen8 halamanProduction Method For Violent TCB Jet Plasma From CavityBarrett GibsonBelum ada peringkat

- Gas-phase reaction plug flow CSTR reactor volumes conversionsDokumen8 halamanGas-phase reaction plug flow CSTR reactor volumes conversionsAlejandra SanchezBelum ada peringkat

- Water Tank System ResponseDokumen23 halamanWater Tank System ResponseChristian Eduardo Fabian100% (1)

- Parallel Operation of GeneratorsDokumen6 halamanParallel Operation of GeneratorsKhaldoon AlnashiBelum ada peringkat

- Polymer Engineering ExerciseDokumen10 halamanPolymer Engineering ExerciseMiguel A. GraneroBelum ada peringkat

- Saponification Reaction Kinetics in a PFRDokumen19 halamanSaponification Reaction Kinetics in a PFRKangae IlhamBelum ada peringkat

- Parameters Influencing Boiler Efficiency: IssueDokumen11 halamanParameters Influencing Boiler Efficiency: IssueJohn NgwokeBelum ada peringkat

- Causes and Cures of The Dynamic ShrinkDokumen3 halamanCauses and Cures of The Dynamic Shrinkmiths_0087Belum ada peringkat

- Module 1 - 7 PSP Overcurrent Protection TSM PSMDokumen19 halamanModule 1 - 7 PSP Overcurrent Protection TSM PSMsrinimeha@gmail.comBelum ada peringkat

- Purifier optimization lab resultsDokumen8 halamanPurifier optimization lab resultspapaki2Belum ada peringkat

- TRK 01 - Conversion & Reactor SizingDokumen17 halamanTRK 01 - Conversion & Reactor SizinggifitrianggraeniBelum ada peringkat

- CSTR Saponification Reaction AnalysisDokumen26 halamanCSTR Saponification Reaction AnalysisHazieqahBelum ada peringkat

- Reservoir-Fluid Property CorrelationsDokumen8 halamanReservoir-Fluid Property Correlationscapl930Belum ada peringkat

- CHEN3005 Process Control Tutorial 1Dokumen4 halamanCHEN3005 Process Control Tutorial 1eddyBelum ada peringkat

- Reactor Non IsothermicsDokumen9 halamanReactor Non IsothermicsMelgi159Belum ada peringkat

- Troubleshooting of Amine RegnDokumen8 halamanTroubleshooting of Amine RegnSekarNTutyBelum ada peringkat

- Proportionality of hydraulic control systemsDokumen7 halamanProportionality of hydraulic control systemsradharaman_znaBelum ada peringkat

- ECE 4501 Motor Drives Lab Manual Buck and Four-Quadrant Chopper DrivesDokumen12 halamanECE 4501 Motor Drives Lab Manual Buck and Four-Quadrant Chopper DrivesJose AguilarBelum ada peringkat

- CSTR Experiment: Effects of Process Variables on Reaction RateDokumen17 halamanCSTR Experiment: Effects of Process Variables on Reaction RateAllyssa BadilloBelum ada peringkat

- Performance Analysis of The Catalytic Converter: Experimental WorkDokumen15 halamanPerformance Analysis of The Catalytic Converter: Experimental WorkRamya MandavaBelum ada peringkat

- Moog ValveDokumen76 halamanMoog Valveramkrishna100% (1)

- Medición Del Factor de Contracción Ó de Merma en El Sitio Del PozoDokumen5 halamanMedición Del Factor de Contracción Ó de Merma en El Sitio Del PozoMagno GuzmanBelum ada peringkat

- Optimise Pump MaintenanceDokumen5 halamanOptimise Pump MaintenancebajrangkaswanBelum ada peringkat

- Runge KuttaDokumen10 halamanRunge Kuttaadithya100% (1)

- Chemical Engineering Laboratory Ii: /DT Term Is Zero SinceDokumen9 halamanChemical Engineering Laboratory Ii: /DT Term Is Zero SinceKayathre Raveendran100% (1)

- GCV SRV Calib..Dokumen36 halamanGCV SRV Calib..bhavansaravanabeBelum ada peringkat

- Improve Control: Level LoopsDokumen8 halamanImprove Control: Level LoopsCraigUnderwoodBelum ada peringkat

- Conversion & Reactor SizingDokumen39 halamanConversion & Reactor SizingReyhan97Belum ada peringkat

- Practice Problem Set 1Dokumen2 halamanPractice Problem Set 1oprudra2000Belum ada peringkat

- Optimizing Temperature in Fixed-Bed ReactorsDokumen15 halamanOptimizing Temperature in Fixed-Bed ReactorsvijendranbBelum ada peringkat

- MCQDokumen26 halamanMCQAbhijit Nath100% (1)

- Marcet BoilerDokumen7 halamanMarcet BoilerSt Oong100% (1)

- Influence of The Reynolds Number On The Performance of Centrifugal CompressorsDokumen3 halamanInfluence of The Reynolds Number On The Performance of Centrifugal CompressorsAmbrish SinghBelum ada peringkat

- Effect of superheating on ORC efficiencyDokumen9 halamanEffect of superheating on ORC efficiencyVLADIMIRBelum ada peringkat

- Dynamics of H2 Production by Steam ReformingDokumen7 halamanDynamics of H2 Production by Steam ReformingMuhammad HarisBelum ada peringkat

- Procedures: Safety Googles, Gloves and Lab Coat Were Worn When Handling These Chemicals)Dokumen4 halamanProcedures: Safety Googles, Gloves and Lab Coat Were Worn When Handling These Chemicals)JxinLeeBelum ada peringkat

- Wartsila CPP PaperDokumen4 halamanWartsila CPP Papergatheringforgardner9550Belum ada peringkat

- Chemical Reactors: DC DT RDokumen8 halamanChemical Reactors: DC DT ROsas Jessica UwoghirenBelum ada peringkat

- Effect of Step Changes On Volume and Pressure in A Separator 1. SummaryDokumen9 halamanEffect of Step Changes On Volume and Pressure in A Separator 1. SummaryBernard HoeBelum ada peringkat

- Control ActionsDokumen5 halamanControl ActionsJitendra KumarBelum ada peringkat

- CREII-Module-I - Lecture 5 PDFDokumen17 halamanCREII-Module-I - Lecture 5 PDFshubhamBelum ada peringkat

- Anti Surge ControlDokumen7 halamanAnti Surge Controlachueth100% (1)

- Introduction To CSTR and PFRDokumen4 halamanIntroduction To CSTR and PFRaravind1997muraliBelum ada peringkat

- Distillation Column Relief Loads - Part 1Dokumen8 halamanDistillation Column Relief Loads - Part 1Behnam Hosseinzadeh50% (2)

- Tutorial 5Dokumen7 halamanTutorial 5Saints Burner ChristopherBelum ada peringkat

- UEMK4353 Assignment - Mech DesignDokumen2 halamanUEMK4353 Assignment - Mech DesignSaints Burner ChristopherBelum ada peringkat

- Visio Stream Table Part3Dokumen1 halamanVisio Stream Table Part3Saints Burner ChristopherBelum ada peringkat

- Garbage Enzyme University SarawakDokumen6 halamanGarbage Enzyme University SarawakSaints Burner ChristopherBelum ada peringkat

- HAZOP TemplateDokumen12 halamanHAZOP TemplateSaints Burner ChristopherBelum ada peringkat

- Disc Bowl Flow ChartDokumen3 halamanDisc Bowl Flow ChartSaints Burner ChristopherBelum ada peringkat

- Industrial Training Report UtarDokumen29 halamanIndustrial Training Report UtarSaints Burner Christopher100% (1)

- Visio IndexDokumen1 halamanVisio IndexSaints Burner ChristopherBelum ada peringkat

- P&IDDokumen1 halamanP&IDSaints Burner ChristopherBelum ada peringkat

- Gas Absorption Report PDFDokumen13 halamanGas Absorption Report PDFSaints Burner Christopher100% (1)

- Fluidiesed BedDokumen14 halamanFluidiesed BedSaints Burner ChristopherBelum ada peringkat

- Chemical Reaction Engineering Catalyst ResearchDokumen4 halamanChemical Reaction Engineering Catalyst ResearchSaints Burner ChristopherBelum ada peringkat

- Introduction For Batch Reactor ExperimentDokumen5 halamanIntroduction For Batch Reactor ExperimentSaints Burner Christopher25% (4)

- Experiment 1: Batch Reactor: Experiment 1: 6.1. Calibration Curve - Conductivity Vs ConversionDokumen2 halamanExperiment 1: Batch Reactor: Experiment 1: 6.1. Calibration Curve - Conductivity Vs ConversionSaints Burner ChristopherBelum ada peringkat

- Foodchapter 1 PDFDokumen1 halamanFoodchapter 1 PDFSaints Burner ChristopherBelum ada peringkat

- Assignment 1 (CRE 2)Dokumen1 halamanAssignment 1 (CRE 2)Saints Burner ChristopherBelum ada peringkat

- Microsoft Word - Cpci Assignment NewDokumen25 halamanMicrosoft Word - Cpci Assignment NewSaints Burner ChristopherBelum ada peringkat

- Chemical Engineering Compulsory SubjectDokumen1 halamanChemical Engineering Compulsory SubjectSaints Burner ChristopherBelum ada peringkat

- Liquid phase cis–trans isomerization reactor sizingDokumen21 halamanLiquid phase cis–trans isomerization reactor sizingSaints Burner Christopher100% (1)

- Dow Chemical Company CSTR IssuesDokumen7 halamanDow Chemical Company CSTR IssuesSaints Burner ChristopherBelum ada peringkat

- Table 10.4 Food Packaging ConsiderationsDokumen1 halamanTable 10.4 Food Packaging ConsiderationsSaints Burner ChristopherBelum ada peringkat

- Chapter 3 - Tutorial SolutionDokumen8 halamanChapter 3 - Tutorial SolutionSaints Burner ChristopherBelum ada peringkat

- For Temperature Changes Per TimeDokumen1 halamanFor Temperature Changes Per TimeSaints Burner ChristopherBelum ada peringkat

- For Temperature Changes Per TimeDokumen1 halamanFor Temperature Changes Per TimeSaints Burner ChristopherBelum ada peringkat

- Ni Hao Hi Chi Le Ma? Have You Eaten? Zai Jian Good ByeDokumen1 halamanNi Hao Hi Chi Le Ma? Have You Eaten? Zai Jian Good ByeSaints Burner ChristopherBelum ada peringkat

- For Temperature Changes Per TimeDokumen1 halamanFor Temperature Changes Per TimeSaints Burner ChristopherBelum ada peringkat

- Eis AssignmentDokumen4 halamanEis AssignmentSaints Burner ChristopherBelum ada peringkat

- Flash Card FrenchDokumen6 halamanFlash Card FrenchSaints Burner ChristopherBelum ada peringkat

- French Flash Card 18Dokumen1 halamanFrench Flash Card 18Saints Burner ChristopherBelum ada peringkat