Access Chamber or Confined Space) Is The Top Opening To An Underground Utility Vault Used To

Diunggah oleh

Eng Bagaragaza RomualdJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Access Chamber or Confined Space) Is The Top Opening To An Underground Utility Vault Used To

Diunggah oleh

Eng Bagaragaza RomualdHak Cipta:

Format Tersedia

A manhole

A manhole (alternatively utility hole, cable chamber, maintenance hole, inspection chamber,

access chamber or confined space) is the top opening to an underground utility vault used to

house an access point for making connections or performing maintenance on underground and

buried public utility and other services including sewers, telephone, electricity, storm drains and

gas.

VALVES CHAMBERS

1. To control the rate of flow of water

2. To release or admit air into pipeline according to the situation

3. To prevent or detect leakages

4. To meet the demand during emergency and

5. Ultimately to improve the efficiency of the distribution

SLUICE VALVES CHAMBER

These valve control the flow of water through pipes. They are provided in straight pipeline

at 150-200m intervals. When two pipes lines interest, valves are fixed in both sides of

intersection. When sluice valve is closed, it shuts off water in a pipeline to enable to

undertake repairs in that particular block.

CHECK VALVE or REFLUX VALVE CHAMBER

These valves are also known as non-return valves. A reflux valve is an automatic device which

allows water to go in one direction only. The swing type of reflux valve is widely used in

practice.

When the water moves in the direction of arrow, the valve swings or rotates around the

pivot and it is kept in open position due to the pressure of water. When the flow of water in this

direction ceases, the water tries to flow in a backward direction. But this valve prevents passage

of water in the reverse direction.

AIR VALVES

AIR INLET VALVES CHAMBER

These valves open automatically and allow air to enter into the pipeline so that the development

of negative pressure can be avoided in the pipelines. The vacuum pressure created in the down

streamside in pipelines due to sudden closure of sluice valves. This situation can be avoided by

using the air inlet valves.

AIR RELIEF VALVES CHAMBER

Sometimes air is accumulated at the summit of pipelines and blocks the flow of water due to air

lock. In such cases the accumulated air has to be removed from the pipe lines. This is done

automatically by means of air relief valves.

This valve consists of a chamber in which one or two floats are placed and is connected

to the pipe line. When there is flow under pressure in the pipeline water occupies the

float chamber and makes the float to close the outlet. But where there is accumulation of air in

the pipeline, air enters the chamber, makes the float to come down, thus opening the outlet. The

accumulated air is driven out through the outlet.

DRAIN VALVES OR BLOW OFF VALVES CHAMBER

These are also called wash out valves they are provided at all dead ends and depression

of pipelines to drain out the waste water. These are ordinary valves operated by hand.

SCOUR VALVES CHAMBER

These are similar to blow off valves. They are ordinary valves operated by hand. They are

located at the depressions and dead ends to remove the accumulated silt and sand. After the

complete removal of silt; the value is to be closed.

Pumping stations are facilities including pumps and equipment for pumping fluids from one

place to another. They are used for a variety of infrastructure systems, such as the supply of

water to canals, the drainage of low-lying land, and the removal of sewage to processing sites.

Suction Tanks

If large steam pumps, such as are used for fire pumps and to fill house tanks on tall buildings,

were allowed to pump water direct from the city mains, they would cause considerable

annoyance while operating by reducing the pressure and thus decreasing the flow of water in

other supply systems in the neighborhood.

Anda mungkin juga menyukai

- Appurtanances Water Supply EngineeringDokumen9 halamanAppurtanances Water Supply EngineeringNaveen KrishnaBelum ada peringkat

- Water Supply AppurtenancesDokumen26 halamanWater Supply AppurtenancesPrashna Shrestha100% (1)

- Activity 3Dokumen9 halamanActivity 3Rachita SheelavantBelum ada peringkat

- Water Supply Service SystemDokumen27 halamanWater Supply Service SystemWaqarSaleemChBelum ada peringkat

- Appurtenances Commonly Used in A Distribution System - Water EngineeringDokumen12 halamanAppurtenances Commonly Used in A Distribution System - Water Engineering200102018Belum ada peringkat

- Building Services - I (Water Supply and Sanitation) 15 ENG 4.3Dokumen12 halamanBuilding Services - I (Water Supply and Sanitation) 15 ENG 4.3VarunBelum ada peringkat

- Types of ValvesDokumen47 halamanTypes of Valvesgsmrbharath_91Belum ada peringkat

- Zamora Bsce3b Cea132 Assignment-2Dokumen9 halamanZamora Bsce3b Cea132 Assignment-2Mrdy CaiBelum ada peringkat

- Steve ReportDokumen7 halamanSteve Reportmillansteve1Belum ada peringkat

- Building Utilities 1Dokumen42 halamanBuilding Utilities 1Mark Estrella100% (1)

- WS & WWML PresentationDokumen15 halamanWS & WWML Presentationharooniii officialBelum ada peringkat

- Module 1 - Introduction: Universal Human Values & Professional EthicsDokumen26 halamanModule 1 - Introduction: Universal Human Values & Professional EthicsHarshita MittalBelum ada peringkat

- WS Chapter 9981256023 PDFDokumen27 halamanWS Chapter 9981256023 PDFSandesh KhadkaBelum ada peringkat

- M2.7 ValvesDokumen27 halamanM2.7 ValvesUJWAL UMESHBelum ada peringkat

- Plumbing ReviewerDokumen22 halamanPlumbing ReviewerMary Joy Lumacang100% (3)

- Water Supply System OverviewDokumen36 halamanWater Supply System OverviewDharmesh YadavBelum ada peringkat

- Water Supply ApprurtenancesDokumen20 halamanWater Supply ApprurtenancesSushmita AdhikariBelum ada peringkat

- Plumbing ReviewerDokumen21 halamanPlumbing ReviewerChica GoghBelum ada peringkat

- Plumbing Code TerminologyDokumen21 halamanPlumbing Code Terminologyaseec2012_agustinBelum ada peringkat

- RSWMT01 Plumbing System - Ar BuDokumen11 halamanRSWMT01 Plumbing System - Ar BuIan GamitBelum ada peringkat

- FE Semister II PlumbingDokumen7 halamanFE Semister II PlumbingHugh G. RectionBelum ada peringkat

- Spillwaysfinalppt 180319085104Dokumen37 halamanSpillwaysfinalppt 180319085104Ann Nazmun SakibBelum ada peringkat

- PlumbingDokumen31 halamanPlumbingRupali Khatri100% (3)

- DMV SystemDokumen4 halamanDMV Systemgerard.banlasanBelum ada peringkat

- 2 - ValvesDokumen7 halaman2 - ValvesDumindu Chandana PunchihewaBelum ada peringkat

- Chapter 5dropsturcuturesDokumen38 halamanChapter 5dropsturcuturesMahmoud I. MahmoudBelum ada peringkat

- Gatehouse structures for controlling dam water flowDokumen1 halamanGatehouse structures for controlling dam water flowManish KumarBelum ada peringkat

- Sewerage Pipe Size: MisconceptionsDokumen6 halamanSewerage Pipe Size: MisconceptionsSaadSikandarBelum ada peringkat

- Summary UtilitiesDokumen8 halamanSummary Utilitiesar.acnapolesBelum ada peringkat

- Plumbing vent types and sizes guideDokumen15 halamanPlumbing vent types and sizes guideIRA CLARIZZE JACOBBelum ada peringkat

- UtilitiesDokumen15 halamanUtilitiesPAUBelum ada peringkat

- SANITARY AND PLUMBING SYSTEMS GUIDEDokumen8 halamanSANITARY AND PLUMBING SYSTEMS GUIDEJamil RoldanBelum ada peringkat

- Spillwaysfinalppt 180319085104Dokumen37 halamanSpillwaysfinalppt 180319085104omkar ravipudiBelum ada peringkat

- ValvesDokumen4 halamanValvesKevinNavidadBelum ada peringkat

- FixturesDokumen3 halamanFixturesEricka Mae FedereBelum ada peringkat

- Plumbing ValvesDokumen9 halamanPlumbing Valvesruel_galutanBelum ada peringkat

- 4 Water - PlumbDokumen14 halaman4 Water - PlumbAman KeltaBelum ada peringkat

- Report Water Resources - Spillways, Crest Gates, and Outlet WorksDokumen13 halamanReport Water Resources - Spillways, Crest Gates, and Outlet WorksChristian BaldoBelum ada peringkat

- Instruction: Please Do Research On Any Occurrence of Water Hammer and DiscussDokumen1 halamanInstruction: Please Do Research On Any Occurrence of Water Hammer and DiscussTalal SultanBelum ada peringkat

- Canal ExampleDokumen2 halamanCanal ExampleRenzo Rufin PoliñoBelum ada peringkat

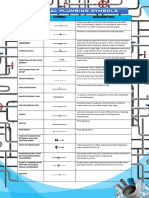

- General Plumbing Symbols: Name Symbol DescriptionDokumen3 halamanGeneral Plumbing Symbols: Name Symbol DescriptionJohn Dave RamirezBelum ada peringkat

- SPDI Recent and Similar Board Questions MPLE 2022Dokumen7 halamanSPDI Recent and Similar Board Questions MPLE 2022Jeinevie T. MaurilloBelum ada peringkat

- Taps and Valves NotesDokumen7 halamanTaps and Valves NotesEdwin Nyaga67% (3)

- Building Services and Workshop TechnologyDokumen21 halamanBuilding Services and Workshop Technologytiffa BosiboriBelum ada peringkat

- Plumbing For ArchitectureDokumen102 halamanPlumbing For ArchitectureMd. Abdul QuayumBelum ada peringkat

- Water Supply & Treatment Engineering: I C E A SDokumen18 halamanWater Supply & Treatment Engineering: I C E A SLavina Edward JosephBelum ada peringkat

- Plumbing TerminologiesDokumen10 halamanPlumbing TerminologiesElyssa GamboaBelum ada peringkat

- Master Plumber Exam Review GuidesDokumen26 halamanMaster Plumber Exam Review GuidesJacky Lynne Regis Agustin85% (13)

- UNIT I Part V Sewer AppurtenancesDokumen16 halamanUNIT I Part V Sewer AppurtenancesPalaka RahulBelum ada peringkat

- Essential Plumbing Tools GuideDokumen8 halamanEssential Plumbing Tools GuideMaribel B GarciaBelum ada peringkat

- Building Utilities 01Dokumen5 halamanBuilding Utilities 01Authentic Sophia100% (1)

- Check Valve: Valve Fluid Liquid GasDokumen5 halamanCheck Valve: Valve Fluid Liquid GasMarcelene Justine DionisioBelum ada peringkat

- Types of valves in piping systems explainedDokumen7 halamanTypes of valves in piping systems explainedShahzad AliBelum ada peringkat

- Irrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsDari EverandIrrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsBelum ada peringkat

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDari EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingPenilaian: 5 dari 5 bintang5/5 (3)

- Crap, The Shitter Is Broke! -Or- How To Fix Common Problems With Your ToiletDari EverandCrap, The Shitter Is Broke! -Or- How To Fix Common Problems With Your ToiletBelum ada peringkat

- Design of The Rotor Blades of A Mini Hydraulic Bulb-Turbine PDFDokumen9 halamanDesign of The Rotor Blades of A Mini Hydraulic Bulb-Turbine PDFEng Bagaragaza RomualdBelum ada peringkat

- Interturn Short-Circuit Detector For Turbine-Generator Rotor WindingsDokumen6 halamanInterturn Short-Circuit Detector For Turbine-Generator Rotor WindingsEng Bagaragaza Romuald100% (1)

- A Smart Experimental Setup For Vibration Measurement andDokumen11 halamanA Smart Experimental Setup For Vibration Measurement andEng Bagaragaza RomualdBelum ada peringkat

- Preventing Destructive PDFDokumen25 halamanPreventing Destructive PDFEng Bagaragaza RomualdBelum ada peringkat

- A I RS: David G. Dorrell, William ThomsonDokumen11 halamanA I RS: David G. Dorrell, William ThomsonEng Bagaragaza RomualdBelum ada peringkat

- Water Hammer Analysis of Run-of-River Hydro PlantDokumen9 halamanWater Hammer Analysis of Run-of-River Hydro PlantEng Bagaragaza RomualdBelum ada peringkat

- Vibration and Cavitation Prediction and Control of Turbine Alternator in HydroDokumen11 halamanVibration and Cavitation Prediction and Control of Turbine Alternator in HydroEng Bagaragaza RomualdBelum ada peringkat

- Performance Analysis of A Three-Phase InductionDokumen8 halamanPerformance Analysis of A Three-Phase InductionEng Bagaragaza RomualdBelum ada peringkat

- Condition Monitoring System For Hydro TurbinesDokumen4 halamanCondition Monitoring System For Hydro TurbinesEng Bagaragaza RomualdBelum ada peringkat

- Condition of Setting Surge Tanks in Hydropower Plants - A Review PDFDokumen12 halamanCondition of Setting Surge Tanks in Hydropower Plants - A Review PDFEng Bagaragaza RomualdBelum ada peringkat

- Critical Analysis of Vibration Sources of Hydro Aggregates in Operating RegimeDokumen8 halamanCritical Analysis of Vibration Sources of Hydro Aggregates in Operating RegimeEng Bagaragaza RomualdBelum ada peringkat

- Identification of Principal Factors Causing UnbalancedDokumen6 halamanIdentification of Principal Factors Causing UnbalancedEng Bagaragaza RomualdBelum ada peringkat

- Critical Analysis of Vibration Sources of Hydro Aggregates in Operating RegimeDokumen9 halamanCritical Analysis of Vibration Sources of Hydro Aggregates in Operating RegimeEng Bagaragaza RomualdBelum ada peringkat

- 1 s2.0 S2215098616304815 Main PDFDokumen12 halaman1 s2.0 S2215098616304815 Main PDFYanuar KrisnahadiBelum ada peringkat

- Fatigue Life Study of Francis Pump Under Reverse GDokumen15 halamanFatigue Life Study of Francis Pump Under Reverse GEng Bagaragaza RomualdBelum ada peringkat

- Preventing Destructive Effects of Water Hammer in Hydropower Plant PenstocksDokumen25 halamanPreventing Destructive Effects of Water Hammer in Hydropower Plant PenstocksEng Bagaragaza RomualdBelum ada peringkat

- Nr. Crt. Frequency Possible Cause Vibration Amplitude Direction ObservationsDokumen3 halamanNr. Crt. Frequency Possible Cause Vibration Amplitude Direction ObservationsEng Bagaragaza RomualdBelum ada peringkat

- Kapl Turb Inc93 PDFDokumen16 halamanKapl Turb Inc93 PDFEng Bagaragaza RomualdBelum ada peringkat

- Wave Calculation Study of an Air Cushion Surge ChamberDokumen27 halamanWave Calculation Study of an Air Cushion Surge ChamberEng Bagaragaza RomualdBelum ada peringkat

- Preventing DestructiveDokumen25 halamanPreventing DestructiveEng Bagaragaza RomualdBelum ada peringkat

- Modelling and Transient Simulation of Water Flow in Pipelines Using Wanda Transient SoftwareDokumen10 halamanModelling and Transient Simulation of Water Flow in Pipelines Using Wanda Transient SoftwareEng Bagaragaza RomualdBelum ada peringkat

- Critical Analysis of Vibration Sources of Hydro Aggregates in Operating RegimeDokumen8 halamanCritical Analysis of Vibration Sources of Hydro Aggregates in Operating RegimeEng Bagaragaza RomualdBelum ada peringkat

- Study of The Simultaneus Effects of Secundary FlowDokumen11 halamanStudy of The Simultaneus Effects of Secundary FlowJeanPierCajasSocualayaBelum ada peringkat

- 1Dokumen1 halaman1Eng Bagaragaza RomualdBelum ada peringkat

- Erosion Wear On Francis Turbine Components DueDokumen26 halamanErosion Wear On Francis Turbine Components DueEng Bagaragaza RomualdBelum ada peringkat

- Sediment Erosion in Hydro Turbines 1Dokumen414 halamanSediment Erosion in Hydro Turbines 1Eng Bagaragaza RomualdBelum ada peringkat

- 1Dokumen1 halaman1Eng Bagaragaza RomualdBelum ada peringkat

- A Review On Silt Erosion in Hydro TurbinesDokumen14 halamanA Review On Silt Erosion in Hydro TurbinesmanishtubBelum ada peringkat

- Selection of Guide Vane Pro Le For Erosion Handling in Francis TurbinesDokumen9 halamanSelection of Guide Vane Pro Le For Erosion Handling in Francis TurbinesEng Bagaragaza RomualdBelum ada peringkat

- Sediment Erosion in Hydro TurbinesDokumen201 halamanSediment Erosion in Hydro TurbinesAngelcorreajBelum ada peringkat

- Quality Control - Works Inspection: Base Coat For WallDokumen1 halamanQuality Control - Works Inspection: Base Coat For WallParasBelum ada peringkat

- BanbgroupDokumen59 halamanBanbgroupVenkata RajuBelum ada peringkat

- Cassette Inverter (2020) Technical Specification SheetDokumen1 halamanCassette Inverter (2020) Technical Specification SheetOwais AhmedBelum ada peringkat

- SS Cse 01Dokumen191 halamanSS Cse 01Senthil SivasubramaniamBelum ada peringkat

- 9.9 Diaphragms-With-Interior-Shearwalls PDFDokumen4 halaman9.9 Diaphragms-With-Interior-Shearwalls PDFnickBelum ada peringkat

- 2 DR BTM FRZR - cs1400Dokumen40 halaman2 DR BTM FRZR - cs1400Marcella RossiBelum ada peringkat

- Acson Catalogue Air Handling Unit 1201 PDFDokumen12 halamanAcson Catalogue Air Handling Unit 1201 PDFfaiz budiBelum ada peringkat

- VCCT For Abaqus PDFDokumen14 halamanVCCT For Abaqus PDFFelipe Dornellas SilvaBelum ada peringkat

- Concrete Strength Testing ExplainedDokumen32 halamanConcrete Strength Testing ExplainedMinn LwinBelum ada peringkat

- Alloy Steel Round BarDokumen10 halamanAlloy Steel Round BarSingarao KattaBelum ada peringkat

- Tds Az 1500 SeriesDokumen7 halamanTds Az 1500 SeriesIgor_uhuBelum ada peringkat

- Building Envelope Thermal Bridging Guide: Analysis, Applications & InsightsDokumen81 halamanBuilding Envelope Thermal Bridging Guide: Analysis, Applications & InsightsArul Sankaran100% (1)

- Alfa Laval Gphe Catalog 2022Dokumen20 halamanAlfa Laval Gphe Catalog 2022JUAN ANTONIO HERNANDEZ SOSABelum ada peringkat

- Bridge Elastomeric Bearing PadsDokumen10 halamanBridge Elastomeric Bearing PadsShwanBelum ada peringkat

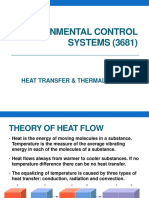

- Heat and Thermodynamics: This Chapter CoversDokumen10 halamanHeat and Thermodynamics: This Chapter CoversLaxankBelum ada peringkat

- Reels: CatalogueDokumen24 halamanReels: CatalogueMatteo BaldassariBelum ada peringkat

- Tool SteelsDokumen31 halamanTool SteelsMaheswaran MuthuBelum ada peringkat

- Bypass Thermostats: Installation InstructionsDokumen1 halamanBypass Thermostats: Installation InstructionsBassieBelum ada peringkat

- ASME 2017 SA 312 Sublimentry RequirementsDokumen2 halamanASME 2017 SA 312 Sublimentry RequirementsKathir VelBelum ada peringkat

- Stalargo Stainless Steel I-Beams: For Demanding ApplicationsDokumen4 halamanStalargo Stainless Steel I-Beams: For Demanding ApplicationsTushar PatilBelum ada peringkat

- Project Report Group 4Dokumen28 halamanProject Report Group 4Akame TakashitaBelum ada peringkat

- Acoustic Emission Testing Method: Questions AnswersDokumen22 halamanAcoustic Emission Testing Method: Questions AnswersSadhasivam Velu100% (2)

- Site Feasibility 4 - Site Conditions Surveyed - Building Survey - Site Measuring 2019Dokumen48 halamanSite Feasibility 4 - Site Conditions Surveyed - Building Survey - Site Measuring 2019Tiep Mai ThanhBelum ada peringkat

- Structural steel advantages in bridge constructionDokumen2 halamanStructural steel advantages in bridge constructionRalph PacilBelum ada peringkat

- METROLOGY & MEASUREMENTSDokumen12 halamanMETROLOGY & MEASUREMENTSmirztrBelum ada peringkat

- ENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3Dokumen73 halamanENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3shariq talatBelum ada peringkat

- Enau Polyla (FDM Filament) : Problem StatementDokumen1 halamanEnau Polyla (FDM Filament) : Problem Statementhakim nasirBelum ada peringkat

- Gang-Nail Connectors - How They Work Gang-Nail Truss SystemDokumen5 halamanGang-Nail Connectors - How They Work Gang-Nail Truss SystemAnonymous acaD5VBelum ada peringkat

- Shear Force Diagram - Bending Moment DiagramDokumen2 halamanShear Force Diagram - Bending Moment Diagrammoondonoo7Belum ada peringkat

- Leak Testing and Refrigerant Charging of Room ACDokumen8 halamanLeak Testing and Refrigerant Charging of Room ACUdara ManawaduBelum ada peringkat