CT02-028 891 01 17 02 PDF

Diunggah oleh

w.h.n100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

720 tayangan128 halamanDocuments may only be used by authorized personnel for rendering services on Siemens Healthcare Products. Siemens reserves the right to change its products and services at any time. The service of equipment described herein is to be performed by qualified personnel.

Deskripsi Asli:

Judul Asli

CT02-028.891.01.17.02.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniDocuments may only be used by authorized personnel for rendering services on Siemens Healthcare Products. Siemens reserves the right to change its products and services at any time. The service of equipment described herein is to be performed by qualified personnel.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

720 tayangan128 halamanCT02-028 891 01 17 02 PDF

Diunggah oleh

w.h.nDocuments may only be used by authorized personnel for rendering services on Siemens Healthcare Products. Siemens reserves the right to change its products and services at any time. The service of equipment described herein is to be performed by qualified personnel.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 128

Siemens, 2005

- For internal use only - All documents may only

be used by authorized personnel for rendering

services on Siemens Healthcare Products. Any

document in electronic form may be printed

once. Copy and distribution of electronic docu-

ments and hardcopies is prohibited. Offenders

will be liable for damages. All other rights are re-

served.

Print No.:

SiemensRamsauer

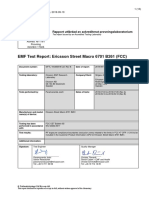

SOMATOM Definition

System

Planning Guide

CT

2005

CT02-028.891.01.17.02

Replaces: CT02-028.891.01.16.02

English

Doc. Gen. Date: 12.11

n.a. H CX CS SD CR-CT

Specific requirements for CT project planning

Siemens, 2005

07740769

2 Copyright / Version / Disclaimer

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 2 of 128

For internal use only

1Copyright / Version / Disclaimer

Copyright

Siemens, 2005 refers to the copyright of a Siemens entity such as Siemens Aktienge-

sellschaft - Germany, Siemens Shenzhen Magnetic Resonance Ltd. - China, Siemens

Shanghai Medical Equipment Ltd. - China, Siemens Medical Solutions USA Inc. - USA

and/or Siemens Healthcare Diagnostics Inc. - USA.

Document Version

Siemens reserves the right to change its products and services at any time.

In addition, manuals are subject to change without notice. The hardcopy documents corre-

spond to the version at the time of system delivery and/or printout. Versions to hardcopy

documentation are not automatically distributed. Please contact your local Siemens office

to order current version or refer to our website http://www.healthcare.siemens.com.

Disclaimer

Siemens provides this documentation as is without the assumption of any liability under

any theory of law.

The service of equipment described herein is to be performed by qualified personnel who

are employed by Siemens or one of its affiliates or who are otherwise authorized by Sie-

mens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with

or authorized by Siemens or one of its affiliates are not entitled to use this documentation

without prior written authority.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Table of Contents 3

Page 3 of 128

For internal use only

0Table of Contents

1 _______ General information______________________________________________ 7

Preamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CT Basic PG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CT Options PG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Notes regarding on-site preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Notes with respect to project plans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Preliminaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Preliminary ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Note with respect to drawings and figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Abbreviations, definitions and explanations of symbols . . . . . . . . . . . . . . . . . . . . . . . . 18

Overview - standard components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Overview - options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2 _______ Room planning_________________________________________________ 26

Notes and regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Room sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Area requirements - Minimal requirements from a technical point of view . . . . . . . 27

Dimensions of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Gantry and patient table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

PDC_A / PDC_B cabinets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

IRSmx2a tower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Tower PCs for syngo Acquisition Workplace / syngo CT Workplace . . . . . . . . . . . . 33

System furniture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Maximum distances between components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Radiation protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Visual radiation warning indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Radiation locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Local dose distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Room configurations - recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Workstation and room lighting - regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Siemens Remote Services (SRS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3 _______ Installation preparation__________________________________________ 42

Installation notes and regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Static requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Flooring for the gantry and patient table - requirements. . . . . . . . . . . . . . . . . . . . . . 43

Existing mounting frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Access floor - subconstruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Floor loading of gantry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Table of Contents

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 4 of 128

For internal use only

Floor and building vibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Installation of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Gantry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Patient table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Dimensions for floor mounting - Gantry and patient table . . . . . . . . . . . . . . . . . . . . . 51

IRSmx2a tower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

PDC_A / PDC_B cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

System furniture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Tower PCs for syngo Acquisition Workplace (ICS) / syngo CT Workplace (IES) . . . 56

Monitor and Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Connection - Cooling system (integrated into gantry) . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

On-site electrical installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Notes and regulations - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Line voltage connection - On-site requirements of the manufacturer . . . . . . . . . . . . 59

On-site line voltage fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Residual current protective device (RCD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Size of connecting terminal for line voltage cable in the PDC_A / PDC_B cabinets . 61

REPO - Remote Emergency Power Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Emergency operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

SIEMENS SIRIUS Logic Relay Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

On-site line voltage connection - proposals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Additional electrical connectivities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Cable/hose inlets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Gantry and patient table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

IRSmx2a tower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

PDC_A / PDC_B cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

System furniture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Tower PCs for syngo Acquisition Workplace / syngo CT Workplace. . . . . . . . . . . . . 77

Cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Regulations and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4 _______ System connections ____________________________________________ 80

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Fiber optic cables - routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Signal and data lines - routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Wiring sets - notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

List of fixed points used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Maximum distances - fixed points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Extensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Wiring scheme - Standard components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Line voltage and protective conductor connections . . . . . . . . . . . . . . . . . . . . . . . . . 82

Control and data lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Wiring schematic - syngo CT Workplace (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Connection to system power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Connection to on-site power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Cable ducts and conduits - Recommended sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Table of Contents 5

Page 5 of 128

For internal use only

5 _______ Technical data _________________________________________________ 91

Dimensions, weight, noise level, and heat dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Temperature, relative humidity and barometric pressure . . . . . . . . . . . . . . . . . . . . . 93

Air intake and air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Air pollution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Loop impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Line voltage, line frequency, power factor, and line impedance . . . . . . . . . . . . . . . . 96

Potential difference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Line voltage-matching transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Power consumption of overall system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

On-site pre-transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

UPS for the overall system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Connection value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Electromagnetic Compatibility EMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Magnetic field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Interference immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Brown-outs and power failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Color information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6 _______ Transport and storage conditions ________________________________ 102

Regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Acceleration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Climatic conditions for transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Moving the CT components: General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Moving in the gantry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Transport device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Transport weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Floor load during transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Standard transport - transport device swiveled out. . . . . . . . . . . . . . . . . . . . . . . . . 107

Transport through narrow passages - transport device swiveled in . . . . . . . . . . . . 108

Crane suspension for the gantry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Moving in the patient table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

7 _______ Cooling system (integrated into gantry) ___________________________ 111

Room planning - requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Detailed dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Delivery data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Hose connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

On-site cooling circuit - schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Water drain for condensed water - Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Inlets - water hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Cable ducts and conduits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6 Table of Contents

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 6 of 128

For internal use only

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Dimensions, weights, noise level, air flow, heat dissipation . . . . . . . . . . . . . . . . . . 121

Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

On-site cooling circuit - requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8 _______ Changes to previous version ____________________________________ 126

9 _______ Index ________________________________________________________ 127

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

General information 7

Page 7 of 128

For internal use only

1- 1General information

Preamble 0

To simplify handling and editorial effort for the current CT System Planning Guide (CT Sys-

tem PG) a common ...

CT Basic Planning Guide (CT Basic PG) and

CT Options Planning Guide (CT Options PG)

were developed.

Therefore, the CT Basic PG and the CT System PG must be used in addition when plan-

ning a CT system.

CT Basic PG 0

It includes both common information as well as facts independent of CT model or version

that are necessary for planning CT systems.

The basic requirements for planning CT systems may be identical for some systems inde-

pendent of the version model.

Therefore, in this CT System PG you find links to the CT Basic PG.

CT Options PG 0

There are CT options available and used by more than one CT system regardless of the

CT model or version.

This CT Options PG includes only the required planning information for the CT options that

are used by more than one CT system.

The content of this CT Options PG is limited to the technically required information to plan

the on-site preparation of the corresponding option only.

Therefore, in this CT System PG you find links to the CT Options PG.

8 General information

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 8 of 128

For internal use only

Validity 1.1

The contents of this System PG address solely technically required planning information

for:

SOMATOM Definition

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

General information 9

Page 9 of 128

For internal use only

Safety information 1.2

NOTE Please observe the additional safety information provided in

the chapter General information of the CT Basic PG, print

number CT00-000.891.02.

Observe and adhere to every warning listed below. These warnings and cautions are

always valid when planning a SOMATOM Definition:

CAUTION

[ hz_pgdoc_F02G09U02M03 ]

Insufficient spacing between the system and the wall may

result in injury to the user and patient.

Risk of injury!

Minimum distances between the system and the wall

have to be observed in accordance with the planning

guide.

CAUTION

[ hz_pgdoc_F02G09U03M03 ]

The extension of the scan range may result in injury to the

user and the patient.

Risk of injury!

Minimum distances between the system and the wall

have to be observed in accordance with the planning

guide.

CAUTION

[ hz_pgdoc_F02G10U03M04 ]

An improperly secured table can cause injury to the user and

patient.

Risk of injury!

Securing the patient table to the floor is mandatory as

specified in the planning guide and installation instruc-

tions.

CAUTION

[ hz_pgdoc_F04G02U05M04 ]

Inadequate room shielding can cause risk of injury to users

and surroundings.

Risk of injury!

Adequate room shielding has to be installed.

10 General information

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 10 of 128

For internal use only

CAUTION

[ hz_pgdoc_F12G03U01M04 ]

Tripping (e.g. due to cables) can cause injury to the user and

the patient.

Risk of injury!

The planning guide describes measures to avoid trip-

ping.

WARNING

[ hz_pgdoc_F13G01U12M04 ]

Failure to observe the guidelines specified in this document

may lead to serious injury or loss of life.

Risk of accident and/or injury!

The guidelines contained in this document have to be

strictly followed.

CAUTION

[ hz_pgdoc_F13G01U16M02 ]

Transport with the rollers swivelled in is permissible only

when narrow places make it impossible to transport the sys-

tem with the rollers swivelled out.

Tipping hazard!

As soon as the system has passed through narrow

passages, the transport rollers must be swivelled out

again.

WARNING

[ hz_pgdoc_F14G02U01M04 ]

In regions prone to earthquakes, the gantry may fall over dur-

ing an earthquake.

Risk of injury!

Observe the special instructions in the planning and

installation guides regarding regions prone to earth-

quake.

CAUTION

[ hz_pgdoc_F14G05U01M02 ]

Incorrect installation of the ceiling-mounted monitor can

cause injury to the user and patient.

Risk of injury!

The ceiling-mounted monitor has to be installed

according to the planning guide and the installation

instructions.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

General information 11

Page 11 of 128

For internal use only

CAUTION

[ hz_pgdoc_F14G06U01M03 ]

An improperly positioned horizontal monitor arm may crush

the operator's hands.

Risk of injury!

Observe the minimum distances described in the plan-

ning guide.

CAUTION

[ hz_pgdoc_F14G06U02M03 ]

Insufficient spacing between the monitor in park position

and the gantry can cause injury to the user.

Risk of injury!

The minimum distances between the monitor in park

position and the gantry have to be observed.

In addition, the following hazard information is applicable specifically to the CARE

Vision CT option from ONDAL (beginning in the year 2010):

CAUTION

[ hz_pgdoc_F21G03U04M02 ]

The mounting of the interface plate was not performed cor-

rectly!

The ceiling support may fall from the ceiling.

The mounting of the interface plate and the anchor

plate connected to the ceiling may be carried out only

by a company specialized in concrete drilling and saw-

ing.

CAUTION

[ hz_pgdoc_F21G03U05M01 ]

Incorrect installation of the ceiling support and ceil-

ing-mounted monitor.

Risk of injury!

The ceiling support and ceiling-mounted monitor have

to be installed in accordance with the planning guide

and installation instructions.

12 General information

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 12 of 128

For internal use only

Additional documentation 1.3

Use the following additional documents when planning:

Tab. 1 Additional planning documents

Document designation Print number

CT Basic Planning Guide CT00-000.891.02

CT Options Planning Guide CT00-000.891.03

All others Shown in the CT Basic PG.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

General information 13

Page 13 of 128

For internal use only

Notes regarding on-site preparations 1.4

For details, refer to the chapter General information in the CT Basic PG, print number

CT00-000.891.02.

14 General information

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 14 of 128

For internal use only

Notes with respect to project plans 1.5

For details, refer to the chapter General information in the CT Basic PG, print number

CT00-000.891.02.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

General information 15

Page 15 of 128

For internal use only

Preliminaries 1.6

The project manager has to clarify the following CT components and accessories on-site

and include them in the order:

Length required for:

system wiring

- e.g. MVT cable W4 / W5

available lengths: 10 m/ 16 m/ 25 m

water hoses for system cooling

- available lengths: 10 m/ 20 m/ 30 m

16 General information

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 16 of 128

For internal use only

Preliminary ordering 1.7

Tab. 2 Recommended preliminary ordering

Tab. 3 Required preliminary ordering

Component Notes

System wiring Refer to System connections (Wiring sets - notes / p. 80).

Installation template For the gantry and patient table.

Order number: 10161596

Department: CS ML

Component Notes

Water/air-split cooling

system

(option)

The cooling system is delivered as a pre-installation kit.

Parts in delivery volume of the option:

Outdoor unit

Indoor unit

Hoses and system cables (data cables)

Connection kit and connection scheme

For details, refer to the chapter Water/air split cooling sys-

tems in the CT Options PG, print number CT00-000.891.03.

The installation parts for installing this cooling system

have to be in place already when the CT system is deliv-

ered.

The primary cooling circuit may be filled and checked

for tightness. The electrical connection may be carried

out first together with the CT system.

Flow heater If needed, the flow heater has to be installed with the cool-

ing system water/air-split at the time.

Parts in delivery volume:

For details, refer to the chapter Flow heater in the CT

Options PG, print number CT00-000.891.03.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

General information 17

Page 17 of 128

For internal use only

Note with respect to drawings and figures 1.8

NOTE All drawings as well as images in this planning guide are not

true to scale. For this reason, they are not suitable for provid-

ing actual dimensioning. If not stated otherwise, all dimen-

sions are provided in [mm].

18 General information

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 18 of 128

For internal use only

Abbreviations, definitions and explanations of symbols 1.9

Tab. 4 Designations for ICS / IES

NOTE For editorial reasons and reasons of familiar technical under-

standing by the Project Managers, the designations ICS

and IES are still used within this PG.

For details, refer to the chapter General information in the CT Basic PG, print number

CT00-000.891.02.

Designation Definitions

ICS syngo Acquisition Workplace

IES syngo CT Workplace

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

General information 19

Page 19 of 128

For internal use only

Overview - standard components 1.10

Tab. 5 Overview - standard components

Component Description

Gantry and PHS The gantry is designed as a self-supporting system. It con-

tains 2 tubes with 2 integrated HV generators. The gantry is

water-cooled with an integrated heat exchanger. Therefore,

the on-site cooling water supply is connected directly to the

gantry.

The PHS includes telescopic height adjustments. The PHS

must be bolted to the floor.

Fig. 1: Gantry and patient table (PHS3)

Power Distribution

Cabinet A (PDC_A)

The PDC_A cabinet converts the line voltage and distributes

part of the power supply voltages to certain subsystems. It

includes the stationary part of the generator (XGS_A). The

UPS and the ethernet switches (internal and external) are

located in the PDC_A cabinet.

Fig. 2: Illustration: PDC cabinet

20 General information

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 20 of 128

For internal use only

Power Distribution

Cabinet B (PDC_B)

The PDC_B cabinet converts the line voltage and distributes

the power supply voltages to the stationary part of the gener-

ator (XGS_B).

Fig. 3: Illustration: PDC cabinet

IRSmx2a tower

(IRS)

The image processor is integrated into a tower chassis and is

used for image reconstruction.

The designation is IRSmx2a tower.

Fig. 4: Illustration: IRSmx2 tower

Image system (IMS)

and components

The IMS includes the syngo Acquisition Workplace (ICS

1

,

tower PC), the Image Reconstruction System (IRSmx2a

tower), one 19 inch monitor, the control box, the PC keyboard,

and a mouse.

PC keyboards may be ordered according to country-specific

requirements.

ICS_PD is a line voltage connector terminal for the IT components of

the syngo Aquisition Workplace and the optional digital video

splitter (DVI). It is attached to the back of the operating con-

sole in the vicinity of the syngo Aquisition Workplace or in the

container.

Component Description

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

General information 21

Page 21 of 128

For internal use only

Monitor One 19 inch monitor is included in the delivery volume.

Additional information and displays:

Refer to the chapter General information in the CT Basic PG,

print number CT00-000.891.02.

Control box Is a console in addition to the standard keyboard of the IMS

and includes all CT-specific control elements. An intercom for

communicating with the patient, ON/OFF functions, functional

buttons, and a radiation indicator are integrated.

Fig. 5: Illustration: Control Box

Router/VPN device For SRS (Siemens Remote Services), all CT systems must be

connected via an Internet Tunnel Connection (VPN) to the

SRS server.

Consider line types such as ISDN or analog as fallback meth-

ods only.

Since the VPN device/router is not automatically deliv-

ered with the CT system, it has to be ordered separately.

Component Description

22 General information

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 22 of 128

For internal use only

Ethernet switch There are 2 Ethernet switches available with the CT system:

Location in the PDC_A cabinet.

Internal switch for data communications between the ICS,

IRS, gantry, and PDC cabinets.

External switch for connecting external equipment, e.g.

syngo CT Workplace, DICOM cameras, network printers,

SRS router, and so on, directly to the CT system.

UPS The UPS is part of the standard delivery volume of the CT sys-

tem. This UPS is located in the PDC_A cabinet. It supplies the

IMS and the Ethernet switches as well as parts of the control

system for 5 minutes in case of power brown-outs or errors.

Fig. 6: UPS - illustration and location in PDC_A

Pos. 1 UPS with accumulator pack

1. The syngo Acquisition Workplace was formerly named ICS.

Component Description

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

General information 23

Page 23 of 128

For internal use only

Overview - options 1.11

Tab. 6 Overview - options

Component Description

All available options Refer to the system information (SI) diagram and information

regarding the price (PM).

Installation template Template incl. footprint information for the gantry and PHS.

Order number: 10161596

Department: CS ML

Earthquake kit

(for gantry)

Available for countries prone to earthquakes.

Order number: 10094393

Includes all installation materials, e.g. screws, anchors, and so

on, to secure the gantry to the floor.

System furniture Different system furniture suitable in optical design is available

for all CT components. It is made to position IMS components,

e.g., the monitor, keyboard, mouse, and so on. Additionally, the

tower PCs and certain UPS can be located in the IMS container.

For details, refer to the chapter System furniture in the CT

Options PG, print number CT00-000.891.03.

Camera For details, refer to the chapter General information in the CT

Options PG, print number CT00-000.891.03.

MPT

(Multi Purpose Table)

Patient table for special medical applications, e.g., radiotherapy,

bariatric patients, and trauma applications. The operator can

exchange the tabletop plate for these special applications.

For details, refer to the chapter MPT (Multi Purpose Table) in

the CT Options PG, print number CT00-000.891.03.

CARE Vision CT CARE Vision CT is a special examination scan mode for inter-

ventions such as biopsies or drainages under CT control.

Images are continuously reconstructed and displayed on a mon-

itor inside the examination room. The examining physician can

monitor the movement of the surgical instrument to avoid inju-

ries of sensitive structures, such as vessels or nerves.

For details, refer to the chapter CARE Vision CT in the CT

Options PG, print number CT00-000.891.03.

Respiratory gating For breathing-controlled CT scans. The option is used mainly for

radiation therapy.

For details, refer to the chapter Respiratory gating in the CT

Options PG, print number CT00-000.891.03.

24 General information

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 24 of 128

For internal use only

syngo CT Workplace

(IES

1

)

The syngo CT Workplace is the primary site for image viewing,

filming, exporting data, 3D reconstruction, and data postpro-

cessing (including reconstruction).

List of components:

One 19 inch monitor

Tower PC

Keyboard

Mouse

Power distributor IES_PD

Ethernet switch

Optional UPS MGE Evolution 1550 VA:

The syngo CT Workplace and allocated monitor may be con-

nected to a separate UPS. During power failure or interrup-

tions, all functions of the syngo CT Workplace and the

monitor are maintained for up to 3 minutes. Additionally, an

acoustic alarm sounds.

The UPS has to be ordered depending on the country of use

- 120 V or 230 V.

If used the UPS can be located within the IMS container.

Fig. 7: UPS: MGE Evolution 1550

Component Description

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

General information 25

Page 25 of 128

For internal use only

Water/air-split cool-

ing system

For cooling the gantry, if no on-site water connection is available.

Consists of an indoor unit and an outdoor unit. The outdoor unit

cools the primary water circuit of the indoor unit. They are con-

nected to each other via water hoses and a power/control cable.

Fig. 8: Illustration: Water/air split cooling system 15 kW

Pos. 1 Indoor unit

Pos. 2 Outdoor unit

For detailed planning information and all available split-cool-

ing options, refer to the chapter Water/air-split cooling sys-

tems in the CT Options PG, print number CT00-000.891.03.

Fixed piping kit DN25 The fixed piping kit DN25 is an additional option for the internal

cooling systems.

The option includes the installation material to connect the deliv-

ered flexible cooling hoses for the cooling systems to on-site

fixed piping.

For details, refer to the chapter Fixed piping kit DN25 /DN32 in

the CT Options PG, print number CT00-000.891.03.

Power injector

(interface)

The purpose of this option is to connect a power injector to the

CT system. It consists of a single cable that serves as an inter-

face from the CT side.

1. The syngo CT Workplace was formerly named IES.

Component Description

26 Room planning

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 26 of 128

For internal use only

2- 2Room planning

Notes and regulations 0

Refer to the chapter Room planning in the CT Basic PG, print number CT00-000.891.02

for:

Visual contact to patient

Minimum distances to systems not provided by Siemens (EMC)

Minimum distance to the patient

Service and safety distances

NOTE During room planning, please integrate country-specific

guidelines, e.g. national regulations with respect to safety

distances for electrically operated systems.

CAUTION

[ hz_pgdoc_F02G09U03M03 ]

The extension of the scan range may result in injury to the

user and the patient.

Risk of injury!

Minimum distances between the system and the wall

have to be observed in accordance with the planning

guide.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Room planning 27

Page 27 of 128

For internal use only

Room sizes 2.1

Tab. 7 Room sizes

Area requirements - Minimal requirements from a technical point of view 0

Minimal technical area requirements without allowances made for safety distances

according to the national guidelines of the country in question.

NOTE The service area beside the right gantry leg has to be kept

clear of any installation on the floor to enable servicing of the

internal water cooling system.

Designation Size Remarks

Room height

(minimal)

2200 mm Technically required minimum room

height.

Area require-

ments

1

1. All area dimensions are related to the dimensions as shown in the next drawing. The space require-

ments for an air conditioning system in the examination room or control room are not included.

Gantry and PHS:

17.82 m

2

PDC_A, PDC_B cabinets:

3.63 m

2

Operating console:

1.92 m

2

The technical minimum area

requirement of the overall system is

derived from the sum of the individ-

ual area requirements of the respec-

tive standard system components.

Including allowances made for

service areas.

Without allowances made for

safety distances according to the

national guidelines of the coun-

try in question.

Complete:

23.28 m

2

Room volume

(minimal)

9.2 m

3

When installing the optional

water/air-split cooling system.

Required for safety reasons in

the room that is used for install-

ing the indoor unit

Reason:

Caused by an error in the amount of

cooling agent in the water/air-split

cooling system (indoor unit) that

exhausts into the air.

The minimum room volume is

required to absorb the cooling agent

into air.

28 Room planning

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 28 of 128

For internal use only

Fig. 9: Minimum technical area requirements: Standard system components with patient table PHS3

Pos. (A) Minimum technical area requirements for the gantry and the patient table (top view)

Pos. (B) Minimum technical area requirements for PDC cabinets (top view)

Pos. (C) Minimum technical area requirements for operating console (top view)

Pos. X Scannable range; stepwise adjustable; refer to the next table

Pos. 1 Minimum clearance required for service

Pos. 2 Phantom

Pos. 3 IRSmx2a tower; can also be located to the left next to the PDC_A cabinet

Tab. 8 Stepwise adjustable scannable range - PHS 3

Adjustable scan-

nable range X

1

PHS3

without phantom

2

with phantom

Range 1

3

2000 2050

Range 2 1600 1650

Range 3 1400 1450

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Room planning 29

Page 29 of 128

For internal use only

Range 4 1200 1250

Range 5 1100 1150

Range 6 950 1000

Range 7 800 850

1. Refer to drawing (Fig. 9 / p. 28).

2. But with add-on components, such as head holder, table extension,

etc.

3. Nominal scannable range of the patient table as delivered.

Adjustable scan-

nable range X

1

PHS3

without phantom

2

with phantom

30 Room planning

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 30 of 128

For internal use only

Dimensions of components 2.2

Gantry and patient table 0

Fig. 10: Detailed dimensions: Gantry and patient table PHS3

Pos. (A) Side view

Pos. (B) Front view

Pos. (C) Top view

Pos. 1 Slice plane

Pos. 2 Laser light

Pos. 3 400 mm with phantom only; 350 mm with add-on components, such as head holder, table extension, etc.

Pos. 4 Travel path of the tabletop support

Pos. 5 Scannable range without Pos. 3

PDC_A / PDC_B cabinets 0

The cabinets are of the same construction and dimensions.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Room planning 31

Page 31 of 128

For internal use only

Fig. 11: Detailed dimensions, PDC cabinets (PDC_A and PDC_B)

Pos. (A) Front view

Pos. (B) Side view

Pos. (C) Top view

Pos. (D) Illustration for floor mounting (top view)

Pos. (E) Illustration for cable inlet (top view)

Pos. (F) Illustration for cable inlet (3D view)

Pos. 1 System cables

Pos. 2 Cut-outs in the base when routed on the floor (dummy plate); cables are routed on the floor through the base of

the cabinet; feed lines are possible from all sides

Pos. 3 Drill holes (all diameters 14 mm) in floor plate for floor mounting

Pos. 4 PDC cabinet base (footprint)

Pos. 5 Cut-out for cable inlet in PDC base; opening is adjustable

Pos. 6 Openings for air circulation/cooling; may not be covered

Pos. 7 For example, the sliding door of a wall closet, and so on.

Pos. 8 For example, a wall; no safety distance for air circulation (cooling) required

Pos. 9 Safety distance for air circulation (cooling); required only at the front

32 Room planning

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 32 of 128

For internal use only

NOTE The safety distances for air circulation (system cooling) must

be maintained. All openings for air circulation in the cabinet

cannot be covered.

IRSmx2a tower 0

Fig. 12: Detailed dimensions: IRSmx2 tower

Pos. (A) Front view

Pos. (B) Back view

Pos. (C) Top view

Pos. (D) Detailed magnification and dimensions of the back of the tower

Pos. 1 Holes for air intake (cooling)

Pos. 2 Spacers, tiltable 90 degrees for transport

Pos. 3 Strain relief for cables

Pos. 4 Hand hold for transport

Pos. 5 Sliding door or similar

Pos. 6 Minimum distance for air circulation

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Room planning 33

Page 33 of 128

For internal use only

NOTE The safety distances for air circulation (system cooling) must

be maintained. All openings for air circulation in the tower

housing cannot be covered.

Tower PCs for syngo Acquisition Workplace / syngo CT Workplace 0

The tower PCs are commercially available standard tower PCs that are subject to version

changes as dictated by the market.

The dimensions that are shown in following drawing are the dimensions of a general stan-

dard size for tower PCs used by Siemens CTs.

34 Room planning

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 34 of 128

For internal use only

Fig. 13: Detailed dimensions - tower PCs (example illustration)

Pos. (A) Front view

Pos. (B) Side view

Pos. (C) Top view

Pos. (C) 3D view

Pos. 1 Air exhaust (fan)

Pos. 2 For example, a wall

Pos. 3 E.g. a sliding door when installing in a cabinet

Pos. 4 Minimum distance for cooling (air circulation)

System furniture 0

E.g. operating consoles, IMS container, miscellaneous furniture elements, and so on.

For details, refer to the chapter System furniture" in the CT Options PG, print number

CT00-000.891.03.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Room planning 35

Page 35 of 128

For internal use only

Maximum distances between components 2.3

The maximum system distances area a result of the lengths of the system wiring available

and the lengths of the water hoses from the optional water/air-split cooling system.

System wiring:

All CT components; refer to (Wiring scheme - Standard components / p. 82).

Water hoses of the cooling system (integrated in gantry):

Refer to (Delivery data / p. 113).

Water hoses of the cooling system water/air-split (option):

For details, refer to the chapter Water/air-split cooling systems in the CT Options PG,

print number CT00-000.891.03.

36 Room planning

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 36 of 128

For internal use only

Radiation protection 2.4

Regulations 0

CAUTION

[ hz_serdoc_F04G02U05M01 ]

Inadequate room shielding can cause risk of injury to users

and surroundings.

Risk of injury!

Adequate room shielding has to be installed.

Additional regulations with respect to:

For details, refer to the chapter Room planning in the CT Basic PG, print number

CT00-000.891.02.

Visual radiation warning indicators 0

A visual radiation indicator according to IEC 60601-2-44 and CFR 21 is already installed

in the gantry.

Location: in the operating panel, front and back.

It is possible to connect

a separate on-site radiation indicator and

an on-site radiation ready indicator according to IEC 60601-2-44 and CFR 21 in the

CT system.

For connection description see (Radiation indicator/ radiation ready indicator / p. 69).

Radiation locking 0

A contact for connecting a door switch that blocks X-rays when the door is opened is

included in the CT system.

For connection description see (Radiation locking (door switch) / p. 67).

Local dose distribution 0

Scanning was performed using a maximum slice thickness of 24 x 1.2 mm (28.8 mm) at

140 kV through the system axis in the horizontal plane. A cylindrical PMMA phantom mea-

suring 32 cm in diameter and 16 cm in length was used for the scatter radiation test. The

phantom was centered in the tomographic plane.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Room planning 37

Page 37 of 128

For internal use only

Fig. 14: Horizontal local dose distribution - measurement values in microGy/1 mAS

Fig. 15: Vertical local dose distribution - measurement values in microGy/1 mAS

38 Room planning

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 38 of 128

For internal use only

NOTE The local dose values in the diagram show the values for

scans taken with both tubes at the same tube current.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Room planning 39

Page 39 of 128

For internal use only

Room configurations - recommendations 2.5

For details, refer to the chapter Room planning" in the CT Basic PG, print number

CT00-000.891.02.

40 Room planning

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 40 of 128

For internal use only

Workstation and room lighting - regulations 2.6

For details, refer to the chapter Room planning" in the CT Basic PG, print number

CT00-000.891.02.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Room planning 41

Page 41 of 128

For internal use only

Siemens Remote Services (SRS) 2.7

In order to pursue a consistent Siemens Med service strategy, all CT systems must have

working SRS connections at the time of hand-over to the customer.

Siemens EPS (Enhanced Productivity Services) and RUH (Remote Update Handling) are

part of the Siemens Med Strategy and require a mandatory broadband VPN connection.

Consider line types such as ISDN or analog as fallback methods only.

All planning-related information for SRS must be taken from the SRS Planning Guide,

print number TDIT-000.891.01.06, established for this purpose.

42 Installation preparation

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 42 of 128

For internal use only

3- 3Installation preparation

Installation notes and regulations 0

For details, refer to the chapter Installation preparation" in the CT Basic PG, print number

CT00-000.891.02.

CAUTION

[ hz_pgdoc_F02G10U03M04 ]

An improperly secured table can cause injury to the user and

patient.

Risk of injury!

Securing the patient table to the floor is mandatory as

specified in the planning guide and installation instruc-

tions.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Installation preparation 43

Page 43 of 128

For internal use only

Static requirements 3.1

Flooring for the gantry and patient table - requirements 0

For details, refer to the chapter Installation preparation" in the CT Basic PG, print number

CT00-000.891.02.

Existing mounting frames 0

The gantry and PHS cannot be installed on existing mounting frames of older CT systems.

Access floor - subconstruction 0

For details, refer to the chapter Installation preparation" in the CT Basic PG, print number

CT00-000.891.02.

Floor loading of gantry 0

The floor structure must withstand the occupied weight of the gantry and the individual con-

tact area loading.

Fig. 16: Measurement points - floor load

Tab. 9 Floor loading of gantry - measurement points

Measurement point (adjustable foot)

1

1. The gantry rests on 4 adjustable feet.

1 2 3 4

F

stat

max

[N]

2

2. Static floor loading due to the gantry's own weight.

5500 6500 7500 6200

Amplitude for F

dyn

[N]

3

3. Difference between minimum and maximum floor loading during gantry rotation.

550 650 750 620

Diameter per adjustable foot [mm] 80 80 80 80

Bearing area per adjustable foot [cm

2

]

50.27 50.27 50.27 50.27

44 Installation preparation

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 44 of 128

For internal use only

NOTE The values provided for floor loading apply only if the gantry

is leveled satisfactorily.

Floor and building vibrations 0

General

Floor and building vibrations can reduce image quality.

Sources that produce vibrations are, e.g.,

Railroad routes

Subways

Roads

Road work and construction sites

Hospital power plants

Mines, open-cast minings, quarries (explosions)

Ferry moorings

Any other sources of striking vibrations

In the 3 spatial directions, the acceleration in vibrations at the mounting points of the com-

puted tomography system (Gantry and Patient Handling System PHS) must not exceed the

thresholds as described in the following sections.

Continuous vibrations

Fig. 17: Permissible acceleration for continuous vibration - diagram

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Installation preparation 45

Page 45 of 128

For internal use only

NOTES:

The threshold is defined as acceleration rms value (root mean square) in m/s

2

of an

FFT spectrum derived with a frequency resolution of 1 Hz and using a Hanning window.

The vibrations have to be measured with a sampling rate of 1000 Hz using an anti-alias-

ing filter with a limit frequency of 250 Hz.

The threshold is valid for vibrations at the installation location with a CT in position.

Measurements are usually taken at the site before the installation of the CT. Changes in

the eigenfrequency of the slab caused by the additional mass of the CT have to be con-

sidered when comparing the frequency spectrum with the threshold.

Values of the threshold are given in (Tab. 10 / p. 45).

Transient vibrations (shocks)

Any transient vibration has to be less than 0.2m/s

2

peak-to-peak in the time domain.

The vibrations have to be measured with a sampling rate of 1000 Hz.

Tab. 10 Threshold values of admissible acceleration (rms value of 1 Hz resolution FFT)

Frequency [Hz] Acceleration rms [mm/s

2

]

1 0.50

2 0.67

3 0.80

4 0.91

5 1.00

6 1.27

7 1.56

8 1.86

9 2.17

10 2.50

11 3.46

12 4.66

13 6.13

14 7.90

15 10.00

16 14.35

17 20.14

18 27.73

46 Installation preparation

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 46 of 128

For internal use only

19 37.53

20 50.00

Frequency [Hz] Acceleration rms [mm/s

2

]

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Installation preparation 47

Page 47 of 128

For internal use only

Installation of components 3.2

Gantry 0

Tab. 11 Installation of gantry

Designation Description Remarks

Subgrade

1

as a rule only concrete floor-

ing/composite flooring

mounting frame

access floor

Concrete class C20/25 to C50/60

according to DIN 1045-1.

Access floor with on-site subconstruc-

tion.

Floor mounting In principle not required for

system operation

Possible through 4 mounting

holes in the gantry base

Only required according to the cur-

rently valid country guidelines, e.g. in

countries prone to earthquakes

Installation materials (e.g. screws,

anchors, and so on) are available in the

optional Earthquake kit; refer to

(Tab. 6 / p. 23)

Evenness of floor The permissible tolerance for the

evenness of the floor is max. 10

mm, referenced to the area of the

adjustable feet of the gantry and

patient table.

Gantry leveling tolerance:

In the Z-direction: 0.2 deg.

In the X-direction: 0.5 deg.

Positioning and

leveling

Stands on 4 adjustable feet.

Leveling with the 4 adjustable

feet.

Gantry and patient table have to be on the

same level (isocenter).

Floor covering Remove the floor covering in the

bearing areas.

The area to be cut out is at least the diame-

ter of the bearing areas of the adjustable

feet (diameter 80 mm).

Intermediate piece Is attached between gantry base

and patient table base.

No on-site preparations are required.

The intermediate piece is locked into the

gantry base and patient table base.

Additionally, it is glued to the floor (dou-

ble-sided adhesive tape is already

attached to intermediate piece).

48 Installation preparation

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 48 of 128

For internal use only

Patient table 0

CAUTION

[ hz_serdoc_F02G10U03M02 ]

An improperly secured table can cause injury to the user and

patient.

Risk of injury!

Securing the patient table to the floor is mandatory as

specified in the planning guide and installation instruc-

tions.

Tab. 12 Installation of the patient table

Installation tem-

plate

(option)

Template with footprint informa-

tion for the gantry and patient

table.

Paper template

on a scale of 1:1

not in standard delivery volume

preliminary ordering is recommended;

refer to (Preliminary ordering / p. 16)

NOTE: This template may not be used as

a drilling template.

Dimensions

(for floor mounting)

Refer to (Dimensions for floor mounting - Gantry and patient table / p. 51).

1. An engineer must test the weight capacity of the concrete flooring or other subgrades.

Designation Description Remarks

Designation Description Remarks

Subgrade

1

As a rule, only concrete

flooring/bonded screed.

Mounting frame

Access flooring

Concrete class C20/25 to C50/60

according to DIN 1045-1.

Access floor with on-site subcon-

struction.

Floor mounting Always - as a rule of thumb!

Floor mounting is handled

via the adjustable feet.

Alternative mounting holes

are available.

Requirement of the manufacturer.

in addition according to currently

valid country guidelines, e.g. in

countries prone to earthquakes

Installation material for floor mount-

ing in concrete is included in the

delivery volume.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Installation preparation 49

Page 49 of 128

For internal use only

Evenness of floor Permissible tolerance for even-

ness of floor is max. 10 mm ref-

erenced to the area of the

adjustable feet of the gantry and

patient table.

Add compensating plates (included in

delivery volume).

Positioning and leveling Stands on four adjustable

feet.

Leveling with the four adjust-

able feet.

Dimensions of the bearing surface of

the adjustable feet:

Inner diameter: 20.5 mm

Outer diameter: 28 mm

NOTE: The gantry and the patient table

have to be on the same (isocenter)

plane.

Minimum extraction

force

2.03 kN at the 2 mounting points

bearing the greatest load at

max.patient travel path and a

230-kg load.

According to IEC 60601-1, it is manda-

tory that the 4-fold safety factor be

observed.

Floor covering Remove the floor cover in the

entire footprint area of the table

base.

The drilling template is equal to the foot-

print of the patient table base and is

used as a help to cut out the floor cov-

ering.

Sealing Transition table base/floor. The project manager has to provide sil-

icone during the installation.

Installation template

(option)

Template with footprint informa-

tion of the gantry and patient

table.

Paper template

on a scale of 1:1

not in standard delivery volume

preliminary ordering is recom-

mended; refer to (Preliminary

ordering / p. 16)

NOTE: This template may not be

used as a drilling template.

Drilling template Metal sheet with the outline of

the patient table base. The posi-

tions of the drill holes are inte-

grated.

In delivery volume of the patient table.

Designation Description Remarks

50 Installation preparation

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 50 of 128

For internal use only

Installation material for floor mounting (included in the delivery volume)

Drilling template

8 x HILTI anchor bolts (2 types)

- Type 1:

4 x HSL-3G M10/60 heavy-duty sleeve anchor bolts;

used without bonded screed.

- Type 2:

4 x HSL-3G M10/120 heavy-duty sleeve anchor bolts;

used with up to 60 mm thick bonded screed.

- Required drill size: 15 mm diameter

- Torque: 35 Nm

- Minimum concrete thickness: 140 mm

- Minimum drill hole depth: 90 mm

Preliminaries - flooring for the patient table

Tab. 13 Preliminaries for the patient table

Adjustable scannable

ranges

The scannable range of the

patient table PHS3 is stepwise

adjustable.

The mechanical end-stop can

be adapted to the on-site room

situation, e.g. in small examina-

tion rooms.

The adjustment must be performed dur-

ing system start-up.

Refer to (Tab. 8 / p. 28) for the step

parameters.

Dimensions

(for floor mounting)

Refer to (Dimensions for floor mounting - Gantry and patient table / p. 51).

1. An engineer must test the weight capacity of concrete flooring or other subgrades.

Designation Description Remarks

Designation Description Remarks

Subgrade Concrete

Bonded screed

Floating screed

Information has to be clari-

fied beforehand by the

project manager and has to

be available for system

installation.

Strength of existing screed

1

1. Determine together with an engineer the floor mounting when measuring screed > 60 mm, as well as

for flooring that deviates from the basic flooring requirements for CT systems. The necessary attach-

ment materials have to be provided on-site.

To determine the depth

of the drill holes.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Installation preparation 51

Page 51 of 128

For internal use only

Anchorage of the HILTI anchors (example)

Fig. 18: Anchoring the PHS with HILTI anchors (example)

Pos. (A) Without bonded screed

Pos. (B) With bonded screed

Pos. 1 Minimum drill hole depth

Pos. 2 Flooring

Pos. 3 Cut-out

Pos. 4 Bonded screed

Pos. 5 Concrete

Pos. 6 HILTI anchor HSL-3G M10/60

Pos. 7 HILTI anchor HSL-3G M10/120

Dimensions for floor mounting - Gantry and patient table 0

Variation 1

The locations and dimensions that are shown in following drawing are valid for gantry serial

numbers:

up to 1011 and

from 1020 to 1029

52 Installation preparation

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 52 of 128

For internal use only

Fig. 19: Floor mounting: Gantry and patient table (variation 1)

Pos. (A) Overview of the location of the adjustable feet and the floor mounting holes

Pos. (B) Detailed dimensions of the adjustable feet and the floor mounting holes

Pos. 1 Slice plane

Pos. 2 Adjustable feet of the gantry; diameter of the bearing area per adjustable foot: 80 mm

Pos. 3 Floor mounting holes of the gantry; diameter: 22 mm

Pos. 4 Floor mounting holes (adjustable feet) of the patient table; inner diameter: 20.5 mm

Pos. 5 Alternative floor mounting holes; diameter: 18 mm

Variation 2

The locations and dimensions that are shown in following drawing are valid for gantry serial

numbers:

from 1012 to 1019

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Installation preparation 53

Page 53 of 128

For internal use only

beginning with 1030

Fig. 20: Floor mounting: Gantry and patient table (variation 2)

Pos. (A) Overview of the location of the adjustable feet and the floor mounting holes

Pos. (B) Detailed dimensions of the adjustable feet and the floor mounting holes

Pos. 1 Slice plane

Pos. 2 Adjustable feet of the gantry; diameter of the bearing area per adjustable foot: 80 mm

Pos. 3 Floor mounting holes of the gantry; diameter: 22 mm

Pos. 4 Floor mounting holes (adjustable feet) of the patient table; inner diameter: 20.5 mm

Pos. 5 Alternative floor mounting holes; diameter: 18 mm

54 Installation preparation

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 54 of 128

For internal use only

IRSmx2a tower 0

The IRSmx2a tower is a stand-alone system. Due to its size and weight, there are no spe-

cial on-site requirements.

Tab. 14 Installation notes - IRSmx2a tower

Designation Description

Static requirements No special requirements.

Subconstructions The project manager must decide if subconstruction is neces-

sary depending on the local floor conditions.

Flooring No special requirements. Can be located on every floor.

Wall distances For system cabling:

Spacers provide and limit the minimum clearance of 100

mm to a wall at the back.

For system cooling:

The tower chassis is an air-cooled system. For air circula-

tion, there are air outlets (fans) in back and front of the hous-

ing.

- Spacers provide and limit the minimum clearance of 100

mm to a wall at the back.

- The minimum distance between the front of the housing

to a wall or other flat surfaces for cooling is 150 mm.

- The IRSmx2d tower may not be installed in a wall cab-

inet without adequate air circulation, cooling air

intake, and so on.

Refer to (Fig. 12 / p. 32).

Service clearance Minimum 950 mm to the front side.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Installation preparation 55

Page 55 of 128

For internal use only

Mounting Required only in accordance with currently valid country reg-

ulations in, e.g., countries prone to earthquakes.

The project manager decides how the tower is mounted to

the floor, e.g., with lashing straps. There are no mounting

holes in the tower chassis.

Mounting material must be provided on-site.

Moving A transport device to locate the IRSmx2a tower in the room is

integrated at the tower housing. There is a handhold on top of

the tower housing and 2 rollers at the bottom back. The rollers

are integrated within the tiltable spacers.

Fig. 21: IRSmx2 tower: Transport devices

Pos. 1 Hand hold

Pos. 2 Tiltable spacers with integrated rollers at both sides

Fig. 22: IRSmx2 tower: Spacers and rollers

Pos. 1 Spacers with rollers UP; transporting position

Pos. 2 Spacers with rollers DOWN; installation position

Designation Description

56 Installation preparation

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 56 of 128

For internal use only

PDC_A / PDC_B cabinets 0

Tab. 15 Installation of the PDC cabinets

System furniture 0

E.g. operating consoles, IMS container, miscellaneous furniture elements, and so on.

For details, refer to the chapter System furniture" in the CT Options PG, print number

CT00-000.891.03.

Tower PCs for syngo Acquisition Workplace (ICS) / syngo CT Workplace (IES) 0

The tower PCs are commercially available standard tower PCs.

For details, refer to the chapter Installation preparation" in the CT Basic PG, print number

CT00-000.891.02.

Monitor and Keyboard 0

For details, refer to the chapter Installation preparation" in the CT Basic PG, print number

CT00-000.891.02.

Designation Description Remarks

Construction / design Cabinets:

PDC_A and

PDC_B

Cabinets of same construction and

dimensions.

Evenness of floor Floor is level. For all cabinets.

Floor mounting Drill holes are included in the

floor plate.

Installation material, e.g.

screws and anchors must be

provided on-site.

A drilling template is

included in the delivery vol-

ume of PDC_A.

In countries prone to earthquakes, the

applicable country-specific guidelines

must be observed as well.

Dimensions Refer to (Fig. 11 / p. 31).

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Installation preparation 57

Page 57 of 128

For internal use only

Control box 0

NOTE The Emergency STOP switch in the control box must be

within easy reach. For this reason, the distance between con-

trol box and the operator at the keyboard must not exceed 2

m.

There are no other special planning requirements for the control box.

58 Installation preparation

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 58 of 128

For internal use only

Connection - Cooling system (integrated into gantry) 3.3

Refer to chapter Cooling system (integrated in gantry) (Cooling system (integrated into

gantry) / p. 111).

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Installation preparation 59

Page 59 of 128

For internal use only

On-site electrical installations 3.4

Notes and regulations - General 0

For details, refer to the chapter Installation preparation" in the CT Basic PG, print number

CT00-000.891.02.

Line voltage connection - On-site requirements of the manufacturer 0

Refer to the chapter Installation preparation" in the CT Basic PG, print number

CT00-000.891.02. for:

Type of line,

Voltage stabilizer,

Protective conductor resistance,

ON/OFF switch to disconnect from the line voltage,

Emergency-Power OFF switch (EPO),

Lightning/overvoltage protection, and

PDC connection.

NOTE It is mandatory to maintain the basic CT system require-

ments with respect to the on-site power supply line.

More electrical data:

Refer to (Electrical data / p. 95).

On-site line voltage fuses 0

For system safety (short-circuit protection), install the required on-site fuses according to

CE and UL requirements.

Tab. 16 Fuse specifications

Residual current protective device (RCD) 0

Function: Switches off power in the event of residual currents.

Voltage range Fuse

380 V to 480 V 2 fuse blocks with 3 fuses each for PDC_A and PDC_B are required:

Fuse type: 125-A NH, Type gl/gG

1

.

1. When using other fuses, observe the values shown in the time-current-characteristics diagram, SIE-

MENS type series 3NA3 0. For details, refer to the Installation preparation chapter in the CT Basic

PG, print number CT00-000.891.02.

60 Installation preparation

SOMATOM Definition CT02-028.891.01.17.02 Siemens, 2005

12.11 H CX CS SD CR-CT

Page 60 of 128

For internal use only

Installation of an RCD, if required by country-specific guidelines, or if it is not

possible to maintain the loop impedance.

In Germany, an RCD is required according to VDE 0100-710.

Must be provided on-site by the customer.

It is not permitted to install an RCD Type B after an RCD Type A.

In Germany, it is a requirement according to the German regulation DIN VDE

0100- 0530 not to install an RCD Type B after an RCD Type A.

Refer to following block diagram:

Fig. 23: Installation of RCD types A and B

Tab. 17 RCD specifications

NOTE The use of RCD type B only is permitted for CTs.

Rated voltage range U

N

RCD specifications

1

1. For each PDC line voltage connection.

380 V to 480 V

(according the line voltage

used in your country)

Type B

I

N

= 125 A

I

N

= 300 mA

2

Selective, and/or short-time delay switch-off

For sinusoidal AC residual currents

For pure and pulsating DC residual currents

Surge-protected

2. In accordance with IEC 60364-7-710, an RCD with I

N

= 30 mA must be installed in group

2 medical locations.

Siemens, 2005 CT02-028.891.01.17.02 SOMATOM Definition

12.11 H CX CS SD CR-CT

Installation preparation 61

Page 61 of 128

For internal use only

Size of connecting terminal for line voltage cable in the PDC_A / PDC_B cabinets0

Tab. 18 Size of connecting terminals in PDC_A / PDC_B