Technical Standard Order: TSO-C54

Diunggah oleh

tdfsksJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Technical Standard Order: TSO-C54

Diunggah oleh

tdfsksHak Cipta:

Format Tersedia

Subject: TSO-C54, STALL WARNING INSTRUMENTS

Department of Transportation

Federal Aviation Administration

Aircraft Certification Service

TSO-C54

Washington, DC

Date: 10/15/61

Technical Standard Order

Technical Standard Orders for Aircraft Materials,

Parts, Processes, and Appliances

Part 514 contains minimum performance standards and specifications of materials, parts,

processes, and appliances used in aircraft and implements the provisions of sections 3.18, 4a.31,

4b.18, 6.18 and 7.18 of the Civil Air Regulations. The regulation uses the Technical Standard

Order system which, in brief, provides for FAA-industry cooperation in the development of

performance standards and specifications which are adopted by the Administrator as Technical

Standard Orders, and a form of self-regulation by industry in demonstrating compliance with

these orders.

Part 514 consists of two subparts. Subpart A contains the general requirements

applicable to all Technical Standard Orders. These provisions are summarized below for the

convenient reference of the public. Subpart B contains the technical standards and specifications

to which a particular product must conform, and each Technical Standard Order is set forth in

the appropriate section of Subpart B. The subject Technical Standard Order is printed below.

ANY TECHNICAL STANDARD ORDER MAY BE OBTAINED BY SENDING A REQUEST

TO FAA, WASHINGTON 25, D.C.

SUBPART A--GENERAL

This subpart provides, in part, that a

manufacturer of an aircraft material, part,

process, or appliance for which standards

are established in Subpart B, prior to its

distribution for use on a civil aircraft of the

United States, shall furnish a written

statement of conformance certifying that the

material, part, process, or appliance meets

the applicable performance standards

established in this part. The statement of

conformance must be signed by a person

duly authorized by the manufacturer, and

furnished to the Chief, Engineering and

Manufacturing Division, Flight Standards

Service, Federal Aviation Agency,

Washington 25, D. C.

Subpart A also requires appropriate

marking of materials, parts, processes, and

appliances as follows:

(a) Name and address of the

manufacturer responsible for compliance,

(b) Equipment name, or type or

model designation,

TSO-C54 10/15/61

(c) Weight to the nearest pound and

fraction thereof,

(d) Serial number and/or date of

manufacture, and

(e) Applicable Technical Standard

Order (TSO) number.

In addition, Subpart A provides that

no deviation will be granted from the

performance standards established in

Subpart B, and that the Administrator may

take appropriate action in the event of

noncompliance with Part 514.

SUBPART B

514.53 Stall warning instruments - TSO-C54-- (a) Applicability - (1) Minimum

performance standards. Minimum performance standards are hereby established for stall

warning instruments which specifically are required to be approved for use on civil aircraft of

the United States. New models of stall warning instruments manufactured for installation on

civil aircraft on or after October 15, 1961, shall meet the standards as set forth in SAE

Aeronautical Standard AS 403A, Stall Warning Instrument, revised J uly 15, 1958,

1/

with

exceptions, and additions to the standards listed in subparagraph (2) of this paragraph.

(2) Exceptions and additions. (i) The following specifically numbered parts in AS 403A

do not concern minimum performance and therefore are not essential to compliance with this

section: Parts 3.1; 3.1.1; 3.1.2; 3.2 (a), (b), (c), (d), (e), and (f).

(ii) In lieu of Part 7, it is a requirement that stall warning instruments covered by this

section be capable of successfully passing the tests in Parts 7.1 through 7.7.

(iii) Thermal shock: This test shall apply to any hermetically sealed component. The

component shall be subject to four cycles of exposure to water at 85 2 C. and 5 2 C.

without evidence of moisture penetration or damage to coating or enclosure. Each cycle of the

test shall consist of immersing the component in water at 85 2 C. for a period of 30 minutes,

and then within 5 seconds of removal from the bath, the component shall be immersed for a

period of 30 minutes in the other bath maintained at 5 2 C. This cycle shall be repeated

continuously, one cycle following the other until four cycles have been completed. Following

this test, the indictor shall be subjected to the Sealing test specified in (iv). No indicator leakage

shall occur as a result of this test.

(iv) Sealing: This performance test shall apply to each hermetically sealed instrument.

The instrument shall be immersed in a suitable liquid, such as water. The absolute pressure of

the air above the liquid shall them be reduced to approximately 1 inch of mercury (Hg) and

maintained for 1 minute, or until air bubbles cease to be given off by the liquid, whichever is

longer. The absolute pressure shall then be increased by 2 inches Hg. Any bubbles coming

from within the indicator case shall be considered as leakage and shall be cause for rejection.

Bubbles which are the result of entrapped air in the various exterior parts of the case shall not be

considered as leakage. Other test methods which provide evidence equal to the immersion test

of the integrity of the instruments seals may be used. If the instrument incorporates

1/ Copies of these may be obtained from the Society of Automotive Engineers, 485 Lexington

Avenue, New York 17, New York.

Page 2

10/15/61 TSO-C54

nonhermetically sealed appurtenances, such as a case extension, these appurtenances may be

removed prior to the sealing test.

(v) Power malfunction indication: Means shall be incorporated in the instrument to

indicate when adequate power (voltage and/or current) is not being made available to all phases

required for the proper operation of the instrument. The indicating means shall indicate a failure

or a malfunction in a positive manner, and be readily discernible under any lighting condition

normally encountered in aircraft.

(b) Marking. In addition to the markings specified in Subpart A, range or rating (voltage)

shall be shown.

(c) Data requirements. (1) The manufacturer shall maintain a current file of complete

design data.

(2) The manufacturer shall maintain a current rule of complete data describing the

inspection and test procedures applicable to his product.

(3) Six copies each, except where noted, of the following shall be furnished to the Chief,

Engineering and Manufacturing Division, Flight Standards Service, Federal Aviation Agency,

Washington 25, D. C.

(i) Manufacturers operating instructions and instrument limitations.

(ii) Drawings of major components or photographs showing exploded views of

instruments.

(iii) Installation procedures with applicable schematic drawings, wiring diagrams, and

specifications, including any limitations, restrictions, or other conditions pertinent to installation.

(iv) One copy of the manufacturers test report.

(d) Quality control. Each stall warning instrument shall be produced under a quality

control system, established by the manufacturer, which will assure that each stall warning

instrument is in conformity with the requirements of this section and is in condition for safe

operation. This system shall be described in the data required under paragraph (c)(2). A

representative of the Administrator shall be permitted to make such inspections and tests at the

manufacturers facility as may be necessary to determine compliance with the requirements of

this standard.

(e) Previously approved equipment. Stall warning instruments approved by the

Administrator prior to October 15, 1961, may continue to be manufactured under the provisions

of their original approval.

(f) Effective date. October 15, 1961.

Page 3

Anda mungkin juga menyukai

- FAR/AIM 2019: Federal Aviation Regulations / Aeronautical Information ManualDari EverandFAR/AIM 2019: Federal Aviation Regulations / Aeronautical Information ManualBelum ada peringkat

- Multi-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideDari EverandMulti-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkridePenilaian: 5 dari 5 bintang5/5 (4)

- Tso C155Dokumen12 halamanTso C155Hosein AlaviBelum ada peringkat

- TSO C124cDokumen6 halamanTSO C124cLeonel E. MoralesBelum ada peringkat

- Tso-C151b Terrain Awareness and Warning SystemDokumen49 halamanTso-C151b Terrain Awareness and Warning SystemKaung MyatToeBelum ada peringkat

- Airworthiness HandbookDokumen15 halamanAirworthiness HandbookSmrti Sattana100% (1)

- Tech Standard Order Gas Turbine APU PDFDokumen25 halamanTech Standard Order Gas Turbine APU PDFMartha Mariana MB0% (1)

- Taws Class A & B - Tsoc151bpaperDokumen49 halamanTaws Class A & B - Tsoc151bpaperMuhammadFikriSBelum ada peringkat

- TSO C124aDokumen4 halamanTSO C124aSilentisticsBelum ada peringkat

- TSO C128aDokumen6 halamanTSO C128aau-au-bergueBelum ada peringkat

- AC 20-154 Incoming InspectionDokumen24 halamanAC 20-154 Incoming Inspectionyvesandrade100% (1)

- 514.5 Design Changes.: by Manufacturer Minor Changes. The ManuDokumen4 halaman514.5 Design Changes.: by Manufacturer Minor Changes. The ManusaeedbabaBelum ada peringkat

- AoA Systems Approval (FAA Memo)Dokumen5 halamanAoA Systems Approval (FAA Memo)buckeyes2015Belum ada peringkat

- C69 CDokumen47 halamanC69 CLena BatboldBelum ada peringkat

- TSO C155bDokumen6 halamanTSO C155bHosein AlaviBelum ada peringkat

- TSO C155aDokumen6 halamanTSO C155aHosein AlaviBelum ada peringkat

- TSO C123bDokumen12 halamanTSO C123bmenonvindBelum ada peringkat

- Tsoc 5 eDokumen4 halamanTsoc 5 eisdapi99Belum ada peringkat

- AC-23-8 ENSAIO EM VÔO Final-Part1Dokumen174 halamanAC-23-8 ENSAIO EM VÔO Final-Part1Marcus DragoBelum ada peringkat

- Technical Standard Order: TSO-C175Dokumen6 halamanTechnical Standard Order: TSO-C175gadsBelum ada peringkat

- Circular Receiving FAADokumen25 halamanCircular Receiving FAALuis AmayaBelum ada peringkat

- Tso C161Dokumen5 halamanTso C161Deyna Anaya LópezBelum ada peringkat

- Tso C197Dokumen6 halamanTso C197rdpereirBelum ada peringkat

- Advisory Circular: Subject: Date: Initiated By: AC NoDokumen6 halamanAdvisory Circular: Subject: Date: Initiated By: AC NoriversgardenBelum ada peringkat

- TSO C153aDokumen79 halamanTSO C153ardpereirBelum ada peringkat

- Advisory Circular: Subject: Guide For Developing A Receiving Date: 12/12/05 Initiated By: AFS-300 AC No: 20-154Dokumen23 halamanAdvisory Circular: Subject: Guide For Developing A Receiving Date: 12/12/05 Initiated By: AFS-300 AC No: 20-154Marco CandoBelum ada peringkat

- Aero Bull 7aDokumen42 halamanAero Bull 7apattsaeroBelum ada peringkat

- Tso PitotDokumen8 halamanTso PitotElkin CuevasBelum ada peringkat

- Tso C139Dokumen5 halamanTso C139Russell GouldenBelum ada peringkat

- AC 20-62D - Excerpt PDFDokumen2 halamanAC 20-62D - Excerpt PDFtwj84Belum ada peringkat

- TSO C145a PDFDokumen8 halamanTSO C145a PDFwangxiaomin1977Belum ada peringkat

- Mechanical Equipment TestingDokumen12 halamanMechanical Equipment TestingChemi YeBelum ada peringkat

- FAR 35 Airworthiness Standards: Propellers: By: Cesar Camilo Caro GonzalezDokumen41 halamanFAR 35 Airworthiness Standards: Propellers: By: Cesar Camilo Caro GonzalezCamilo CaroBelum ada peringkat

- Technical Standard Order: TSO-C110aDokumen4 halamanTechnical Standard Order: TSO-C110aP_leeBelum ada peringkat

- SAEP-20 Equipment Inspection ScheduleDokumen25 halamanSAEP-20 Equipment Inspection Scheduleroutine7675% (4)

- Advisory Circular: Fede Al Av AtionDokumen4 halamanAdvisory Circular: Fede Al Av AtionJack58Belum ada peringkat

- TSO C112e PDFDokumen15 halamanTSO C112e PDFAndres GuerreroBelum ada peringkat

- Civil Aviation Requirements Section 2 - Airworthiness Series I' Part I Issue Ii, 15Th March, 1976 Effective: ForthwithDokumen6 halamanCivil Aviation Requirements Section 2 - Airworthiness Series I' Part I Issue Ii, 15Th March, 1976 Effective: ForthwithManish MishraBelum ada peringkat

- Review MEL & CASR: A. A Document Issued by The Authority For Type DesignDokumen5 halamanReview MEL & CASR: A. A Document Issued by The Authority For Type DesignHerpina Winda sihombingBelum ada peringkat

- Engineer Maint GuideDokumen89 halamanEngineer Maint Guideorea1Belum ada peringkat

- Airworthiness Advisory Circular: Director General of Civil AviationDokumen6 halamanAirworthiness Advisory Circular: Director General of Civil AviationDayakar RanaBelum ada peringkat

- Sti 3258Dokumen6 halamanSti 3258sutanuprojectsBelum ada peringkat

- Saep 20 PDFDokumen25 halamanSaep 20 PDFbrecht1980100% (1)

- FAA 2020 0345 0003 - Attachment - 1Dokumen3 halamanFAA 2020 0345 0003 - Attachment - 1Kevin PangilinanBelum ada peringkat

- CAA AC AWS002 Issue and Renewal Certificate of AirworthinessDokumen11 halamanCAA AC AWS002 Issue and Renewal Certificate of AirworthinessgeoffBelum ada peringkat

- TSO-C153 IMA Hardware ElementDokumen33 halamanTSO-C153 IMA Hardware Elementindra82Belum ada peringkat

- Tso C214Dokumen16 halamanTso C214rdpereirBelum ada peringkat

- 8150.1B DTD May 2002Dokumen32 halaman8150.1B DTD May 2002Yifeng LeongBelum ada peringkat

- Total Technical Specs PDFDokumen259 halamanTotal Technical Specs PDFBhavesh KeraliaBelum ada peringkat

- AC 20-62E (Eligibility Quality and Identification of Aeronautical Replacement Parts (Page 1 & 2)Dokumen2 halamanAC 20-62E (Eligibility Quality and Identification of Aeronautical Replacement Parts (Page 1 & 2)kinqpinzBelum ada peringkat

- National Board Pressure Relief Device Certification Administrative RequirementsDokumen3 halamanNational Board Pressure Relief Device Certification Administrative RequirementsHaroltAlexisLeonTripulBelum ada peringkat

- Aircraft Rules and Regulations Notes (Semester-5) PDFDokumen158 halamanAircraft Rules and Regulations Notes (Semester-5) PDFsatyam singhBelum ada peringkat

- TSO C124b PDFDokumen11 halamanTSO C124b PDFAndres Miguel EscalonaBelum ada peringkat

- Tso C126Dokumen5 halamanTso C126nxuannhuBelum ada peringkat

- Commissioning Template PDFDokumen5 halamanCommissioning Template PDFHadjon PhillBelum ada peringkat

- 009 04 - Fy14 CH1Dokumen10 halaman009 04 - Fy14 CH1Brian Joseph MugrageBelum ada peringkat

- 15kV and 24.2kV Class Automatic Distribution Recloser GED 823 25022008Dokumen25 halaman15kV and 24.2kV Class Automatic Distribution Recloser GED 823 25022008Dante FilhoBelum ada peringkat

- 03 Part 3 Aircraft and Component Original Certification 2 2017Dokumen6 halaman03 Part 3 Aircraft and Component Original Certification 2 2017Duong TramBelum ada peringkat

- Ac 23-8C - Flight Test Guide PDFDokumen265 halamanAc 23-8C - Flight Test Guide PDFMarcus DragoBelum ada peringkat

- FAR-FC 2021: Federal Aviation Regulations for Flight CrewDari EverandFAR-FC 2021: Federal Aviation Regulations for Flight CrewBelum ada peringkat

- DesignGuidelinesfortheSelectionandUseofStainlessSteels 9014 PDFDokumen54 halamanDesignGuidelinesfortheSelectionandUseofStainlessSteels 9014 PDFFadly FaradhilaBelum ada peringkat

- Culver Cadet HandbookDokumen29 halamanCulver Cadet HandbooktdfsksBelum ada peringkat

- 1201 GabeDokumen8 halaman1201 GabetdfsksBelum ada peringkat

- Mechanix Illustrated TeardropDokumen7 halamanMechanix Illustrated TeardropRicky Frentress100% (3)

- Dynamic Analysis Using Response Spectrum Seismic LoadingDokumen24 halamanDynamic Analysis Using Response Spectrum Seismic LoadingEmad Ahmed Khan100% (5)

- Explocat 52 General Description V1.2Dokumen23 halamanExplocat 52 General Description V1.2tdfsksBelum ada peringkat

- Safehull Finite Element Analysis of Hull Structures: Guidance Notes OnDokumen50 halamanSafehull Finite Element Analysis of Hull Structures: Guidance Notes OntdfsksBelum ada peringkat

- Evaluation of The Roll Prediction Method in The Weather CriterionDokumen11 halamanEvaluation of The Roll Prediction Method in The Weather CriteriontdfsksBelum ada peringkat

- Passivating & Pickling Stainless SteelDokumen16 halamanPassivating & Pickling Stainless Steelfeki2607Belum ada peringkat

- Developable SURFACESDokumen6 halamanDevelopable SURFACESleroniusBelum ada peringkat

- FAST99 PaperDokumen12 halamanFAST99 PapertdfsksBelum ada peringkat

- 3 Ym 20Dokumen2 halaman3 Ym 20tdfsksBelum ada peringkat

- Part 23 Airworthiness Standards - Landing Gear - Amdt 48Dokumen12 halamanPart 23 Airworthiness Standards - Landing Gear - Amdt 48tdfsksBelum ada peringkat

- 89 96Dokumen8 halaman89 96tdfsksBelum ada peringkat

- sd20 SpecDokumen1 halamansd20 SpectdfsksBelum ada peringkat

- SH FEA Guide To ColorsDokumen1 halamanSH FEA Guide To ColorstdfsksBelum ada peringkat

- SH FEACorrigenda Feb14Dokumen2 halamanSH FEACorrigenda Feb14tdfsksBelum ada peringkat

- GM Ym Shaft DriveDokumen1 halamanGM Ym Shaft DrivetdfsksBelum ada peringkat

- 3 Ym 30Dokumen2 halaman3 Ym 30tdfsksBelum ada peringkat

- A B Ratio SeatonDokumen3 halamanA B Ratio SeatontdfsksBelum ada peringkat

- GM Ym Sail SpecDokumen1 halamanGM Ym Sail SpectdfsksBelum ada peringkat

- 3 Ym 30Dokumen2 halaman3 Ym 30tdfsksBelum ada peringkat

- 3 Ym 20Dokumen2 halaman3 Ym 20tdfsksBelum ada peringkat

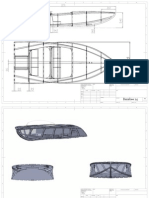

- Banshee 14 Boat SkiffDokumen2 halamanBanshee 14 Boat Skiffjukka_rabdBelum ada peringkat

- 3 Ym 30Dokumen2 halaman3 Ym 30tdfsksBelum ada peringkat

- 1 GM 10Dokumen2 halaman1 GM 10tdfsksBelum ada peringkat

- 3 Ym 20Dokumen2 halaman3 Ym 20tdfsksBelum ada peringkat

- TechnicalDokumen32 halamanTechnicaltdfsksBelum ada peringkat

- A B Ratio SeatonDokumen3 halamanA B Ratio SeatontdfsksBelum ada peringkat

- 2008 - Innovsail08 - Bare Hull Resistance DSYHSDokumen9 halaman2008 - Innovsail08 - Bare Hull Resistance DSYHStdfsksBelum ada peringkat

- Static DischargeDokumen21 halamanStatic DischargeRRBelum ada peringkat

- Mmel 767Dokumen237 halamanMmel 767jjaavvmm100% (1)

- Ad 2022-05-01Dokumen6 halamanAd 2022-05-01Eliana Ayelen TruccoBelum ada peringkat

- UAS FlowchartDokumen1 halamanUAS FlowchartTiffany DacinoBelum ada peringkat

- Faa A&P CourseDokumen21 halamanFaa A&P CourseNakano FidZya100% (1)

- Order 8130 21gDokumen71 halamanOrder 8130 21gphilip00165Belum ada peringkat

- EDTO Module 6 - Flight Operations Considerations PDFDokumen132 halamanEDTO Module 6 - Flight Operations Considerations PDFMaverickBelum ada peringkat

- The Pilot's Handbook of Aeronautical Knowledge 2008 FAAINDEX PDFDokumen471 halamanThe Pilot's Handbook of Aeronautical Knowledge 2008 FAAINDEX PDFNeon100% (2)

- To 4dt or Not 4dtDokumen5 halamanTo 4dt or Not 4dtapi-317683578Belum ada peringkat

- AE 424 PPT 3 Aerodrome PlanningDokumen45 halamanAE 424 PPT 3 Aerodrome PlanningJohn Client Aclan RanisBelum ada peringkat

- Allotment List - Dissertation TopicsDokumen5 halamanAllotment List - Dissertation TopicsanudeepBelum ada peringkat

- SAFO09004Dokumen2 halamanSAFO09004Krikor M.DBelum ada peringkat

- An Evaluation of Life Cycle Cost Analysis of Airport Pavement PDFDokumen6 halamanAn Evaluation of Life Cycle Cost Analysis of Airport Pavement PDFariesBelum ada peringkat

- Aircraft Maintenance Management Question PaperDokumen5 halamanAircraft Maintenance Management Question PaperNikiBelum ada peringkat

- Rule: Airworthiness Directives: Rolls-Royce Deutschland LTD & Co KG Tay 611-8, Tay 611-8C, Tay 620-15, Tay 650-15, and Tay 651-54 Turbofan EnginesDokumen5 halamanRule: Airworthiness Directives: Rolls-Royce Deutschland LTD & Co KG Tay 611-8, Tay 611-8C, Tay 620-15, Tay 650-15, and Tay 651-54 Turbofan EnginesJustia.comBelum ada peringkat

- Army Aviation Digest - May 1979Dokumen52 halamanArmy Aviation Digest - May 1979Aviation/Space History LibraryBelum ada peringkat

- The Week USA - 22 03 2019 PDFDokumen39 halamanThe Week USA - 22 03 2019 PDFGabriel LeeBelum ada peringkat

- How To Support Successful SSP and SMS ImpDokumen10 halamanHow To Support Successful SSP and SMS ImpjuanpgutierrezBelum ada peringkat

- Aircraft Electrical Wire TypesDokumen12 halamanAircraft Electrical Wire Typessakul dejakaisayaBelum ada peringkat

- 2013-15-17Dokumen8 halaman2013-15-17Арсений СафинBelum ada peringkat

- Acrp RPT 137Dokumen84 halamanAcrp RPT 137amenendezamBelum ada peringkat

- Lieutenant D. Jim Nobach Emails (Aviation Division)Dokumen305 halamanLieutenant D. Jim Nobach Emails (Aviation Division)Andrew Charles HendricksBelum ada peringkat

- Lesson Plan Information Sheet: General Review of The MPM Version Date: 07/30/2012Dokumen34 halamanLesson Plan Information Sheet: General Review of The MPM Version Date: 07/30/2012AnandaMandalBelum ada peringkat

- Fail-Safe Design Concept - Aviation Glossary PDFDokumen2 halamanFail-Safe Design Concept - Aviation Glossary PDFOlavo Amorim SantosBelum ada peringkat

- Getting To Grips With ETOPS Vol IDokumen53 halamanGetting To Grips With ETOPS Vol Irahulpattuvam100% (5)

- Bilateral Agreements On Air Transport PDFDokumen17 halamanBilateral Agreements On Air Transport PDFsanofer nishaBelum ada peringkat

- Corrosion Prevention and Control ProgramDokumen21 halamanCorrosion Prevention and Control Programjesus francoBelum ada peringkat

- Flight Manual Supp 208B-12JR - R5-11-7-19Dokumen139 halamanFlight Manual Supp 208B-12JR - R5-11-7-19DennisBelum ada peringkat

- Superior O360/IO360 Installation ManualDokumen117 halamanSuperior O360/IO360 Installation ManualfasilpereiraBelum ada peringkat