FAGERHULT Belysningsplanering UK

Diunggah oleh

Tommyc1024Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

FAGERHULT Belysningsplanering UK

Diunggah oleh

Tommyc1024Hak Cipta:

Format Tersedia

402 www.fagerhult.com www.fagerhult.co.

uk

Lighting planning

Quantities, units and their signicance

For standardised denitions and further clarication of magnitudes, units and concepts, see SS- EN 12 665 - Basic terms and criteria for specifying lighting requirements

Quantity/Concept Symbol Unit Formula Explanation

Luminous intensity candela

(cd)

I=/ Luminous intensity is the intensity in a determined direction. Denition: -

Luminous ux per solid angle ().

Illuminance E

(lx)

Lux

(lm/m

2

)

Illuminance refers to the luminous ux that hits a specic surface.

Denition: - Luminous ux per unit area (m

2

).

Luminance L (cd/m

2

) L=I/A

(L=I/Acos)

This is dened as the luminous intensity in a specic direction from a surface of

a light source, luminaire or lit surface, divided by the projected area.

Luminous ux lumen

(lm)

=I/ Luminous ux refers to the total amount of light emitted from a light source. It is

dened as the amount of light emitted when the light sources radiant luminous

ux, is evaluated against the eyes sensitivity in daylight (l-curve according to CIE).

Design lumen

B

lumen Refers to the light sources luminous ux that is emitted at an ambient tem-

perature of 25 C. The quoted luminous ux may differ from the light sources

maximum luminous ux.

Design efciency

B

The design efciency of the luminaire is used in lighting calculations together

with the design lumen for the light source. The design efciency includes the

correction for BLF when measuring the luminaire and light source in an ambi-

ent temperature of 25 C.

B

=

measured

x BLF.

Ballast Lumen Factor BLF Denes the luminous ux from a light source. It is measured with either a

commercial ballast or a reference ballast, at an ambient temperature of 25C.

Colour temperature kelvin

(K)

CIE 17.4 Colour temperature is the colour impression of a light source. A warm colour

temperature is <4000K and a cold colour temperature is >4000K. A single unit

of Kelvin (K) is equal to 0C e.g. 273.17K= 0C.

Colour reproduction

index

Ra R

a

-index CIE 17.4 Is the measurement of a light sources ability to reproduce colour compared

to a reference light source at a predetermined colour temperature. An Ra

index is used for graduation, which according to CIE, can be at the most 100

and shall for lighting workplaces be a minimum of 80.

Luminous efcacy

- light source

H (lm/W) =/P The luminous efcacy from a light source can be dened as the relationship

between the luminous ux emitted by a light source and the electrical output it

consumes. Luminous efcacy can also be described as a measurement of light

source efciency.

Luminous efcacy

- system (light source

+ ballast)

H (lm/W) =/P The system luminous efcacy from a light source can be dened as the

relationship between the luminous ux emitted by a light source and the

electrical output it consumes including ballast losses.

Glare CIE- 31,

112, 117

Is a visual impairment caused by the extreme contrast or inappropriate

distribution of luminance levels. Glare is normally subdivided into: -discomfort

glare UGR/NB - disability glare TI/GR.

Unformity E

min

/E

ave

L

min

/L

ave

Ratio between the lowest value and the average value of brightness on a

specic surface.

Luminaire luminance - - The average luminance of a luminaires luminous parts measured and/or

calculated in the C-plane at 15 intervals starting at 0, and elevation angles

() of 65, 75 and 85. Usually the manufacturer will provide this data, based

on the light sources total nominal luminous ux in the luminaire.

Shielding angle

(for luminaires light

source)

- - The angle between the horizontal plane and the rst line of sight at which

any part of the luminaires light source becomes directly visible.

Cut-off angle

(for luminaires)

The angle between the luminaires vertical axis & the point at which the light

source & surfaces of high luminance are not visible.

Solid angle steradian

(sr)

=A/r

2

The angle subtended by an area at a point and equal to the quotient of the

projected area on a sphere, centered on the point, by the square of the radius

of the sphere.

Mean mortality rate hours

(h)

Mean mortality rate is the average life span of a light source and is dened as

the time after which 50% of a large number of controlled light sources have

failed (Incandescent lamps, halogen lamps and uorescent lamps).

Service mortality rate hours

(h)

The service mortality rate is dened as the point at which 80% of the lighting

installations original luminous ux remains. The depreciation in luminous ux

depends on the reduced luminous ux and spent light sources.

Economic mortality

rate

hours

(h)

The economic mortality rate is dened as the point at which 70% of the light-

ing installations original luminous ux remains. The depreciation in luminous

ux depends on the reduced luminous ux and spent light sources.

403 www.fagerhult.com www.fagerhult.co.uk

Lighting planning

European Lighting Standard EN 12464-1

Planning the lighting of indoor workplaces

From May 2003 companies in European CEN-countries, have a mutual

standard for the planning of lighting of indoor workplaces.

According to CEN/CENELECs internal provisions the following

countries have been called upon to adopt the new European stan-

dards: Belgium, Denmark, Finland, France, Greece, Ireland, Iceland,

Italy, Luxembourg, Malta, The Netherlands, Norway, Portugal, Switzer-

land, Spain, United Kingdom, Sweden, The Czech Republic, Germany

and Austria.

Lighting of indoor workplaces

The following text is an interpretation of the main guidelines in

the new European standard for the lighting of indoor workplaces

EN 12464-1.

The new standard does not cover all aspects of planning a lighting

installation, and reference should also be made to the SLL code for

lighting. The lighting industry in Sweden intends to publish a planning

guide during the year which will replace Ljuskulturs guidelines for

planning indoor lighting. The new planning guide will provide infor-

mation on how the standards can be applied to the lighting of indoor

workplaces.

Workplace lighting

The new European standard EN 12464-1 highlights the minimum

illuminance requirements of an actual working area rather than the

entire room. The guidelines recommend that the lighting outside the

working area should be adapted to the conditions that apply inside

the working area. The values stated in the collection of tables, refer to

the lowest illuminances in the workspace of a visual object, that can

be either horizontal, vertical or placed at an angle. The illuminances

documented consider the lowest average values for working under

normal conditions. However, the illuminances can be adjusted by the

increments set out below if the visual conditions deviate from the

normal conditions.

20-30-50-75-150-200-300-500-750-1000-1500- 2000-3000-5000 lux

The demands on illuminances used in the workplace, should be regu-

larly reviewed to overcome the following situations:

difcult working conditions

activities that demand great accuracy or high productivity

impairment of visual efciency

viewing objects with ne detail or in low contrasts of light

using DSE terminals for long periods of time

In practice, the specied illumination can be reduced under the fol-

lowing conditions:

when visual objects have an abnormally large size and high contrast

when visual work is in progress for short periods

In workplaces with continuous occupancy the illuminance must not

drop below 200 lux. Continuous occupancy refers to work that is per-

formed for more than two hours.

The recommended values assume that the employees have normal

sight. If a greater number of people have some form of sight im-

pairment, this should be taken into consideration when designing a

lighting installation.

Lighting the visual object

The main objective when lighting

workspaces and objects is that

the light falls in such a manner

that the greatest possible cont-

rast is placed on the visual object.

Under normal conditions the

greatest contrast occurs if the

light falls diagonally from behind

the object.

A work object can have a

horizontal, vertical or inclined

position. It can also consist of varied structures or have different com-

binations of surface characteristics, matt, bright etc, resulting in varied

reective characteristics.

A basic prerequisite for good visual comfort in the workplace, is

that the work objects position and shape, in relation to the direction

of light, does not cause any form of unpleasant glare or glare that

impairs the vision e.g. dazzling luminaires or disturbing reections.

General information about the

Energy directive 2002/91/EC

From January 4, 2006 a new EU directive will enter the statute book

in Sweden and the other EU-countries.

The directive will mean that in future buildings are to be declared

with regard to energy consumption. Energy consumption of the buil-

ding must be calculated and declared in advance. This not only applies

to the lighting installation but also to other energy consuming instal-

lations within the building such as heating, ventilation, cooling, etc.

The directive means that consideration will not only be taken for the

installed output, but also how it is used over time.

Consequently, it will be important to plan for efcient energy usage.

Within the lighting sector the control of lighting will take on greater

signicance, which will result in sensors for daylight and presence

control being utilised on a far larger scale.

The unit for the declaration value will be expressed in kWh/m

2

/year.

The aim of the directive is to reduce energy usage in the future, with

the declaration giving a clear indication of the buildings energy ef-

ciency.

More information will be made available in the near future.

404 www.fagerhult.com www.fagerhult.co.uk

Lighting planning

Standard EN 12464-1

W

a

= width

l

a

=

l

e

n

g

t

h

l

o

=

l

e

n

g

t

h

w

o

= width

0,5 m

Principles for establishing the working area and surrounding calculation surfaces

Lighting of the working area

Denition of the working area

The working area is dened according to EN 12464-1 as the area of

the workplace in which tasks are performed. For areas where the size

and/or placement of the working area is unknown, the area where the

tasks may be performed is to be considered as the working area.

The working area is usually made up of the entire workplace/worksta-

tion. For example, in an ofce workplace, the working area is made up

of a small surface where paper work is carried out. Work with a mo-

nitor and keyboard usually demands a lower illuminance than when

paper work is performed. The illuminance level needs to be adjustable

for work with monitors and to help achieve a suitable balance with

the surrounding area. Adjust relative to the surrounding areas illumi-

nance. In an ofce where paper work is carried out the workspace can

be made up of an entire work table.

In industry, the size of the working area can be harder to dene e.g.

workplaces for work involving microelectronics or a production line for

assembling cars.

When the exact size of the working area is unknown, it is normally

taken as 0.6 m x 0.6 m for an ofce workplace. In this case the working

area is thought to be located directly in front of the persons normal

position and at the front edge of the desk.

The variation of the illuminance, i.e. the ratio between the lowest il-

luminance in relation to the average illuminance on the working area,

Lighting of the immediate surroundings

The lighting of the immediate surrounding area should relate to the

lighting level within the working area and in addition create the con-

ditions for a well-balanced luminance distribution within the normal

eld of vision. Extensive changes to the lighting level around the

working area can cause visual stress and discomfort.

Denition of the immediate surroundings:

The immediate surrounding area is dened as an area around the

working area with a width of at least 0.5 metres. The size of the im-

mediate surroundings should be determined by the planner and may

need to be increased to a width greater than 0.5 metres, for specic

types of workplaces.

The size of the immediate surroundings can be increased:

when the size of the working area is small.

if the illuminance within the working area is high.

with active work.

The illuminance in the immediate surrounding area can be lower than

within the working area, but should not fall below the values stated in

the table below.

The variation of the illuminance, i.e. the ratio between the lowest

illuminance in relation to the average illuminance in the immediate

surroundings, should be as small as possible and not fall below 0.5.

Lighting of the peripheral surroundings

There are no dened demands on the illuminance within the perip-

heral surrounding areas in the EN 12464-1, i.e. the area outside of the

immediate surrounding area. This area is dened as the area outside

the surrounding areas, to a distance of 0.5 metres from the rooms

walls.

However, within a workroom the relation between the illuminance

on the working area and the lowest illuminance in the workroom in

the zones where there are no workplaces, should not exceed 5:1. For

example, circulation areas.

If, for example, demands on the illuminance within the working

area are 500 lux on the workplace, the lowest illuminance in the

premises should not fall below 100 lux. The lowest illuminance is cal-

culated within a zone outside of the immediate surroundings, to half a

metre (0.5) from the rooms walls.

Uniformity within the peripheral surroundings should not fall

below 0.5.

The lighting around the working area should contribute towards good

visual adaptation, as recommended in the luminance distribution and

luminance limitations section of the report.

As a rule in work areas with bright walls, the relation between the

illuminance within the working area and the average illuminance on

the rooms walls should not exceed 3:1.

Working area (l

a

x w

a

)

Size and position are established by the lightplanner.

Immediate Surrounding area (l

o

x w

o

)

The size to be established by the light planner.

(l

a

+2x0.5m) x (W

a

+2x0.5m)

Outer surrounding area

0.5 metres from the rooms walls.

Example of the workspace for a typical workplace.

Relations between different illuminances and unformity demands

Table of uniformity demands and the relation between illuminances within the

immediate surroundings of the working area.

Illuminance Illuminance within

within the working area the immediate surroundings

750 lx 500 lx

500 lx 300 lx

300 lx 200 lx

200 lx 200 lx

Uniformity (E

min

/E

ave

) 0,7 Uniformity (E

min

/E

ave

) 0,5

405 www.fagerhult.com www.fagerhult.co.uk

Lighting planning

Standard EN 12464-1

Glare

Glare occurs when part of an interior space, is signicantly brighter

than the rooms luminosity. In this instance the eyes are exposed to

a more intense light than they are normally adapted to. The most

common cause of glare occurs when the luminaire and window can be

seen directly or via reections, within the normal eld of vision. Elderly

people are usually more irritated by glare than young people. This is

mainly due to the increased clouding of the eyes lens experienced

with age as well as a reduction in the ability to adapt.

Glare can be divided into two different types:

Disability glare.

Discomfort glare.

Sight impairment glare and discomfort glare can occur simultaneously

or separately.

Disability glare

Disability glare usually occurs when an object in the vicinity of the

normal line of sight, has a signicantly higher luminosity or luminance

than that wich usually occurs in the eld of vision. If an eye is exposed

to a continuous intense light, the eyes adaptation can be affected

negatively and cause deterioration in visibility, or what is known as

contrast reduction.

This contrast reduction can be sufcient to make words and images

barely visible and in doing so make it difcult to carry out the visual

task. Alternatively, if the light source causing the glare is directly in the

line of sight this can cause noticeable after-images. The most common

source of sight impairment glare internally, is the sun and sky viewed

from a window or a badly sheilded light source observed directly or via

reection.

Disability glare should therefore be prevented through using lumin-

aires that effectively shield the light source (see the table below).

The values in the table do not include indirect luminaires or luminaires that are

installed below normal eye level.

Discomfort glare from

electric light

Discomfort glare is an immediate

occurrence and arises from light

sources or luminaires whose

luminance is greater than the

eye can adapt to, but can also

become noticeable after a period

of time.

The degree of discomfort glare,

depends on several factors; the

luminance and the size of the

glare source, the position of the

glare source in relation to the line of sight and the background lumi-

nance against which the glare source is viewed. These are all factors

that can increase the degree of discomfort glare.

Consequently, when light planning, the luminaires luminance

should always be considered in relation to the background luminance.

The closer the dazzling surface is to the eye, the greater the risk of

discomfort glare. In open luminaires, especially those for compact and

other intense light sources with high luminous ux, it is generally the

light source itself or a mirror image in the specular reector that cau-

ses the glare effect. One way to reduce discomfort glare is to use satin

matt reectors and luminaires with a larger surface area.

Discomfort glare can also be reduced by increasing the luminosity on

walls and ceiling of a room. This can be achieved in different ways:

Using luminaires with an uplight component.

Luminaires can be positioned closer to the room walls.

The walls can be lit separately or the luminosity increased by choo-

sing higher reection factors on the wall surfaces.

Walls that appear brighter in relation to the visual object can create

adaptation problems. The luminosity of the room surfaces should the-

refore be adapted to the visual conditions and be limited as described

in the Luminance distribution and luminance limitations chapter of

the EN 12464-1.

Calculation of the glare index

The degree of discomfort glare for indoor installations can be estima-

ted by calculating the glare index according to the UGR method. The

method will, through the introduction of the new standard EN 12464-1,

replace the previous European calculation method (NB-method). The

demands on the glare index documented in EN 12464-1 refer to the

highest average value for the lighting. The UGR-method (Unied Glare

Rating) is described in CIEs publication no 117-1995.

The UGR glare index for discomfort glare is ranked on a scale, which

in practice runs from 13 to 28 where the higher the glare index the hig-

her the level of glare. The smallest change in the glare index denoting a

signicant difference is 3.

The glare number should be calculated according to the table met-

hod to check whether the recommended glare index in the standards

tables is met by a specic lighting installation. (The method is described

in CIEs publication no 117-1995). However, this method assumes that

the luminaires in the room are positioned symmetrically and feature

symmetrical light distribution across and along the luminaire.

Luminaire manufacturers provide information/table data as a part of

the luminaires photometric data to calculate the lighting installations

glare index.

Discomfort glare from windows

An awkward and unpleasant glare

arises when a person looks out of

a window in the direction of the

sun, or when direct sunlight falls

against surfaces within the normal

eld of vision. In these situations

even discomfort in the form of

increased heat radiation can also

occur. Sun screens can be used in

these instances. Screening can be

achieved through the design of the

building, external sun screens, low

transmitting glass (sun glass win-

dows) or through Venetian blinds or curtains. Glare can also occur from

a diffuse sky viewed through a window. This form of glare can usually be

reduced by choosing lighter colours for the walls near the window or by

increasing the luminosity of the walls with separate lighting.

Examples of discomfort glare from a window:

Reective glare.

Reections on visual objects or their surroundings can completely

impair sight.

Even if glare does not occur from a luminaire or other highly reective

surfaces, it can occur in the form of reection. Polished and reective

materials should not be placed in areas where glare can arise, especially

in work areas. If polished surfaces cannot be avoided lighter surfaces are

more preferable than darker surfaces. An example is a computer monitor

screen surface where reections are usually perceived as more disturbing

on monitors with dark backgrounds and light text, than on monitors

with light backgrounds and dark text.

Reections from reective materials or reective glare can usually be

prevented with the following actions:

Suitable luminaire positioning.

Selecting luminaires with low luminous intensity and effective

screening.

Selecting matt materials for reective surfaces.

Selecting luminaires with a larger surface area.

Select light colours for ceilings and walls.

Lowest shielding angle for the light sources luminance

Light sources luminance Minimum shielding angle

20 to < 50 15

50 to < 500 20

500 30

406 www.fagerhult.com www.fagerhult.co.uk

Lighting planning

Standard EN 12464-1

Luminance distribution and luminance limitations

The distribution of light around the workplace and inside the area is

extremely important for the perception of a room and its appearance.

Luminance distribution within the general eld of vision determines

the eyes adaptation i.e. its ability to adapt to different luminous

intensities.

A well-balanced luminance for adaption is essential to increase:

The visual clarity.

Contrast sensitivity (ability to detect small differences in luminance).

The effectiveness of the eyes ocular functions (e.g. accommodation,

convergence, pupillary contraction, eye movements, etc.).

Luminance should be considered in the increments set out below:

5-10-20-30-50-75-150-200-300-500-750-1000-1500-2000-3000-5000 cd/m

2

.

Luminance distribution within the normal eld of vision also affects

the visual comfort.

The following should be avoided:

High luminances that can cause glare.

Large luminance contrasts that cause visual tiredness where the eye

tries to continuously adapt.

Low luminance contrasts, which result in a staid atmosphere that

does not stimulate.

Contrast can be calculated or measured as a relation between different

luminances. The luminance of all surfaces is important and is determi-

ned by the reective characteristics and illuminance of the surfaces.

The lighting of workplaces with DSE should be designed for all tasks

that may take place at the workplace i.e. reading from the monitor,

working on the monitor, paper work and using a keyboard.

For these tasks, the choice of

lighting system should cor-

respond to; the size of the wor-

king area, the type of visual tasks,

and the condition of the room ac-

cording to the standards criteria.

Working with DSE and in some

situations the keyboard, can be

hindered by reective glare and

discomfort glare. Therefore it is

important that the choice and

positioning of the luminaires in

workplaces with DSE is conside-

red to prevent this type of glare.

The vertical illuminance on the DSE with a dark background (negative

polarity) should not exceed 200 lux.

Limitation of the luminaire luminance with DSE work

In premises where increased amounts of work is performed with com-

puters, the luminaires luminous intensity should be limited around

the normal lines of sight, to prevent distracting reections from the

screen.

Note: In special conditions, for example, when screens that are especially sensitive

to reections are used or when the screens angle of incline is greater than normal,

the table should be used with a lower elevation angle (e.g. 55) from the luminaire.

Other factors

Colour reproduction

It is important for the visual experience and comfort of the sur-

roundings, that such things as colours of objects and peoples skin,

are rendered in a natural and attractive manner. Therefore the light

sources colour rendering index within work premises should not fall

below an Ra value of 80 and for working premises with especially high

demands, the Ra value should not fall below 90.

Establishing the maintenance factor

As the values stated in the standards tables are to be considered as

maintained values, the light planner must establish the installations

maintenance factor for the lighting calculation. The value of the main-

tenance factor should be based on the maintenance schedule of the

lighting installation e.g. cleaning periods.

The designer has been given greater planning responsibility and must

present the following:

A guideline of the conditions used to produce the nal value for the

maintenance factor.

The selected maintenance factor.

A list of equipment to suit the installation conditions.

Draw up and present a comprehensive maintenance schedule, which

applies to the chosen maintenance factor. The maintenance sche-

dule should include relamping intervals as well as instructions and

times for cleaning and maintaining the luminaires as well as which

cleaning methods to employ.

Flicker and stroboscopic effects

Flicker can cause disturbances and in some cases cause headaches.

Stroboscopic effects can result in an increased accident rate where

rotating machines appear to be moving in reverse. This effect can be

prevented by powering the luminaires light sources with HF-ballasts.

Energy usage

The lighting installation should conform to the lighting demands for

the workplace without compromising energy efciency and visual

comfort. This requires a suitable lighting system, with appropriate

equipment, controls and the use of daylight.

Daylight

The benets of daylight should be utilised during light planning.

Lighting controls can be employed to utilise the natural daylight and

to promote interaction between the daylight and the articial lighting

in the room.

Luminance limitations for luminaires with downward light

The following table states the limitations of the luminaires average lumi-

nous intensity at an elevation angle (radiant angle) of 65 or more from

the downward vertical, radially around the luminaire, for a workplace

with a vertical screen, or with an inclination up to 15 from the vertical.

Appropriate reectance factors for common room surfaces

Lighting of workplaces with display

screen equipment (DSE)

Room surface Reectance

Ceiling 0,6-0,9

Walls 0,3-0,8

Workspaces 0,2-0,6

Floor 0,1-0,5

Monitor classication in

accordance with ISO 9241-7

I II III

Monitor quality good average normal

Highest average luminance

for luminaires that may

reect in the monitor

1000 cd/m

2

200 cd/m

2

407

L

max

< 1500 cd/m

2

L

ave

< 500 cd/m

2

L

max

< 1000 cd/m

2

www.fagerhult.com www.fagerhult.co.uk

Lighting planning

Instructions for planning and calculations

The luminance from the rooms surfaces must be

relative to the luminance from the working plane,

in order to conform to EN 12464-1 demands. For

example, when using low luminance luminaires and

downlights, there is a risk that the tops of the walls

and the ceiling, may be too dark.

The difference in luminance can be calculated or

measured as a relation between different surface

luminances.

The following luminance conditions are recommen-

ded for the workplace:

the working area (inner eld of vision) - immediate

surroundings (the near eld) 3:1.

the working area (inner eld of vision) - surroun-

dings (adjacent walls within the eld of vision) 5:1.

the working area (inner eld of vision) - periphery

wall surfaces (background) 10:1.

Luminance conditions with indirect lighting

With indirect lighting the average luminance on

the ceiling should not exceed 500 cd/m

2

, with a

maximum acceptable luminance of 1500 cd/m

2

.

The luminance transition should vary gradually

across the surface being lit to avoid the lighting

from being distracting and uneven. The luminance

balance (L

min

/L

ave

) should not exceed 1:10.

For the background lighting on the walls the

maximum luminance should be limited to 1000

cd/m

2

.

Flow chart for light planning

1. Analysis of the planning objective

Dene the activities and different

visual work that may be perfor-

med in the premises at different

times of the day.

Dene the lighting demands with

regard to safety, visual needs and

the visual experience.

Examine the need for emergency

lighting. Dene the aims for en-

ergy consumption, environment

and maintenance of the lighting

installation.

2. Analysis of planning conditions

Dene applicable provisions,

standards, recommendations as

well as special demands from the

client and users.

Dene the conditions for lighting

the room, the type of workplace

and its working area, etc.

Investigate the conditions for the

premises design, furnishings, type

of monitors, exibility, daylight

and the character of the premises.

Establish the economic prerequi-

sites for the installation and the

maintenance conditions for the

lighting installation.

3. Overall planning

Investigate the conditions for

interaction between electric light

and natural daylight. Check the

possibility of daylight screening.

Investigate which light sources,

luminaires and lighting systems

best satisfy the demands aims and

conditions.

Investigate the control possibilities

for the lighting to increase com-

fort and improve energy usage.

Investigate the overall co-ordina-

tion with other installations,

colour setting and furnishings.

4. Detailed planning

Evaluate the different lighting

systems; technically, visually and

economically.

Establish the lighting systems op-

timal maintenance factors taking

the maintenance conditions into

consideration.

Make a nancial evaluation by cal-

culating the life cycle costs based

on the investment, operation and

maintenance.

Compare the selected lighting sys-

tems with regard to other instal-

lations, colour setting, furnishings

and the chosen equipment.

5. Documentation

Should be prepared as shown be-

low with supplements according

to the clients wishes.

Include Installation drawings,

control and assembly instructions

as well as associated lists of light

sources and luminaires.

Lighting calculations and visua-

lisations that verify under which

conditions the system operates

to the specied demands. Present

calculation prerequisites and the

lighting systems maintenance

plan.

Present calculation prerequisites

and the lighting systems mainte-

nance plan (see instructions in the

Lighting template).

Recommended luminance conditions between the

working area and the rooms surfaces

1)

The values apply in daylight - without daylight the relative

illuminance should not exceed 0.2 provided that the glazed

surfaces do not have bright curtains.

Room surface Recommended Relative

reectance illuminance

Ceiling 0,6-0,9 0,2-0,9

Walls 0,3-0,8 0,2-0,6

Window wall >0,6 0,3-0,6

1)

Workspaces 0,2-0,6 1,0-

Floor 0,1-0,5

In order to achieve good visual comfort within an

area, the average luminance on the rooms walls, as

a general rule, should not fall below 30 cd/m

2

. It is

normal practice to translate luminance conditions

to relative illuminance, as illuminances are used as

guide values in light planning. Nevertheless, in this

context it should be pointed out that todays com-

puterised calculation programs allow the calculation

and documentation of different luminances for room

surfaces. The table below provides information about

recommended relative illuminances between the

workspace and room surfaces for a typical area.

The luminance ratio between the working area and the wall is less than 5:1.

Limitations of luminaire luminance at

workplaces with monitors classied in

accordance with in ISO 9241-7

Luminaires maximum average luminance cd/m

2

(applies to luminaires that can be reected on the monitor)

Negative monitor polarity

(dark background)

Positive monitor polarity

(light background)

Monitor class I and II direct lighting

Good, average or normal reection treatment

1000 cd/m

2

1500 cd/m

2

Monitor class III direct lighting

Inferior screen quality without reection treatment

200 cd/m

2

500 cd/m

2

Monitor class III dir./indir. (10% uplight)

Inferior screen quality without reection

treatment

500 cd/m

2

Luminance limitation for luminaires that can be reected in the monitor

408 www.fagerhult.com www.fagerhult.co.uk

Lighting planning

Planning and calculation tips

Fagerhult can help you communi-

cate your lighting ideas through

different types of visualisation

services.

DIALux

Effective, modern and compre-

hensive tool for lighting plan-

ning, intended for the calculation

of outdoor and indoor areas,

including room surfaces.

Interpretation of the calculation result.

1. Scrutinize carefully

To prevent glare - check the luminance

conditions in the room.

2. Maintenance factor

Has the maintenance factor been

adapted to a maintenance plan for the

lighting installation?

NOTE - the maintenance factor affects

the lighting systems energy consump-

tion.

3. Calculation conditions

Have the conditions for the lighting

calculations been checked?

Has the size of the working area and im-

mediate surroundings been established?

Has the calculation area for the periph-

eral area been dened?

Have the room surfaces reectance

values been checked?

Has the luminaires average luminance

been checked in rooms used for monitor

work?

4. Uniformity demands.

When calculating the illuminance

uniformity i.e. the ratio between the

minimum value and the average value

in the working area and the immediate

surroundings, it is important that the

distance between the calculation points

is documented. For normal working ar-

eas a maximum spacing of 0.25 metres

between calculation points applies.

5. Graduation implication

Use the scales for illuminances and

luminances stated in the standard

EN 12464-1.

6. UGR-glare index.

Check, where appropriate, that the

systems average glare index conforms

to the value stated in the standard. To

calculate the glare number, see page

405.

Checking the lighting installation

1. Scope

What should be evaluated?

electric lighting, emergency lighting,

daylight conditions, functionality and

control, maintenance plan, electrical

efciency, etc ...

2. Conditions

Regarding the control of new systems,

which conditions applied when plan-

ning?

Evaluation of existing systems?

Evaluation with or without daylight?

Are the measured values new values or

maintained values?

3. Implementation/checks with light

measurement

Illuminances - mean value/uniformity

for the working area, immediate sur-

roundings and the lowest illuminance

within peripheral areas.

Luminaires mean luminances.

Calculate where appropriate the UGR-

glare index.

Luminance conditions in the premises.

Luminaires cut-off angle.

Light sources colour reproduction and

colour temperature.

Perform visual evaluation and interview

personnel.

Perform a functional check.

Check the calibration, burn-in time and

prevailing operating conditions before

light measurement.

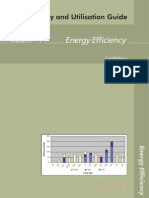

120

100

80

60

40

20

0

1,00 0,90 0,80 0,70 0,60 0,50

43%

18%

Relative power output (%)

Maintenance factor

The maintenance factor affects energy consumption.

The new standards give light planners greater responsibility for the

system, as the installations maintenance factor has a direct effect on

the energy consumption. To select a high maintenance factor a great

deal of care must be exercised when choosing light sources, luminai-

res and the lighting system.

The choice of T5 luminaires gives the best conditions for achieving a

high maintenance factor.

Energy efciency in lighting installations

A lighting installation needs to conform to lighting demands for a

specic area without wasting energy and sacricing good lighting

comfort. This requires careful consideration regarding appropriate

lighting systems, equipment, control systems and the use of daylight.

A measurement of efciency in a lighting installation is the installed

output, in W/m

2

, that is required to meet dened demands.

Example of installed lighting outputs

Installation type Installed lighting

output.

Required

illuminance while

operational. (lux)

Notes.

Corridors 5-10 W/m

2

100 lux

Corridors 10 W/m

2

200 lux

General public areas 10-12 W/m

2

300 lux

Workplaces 10-12 W/m

2

300 lux *

Workplaces 10-15 W/m

2

500 lux *

Workplaces 15-30 W/m

2

1000 lux *

* Required illuminance within the working zone according to applicable Swedish

Standard SS-EN 12464-1. The lower value normally presupposes a localised ligh-

ting system adapted to the working area in the workplace.

General advice

The following points should be

considered in order to create low

energy usage in a lighting instal-

lation:

selection of light sources with

optimal luminous efcacy for the

required colour reproduction.

energy efcient lighting system

with installed lighting output suita-

ble for the required task.

efcient luminaires with the correct

light distribution and good cut-off

properties.

efcient utilisation of daylight.

efcient utilisation of articial and

natural light through the selection

of a light interior colour scheme.

control of lighting through presence

detection.

possibility of localised control by the

individual.

high frequency operation with dim-

ming.

well planned maintenance of the

lighting installation to obtain a high

maintenance factor.

Energy usage

In addition to a low installed output, energy usage should be limited

in an installation with the help of different control systems.

A better method to assess the energy efciency of a lighting system

is to evaluate the annual energy consumption per square metre.

(kWh/m

2

/year). This gure will also form the basis of the new energy

declarations dened in the EU directive concerning a buildings energy

performance.

Fagerhult light design centre

The maintenance factor affects energy consumption

DIALux facts

Adaptable menus

Help functions

Displays light distribution and

aiming point for easier luminaire

alignment

Transfer of DXF

Calculation planes and points can

be freely set in the room

Built-in object library

Material symbols linked to furniture

and room surfaces

High quality 3D-visualisation with

texture handling

A luminaire database is available

from Fagerhults website

Luminaire databases from Europes

major manufacturers available for

the program

409 www.fagerhult.com www.fagerhult.co.uk

Visual ergonomic aspects of the

workplaces design are important

for a stimulating working environ-

ment. There is an excellent method

called visual evaluation available

to review and assess a room with an

installed lighting system, which is

simply based on describing what you

see in the room. This allows you to

evaluate the room visually through

its lighting system, colours and de-

sign. These factors affect each other

and are difcult to assess individu-

ally. The room colours should not be

distorted, and visual work should be

possible without the discomfort of

glare or reections.

The rooms visual quality governs,

to a large extent, your health and

your performance capacity. It is

therefore important that you do not

completely rely on computer calcu-

lated results. Try to make a visual

evaluation of your own workplace

using the tables below.

Rank the evaluation results on a

scale of 1-5.

Visual evaluation of lighting systems in work areas

Lighting planning

Light and stimulation

Light or light radiation does not only affect our visual centre but also

the whole bodys alertness, well-being and performance.

Our diurnal rhythm and seasonal variations together form the

chronobiological system, which is linked to, among others, the pineal

body gland, pituitary gland and hypothalamus region. The rhythms

are genetically anchored, yet to a certain degree are regulated by sur-

rounding factors, primarily light, which via the nerve paths from the

eyes retina to the suprachiasmatic nerve bundle in the hypothalamus

and on to the pineal body gland, signals to the melatonin producing

cells to stop secreting the melatonin hormone which in turn happens

to control our diurnal rhythm.

Disturbances to our diurnal rhythm due to a lack of daylight during

the period from October to March are considered to be mainly caused

by the pattern of symptoms known as Seasonal Affective Disorder

(SAD) (Rosenthal et al, 1984; Magnusson and Boivin, 2003).

New research carried out by David M Bensson and others at the

Brown University and George Brainard at the Texas University, USA

have indicated that light also affects a new third receptor over and

above the earlier known cones and rods.

This receptor affects different hormones in the brain where the

pineal body gland is extremely important for the secretion of the

sleep hormone melatonin, which is produced at low light levels or in

darkness. In contrast, at high light levels the stress hormone cortisol is

produced by the adrenal medulla.

Lighting and health

Concept Description Evaluation

Light level - whether it is dark or light in the room or at the

workplace?

dark - light

Light

distribution

- how is the light distributed in the room or at the

workplace?

varied - equally

Light

colour

- is the light colour experienced as warm or cold? warm - cold

Colour - how are the colours and objects viewed? distorted - natural

Glare - does unpleasant glare occur? troublesome - not noticeable

Shadows - whether they are hard or soft? hard - soft

Reections - whether they are intense or diffuse? intense - diffuse

How is lighting planning affected?

Within healthcare, light has been used for some time for the medical

treatment of skin diseases and to reduce the effects of SAD (Seasonal

Affective Disorder).

The discovery that some parts of light radiation also affect our well-

being will in future affect the design and appraisal of lighting in our

rooms.

We will, probably more than we do today, focus on lighting our sur-

rounding surfaces but also varying the lighting and light colour over

time. This will be especially important in rooms that do not receive

daylight.

Sufcient application research has not been carried out yet to

establish recommended values; however, comprehensive studies are

currently in progress to enable suitable guidelines to be produced, not

least for our work premises.

24 24 24 12 12 06 06 06 18 18

Alertness

Body temperature

Melatonin

Cortisol

410

1. C-plane angles: 0 C

x

< 360

2. -angle: 0 180

71 W/12V

HRGI (QR-CBC 51)

Half beam angle 42

Shielding angle 35

107

108

435

385

234

217

2500

2000

1500

1000

1,0 0,5 0,0

7485

1871

832

299

208 (cd)

lx

468

0,5

1,0

1,5

2,0

2,5

3,0

(m)

88

27

7

www.fagerhult.com www.fagerhult.co.uk

Illuminance (lx)

Half beam intensity angle

Cut-off angle

Luminous intensity [cd]

The light distribution curve drawn in a polar diagram denotes the

luminaires luminous intensity in different directions as a function of

viewing angle in one or more planes. It is usually represented by an

unbroken line that indicates the light distribution perpendicular to the

light sources longitudinal axis and with a dashed line that indicates

the light distribution in direction of the longitudinal axis. The values of

the light distribution curves are scaled to correspond to 1000 lm from

the light source (cd/1000 lm, cd/klm). This is why it is often possible to

show luminaires with different outputs on a common polar diagram.

Symmetrical light distribution

A 28W uorescent lamp (2600 lm)

gives, in a straight down direction,

approximately 375 cd/klm.

Asymmetrical light distribution

At a maximum luminous intensity

angle of 25 a 28W uorescent lamp

gives approximately 580 cd/klm.

The luminaires light distribution is measured on several C-planes around the

luminaire, at least every 15 degrees around the luminaire. First measurement

plane (C=0-180) the plane is across the lamps longitudinal axis. -angles several

angles are measured, at least every 5 degrees.

Light distribution curve

Isolux diagram Combined diagram for spotlights

The diagram shows, using curves (or scales) a predened area, inside

which the horizontal illuminance exceeds the curves lux value. The

position of the luminaire is usually indicated on the diagram.

Alternatively, the isolux diagram can be represented by a 3D dia-

gram, which is best suited for showing the unformity of the lighting

installation. The calculation points illuminance values can be introdu-

ced onto the premises layout drawing and the results given in table

form. The results are available in all the above mentioned forms in the

DIALux and F-plan programs.

Example:

The isolux diagram shows Apollo Beta 3x28W in an ofce module.

The calculations have been made using our light calculation pro-

gram F-plan with the following conditions:

Room dimensions: 2.4x3.7 m

Ceiling height: 2.7 m

Luminaire height: 2.1 m (underside to the oor)

Reectance: Ceiling 80%

Walls 50%

Floor 20%

Window 10%

Luminous ux (per lamp): 2600 lm

Maintenance factor: 0.85

Calculation plane: 0.75 m above the oor.

A combined diagram shows the light distribution curve and the cal-

culation result in the same gure. The combined diagram is primarily

used for directional luminaires, which have rotational symmetric light

distribution.

The right-hand side of the diagram shows half the light distribu-

tion curve, as all curve halves are the same due to the symmetry.

The light distribution curve is not scaled, graduation is directly in

candelas (cd).

The left-hand side of the diagram contains the illuminances directly

under the luminaire. The distance from the luminaire is stated on

the vertical axis and the horizontal distance from the luminaires

centre, on the horizontal axis. The illuminance at each co-ordinate

on the horizontal plane is stated in lux (lx) at each intersection.

Lighting planning

Technical information

Light measurement

Anda mungkin juga menyukai

- Zumbotel Lighting HandbookDokumen298 halamanZumbotel Lighting HandbookPrecious DeDeBelum ada peringkat

- Electronics 3 Checkbook: The Checkbooks SeriesDari EverandElectronics 3 Checkbook: The Checkbooks SeriesPenilaian: 5 dari 5 bintang5/5 (1)

- Licht Hand BuchDokumen298 halamanLicht Hand BuchsumanthdixitBelum ada peringkat

- EUROPEAN STANDARD GUIDELINES FOR INDOOR WORKPLACE LIGHTINGDokumen3 halamanEUROPEAN STANDARD GUIDELINES FOR INDOOR WORKPLACE LIGHTINGAnonymous xX7na2JBelum ada peringkat

- Handbook of Energy Data and Calculations: Including Directory of Products and ServicesDari EverandHandbook of Energy Data and Calculations: Including Directory of Products and ServicesBelum ada peringkat

- Light Level MeasurementDokumen10 halamanLight Level Measurementpatel1029poojaBelum ada peringkat

- An Illustrated Guide to Making Magic Lanterns and TelescopesDari EverandAn Illustrated Guide to Making Magic Lanterns and TelescopesBelum ada peringkat

- Illumination Practices: For Diploma in Electrical EnginneringDokumen15 halamanIllumination Practices: For Diploma in Electrical EnginneringJyotirmoy RoyBelum ada peringkat

- LED Lighting for Your Home & Business: LED Lights Save Money and Make Your Home Lighting SpectacularDari EverandLED Lighting for Your Home & Business: LED Lights Save Money and Make Your Home Lighting SpectacularBelum ada peringkat

- Daylight Factor ExplainedDokumen13 halamanDaylight Factor ExplainedGagan DeepBelum ada peringkat

- Dimming Fluorescent Lighting GuideDokumen9 halamanDimming Fluorescent Lighting GuideshounakroyBelum ada peringkat

- Lighting Part2 LPQIDokumen8 halamanLighting Part2 LPQIJorge MazorraBelum ada peringkat

- Lighting Retrofit and Relighting: A Guide to Energy Efficient LightingDari EverandLighting Retrofit and Relighting: A Guide to Energy Efficient LightingBelum ada peringkat

- Energy Estimation & AuditDokumen43 halamanEnergy Estimation & Auditrohith mukkamalaBelum ada peringkat

- Residential Interior Design: A Guide To Planning SpacesDari EverandResidential Interior Design: A Guide To Planning SpacesPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Lightingdesignstudentsguide Lec EUDokumen133 halamanLightingdesignstudentsguide Lec EUCassandra PeredaBelum ada peringkat

- Installation AllDokumen45 halamanInstallation AllDaaniyyee AbdiisaaBelum ada peringkat

- 15 Technical PDFDokumen26 halaman15 Technical PDFAhmad Hamouda100% (1)

- Eacm R16 - Unit-2-2Dokumen36 halamanEacm R16 - Unit-2-2GVRS EEEBelum ada peringkat

- Energy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamDari EverandEnergy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamBelum ada peringkat

- Lighting Design Students Guide - CIBSE PDFDokumen133 halamanLighting Design Students Guide - CIBSE PDFsameerray12100% (1)

- DIY Guide: Repairing PAR Lights, 12V SMPS, 5V SMPS, and Pixel LEDDari EverandDIY Guide: Repairing PAR Lights, 12V SMPS, 5V SMPS, and Pixel LEDBelum ada peringkat

- Illum Lec1Dokumen148 halamanIllum Lec1Minerva AbantoBelum ada peringkat

- Solar Energy in Buildings: Thermal Balance for Efficient Heating and CoolingDari EverandSolar Energy in Buildings: Thermal Balance for Efficient Heating and CoolingBelum ada peringkat

- Is 3646 - 1Dokumen35 halamanIs 3646 - 1Krishna VenkataramanBelum ada peringkat

- Design Guide for Lighting SystemsDokumen41 halamanDesign Guide for Lighting SystemsAshutosh SharmaBelum ada peringkat

- Lighting Handbook 08Dokumen324 halamanLighting Handbook 08Albert TuazonBelum ada peringkat

- Notes On Ligthing TeachersDokumen45 halamanNotes On Ligthing TeachersNKWENTI FLAVIOUS TANUEBelum ada peringkat

- Architecture BLD NOTES 2Dokumen12 halamanArchitecture BLD NOTES 2Mwaniki WilBelum ada peringkat

- Licht Hand BuchDokumen370 halamanLicht Hand BuchMochammad SholichudinBelum ada peringkat

- Light Illumination PDFDokumen18 halamanLight Illumination PDFKirti gargBelum ada peringkat

- Eficiencia Energética en IluminaciónDokumen10 halamanEficiencia Energética en IluminaciónMario GonzálezBelum ada peringkat

- Electric Power Utilisation and Energy AuditingDokumen14 halamanElectric Power Utilisation and Energy Auditingrpdmohan100% (2)

- Lighting FundamentalsDokumen31 halamanLighting FundamentalsAnil NairBelum ada peringkat

- Lighting Fundamentals: The Two Objectives of The Lighting Designer AreDokumen58 halamanLighting Fundamentals: The Two Objectives of The Lighting Designer AresenthilkumarBelum ada peringkat

- Chapter One: IlluminatonDokumen50 halamanChapter One: IlluminatonMirkena kebedeBelum ada peringkat

- Product CatalogDokumen107 halamanProduct CatalogUjjwal ModiBelum ada peringkat

- cc2715 Lighting Solutions 2015 11technical and Index Lighting Design Guide PDFDokumen2 halamancc2715 Lighting Solutions 2015 11technical and Index Lighting Design Guide PDFABELWALIDBelum ada peringkat

- Lighting: CHAPTER - 1: Building Electrical Installation CalculationDokumen13 halamanLighting: CHAPTER - 1: Building Electrical Installation CalculationMr NobodyBelum ada peringkat

- The Fundamentals of Lighting PDFDokumen20 halamanThe Fundamentals of Lighting PDFVasilis Karageorgiou100% (1)

- En Erco Photo Metric DataDokumen12 halamanEn Erco Photo Metric DataLinSeen LeeBelum ada peringkat

- Lighting Handbook PhilipsDokumen223 halamanLighting Handbook PhilipsfmtzvargasBelum ada peringkat

- Interior Lighting Design StandardsDokumen4 halamanInterior Lighting Design StandardsNik LuckBelum ada peringkat

- Optical Measurement Guidelines: For High-Power Leds and Solid State Lighting ProductsDokumen12 halamanOptical Measurement Guidelines: For High-Power Leds and Solid State Lighting ProductsAlfredo Lopez CordovaBelum ada peringkat

- Mine Environmental Engineering Assignment-2: Prepared By:-Manas Ranjan Bhoi 108MN028Dokumen25 halamanMine Environmental Engineering Assignment-2: Prepared By:-Manas Ranjan Bhoi 108MN028Krishna PrasadBelum ada peringkat

- Lecture (3d) - Calculating Illuminance LevelsDokumen19 halamanLecture (3d) - Calculating Illuminance LevelsNuno HenriquesBelum ada peringkat

- Day LightingDokumen37 halamanDay LightingMonika JamwalBelum ada peringkat

- Luminaire EfficacyDokumen2 halamanLuminaire EfficacyIulian BadoiBelum ada peringkat

- Interior Lighting DesignDokumen4 halamanInterior Lighting DesignEvon ChayBelum ada peringkat

- Lighting SystemsDokumen7 halamanLighting SystemsSuhas AcharyaBelum ada peringkat

- Zonal Cavity & Lumen MethodDokumen36 halamanZonal Cavity & Lumen MethodAnanda DuttaBelum ada peringkat

- LG3update Lighting Guide 3 Addendum 2001Dokumen7 halamanLG3update Lighting Guide 3 Addendum 2001S E Krishnan IyerBelum ada peringkat

- Building Services - IiDokumen17 halamanBuilding Services - IiyashaswiniBelum ada peringkat

- Hyd Problem SolvingDokumen0 halamanHyd Problem SolvingKhin Aung ShweBelum ada peringkat

- A Proven Quality System: Changing The GameDokumen3 halamanA Proven Quality System: Changing The GameTommyc1024Belum ada peringkat

- Current Affairs 2013Dokumen283 halamanCurrent Affairs 2013Tommyc1024Belum ada peringkat

- Vs AnchorageDokumen100 halamanVs AnchorageTommyc1024Belum ada peringkat

- Natural Resources ConservationDokumen22 halamanNatural Resources ConservationTommyc1024100% (1)

- Photometrics PDFDokumen3 halamanPhotometrics PDFസഞ്ജയ്100% (1)

- Building Construction: Thirtieth Edition 2012....Dokumen4 halamanBuilding Construction: Thirtieth Edition 2012....Haroun EdressBelum ada peringkat

- The hidden message in the English alphabet (26 lettersDokumen1 halamanThe hidden message in the English alphabet (26 lettersTommyc1024Belum ada peringkat

- 100 PowerPoint IdeasDokumen51 halaman100 PowerPoint IdeasTommyc1024Belum ada peringkat

- Compass TraversingDokumen30 halamanCompass TraversingCboh Pdh P-janzBelum ada peringkat

- SSL Energy Savings Report 10 30Dokumen54 halamanSSL Energy Savings Report 10 30Tommyc1024Belum ada peringkat

- Ratan Tata EbookDokumen20 halamanRatan Tata EbookDilip Katekar100% (3)

- Illuminance Calculation 2Dokumen9 halamanIlluminance Calculation 2Tommyc1024Belum ada peringkat

- Calculating Illuminance and Luminous Intensity: CalculationDokumen2 halamanCalculating Illuminance and Luminous Intensity: CalculationTommyc1024Belum ada peringkat

- Calculating Illuminance and Luminous Intensity: CalculationDokumen2 halamanCalculating Illuminance and Luminous Intensity: CalculationTommyc1024Belum ada peringkat

- 06223560Dokumen4 halaman06223560Tommyc1024Belum ada peringkat

- Blackwell ModelDokumen31 halamanBlackwell ModelTommyc1024Belum ada peringkat

- Illuminance Calculation 2Dokumen9 halamanIlluminance Calculation 2Tommyc1024Belum ada peringkat

- Ongc GK 2011Dokumen5 halamanOngc GK 2011Tommyc1024Belum ada peringkat

- Ongc GK 2012Dokumen1 halamanOngc GK 2012Tommyc1024Belum ada peringkat

- HostDokumen1 halamanHostTommyc1024Belum ada peringkat

- Object: 1 Trisolation: 1: Solid Modelling Object ReportDokumen1 halamanObject: 1 Trisolation: 1: Solid Modelling Object ReportTommyc1024Belum ada peringkat

- CMRI Research PapersDokumen8 halamanCMRI Research PapersTommyc1024Belum ada peringkat

- Model Shuttle Car Braking Using Infrared SensorDokumen5 halamanModel Shuttle Car Braking Using Infrared SensorTommyc1024Belum ada peringkat

- Neural Networks - A Comprehensive Foundation - Simon HaykinDokumen823 halamanNeural Networks - A Comprehensive Foundation - Simon HaykinTommyc1024Belum ada peringkat

- GAP804Dokumen98 halamanGAP804Tommyc1024Belum ada peringkat

- Assignment 1 110mn0434Dokumen1 halamanAssignment 1 110mn0434Tommyc1024Belum ada peringkat

- CMR 1957Dokumen140 halamanCMR 1957Tommyc1024Belum ada peringkat

- Cie 140 PDFDokumen29 halamanCie 140 PDFAnonymous 7z6OzoBelum ada peringkat

- Design Transformation For The Sustainability of High-Rise Residential Buildings PDFDokumen6 halamanDesign Transformation For The Sustainability of High-Rise Residential Buildings PDFzajednosexBelum ada peringkat

- Enriching Designs Elevated Experiences: Kone I MonospaceDokumen12 halamanEnriching Designs Elevated Experiences: Kone I MonospaceUzair AhmedBelum ada peringkat

- Thurulie - Clothing Factory Sri Lanka PDFDokumen86 halamanThurulie - Clothing Factory Sri Lanka PDFRanil Fernando100% (2)

- 3D Printed PeltonDokumen63 halaman3D Printed PeltonRENZ JOHN AMPOSTABelum ada peringkat

- ETI (Stralis) PRESENTATION 2010-04-09Dokumen14 halamanETI (Stralis) PRESENTATION 2010-04-09César Arturo Pajuelo EspinozaBelum ada peringkat

- CCT Minuette Range DatasheetDokumen4 halamanCCT Minuette Range DatasheetvishakBelum ada peringkat

- Pengaruh Pemberian Cahaya Terhadap Waktu Perkecambahan Tanaman Bayam (AmaranthusDokumen11 halamanPengaruh Pemberian Cahaya Terhadap Waktu Perkecambahan Tanaman Bayam (AmaranthusMARIA ANGGIE CANTIKA DEWANIBelum ada peringkat

- Simple Magazine #9Dokumen4 halamanSimple Magazine #9Ngôn ngữ AnhBelum ada peringkat

- Statutory Provisions by S.ghatakDokumen27 halamanStatutory Provisions by S.ghatakThota RohithBelum ada peringkat

- Getting Started Series of Online VideosDokumen26 halamanGetting Started Series of Online Videosramdasnambisan3294Belum ada peringkat

- Listening - Turn On That LightDokumen1 halamanListening - Turn On That LightCarla Fontela González0% (1)

- General Management Guide Commercials Bovans WhiteDokumen41 halamanGeneral Management Guide Commercials Bovans Whitegcolobon60% (5)

- Design by Piero CastiglioniDokumen14 halamanDesign by Piero CastiglioniPedro HenriquesBelum ada peringkat

- Woollaston Winery Gravity-Fed DesignDokumen15 halamanWoollaston Winery Gravity-Fed DesignManogna Kavuru100% (1)

- Eic Led Street Lighting SolutionsDokumen7 halamanEic Led Street Lighting Solutionsapi-33098623Belum ada peringkat

- Lighting Calculations ExplainedDokumen26 halamanLighting Calculations Explainedtalal ilyasBelum ada peringkat

- Exhibition Design by Ivan KucinaDokumen4 halamanExhibition Design by Ivan KucinaRotorPoligonBelum ada peringkat

- Faced With The Enemy: Crew Works to Escape Attacking AliensDokumen3 halamanFaced With The Enemy: Crew Works to Escape Attacking AliensCleev LeeBelum ada peringkat

- SUNPIPE CataloguesDokumen17 halamanSUNPIPE Cataloguestrantrunghoa1984Belum ada peringkat

- Project Sustainable Design Management: Methodology For Sustainable Solutions (BIM Book)Dokumen47 halamanProject Sustainable Design Management: Methodology For Sustainable Solutions (BIM Book)Nhan DoBelum ada peringkat

- The Essential Guide To Retail LightingDokumen15 halamanThe Essential Guide To Retail Lightingyordanos hailuBelum ada peringkat

- SM 24 PDFDokumen1.161 halamanSM 24 PDFMango PapajaBelum ada peringkat

- SM 17Dokumen152 halamanSM 17Sebastian TataranBelum ada peringkat

- CM Surgical Lamp PPDokumen13 halamanCM Surgical Lamp PPHyacinthe KOSSIBelum ada peringkat

- Mercedes Benz C250 Car Full ManualDokumen356 halamanMercedes Benz C250 Car Full ManualSclaffen100% (2)

- Catalogue - Decentral and Central Supply For Safety Lighting V04 - ENG - H - 805400007 - K2021-09Dokumen64 halamanCatalogue - Decentral and Central Supply For Safety Lighting V04 - ENG - H - 805400007 - K2021-09Sajid RazaBelum ada peringkat

- Legrand Wiring Devices CatalogueDokumen236 halamanLegrand Wiring Devices CatalogueagustinusidBelum ada peringkat

- Parking RequirementsDokumen11 halamanParking RequirementsPrashna ShresthaBelum ada peringkat

- POH Cessna Skymaster-337Dokumen63 halamanPOH Cessna Skymaster-337Gustavo Avila Rodriguez100% (2)

- Juka Innovations v. Uxoz Direct - ComplaintDokumen64 halamanJuka Innovations v. Uxoz Direct - ComplaintSarah BursteinBelum ada peringkat