Data Sheet (English) - 8001

Diunggah oleh

Nabil ShaukatHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Data Sheet (English) - 8001

Diunggah oleh

Nabil ShaukatHak Cipta:

Format Tersedia

(732) 938-2000 / 800-LAB-VOLT, FAX: (732) 774-8573, E-MAIL: us@labvolt.

com

(418) 849-1000 / 800-LAB-VOLT, FAX: (418) 849-1666, E-MAIL: ca@labvolt.com

INTERNET: http://www.labvolt.com

System shown with optional equipment.

A

Electric Power / Controls 0.2-kW ELECTROMECHANICAL

TRAINING SYSTEM, MODEL 8001 0.2 kW

GENERAL DESCRIPTION

The Lab-Volt 0.2-kW Electromechanical Training System

(EMS), Model 8001, is a modern modular instructional

program. It represents an approach to teaching electric

power technology through laboratory observations. The

program, presented in four subsystems, deals with the

different techniques associated with the generation and

use of electrical energy. The subsystems cover the com-

mon machines, and each subsystem is offered with its

courseware presented in a student manual.

Each subsystem is available as a package that

consists of the equipment necessary to perform the

laboratory exercises presented in the correlated student

manual.

0.2-kW ELECTROMECHANICAL TRAINING SYSTEM

MODEL 8001

This modular instructional program gives the in-

structor complete versatility in selecting a program

adapted to students specific career objectives.

The EMS System was developed by educators to

satisfy educational requirements that include industrial

applications of electric power technology. The design

objective was to develop a low-power (0.2 kW or hp)

educational system with equipment that operates like

industrial equipment. Through careful attention to

engineering detail, the Lab-Volt EMS System meets this

objective, and in so doing, provides laboratory results that

are easy to understand, with data values that are easily

observed. The data, when applied to formulas, provides

results that verify electrical laws rather than deny them

because of large operational tolerance errors.

Laboratory manuals guide students step-by-step

through the experiments and provide the necessary theo-

retical background to allow students to successfully com-

plete the educational objectives. These manuals contain

experiments that correlate with the training equipment for

hands-on involvement with the subject matter. The

instructor can select those experiments that will satisfy

the objectives of technical courses or university programs.

The flexibility of this system allows students to use their

own initiative during the laboratory sessions. Under the

direction of an instructor, students can gain the required

competencies for successful employment.

The systems modular approach allows new equip-

ment to be added to existing EMS laboratories without

needless duplication of equipment. There are two

standard module sizes: full size, 308 mm (12.1 in) high,

and half size, 154 mm (6.1 in) high. All modules can be

inserted into a Mobile Workstation (Model 8110). With the

exception of motor modules, they all have steel face

plates. The modules are constructed of heavy-gauge

steel, finished in baked enamel. Symbols and diagrams

specific to each module are clearly silk-screened on the

steel faceplates. Standard, color-coded, 4-mm safety

jacks are used to interconnect all system components.

The mobile workstation is equipped with four swivel

casters. It contains a general storage cabinet, a pull-out

work surface at standard table or desk level, and spaces

to insert the modules required for each experiment. Six

full-size, or twelve half-size, modules plus three additional

half-size modules can be used simultaneously. For

applications requiring additional modules, a Three-Module

Workstation (Model 8131) can easily be bolted on top of

the mobile workstation. The modules are guided into

position along stainless steel guide rails and are held

securely in place by a holding mechanism. Front-mounted

release levers allow easy removal of modules from the

workstation. Safety locking devices prevent students from

removing modules from the workstation during lab

exercises.

All unused modules can be placed in a Storage

Cabinet (Model 8150). Only the necessary modules for

a given experiment are placed in the console so that

students are not distracted by the unused instruments.

All motor are mounted in standard size modules.

These modules are equipped with a clear plastic

faceplate fitted with a chrome-plated piano hinge. The

faceplate can be lowered for access to the machine, and

when closed, it is secured by two quick-lock fasteners.

Each motor module is provided with a safety locking

device that prevents students from lowering the faceplate

during lab exercises.

All machines have open bell housings (front and rear)

to permit visual inspection of the internal construction and

observation of the machine during operation with the aid

of a Stroboscope (Model 8922). Externally mounted

components such as centrifugal switches, capacitors,

brushes, slip rings, and commutators in addition to the

exposed squirrel cage and wound rotors permit

students to clearly determine component function as well

as to understand relative position, turns, and wire sizes

of the machinery.

The shaft of each machine has a concave slotted end

to facilitate the use of tachometers, holding brakes,

plugging switches, and inertia wheels. A geared pulley

is fitted on each machine shaft to mechanically couple

machines together using a non-slip timing belt. The

Timing Belt (Model 8942) has molded teeth, which mesh

with the geared machine pulleys. Tension for the timing

belt is provided by the idler-tensioning ball bearings

mounted on each machine module.

Resistive, inductive, and capacitive load components,

housed in separate modules, are designed to provide

equal load magnitudes for all three types of loads. The

load impedance can be varied in equal steps of unity

value by switches provided in all load modules. These

characteristics simplify calculations required in the

learning process.

The metering modules are designed to cover the

complete range of required measurements with a

minimum number of meters. The AC ammeter and

voltmeter modules each contains three meters for

simultaneously measuring all three currents and voltages

on a three-phase system. All meters are designed to

sustain starting currents even when used on a low range.

Wattmeters are internally connected to read power

directly when the input is connected to the source and the

output to the load. Protection of vulnerable meter

components is accomplished without fuses.

A separate power supply for each workstation

provides total control of the necessary power sources.

This allows the student maximum use of laboratory

equipment and reduces interference with other

simultaneous laboratory experiments. The power supply

module provides all AC and DC power sources required

at each station.

The speed of the machines can be measured with a

hand tachometer (Model 8920), or an optional electrical

tachometer (Model 8931), which is easily mounted on the

machine.

The machines and various components of the system

are connected with flexible PVC-insulated connecting

leads terminated with 4-mm safety plugs. These leads

allow safe connection of components without danger of

electrical shock, since the live parts of their plugs are

concealed and insulated in such a way that they cannot

be contacted accidentally. They come in three different

lengths, each identified by a distinctive color. A handy

rack can be attached to the workstation side for inventory

and storage of these leads.

TABLE OF CONTENTS OF THE STUDENT MANUALS

Power Circuits, Volume 1 (25986-00)

Series and Parallel Equivalent Resistances

Resistances in Parallel

Resistances in Series and in Series-Parallel

Safety and the Power Supply

Ohms Law

Circuit Solution, Part I

Circuit Solution, Part II

Power in DC Circuits, Part I

Power in DC Circuits, Part II

The Transmission Line

AC Voltage and Current

AC Voltage and Current Measurement

The Wattmeter

Phase Angle, Real and Apparent Power

Capacitive Reactance

Inductive Reactance

Watt, Var, Volt-Ampere and Power Factor

Vectors and Phasors Series Circuits

Vectors and Phasors Parallel Circuits

Impedance

Three-Phase Circuits

Three-Phase Watts, Vars and Volt-Amperes

Three-Phase Power Measurement

Phase Sequence

DC Machines, Volume 2 (25987-00)

Prime Mover & Torque Measurement

The Direct Current Motor, Part I

The Direct Current Motor, Part II

The DC Shunt Motor

The DC Series Motor

The DC Compound Motor

The DC Separately-Excited Shunt Generator

The DC Self-Excited Shunt Generator

The DC Compound Generator

The DC Motor Starter

SCR Speed Control, Part I

SCR Speed Control, Part II

Single-Phase Transformers and AC Machines,

Volume 3 (25988-00)

The Single-Phase Transformer

Transformer Polarity

Transformer Regulation

The Autotransformer

Transformers in Parallel

Distribution Transformer

Prime Mover & Torque Measurement

The Split-Phase Induction Motor, Part I

The Split-Phase Induction Motor, Part II

The Split-Phase Induction Motor, Part III

The Capacitor-Start Motor

The Capacitor-Run Motor

The Universal Motor, Part I

The Universal Motor, Part II

Three-Phase Transformers and AC Machines,

Volume 4 (25989-00)

Three-Phase Transformer Connections

Prime Mover & Torque Measurement

The Wound-Rotor Induction Motor, Part I

The Wound-Rotor Induction Motor, Part II

The Wound-Rotor Induction Motor, Part III

The Squirrel-Cage Induction Motor

The Synchronous Motor, Part I

The Synchronous Motor, Part II

The Synchronous Motor, Part III

The Three-Phase Alternator

The Alternator Under Load

Alternator Synchronization

Alternator Power

The Three-Phase Induction Motor Starters

Frequency Conversion

Reactance and Frequency

Selsyn Control

Investigations in Electric Power

Technology (11627-00)

Series and Parallel Equivalent Resistances

Resistances in Parallel

Resistances in Series and in Series-Parallel

Safety and the Power Supply

Ohms Law

Circuit Solution, Part I

Circuit Solution, Part II

Power in DC Circuits, Part I

Power in DC Circuits, Part II

The Transmission Line

The Direct Current Motor, Part I

The Direct Current Motor, Part II

AC Voltage and Current

AC Voltage and Current Measurement

0.2-kW ELECTROMECHANICAL TRAINING SYSTEM

MODEL 8001

Investigations in Electric Power

Technology (11627-00) (contd')

The Wattmeter

Phase Angle, Real and Apparent Power

Capacitive Reactance

Inductive Reactance

Watt, Var, Volt-Ampere and Power Factor

Vectors and Phasors - Series Circuits

Vectors and Phasors - Parallel Circuits

Impedance

The Synchronous Motor and the

Electrodynamometer

The DC Shunt Motor

The DC Series Motor

The DC Compound Motor

The DC Separately-Excited Shunt Generator

The DC Self-Excited Shunt Generator

The DC Compound Generator

The DC Series Generator

The Split-Phase Induction Motor, Part I

The Split-Phase Induction Motor, Part II

The Split-Phase Induction Motor, Part III

The Capacitor-Start Motor

The Capacitor-Run Motor

The Universal Motor, Part I

The Universal Motor, Part II

The Single-Phase Transformer

Transformer Polarity

Transformer Regulation

The Autotransformer

Transformers in Parallel

Distribution Transformer

1

Three-Phase Circuits

Three-Phase Watts, Vars and Volt-Amperes

Three-Phase Power Measurement

Three-Phase Transformer Connections

The Wound-Rotor Induction Motor, Part I

The Wound-Rotor Induction Motor, Part II

The Wound-Rotor Induction Motor, Part III

The Squirrel-Cage Induction Motor

The Synchronous Motor, Part I

The Synchronous Motor, Part II

The Synchronous Motor, Part III

The Three-Phase Alternator

The Alternator Under Load

Alternator Synchronization

Alternator Power

Phase Sequence

Frequency Conversion

Reactance and Frequency

Three-Phase to Two-Phase Conversion

Selsyn Control

SCR Speed Control, Part I

SCR Speed Control, Part II

SYSTEM CONFIGURATIONS

DESCRIPTION SYSTEM

Complete 0.2-kW EMS - Modular

(supported by four student manuals, Vol. 1 to 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8001-1

0.2-kW EMS - Power Circuits

(supported by student manual Vol. 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8001-2

0.2-kW EMS - DC Machines

(supported by student manual Vol. 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8001-3

0.2-kW EMS - Single-Phase Transformers and AC Machines

(supported by student manual Vol. 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8001-4

0.2-kW EMS - Three-Phase Transformers and AC Machines

(supported by student manual Vol. 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8001-5

Complete 0.2-kW Electromechanical Training System (EMS)

(supported by a 65-experiment laboratory manual - Investigations in Electric Power Technology) . . . . . . . . . . 8001-6

Compared to the "Complete 0.2-kW EMS Modular" system, Model 8001-1, this system does not include the two following exercises : "The

DC Motor Starter" and "The Three-Phase Induction Motor Starters". On the other end, it includes the two following exercises : "The DC

Series Generator" and "Three-Phase to Two-Phase Conversion".

1

Not Available in 220/380 - 50 Hz Laboratory Manual

2

lbf@in scale: Model 8911; N@m scale: 8911-1

LIST OF EQUIPMENT FOR DIFFERENT SYSTEM CONFIGURATIONS

SYSTEM

8

0

0

1

-

1

8

0

0

1

-

2

8

0

0

1

-

3

8

0

0

1

-

4

8

0

0

1

-

5

8

0

0

1

-

6

DESCRIPTION MODEL NUMBER QTY

Mobile Workstation 8110 1 1 1 1 1 1

Storage Cabinet 8150 1 1 1 1 1 1

DC Motor/Generator 8211 1 1 1 1

Four-Pole Squirrel-Cage Induction Motor 8221 1 1 1

Three-Phase Wound-Rotor Induction Motor 8231 1 1 1

Three-Phase Synchronous Motor/Generator 8241 1 1 1 1

Capacitor-Start Motor 8251 1 1 1

Capacitor-Run Motor 8253 1 1 1

Universal Motor 8254 1 1 1

Resistive Load 8311 1 1 1 1 1 2

Inductive Load 8321 1 1 1 1 1

Capacitive Load 8331 1 1 1 1 2

Single-Phase Transformer 8341-2 3 2 3 3

DC Voltmeter/Ammeter 8412 1 1 1 1 1 1

AC Ammeter 8425 1 1 1 1 1 1

AC Voltmeter 8426 1 1 1 1 1 1

Single-Phase Wattmeter 8431 1 1 1 1

Three-Phase Wattmeter 8441 1 1 1 1

Synchronizing Module 8621 1 1 1 1

Manual DC Motor Starter 8631 1 1

Synchronous Motor Starter 8641 1 1

Three-Phase Full-Voltage Starter 8651 1 1

Three-Phase Rheostat 8731 1 1 1

Power Supply 8821 1 1 1 1 1 1

Electrodynamometer 89111

2

1 1 1 1 1

Digital Tachometer 8920 1 1 1 1 1

Timing Belt 8942 1 1 1 1 1

Digital Multimeter 8946

2

1 1 1

Connection Leads 8951 1 1 1 1 1 1

Thyristor Speed Controller 9017 1 1 1

Student Manuals and Instructor Guides included (see Courseware section) 1 1 1 1 1 1

OPTIONAL EQUIPMENT

DESCRIPTION ORDERING NUMBER

Workstation (can replace model 8110) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8134

DC Voltmeter/Ammeter (can replace model 8412) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8412-1

Full-Size Blank Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8160

Half-Size Blank Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8161

Prony Brake (can replace model 8911) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8913

Prony Brake (can replace model 8911-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8913-1

Speed Sensor / Tachometer (can replace model 8920) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8931

Four-Quadrant Dynamometer/Power Supply (can replace model 8911) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8960-B

0.2-kW ELECTROMECHANICAL TRAINING SYSTEM

MODEL 8001

3

The ordering numbers shown apply to the English 120-V version. Other versions are available. Refer to the Ordering Numbers section.

4

N/A = Not available

COURSEWARE

ORDERING NUMBERS

3

Student Manuals

Investigations In Electric Power Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11627-00

Power Circuits, Volume 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25986-00

DC Machines, Volume 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25987-00

Single-Phase Transformers and AC Machines, Volume 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25988-00

Three-Phase Transformers and AC Machines, Volume 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25989-00

Instructor Guides

Investigations In Electric Power Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11627-01

Modularized Systems (Volumes 1 to 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25990-01

Textbook (optional)

Electrical Power Technology, T. Wildi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17708-00

Manuals on CD-ROM (optional)

Manuals 120 V (11627, 25986, 25987, 25988, 25989, 11627-1, and 25990-1) . . . . . . . . . . . . . . . . . . . . . . 25986-A0

Manuals 220 V (24769, 25986-5, 25986-15, 25987-5, 25988-5, 25989-5, and 24769-1) . . . . . . . . . . . . . . 25986-A5

Manuals 240 V (25986-0A, 25986-1A, 25987-0A, 25988-0A, and 25989-0A) . . . . . . . . . . . . . . . . . . . . . . . 25986-AA

SPECIFICATIONS

Model 8001 0.2-kW Electromechanical Training System 120/208 V 60 Hz 220/380 V 50 Hz 240/415 V 50 Hz

Power Requirement Current 15 A 10 A

Electrical Distribution 3-phase, 5 wires, star (wye) connected, including neutral and ground

Wall Outlet (Lab-Volt P/N) 24582-00 24183-00 N/A

4

Physical Characteristics Space required per system workstation 5 m

2

(54 ft

2

)

Standard-size module dimensions (H x W x D) 308 x 286 x 419 mm (12.1 x 11.3 x 16.5 in)

Half-size module dimensions (H x W x D) 154 x 286 x 419 mm (6.1 x 11.3 x 16.5 in)

Net Weight: System 8001-1 439 kg (966 lb)

System 8001-2 267 kg (587 lb)

System 8001-3 307 kg (675 lb)

System 8001-4 332 kg (730 lb)

System 8001-5 371 kg (816 lb)

System 8001-6 440 kg (970 lb)

ORDERING NUMBERS

120/208 V 60 Hz 220/380 V 50 Hz 240/415 V 50 Hz

ENGLISH FRENCH SPANISH ENGLISH FRENCH SPANISH ENGLISH

8001-10 8001-11 8001-12 8001-15 8001-16 8001-17 8001-1A

8001-20 8001-21 8001-22 8001-25 8001-26 8001-27 8001-2A

8001-30 8001-31 8001-32 8001-35 8001-36 8001-37 8001-3A

8001-40 8001-41 8001-42 8001-45 8001-46 8001-47 8001-4A

8001-50 8001-51 8001-52 8001-55 8001-56 8001-57 8001-5A

8001-60 8001-61 8001-62 8001-65 8001-66 8001-67 8001-6A

8110-20 8110-20 8110-20 8110-20 8110-20 8110-20 8110-20

8134-20 8134-20 8134-20 8134-20 8134-20 8134-20 8134-20

8150-10 8150-10 8150-10 8150-10 8150-10 8150-10 8150-10

8160-00 8160-00 8160-00 8160-00 8160-00 8160-00 8160-00

8161-00 8161-00 8161-00 8161-00 8161-00 8161-00 8161-00

8211-00 8211-01 8211-02 8211-05 8211-06 8211-07 8211-0A

8221-00 8221-01 8221-02 8221-05 8221-06 8221-07 8221-0A

8231-00 8231-01 8231-02 8231-05 8231-06 8231-07 8231-0A

8241-00 8241-01 8241-02 8241-05 8241-06 8241-07 8241-0A

8251-00 8251-01 8251-02 8251-05 8251-06 8251-07 8251-0A

8253-00 8253-01 8253-02 8253-05 8253-06 8253-07 8253-0A

8254-00 8254-01 8254-02 8254-05 8254-06 8254-07 8254-0A

8311-00 8311-01 8311-02 8311-05 8311-06 8311-07 8311-0A

8321-00 8321-01 8321-02 8321-05 8321-06 8321-07 8321-0A

8331-00 8331-01 8331-02 8331-05 8331-06 8331-07 8331-0A

8341-20 8341-21 8341-22 8341-25 8341-26 8341-27 8341-2A

8412-00 8412-01 8412-02 8412-05 8412-06 8412-07 8412-05

8412-10 8412-11 8412-12 8412-15 8412-16 8412-17 8412-15

8425-00 8425-01 8425-02 8425-05 8425-06 8425-07 8425-0A

8426-00 8426-01 8426-02 8426-05 8426-06 8426-07 8426-05

8431-20 8431-21 8431-22 8431-25 8431-26 8431-27 8431-25

8441-20 8441-21 8441-22 8441-25 8441-26 8441-27 8441-2A

8621-00 8621-01 8621-02 8621-05 8621-06 8621-07 8621-0A

8631-00 8631-01 8631-02 8631-05 8631-06 8631-07 8631-05

8641-00 8641-01 8641-02 8641-05 8641-06 8641-07 8641-0A

8651-00 8651-01 8651-02 8651-05 8651-06 8651-07 8651-0A

8731-00 8731-01 8731-02 8731-05 8731-06 8731-07 8731-0A

8821-20 8821-21 8821-22 8821-25 8821-26 8821-27 8821-2A

8911-00 8911-01 8911-02 N/A N/A N/A N/A

8911-10 8911-11 8911-12 8911-15 8911-16 8911-17 8911-15

8913-00 8913-01 8913-02 8913-00 8913-01 8913-02 8913-00

8913-10 8913-11 8913-12 8913-10 8913-11 8913-12 8913-10

8920-40 8920-40 8920-40 8920-40 8920-40 8920-40 8920-40

8931-00 8931-01 8931-02 8931-00 8931-01 8931-02 8931-00

8942-00 8942-00 8942-00 8942-00 8942-00 8942-00 8942-00

8946-20 8946-20 8946-20 8946-20 8946-20 8946-20 8946-20

8951-00 8951-00 8951-00 8951-00 8951-00 8951-00 8951-00

8960-B0 8960-B1 8960-B2 8960-B5 8960-B6 8960-B7 8960-BA

9017-00 9017-01 9017-02 9017-00 9017-01 9017-02 9017-00

Table 1. Equipment Ordering Numbers (continued on next page).

0.2-kW ELECTROMECHANICAL TRAINING SYSTEM

MODEL 8001

5

TBE = To be established (Contact your Lab-Volt representative for additional information.)

Reflecting Lab-Volt's commitment to high quality standards in product, design, development, production, installation, and service, our manufacturing and distribution

facility has received the ISO 9001 certification.

Lab-Volt reserves the right to make product improvements at any time and without notice and is not responsible for typographical errors. Lab-Volt recognizes all product

names used herein as trademarks or registered trademarks of their respective holders. Lab-Volt 2013. All rights reserved.

15068-00 Rev. H5

ORDERING NUMBERS (cont'd)

120/208 V 60 Hz 220/380 V 50 Hz 240/415 V 50 Hz

ENGLISH FRENCH SPANISH ENGLISH FRENCH SPANISH ENGLISH

11627-00 23217-00 11627-04 24769-00 24770-00 N/A 11627-0A

11627-01 N/A 11627-05 24769-01 11627-16 N/A 11627-1A

17708-00 25267-00 N/A 17708-00 25267-00 N/A 17708-00

25986-00 N/A 25986-02 25986-05 N/A N/A 25986-0A

25986-A0 25986-A1 25986-A2 25986-A5 TBE

5

TBE 25986-AA

25987-00 N/A 25987-02 25987-05 N/A N/A 25987-0A

25988-00 N/A 25988-02 25988-05 N/A N/A 25988-0A

25989-00 N/A 25989-02 25989-05 N/A N/A 25989-0A

25990-01 N/A 25990-12 25986-15 N/A N/A 25986-1A

Table 1. Equipment Ordering Numbers (cont'd)

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Top 10 API Security Risks 2019 PDFDokumen31 halamanTop 10 API Security Risks 2019 PDFNabil ShaukatBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Changes in PMBOK® Guide 6th Edition08042018 PDFDokumen1 halamanChanges in PMBOK® Guide 6th Edition08042018 PDFNabil ShaukatBelum ada peringkat

- 3aua0000159922 Revc PDFDokumen2 halaman3aua0000159922 Revc PDFNabil ShaukatBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- ACS355-UM RevC Screen A5Dokumen436 halamanACS355-UM RevC Screen A5vigneshwaranj87Belum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- (IEEE Spectrum May 05) - Homemade Fab Lab (Rapid Prototyping Using 3D Printing of Parts) - Institute of Electrical & Electronics EngineeDokumen8 halaman(IEEE Spectrum May 05) - Homemade Fab Lab (Rapid Prototyping Using 3D Printing of Parts) - Institute of Electrical & Electronics EngineeNabil ShaukatBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- 3aua0000159922 Revc PDFDokumen2 halaman3aua0000159922 Revc PDFNabil ShaukatBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Modular Offers Catalog 2014Dokumen124 halamanModular Offers Catalog 2014Nabil ShaukatBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Dsa 9063Dokumen20 halamanDsa 9063Nabil ShaukatBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Instrumentation TrendDokumen51 halamanInstrumentation TrendNabil Shaukat100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Computer-Based Learning For Electromechanical Systems - 85042 - 00Dokumen2 halamanComputer-Based Learning For Electromechanical Systems - 85042 - 00Nabil ShaukatBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Dsa 9063Dokumen20 halamanDsa 9063Nabil ShaukatBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Quanser Course Material Sample - Ball and Beam Rotary WorkstationDokumen12 halamanQuanser Course Material Sample - Ball and Beam Rotary WorkstationNabil Shaukat100% (1)

- Data Sheet (English) - 8022 - Winding KitDokumen4 halamanData Sheet (English) - 8022 - Winding KitNabil ShaukatBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Instrumentation and Process Control Training System Series 3531Dokumen60 halamanInstrumentation and Process Control Training System Series 3531Bismark Kofi BoatengBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Arabi Ka Muallim Vol 2Dokumen336 halamanArabi Ka Muallim Vol 2Muneer BashaBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- 3550 Calibration Bench Data SheetDokumen2 halaman3550 Calibration Bench Data SheetNabil Shaukat50% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Data Sheet (English) - 8036 Industrial ControlsDokumen44 halamanData Sheet (English) - 8036 Industrial ControlsNabil ShaukatBelum ada peringkat

- Arabi Ka Muallim Vol 2Dokumen336 halamanArabi Ka Muallim Vol 2Muneer BashaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Kaleed Arabi Ka Muallim - 4 - by Shaykh Abdus Sattaar KhanDokumen98 halamanKaleed Arabi Ka Muallim - 4 - by Shaykh Abdus Sattaar KhanMusalman Bhai100% (10)

- Pump and FlowDokumen1 halamanPump and FlowNabil ShaukatBelum ada peringkat

- ArabicTutorpart 1ByMaulanaAbdulSattarKhanDokumen201 halamanArabicTutorpart 1ByMaulanaAbdulSattarKhanMoulana Mohammad Musa ShakirBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- ArabicTutorpart 2ByMaulanaAbdulSattarKhanDokumen185 halamanArabicTutorpart 2ByMaulanaAbdulSattarKhanMoulana Mohammad Musa ShakirBelum ada peringkat

- Journeyman Catalog 2009Dokumen58 halamanJourneyman Catalog 2009Nabil ShaukatBelum ada peringkat

- Arabi Ka Muallim Vol 1Dokumen529 halamanArabi Ka Muallim Vol 1Muneer Basha100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Arabi Ka Muallim Vol 2Dokumen336 halamanArabi Ka Muallim Vol 2Muneer BashaBelum ada peringkat

- Matlab ProjectDokumen1 halamanMatlab ProjectNabil ShaukatBelum ada peringkat

- Matlab ProjectDokumen1 halamanMatlab ProjectNabil ShaukatBelum ada peringkat

- Owner'S Manual FOR Duoseal® Vacuum Pumps Models: 1400, 1405, 1402, 1376, 1397, 1374, 1399, 1380, 1392Dokumen42 halamanOwner'S Manual FOR Duoseal® Vacuum Pumps Models: 1400, 1405, 1402, 1376, 1397, 1374, 1399, 1380, 1392ckkimbleBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- MR615 Product GuideDokumen16 halamanMR615 Product GuideDinesh RajaBelum ada peringkat

- Standard Pilot, Steel Seat, Pilot-To-Open Check Valve Ckeb: 30 GPM (120 L/min.)Dokumen4 halamanStandard Pilot, Steel Seat, Pilot-To-Open Check Valve Ckeb: 30 GPM (120 L/min.)Alex RamirezBelum ada peringkat

- BetaD50 ManualDokumen57 halamanBetaD50 Manualmrb88Belum ada peringkat

- Generator Protection PDFDokumen162 halamanGenerator Protection PDFhemantgupta226100% (1)

- Peterbilt Rear Air Suspensions AdjustmentDokumen42 halamanPeterbilt Rear Air Suspensions AdjustmentCellblocX83% (6)

- Ather Specifications SheetDokumen2 halamanAther Specifications SheetKarthikeyan VenkatesanBelum ada peringkat

- 520AOD01 CS enDokumen13 halaman520AOD01 CS enBhageerathi SahuBelum ada peringkat

- Tiristor 3ct12a 500 V 12 A To220 0Dokumen5 halamanTiristor 3ct12a 500 V 12 A To220 0morucha_chicleBelum ada peringkat

- Adani BessDokumen45 halamanAdani Bessdan_geplBelum ada peringkat

- Content - Fisher RegulatorsDokumen44 halamanContent - Fisher Regulatorsbcjal100% (1)

- Simatic st80 STPC Chap02 English 2013Dokumen138 halamanSimatic st80 STPC Chap02 English 2013Eduardo Bueno LemesBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Report TextDokumen9 halamanReport TextAngka NaBelum ada peringkat

- AeromechDokumen31 halamanAeromechMohd Kamaruddin LiauBelum ada peringkat

- Tc5 30 Brochure Apac enDokumen4 halamanTc5 30 Brochure Apac enmuhammadnainBelum ada peringkat

- Volkswagen Passat B4 GLX STEERING COLUMNDokumen8 halamanVolkswagen Passat B4 GLX STEERING COLUMNNPBelum ada peringkat

- Mitsubishi PUHZ RP250YKADokumen142 halamanMitsubishi PUHZ RP250YKAAlexandru BocosBelum ada peringkat

- DTASwin v89.00 Release NotesDokumen3 halamanDTASwin v89.00 Release NotesMenuBelum ada peringkat

- Flyer RCS 9698G H GatewayDokumen2 halamanFlyer RCS 9698G H GatewayBorisBelum ada peringkat

- BKN Type: Technical DataDokumen8 halamanBKN Type: Technical DataLaura Melissa Espitia GalloBelum ada peringkat

- Outdoor Box Isolated AP300 AP400 2012-03Dokumen29 halamanOutdoor Box Isolated AP300 AP400 2012-03Alfian LinuxBelum ada peringkat

- Performance Tests: Air Handling UnitsDokumen4 halamanPerformance Tests: Air Handling UnitseslamBelum ada peringkat

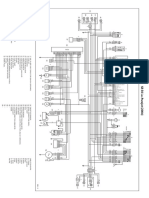

- Aprilia SR50 Purejet Wiring Diagram 2004Dokumen1 halamanAprilia SR50 Purejet Wiring Diagram 2004mylitter5391Belum ada peringkat

- 3TM Vacuum Contactors: Medium-Voltage EquipmentDokumen44 halaman3TM Vacuum Contactors: Medium-Voltage EquipmentDennyIndBelum ada peringkat

- Babylock BL18 SMDokumen22 halamanBabylock BL18 SMDavid GarnerBelum ada peringkat

- MillerDokumen88 halamanMillerkimba worthBelum ada peringkat

- 03 - Omniksol 2.5k 3k TL2 S EN PDFDokumen2 halaman03 - Omniksol 2.5k 3k TL2 S EN PDFomnikshanBelum ada peringkat

- Chapter 25 Equipment - FurnishingDokumen63 halamanChapter 25 Equipment - FurnishingHartomo DK.Belum ada peringkat

- KTM RC8 Repair ManualDokumen460 halamanKTM RC8 Repair ManualMats Mehis100% (9)

- PSV PDFDokumen3 halamanPSV PDFKasnowo DiponegoroBelum ada peringkat