Pressure Points - HSB Newsletter - April 2014

Diunggah oleh

imran jamilHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pressure Points - HSB Newsletter - April 2014

Diunggah oleh

imran jamilHak Cipta:

Format Tersedia

HSB GLOBAL STANDARDS

(continued on page 2)

APRIL 2014

Every year, HSB Global Standards participates in a

number of industry events to promote our services to new

and existing customers.

Many of our staff that focuses on Codes and Standards

development will be attending the ASMEs Boiler and

Pressure Vessel Code meeting and the 83

rd

General Meeting

of the National Board of Boiler and Pressure Vessel

Inspectors held May 11 16, 2014 in Bellevue, Washington.

Our participation provides feedback for continued Code

development from an inspectors point of view and a way to

gain feedback from our customers.

Internationally, HSB Global Standards is exhibiting

and attending PowerGen Europe, June 3 5, 2014, located

at Booth 7K15. November 11 13, 2014, HSB Global

Standards is exhibiting and PowerGen Brazil in So Paulo,

Booth C821. June 23 24, 2014, HSB Global Standards is

presenting at the ASME Shale Gas Seminar in Argentina.

In the United States, HSB Global Standards is exhibiting

and attending Power Gen International in Orlando, Florida,

December 9 11, 2014 at the Orlando County Convention

Center, located at booth 3251.

UPCOMING EVENTS

HSB GLOBAL STANDARDS

ESTABLISHES A LEGAL ENTITY IN

BRASIL

HSB Global Standards, a worldwide leader in inspection

services for boilers, pressure vessels, nuclear components,

and power and process plants, recently announced that it has

established an international subsidiary, HSB Brasil Servios

de Engenharia e Inspeo, Ltda., based in So Paulo, Brasil.

HSB Global Standards performs inspections for the pressure

vessel industry offering local availability, global coverage

and technical experience with consistent measureable results.

Pressure equipment demand is growing in Brasil driven

predominately by the refning and petrochemical industries,

power and manufacturing, said Fred Bull, president, HSB

Global Standards. HSB Global Standards worldwide

presence gives us the ability to manage third-party

certifcation for virtually any type of pressure equipment in

the world.

The Brasilian pressure equipment market is regulated.

All pressure equipment installed must meet the requirements

of its NR-13 Brasilian regulations. Any code recognized

by the Brasilian government may be used to establish the

design/fabrication requirements for the equipment, including

the ASME Boiler and Pressure Vessel Code.

The establishment of a legal entity in Brasil will

strengthen our position within Brasil and South America,

said Fred Bull. Owners and users of pressure vessel

equipment are increasingly demanding that the ASME Code

be met for equipment purchased domestically and abroad.

There is a recognized need for increased technical support

for the formal implementation of ASME Code requirements

including stamping of pressure vessel equipment ordered to

the Code.

Even though formal ASME Code Stamping is not

currently the norm in Brasil, compliance with the ASME

Code requirements is generally required by purchasers of

pressure equipment to meet NR-13 requirements. Other

recognized codes may also be used, but ASME is the

predominant standard in Brasil owing to its familiarity to

buyers, fabricators and designers.

INSIDE

Upcoming Events .............................................. 1

HSB GS Establishes a Legal Entity .................. 1

Ask the Engineer ............................................... 2

HSB GS PED Services Improvement ............... 2

ASME Section III Use of Source ...................... 3

IBR - Indian Boiler Regulations ....................... 4

EVENT DATE LOCATION BOOTH

PowerGen June

Europe 3 5, 2014

PowerGen November

Brazil 11 14, 2014

PowerGen December

International 9 11, 2014

Cologne, Germany 7K15

So Paulo, Brazil C821

Orlando, Florida 3251

The Ofcial Newsletter of HSB Global Standards

P R E S S U R E

P O I N T S

P R E S S U R E

P O I N T S

Third-party inspection is typically required by owners/

users in Brasil for equipment they import, to ensure

compliance with their specifcations. These specifcations

have evolved from the ASME Code requirements over time;

giving HSB Global Standards an opportunity to leverage its

ASME knowledge as a differentiator and to uniquely qualify

itself to provide third-party inspection services in Brasil.

For more information contact GetInfo@hsbct.com

ASK THE ENGINEER

By Codes and Standards Group

How many sets of Impact test specimens are required for

material over 1 [ 38mm ] thick when qualifying

welding procedures with impact testing in accordance

with ASME Section VIII Division 1 2013 Edition?

While UG-84(h)(3) seems to provide an immediate

straightforward answer to this question, there is more to

it when you carefully read the paragraph. It says three sets

of impact specimens are required and out of those three,

two of them are required to be removed from the weld

and it leads to the short answer: 2 sets from the weld and

1 set from the HAZ.

However, UG-84(h)(3) makes reference to UG-84(g)

(2) for the HAZ specimens. UG-84(g)(2) says the HAZ

specimens shall be removed in accordance with Figure

UG-84.5 and Table UG-84.6. Per Table UG-84.6, two sets

of HAZ specimens are required when the material

thickness is greater or equal to 1 . Note that Paragraph

UG-84(h)(3) recognizes (g)(2) as one set. The one set for

the HAZ is all encompassing. If (g)(2) requires more

than one subset then all of those subsets are

considered the one set for HAZ specifed in (h)(3).

Therefore, four (4) sets of impact test specimens [2 sets

from the weld and 2 sets from the HAZ ] are required for

thicknesses over 1 [ 38mm ].

I am designing a pressure vessel using SA-240 Type 316

L plate. Paragraph 8.1 of SA-480 [Specifcation for

General Requirements for Flat-Rolled Stainless and Heat-

Resisting Steel Plate Sheet, and Strip ] says the following

for Material Test Report and Certifcation:

8.1 A report of the results of all tests required by the

product specifcation shall be supplied to the

purchaser. This material test report shall reference the

product specifcation designation and year date

indicating that the material was manufactured,

sampled, tested, and inspected in accordance with

requirements of the product specifcation and has

been found to meet those requirements. The

material test report shall report the melting process

when the purchase order requires either a specifc

type of melting or requires that the melting process

used is to be reported.

Is it required that the words shown above in bold from

paragraph 8.1 appear in the Material Test Report for this

material?

There is a very specifc Interpretation published by

ASME for SA-240/SA-480 that speaks to this issue

directly for stainless steel plate (IIA-04-09R, copied

below). The reason why an MTR with those specifc

words is not required per SA-480, 8.1 is because of the

way that the words are written: This material test report

shall reference the product specifcation designation and

year date indicating that the material was manufactured,

sampled, tested, and inspected in accordance with

requirements of the product specifcation and has

been found to meet those requirements. This could

be rewritten as: This material test report shall reference

the product specifcation designation and year date

which indicates that the material was manufactured,

sampled, tested, and inspected in accordance with

requirements of the product specifcation and has been

found to meet those requirements. So, the listing of the

product specifcation designation and year date alone is

the certifcation by the material manufacturer that it

meets the requirements of the specifcation, and a

separate certifcation statement is not required.

Interpretation: II-A-04-09R

Subject: Material Test Report Requirement for

SA-240/SA-240M, Section II, Part A

(2001 Edition, 2002 and 2003 Addenda)

Date Issued: September 28, 2004

File: BC04-1068

For stainless steel plate, sheet or strip supplied to SA-

240/SA-240M, is it necessary for the certifcation to

include the following sentence on the material test report:

The material was manufactured, sampled, tested, and

inspected in accordance with the requirements of

SA-240/SA-240M and has been found to meet those

requirements?

No.

HSB GLOBAL STANDARDS PED SERVICES

IMPROVEMENTS

In continued support of our customers, we have made

HSB Global Standards Establishes... (continued from page 1)

2 PRESSURE POINTS

Q

A

Q

A

Q

A

further investments in our PED services to better serve our

customers. We have merged our Design Review location with

our Certifcation location to improve review effciency.

The Benefts of our PED Services:

Improved effciencies transmitting and reviewing design

fles electronically.

Continued access to technical specialists that focus on

pressure vessel inspection services.

Experience completing more than 200 HRSG projects

involving multiple subcontractors in different world

regions that are complex in nature.

Local representation in Europe, Asia and the Americas.

Our knowledge and experience of the ASME Codes

and Standards, quality development, and

surveillance activity, along with a unique understanding of

many country codes, which helps save time and

money while navigating the PED process.

The address for the sending design and certifcation fles is:

HSB Global Standards

Landersumer Weg 40

D-48431 Rheine, Germany

Tel: +49-5971-91436 0

Design Reviews can be sent electronically to:

HSBI_Design_Documents@hsbct.com

Please continue to contact your local Account Manager for all

PED services.

ASME SECTION III USE OF SOURCE

MATERIAL AND MATERIAL

Certifed Material Test Reports (CMTRs) attest that

material is in accordance with specifed requirements,

including the actual results of all required chemical analyses,

tests, and examinations. Product form conversion, as

described in NCA-3800, is the conversion of source material

into material. Upon completion of product form conversion,

the metallic product, now known as material, conforms to a

SA, SB, SFA, or any other material specifcation permitted in

Section III.

When used for Section III applications, metallic products

can be purchased by N-type Certifcate holders or Materials

Organizations from approved suppliers to manufacture

material. Approved suppliers are audited and evaluated

by N-type Certifcate holders or Materials Organizations,

to verify compliance with the requirements of NCA-3800.

Metallic products that come from approved suppliers are

known as Qualifed Source Material. N-type Certifcate

holders or Materials Organizations can also use suppliers

which do not meet the requirements of NCA-3800. In doing

so, N-type Certifcate holders or Materials Organizations can

only use these metallic products by meeting the provisions of

NCA-3855.5. Metallic products from unqualifed suppliers are

known as Unqualifed Source Material.

Metallic products become known as Source Material

when the fnal chemical compositions are established at the

mill and documented in a product analysis. Source material

then becomes material when the fnal mechanical properties

are established, the material conforms to a SA, SB, SFA,

or any other material specifcation permitted in Section III,

and documented on a CMTR. Source material can already

conform to material specifcation permitted in Section III if

the fnal specifcation requires product form conversion to

any other material specifcation permitted in Section III. An

example of such a conversion would be using plate SA-240

machined into a blind fange with dimensions compatible with

ASME B16.5.

For more information on ASME Section III, please contact

Paul Coco at Paul_Coco@hsbct.com

PRESSURE POINTS 3

One State Street

PO Box 299

Hartford, CT 06141-0299

(800) 417-3437 (860) 722-5705 Fax

Editor:

Stephen McKelvey

(860) 722-5450

Stephen_McKelvey@hsbct.com

HSB Global Standards

Pressure Points is published by

Contributors:

Paul Coco

Richard Prendergast

Jayaram Vattappilly

Delinda Whiting

HSB Global Standards PED Services... (continued from page 2)

IBR - INDIAN BOILER REGULATIONS

HSB Global Standards is pleased to announce the release

of Indian Boiler Regulations (IBR) services. The IBR services

include design review, inspection, material certifcation and

welder qualifcations for equipment that will be installed in

India. Our accreditation with the Central Boiler Board in India

is for services provided in all countries with the exception of

China and India.

India is the worlds fourth largest energy consumer after

United States, China and Russia. Currently, India is suffering

from a major shortage of electricity generation capacity. The

International Energy Agency estimates India will add between

600 to 1200 GW of additional new power generation capacity

before 2050. Global manufacturers have been exporting to

India over the past decade and with the release of this Program,

HSB GS customers will now be able to use one inspection body

to support their exporting needs.

HSB Global Standards offers a wide range of inspection

services for boilers, pressure vessels, nuclear components, and

process and power plants. Established in 1866, we provided

engineering services to users of steam powered equipment.

Today, HSB Global Standards has grown to be a worldwide

leader in the interpretation and application of boiler and

pressure vessel codes, standards, directives and customer

specifcations. HSB Global Standards has operations in 16

countries and employs more than 500 people worldwide.

With local representation and jurisdictional experience,

HSB Global Standards provides virtually every aspect

of boiler and pressure vessel inspection and certifcation

globally.

For more information on Indian Boiler Regulations

services, please contact Delinda Whiting at

Delinda_Whiting@hsbct.com

4 PRESSURE POINTS

If you would like to receive an electronic copy of

Pressure Points, please email GetInfo@hsbct.com

Anda mungkin juga menyukai

- Confirmation of Product Type ApprovalDokumen4 halamanConfirmation of Product Type ApprovalisaenitBelum ada peringkat

- ABS P1 Series PDA Thru 12-12-2024Dokumen4 halamanABS P1 Series PDA Thru 12-12-2024DHANEESH VELLILAPULLIBelum ada peringkat

- Confirmation of Product Type ApprovalDokumen4 halamanConfirmation of Product Type ApprovalisaenitBelum ada peringkat

- To Stamp Not StampDokumen4 halamanTo Stamp Not Stampkinjalpatel12345Belum ada peringkat

- HSB Pressure Points 2017 MayDokumen6 halamanHSB Pressure Points 2017 MayzaheerBelum ada peringkat

- Confirmation of Product Type ApprovalDokumen3 halamanConfirmation of Product Type ApprovalisaenitBelum ada peringkat

- Confirmation of Product Type Approval: Product Name: Ship Sound Signal, Horn Model Name(s) : KB-30ADokumen2 halamanConfirmation of Product Type Approval: Product Name: Ship Sound Signal, Horn Model Name(s) : KB-30AanyBelum ada peringkat

- Certificado Type ApprovalDokumen2 halamanCertificado Type ApprovalGilmar Rocha LimaBelum ada peringkat

- PP 2006 03Dokumen4 halamanPP 2006 03Born ToSinBelum ada peringkat

- General Requirements For ValvesDokumen16 halamanGeneral Requirements For ValvesKrishna Prasad R100% (1)

- Air Vent Head-Abs Type Approval Certificate RKDokumen2 halamanAir Vent Head-Abs Type Approval Certificate RKdirayBelum ada peringkat

- P08flexible Hose UlDokumen9 halamanP08flexible Hose Ulyucai.chenBelum ada peringkat

- SM 001 SRV SpecDokumen5 halamanSM 001 SRV Specvardan_vardanBelum ada peringkat

- Standard Welding Procedures: by Walter J. SperkoDokumen4 halamanStandard Welding Procedures: by Walter J. SperkoK ArunsiddharthBelum ada peringkat

- Abs Typeapp Fiberbond 20fr16 y 16 CDokumen2 halamanAbs Typeapp Fiberbond 20fr16 y 16 CLeonardo AlayolaBelum ada peringkat

- ABS Cer'tDokumen3 halamanABS Cer'tgrenjithBelum ada peringkat

- The Pressure News: Season's GreetingsDokumen4 halamanThe Pressure News: Season's Greetingskatchani123Belum ada peringkat

- 1030Dokumen6 halaman1030mgoethalsBelum ada peringkat

- Pressure VesselDokumen3 halamanPressure Vesselzahid_497Belum ada peringkat

- API 682 GuidelinesDokumen28 halamanAPI 682 GuidelinesSergio Solano100% (3)

- Materials System Specification: Saudi Aramco Desktop StandardsDokumen14 halamanMaterials System Specification: Saudi Aramco Desktop StandardsMoustafa Bayoumi100% (1)

- IHS PetroChem Collection Listing Aug13Dokumen48 halamanIHS PetroChem Collection Listing Aug13OumorsyBelum ada peringkat

- 17 ValvesDokumen4 halaman17 ValvesTrung NguyenBelum ada peringkat

- Spec For Process StrainerDokumen11 halamanSpec For Process StrainerHarish GundaBelum ada peringkat

- Agenda 20 - G4.4 Sample Owner QA ManualDokumen43 halamanAgenda 20 - G4.4 Sample Owner QA Manualjcarlos7411Belum ada peringkat

- Welding Procedure: Job Knowledge 39Dokumen6 halamanWelding Procedure: Job Knowledge 39manimaranBelum ada peringkat

- 05.40.00 Cold-Formed Metal Framing Specification Updated June 2015Dokumen26 halaman05.40.00 Cold-Formed Metal Framing Specification Updated June 2015mishikhanBelum ada peringkat

- 02 e PDokumen34 halaman02 e PAmro HassanBelum ada peringkat

- GIS 18 012 31 October 2007Dokumen11 halamanGIS 18 012 31 October 2007Jose Carlos100% (1)

- Designing A CGMP BioprocessDokumen5 halamanDesigning A CGMP Bioprocesshareesh13hBelum ada peringkat

- OTC 21475 New Certification Procedures For Offshore Mooring Fiber RopesDokumen6 halamanOTC 21475 New Certification Procedures For Offshore Mooring Fiber RopesSharon FreemanBelum ada peringkat

- MSS SP 54 Radiographic Examination MethodDokumen9 halamanMSS SP 54 Radiographic Examination MethodSunil Kumar100% (1)

- Pressure Relief Valve Engineering-1Dokumen2 halamanPressure Relief Valve Engineering-1Susheel WankhedeBelum ada peringkat

- TWI - Welding Procedure - Job Knowledge 39Dokumen9 halamanTWI - Welding Procedure - Job Knowledge 39tuanBelum ada peringkat

- Parafusos Tech ManualDokumen92 halamanParafusos Tech Manualmario fisgaBelum ada peringkat

- Inspection Pressure Vessel and Piping Code Petroleum Refining and Chemical Process IndustriesDokumen14 halamanInspection Pressure Vessel and Piping Code Petroleum Refining and Chemical Process Industriesbakkali_bilalBelum ada peringkat

- Pressure Vessel PlateDokumen4 halamanPressure Vessel PlateYetkin ErdoğanBelum ada peringkat

- Anubar SpecDokumen8 halamanAnubar SpecSHIVAJI CHOUDHURYBelum ada peringkat

- TEMPER BEAD WELDING As CASTIDokumen4 halamanTEMPER BEAD WELDING As CASTIsivaavissriBelum ada peringkat

- Confirmation of Product Type ApprovalDokumen4 halamanConfirmation of Product Type ApprovalisaenitBelum ada peringkat

- Johnson Cut Less Abs Type ApprovalDokumen2 halamanJohnson Cut Less Abs Type ApprovalNolberto ValdezBelum ada peringkat

- 04-SAMSS-035 ARAMCO General Reuirement For ValvesDokumen18 halaman04-SAMSS-035 ARAMCO General Reuirement For ValvesAhmed100% (4)

- GS 142 4 PDFDokumen23 halamanGS 142 4 PDFjast111Belum ada peringkat

- Pressure Points: 2019 Edition of The Boiler Pressure Vessel CodeDokumen5 halamanPressure Points: 2019 Edition of The Boiler Pressure Vessel CodemohdfirdausBelum ada peringkat

- GFDS, Mnbfdlkyfdsdfgbn NgregnDokumen13 halamanGFDS, Mnbfdlkyfdsdfgbn NgregnAnonymous 7YilBuIuQm100% (1)

- Routes To Welding Procedure ApprovalDokumen6 halamanRoutes To Welding Procedure ApprovalJose Marie Rmgrocks BatoBelum ada peringkat

- Itp HeDokumen15 halamanItp HeAldeline SungahidBelum ada peringkat

- Date: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17KDokumen2 halamanDate: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17Kisraelita77671Belum ada peringkat

- Sae As1650b-2010Dokumen23 halamanSae As1650b-2010EchoZhangBelum ada peringkat

- Inspection and Test Plan (Itp) For Control ValvesDokumen15 halamanInspection and Test Plan (Itp) For Control ValveszakariaBelum ada peringkat

- Inspection and Test Plan For Pressure Reliving Devices 1707841397Dokumen16 halamanInspection and Test Plan For Pressure Reliving Devices 1707841397BernathTurnipBelum ada peringkat

- Welder Qualifications and The ASME CodeDokumen2 halamanWelder Qualifications and The ASME CodeWaqas WaqasBelum ada peringkat

- Abs Certification Blue Gard 3000 3200Dokumen3 halamanAbs Certification Blue Gard 3000 3200SreekanthBelum ada peringkat

- Gs118 5WeldingOfcarbonSteelPipework ToB31.3Dokumen36 halamanGs118 5WeldingOfcarbonSteelPipework ToB31.3Mohd Khairul100% (1)

- NCPWB February 2000Dokumen8 halamanNCPWB February 2000Claudia MmsBelum ada peringkat

- KLOMAC Draft ReportDokumen12 halamanKLOMAC Draft Reportcameron toolseeBelum ada peringkat

- How to prepare Welding Procedures for Oil & Gas PipelinesDari EverandHow to prepare Welding Procedures for Oil & Gas PipelinesPenilaian: 5 dari 5 bintang5/5 (1)

- BGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&ADari EverandBGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&ABelum ada peringkat

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Dari EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Penilaian: 3.5 dari 5 bintang3.5/5 (3)

- Machinery Component Maintenance and RepairDari EverandMachinery Component Maintenance and RepairPenilaian: 5 dari 5 bintang5/5 (1)

- COQ - An Overview (Rev 01)Dokumen25 halamanCOQ - An Overview (Rev 01)imran jamilBelum ada peringkat

- Intl Journal of Business Performance MGMT Vol 14 Issue 2 2013 Arena, Marika - Risk and Budget in An Uncertain WorldDokumen15 halamanIntl Journal of Business Performance MGMT Vol 14 Issue 2 2013 Arena, Marika - Risk and Budget in An Uncertain Worldimran jamilBelum ada peringkat

- 13 - ABC of Risk Culture - Hillson PaperDokumen9 halaman13 - ABC of Risk Culture - Hillson Paperimran jamilBelum ada peringkat

- Lisa K. Meulbroek - A Senior Manage's Guide To Integrated Risk Management PDFDokumen17 halamanLisa K. Meulbroek - A Senior Manage's Guide To Integrated Risk Management PDFimran jamilBelum ada peringkat

- What Is Risk - A Common DefinitionDokumen2 halamanWhat Is Risk - A Common Definitionimran jamilBelum ada peringkat

- ABS Journal RankingDokumen54 halamanABS Journal RankingEmad RashidBelum ada peringkat

- Sr. No. Title of Training Dates Year - 2008Dokumen2 halamanSr. No. Title of Training Dates Year - 2008imran jamilBelum ada peringkat

- WQM 2015 ROI of Quality Fact Sheet FDokumen1 halamanWQM 2015 ROI of Quality Fact Sheet Fimran jamilBelum ada peringkat

- Mapping ISO 9001-2008 To 2015Dokumen2 halamanMapping ISO 9001-2008 To 2015imran jamilBelum ada peringkat

- CQI NCR Training PresentationDokumen34 halamanCQI NCR Training Presentationimran jamilBelum ada peringkat

- Katalog Weldotherm 10 2013 GB EmailDokumen40 halamanKatalog Weldotherm 10 2013 GB Emailimran jamilBelum ada peringkat

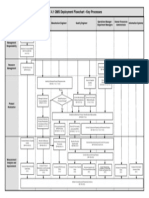

- QMS Deployment FlowchartDokumen1 halamanQMS Deployment Flowchartimran jamilBelum ada peringkat

- WQM 2015 ProclamationDokumen1 halamanWQM 2015 Proclamationimran jamilBelum ada peringkat

- Beyond CapaDokumen6 halamanBeyond CapaJorge Humberto HerreraBelum ada peringkat

- Iso 9001 - AsqDokumen7 halamanIso 9001 - Asqimran jamilBelum ada peringkat

- Production and Operation Management PPT at BEC DOMS BAGALKOTDokumen238 halamanProduction and Operation Management PPT at BEC DOMS BAGALKOTBabasab Patil (Karrisatte)67% (3)

- Imperfections in Welds - PorosityDokumen3 halamanImperfections in Welds - Porosityimran jamilBelum ada peringkat

- Integrated Management System (IMS) QMS/EMS/OHSDokumen17 halamanIntegrated Management System (IMS) QMS/EMS/OHSamitbanerjee51Belum ada peringkat

- PMI Project Risk ManagementDokumen21 halamanPMI Project Risk Managementimran jamilBelum ada peringkat

- 2 Main Categories of NCRsDokumen4 halaman2 Main Categories of NCRsimran jamilBelum ada peringkat

- Risk Management (RMP) PMI Sample QuestionsDokumen7 halamanRisk Management (RMP) PMI Sample Questionsimran jamil100% (1)

- Project System Audit Checklist Planning and Scheduling GroupDokumen6 halamanProject System Audit Checklist Planning and Scheduling Groupimran jamil100% (1)

- Torn DiagDokumen4 halamanTorn Diagimran jamilBelum ada peringkat

- Inspection and Test Plan..Construction ProjectsDokumen5 halamanInspection and Test Plan..Construction Projectsimran jamilBelum ada peringkat

- Leadership Development PMI - Jan 2012 - DR - GhufranDokumen11 halamanLeadership Development PMI - Jan 2012 - DR - Ghufranimran jamilBelum ada peringkat

- Project Quality Management - PMI PMBOKDokumen92 halamanProject Quality Management - PMI PMBOKimran jamil50% (2)

- ASQ GSQ Discoveries 2013Dokumen40 halamanASQ GSQ Discoveries 2013mseymour91Belum ada peringkat

- Importance of Quality in ProjectsDokumen16 halamanImportance of Quality in Projectsimran jamilBelum ada peringkat

- Importance of Welding: QA/QC DepartmentDokumen55 halamanImportance of Welding: QA/QC Departmentimran jamil0% (1)

- Bajar 1498 - 1507Dokumen60 halamanBajar 1498 - 1507Bea BajarBelum ada peringkat

- Permission To MortgageDokumen14 halamanPermission To MortgageAabad BrandBelum ada peringkat

- E Health Business PlanDokumen36 halamanE Health Business PlanZaman Ali100% (1)

- Recruitment, Selection, Induction, Training and Development ProcessDokumen4 halamanRecruitment, Selection, Induction, Training and Development ProcessMayurRawoolBelum ada peringkat

- Construction Cost Handbook CNHK 2023Dokumen63 halamanConstruction Cost Handbook CNHK 2023wlv hugoBelum ada peringkat

- OTS Prepay and Valuing Individual Mortgage Servicing Contracts - A Comparison Between Adjust Rate Mortgages and Fixed Rate MortgagesDokumen16 halamanOTS Prepay and Valuing Individual Mortgage Servicing Contracts - A Comparison Between Adjust Rate Mortgages and Fixed Rate MortgagesfhdeutschmannBelum ada peringkat

- Case 15 Pacific Healthcare - B - Student - 6th EditionDokumen1 halamanCase 15 Pacific Healthcare - B - Student - 6th EditionAhmed MahmoudBelum ada peringkat

- Introduction To Operation ManagementDokumen78 halamanIntroduction To Operation ManagementNico Pascual IIIBelum ada peringkat

- Web Based Crime Management SystemDokumen22 halamanWeb Based Crime Management SystemZain Ul Abedin SaleemBelum ada peringkat

- Front Office ManagementDokumen3 halamanFront Office ManagementLu XiyunBelum ada peringkat

- GRC Expert - User Access Reviews1Dokumen11 halamanGRC Expert - User Access Reviews1Rohit KumarBelum ada peringkat

- Announcement Invitation For Psychotest (October)Dokumen17 halamanAnnouncement Invitation For Psychotest (October)bgbfbvmnmBelum ada peringkat

- Civil Code of The Philippines Common CarriersDokumen4 halamanCivil Code of The Philippines Common CarriersKathrynne NepomucenoBelum ada peringkat

- Chapter 1Dokumen4 halamanChapter 1Micaela BakerBelum ada peringkat

- Form Restoran Sederhana Masakan PadangDokumen30 halamanForm Restoran Sederhana Masakan PadangLuthfi's Mzakki'sBelum ada peringkat

- RAD Project PlanDokumen9 halamanRAD Project PlannasoonyBelum ada peringkat

- El 1204 HHDokumen6 halamanEl 1204 HHLuis Marcelo HinojosaBelum ada peringkat

- Competitors and CustomersDokumen2 halamanCompetitors and Customerslk de leonBelum ada peringkat

- Latihan AdvanceDokumen9 halamanLatihan AdvanceMellya KomaraBelum ada peringkat

- PGEresponseDokumen37 halamanPGEresponseABC10Belum ada peringkat

- Best Practices Guide For IT Governance & ComplianceDokumen14 halamanBest Practices Guide For IT Governance & ComplianceAnonymous 2WKRBqFlfBelum ada peringkat

- Salary Slip & Transfer Confirmation: Date: Period: Bank: Account # Name: Title: Dept: Emp #Dokumen2 halamanSalary Slip & Transfer Confirmation: Date: Period: Bank: Account # Name: Title: Dept: Emp #Adheesh SanthoshBelum ada peringkat

- Share Holders Right To Participate in The Management of The CompanyDokumen3 halamanShare Holders Right To Participate in The Management of The CompanyVishnu PathakBelum ada peringkat

- Marketing IndividualDokumen2 halamanMarketing Individualsinyi0Belum ada peringkat

- 2017 Walters Global Salary SurveyDokumen428 halaman2017 Walters Global Salary SurveyDebbie CollettBelum ada peringkat

- (70448314976) 08112022Dokumen2 halaman(70448314976) 08112022DICH THUAT LONDON 0979521738Belum ada peringkat

- Etom Marketing and Offer Managment ProcessesDokumen6 halamanEtom Marketing and Offer Managment ProcessesMostafa GhafourianBelum ada peringkat

- Sr. No. Name of Institution Address Board Line Fax No.: 1 Allahaba D BankDokumen9 halamanSr. No. Name of Institution Address Board Line Fax No.: 1 Allahaba D Banksaurs2Belum ada peringkat