Parametric Modelling of Straight Bevel Gearing System and Analyze The Forces and Stresses by Analytical Approach

Diunggah oleh

seventhsensegroupJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Parametric Modelling of Straight Bevel Gearing System and Analyze The Forces and Stresses by Analytical Approach

Diunggah oleh

seventhsensegroupHak Cipta:

Format Tersedia

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 9- September 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 3837

Parametric Modelling of Straight Bevel Gearing

system and Analyze the Forces and Stresses by

Analytical Approach

A.V.Ramana Rao

1

, CH.Bhanu Prakash

2

, M.N.V.S.A.Sivaram.K

3

1

Asst.Prof., Mechanical Engineering Department, Vishnu Institute of Technology, Bhimavaram, A.P, INDIA

2

Asst.Prof., Mechanical Engineering Department, Vishnu Institute of Technology, Bhimavaram, A.P, INDIA

3

Asst.Prof., Mechanical Engineering Department, Vishnu Institute of Technology, Bhimavaram, A.P, INDIA

Abstract The three-dimensional parametric modelling of

straight bevel gear pair using CATIA V5 software system. Gears

modelling are based on geometric and perspective

transformation. Parameter modelling application makes possible

the control of created 3D gear model through previous defined

parameter which is based on relations and geometric constraints.

The final shape of gear changes by changing of values of

parameters, and that makes model creation in short time and

analysis of forces and stress by analytical approach. Modelling

methodology and functionality that is described by selected

example can be used in cone crusher.

Keywords Bevel gears, parametric modelling, CATIA V5.

I. INTRODUCTION

A bevel gear is one of the most fundamental types of gear; it

is widely used in aircrafts, automobiles and heavy engineering

machines, etc... Two important concepts in gearing are pitch

surface and pitch angle. The pitch surface of a gear is the

imaginary toothless surface that you would have by averaging

out the peaks and valleys of the individual teeth. The pitch

surface of an ordinary gear is the shape of a cylinder. The

pitch angle of a gear is the angle between the face of the pitch

surface and the axis. The most familiar kinds of bevel gears

have pitch angles of less than 90 degrees and therefore are

cone-shaped. This type of bevel gear is called external

because the gear teeth point outward. The pitch surfaces of

meshed external bevel gears are coaxial with the gear shafts;

the apexes of the two surfaces are at the point of intersection

of the shaft axes. Bevel gears that have pitch angles of greater

than ninety degrees have teeth that point inward and are

called internal bevel gears.Bevel gears that have pitch angles

of exactly 90 degrees have teeth that point outward parallel

with the axis and resemble the points on a crown. That's why

this type of bevel gear is called a crown gear. Straight bevel

gears are the most economical of the various bevel gears,

owing to their ease of manufacture. The drive unit for cone

crusher is affected by the frequent failures of bevel gear pair

at higher loads. So these gears are again redesigned but the

surface profile of the gear teeth is relatively difficult to draw

accurately. . Either of these will require an exact CAD model

of the tooth geometry, and approximate methods will not

always meet the requirements.

II. GEAR TERMINOLOGY

(1) Pitch circle: Theoretical circle upon which all gear

calculations are usually based. Pitch circles of mating gears

are tangent to one another.

(2) Pitch diameter: The diameter of the pitch circle.

(3) Number of teeth: The number of teeth on the gear.

(4) Diametric pitch: The number of teeth of a gear per inch of

its pitch diameter.

(5) Module: The ratio of pitch diameter to the number of teeth.

It is reciprocal of the diametric pitch. The pitch diameter is

specified either in inches or millimeters.

(6) Pressure angle: The angle through which forces are

transmitted between meshing gears. It is either 14.5or 20. It

defines the geometry of the gear tooth and also determines the

diameter of the base circle.

(7) Addendum: The amount of tooth that protrudes above the

pitch circle (fromtop land to pitch circle)

(8) Dedendum: The Radial distance fromthe pitch circle to

the bottomof the tooth space.

(9) Clearance circle: the circle tangent to the addendumcircle

of the mating gear.

(10) Clearance: the distance between the tooth top surface and

the bottomsurface of a mating gear.

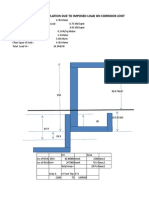

Fig.1 Geometry of straight bevel gear

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 9- September 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 3838

III.GEOMETRY OF STRAIGHT BEVEL GEARS

The geometry of bevel gears is shown in Fig.2. They have

teeth that are straight and tapered, if extended inward, the

teeth would intersect at a common point. The shaft angle is

90

0

, which is the sumof the pitch cone angle of gear and

pinion. In order to secure uniform bearing along the tooth, the

face width is generally not made longer than one-third of the

pitch cone length R, usually b=

R

.R. The gear ratio is

i=n1/n2, 1270/400 =3.175 (1)

Fig.2 Geometry of straight bevel gear

Fig. 3 Back cone and shape of the teeth

As shown in Fig.2 and Fig.3, the size and shape of the straight

bevel gears teeth are defined at the large end, on the back

cone, which have standard involute profiles.

r

e

= d/2 cos (2)

The length of back cone has relationship with the pitch

diameter as equation -2; it is equal to the pitch circle radius of

bevel gears virtual spur gear.

Fig. 4 Involute curve

An involute curve is the loci of a point on the generating line,

as the line rolls without slipping along a base circle, see Fig.4.

Gear teeth are cut in the shape of an involute curve between

the base and the addendum circles, while the part of the tooth

between the base and dedendumcircles is generally a radial

line. In Cartesian coordinate system, the involute curve is

expressed as follows:

x =r

b

(cos + sin)

y =r

b

(sin - cos)

Where r

b

is radius of the base circle, is the spread angle.

IV.PARAMETRIC DESIGN OF STRAIGHT BEVEL

GEARING SYSTEM

Determination of Coordinates control points:

Before cearing parametric design, some coordinates points

must be determined, according to the design variables. Thus, a

Cartesian coordinate system was set up, as shown in Fig.5,

whose origin is at the apex of the back cone. In this coordinate

systemall the control points were determined, referring to

Fig.5 and Table-1.

Fig. 5 Cross section of a bevel gear

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 9- September 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 3839

TABLE-1

Control points coordinates determination

Points x y

O 0 0

O x

0

=0 y

0

=R/cos

2

A x

a

=d

f2

/ 2 y

a

=d

f2

* i

/2

B x

b

=d

a2

/ 2 y

b

=d

a2

* i/2

C x

c

=(1-

R

) * cos

2

+x

d

y

c

=(1-

R

) * h * sin

2

+y

d

D x

d

=(1-

R

) * d

f

/ 2 y

d

=y

e

E x

e

=0 y

e

=(y

0

y

a

) *

R

+y

a

F x

f

=0 y

f

=y

g

G

x

g

=(1- ) *

x

a

y

g

=(1- )

* y

a

According to the above parametric equations, design systems

for straight bevel gears were achieved. The cone crusher drive

unit straight bevel gear and straight bevel gear pinion were

modelled as Shown in Fig. 6&7.

Fig. 6 Parametric modelling of Straight bevel pinion gear and

straight bevel gear wheel

Fig. 7 Isometric views of straight bevel gear pair

V.DESIGN OF STRAIGHT BEVEL GEAR PAIR BY

ANALITICALLY

In straight bevel gears the teeth are straight and parallel to the

generators of the cone. This is the simplest formof bevel gear.

It resembles a spur gear, only conical rather than cylindrical.

TABLE-2

Design data for straight bevel gear pair

S.No Parameter pinion Gear

1 No. of teeth (z) 17 54

2 Module (m) 15.5613 mm

3 Pressure angle () 20

0

4 Shaft angle =

1

+

2

=90

0

5 Face width (b) 180 mm

6 Speed (n) 1270 rpm 400 rpm

7 Power (P) 200 kW

Design of straight bevel pinion gear:

In the present cone crusher, the drive system consists of

straight bevel gear pair in which the pinion gear acts as a drive

gear, transmits power of 200kW with speed 1270 rpm, having

17 teeth, normal module of 15.5613 mmand spiral angle is 0

0

.

Calculations of pinion gear:

Transmission ratio (i) =3.175

Tooth ratio ratio (u) =3.176

Pitch cone angle (

1

) =17.475

0

Middle pitch cone distance (R

m

) =440.478 mm

Outer pitch cone distance (R

a

) =530.478 mm

Inner pitch cone distance (R

i

) =350.478 mm

Outer transverse module (m

to

) =18.740 mm

Middle transverse module (m

tm

) =15.5613 mm

Inner transverse module (m

ti

) =12.381 mm

Outer normal module (m

no

) =18.7408 mm

Middle normal module (m

nm

) =15.5613 mm

Inner normal module (m

ni

) =12.3818 mm

Outer pitch diameter (d

1

) =318.593 mm

Middle pitch diameter (d

m1

) =264.542 mm

Inner pitch diameter (d

i1

) =210.49 mm

Addendum(h

a1

) =21.926 mm

Similarly addendum(middle and inner) =18.263 mm, 15.164

mmrespectively.

Dedendum(h

f1

) =13.455 mm

Similarly dedendum (middle and inner) =11.172 mm, 9.276

mmrespectively.

Outer tip circle diameter (d

a1

) =365.786 mm

Middle tip circle diameter (d

am1

) =303.370 mm

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 9- September 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 3840

Inner tip circle diameter (d

ai1

) =240.1 mm

Base circle radius of the involute spiral (B

r

) =440.478 mm

Middle transverse pitch (p

tm

) =48.887 mm

Diameteral pitch (p

d

) =0.0533 mm

Circular pitch (p

c

) =58.876 mm

Tooth thickness on outer PCD (t

po

) =34.590 mm

Tooth thickness on inner PCD (t

pi

) =22.853 mm

Clearance (c) =2.925 mm

Virtual number of tooth (z

v1

) =17.822

The correction factor of the virtual toothing (x

v1

) =+0.3200

Design of straight bevel gear wheel:

In the present cone crusher, the drive system consists of

straight sided bevel gear pair in which the gear wheel acts as a

drive gear, transmits power of 200kW with speed 400 rpm,

having 54 teeth, normal module of 15.5613 mm and spiral

angle of 0

0

.

Calculations of gear wheel:

Transmission ratio (i) =3.175

Tooth ratio ratio (u) =3.176

Pitch cone angle (

1

) =17.475

0

Middle pitch cone distance (R

m

) =440.478 mm

Outer pitch cone distance (R

a

) =530.478 mm

Inner pitch cone distance (R

i

) =350.484 mm

Outer transverse module (m

to

) =18.740 mm

Middle transverse module (m

tm

) =15.5613 mm

Inner transverse module (m

ti

) =12.381 mm

Outer normal module (m

no

) =18.7408 mm

Middle normal module (m

nm

) =15.5613 mm

Inner normal module (m

ni

) =12.3818 mm

Outer pitch diameter (d

2

) =1012.003 mm

Middle pitch diameter (d

m2

) =840.310 mm

Inner pitch diameter (d

i2

) =668.617 mm

Addendum(h

a2

) =9.9326 mm

Similarly addendum(middle and inner) =8.247 mm, 6.848

mmrespectively.

Dedendum(h

f2

) =25.450 mm

Similarly dedendum (middle and inner) =21.132 mm, 17.547

mmrespectively.

Outer tip circle diameter (d

a2

) =1019.657 mm

Middle tip circle diameter (d

am2

) =846.25 mm

Inner tip circle diameter (d

ai2

) =673.674 mm

Base circle radius of the involute spiral (B

r

) =440.478 mm

Middle transverse pitch (p

tm

) =48.887 mm

Diameteral pitch (p

d

) =0.0533 mm

Circular pitch (p

c

) =58.876 mm

Tooth thickness on outer PCD (t

po

) =24.590 mm

Tooth thickness on inner PCD (t

pi

) =16.045 mm

Clearance (c) =2.925 mm

Virtual number of tooth (z

v1

) =179.826

The correction factor of the virtual toothing (x

v1

) =-0.3200

Forces and stress analysis of the straight bevel gear pair:

For force analysis of a pair of mating straight bevel gears, it is

assumed that the total force F

N

acting on straight bevel gear

teeth is resolved into three mutually perpendicular

components, they are:

1. Tangential tooth load (f

t

)

2. Axial thrust (f

a

)

3. Radial separating force (f

r

)

The tangential tooth load (f

t

):

f

t

=(2T

1

/d

m1

) x 1000 N

Here T is torque on bevel gear pair.

The axial thrust (f

a

):

The radial separating force (f

r

):

Calculation of stresses in straight bevel gear pair:

In general, for contact stress calculations in case of straight

bevel gear pair, it is sufficient to check the stress at the pitch

point P to ensure the Hertzian pressure at the pitch point is

within the allowable limit.

In the above equation y

m

is the material coefficient; y

p

is the

pitch point coefficient.

VI .RESULTS & DISCUSSION

TABLE-3

Determined forces and stresses of straight bevel gear pair

S.No Parameter Pinion Gear Units

1 Torque 1503.937 4775 N-m

2 Tangential force 11370.11 N

3 Normal force 12099.82 N

4 Axial force 1242.70 3947.39 N

5 Radial force 3947.39 1242.70 N

6 Contact stresses 134.5 75.5 MPa

In this study, structural features of straight bevel gear were

analyzed; design variables were specified, and then the

interactive interface was designed; Further, a Cartesian

coordinate systemwas set up and coordinates of control points

were determined according to its geometric relationship. The

parametric design of straight bevel gear has been implemented,

running results showed that the parametric modeling of bevel

gear was speedy and accurate, which will facilitate the 3D

|

|

.

|

\

|

=

1

1

9550

n

P

T

( )

cos sin sin tan

cos

m

m

t

a

f

f +

|

|

.

|

\

|

=

( )

sin sin cos tan

cos

m

m

t

r

f

f

|

|

.

|

\

|

=

|

|

|

.

|

\

|

+

|

|

.

|

\

|

=

u

u

d b

f

y y

m

t

p m

) 1 (

2

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 9- September 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 3841

modeling of straight bevel gear pair in CATIA and the

appropriate forces were found which are acting on straight

bevel gear pair and analyze the contact stresses by analytical

approach.

However, the methodology proposed in this paper is mainly

addressed for straight bevel gears which intersect at right

angle.

VII .CONCLUSION

In geometric gear modelling, we do not have to create shape

directly, but, instead of that, we can put parameters integrated

in geometric and/or dimensional constraints. We get resulted

solid straight bevel gear model by parameters changing. In

this way, designer can create more alternative designing

samples. Time used for creating more designing samples is

reduced for 50%, by parameter modelling. These results can

be seen in reducing the production cost, and the production

also increases. In that way, better profit and price of products

are lower. This type of functionality makes possible flexibility

and it could be used in combination with traditional geometric

modelling approach.

REFERENCES

[1] HIROFUMI SENTOKU AND TOMONOBU ITOU,

Study on transmission error of straight bevel gears,

JSME International Journal Series C, Vil. 47, No.1 (2004),

pp.391-397

[2] XU Jie.Research on Gears 3D Parametrical Design

Based on Solidworks.Machinery & Electricity

Messages[J] ,2010.30, PP130-131.

[3] LI Jun-wei, PAN Yu-tian. Parametric Design and Finite

Element Analysis of Straight Bevel Gear Based on

SolidWorks[J].Modern

[4] Mathematic Manual Compiling Group. Mathematic

Manual[M]. Beijing:Higher Education Press,1979,PP380-

381.

[5] Robert L. Norton, Machine Design an Integrated

Approach Pearson publication, Second Edition, ISBN

978-81-317-0533-9.

[6] Gitin M Maitra, Handbook of Gear Design, Tata

McGraw-Hill, Second Edition, ISBN 0-07-460237-3.

[7] Shigley, Mechanical Engineering, McGrawHill Primis,

Eighth Edition, ISBN: 0390764876.

[8] R. J. Roark, Formula for Stress and Strain, 4th edition,

McGraw-Hill, New York, 1965.

[9] Faydor L. Ltivin, Alfonso Fuentes, Qi Fan, et al.

Computerized design, simulation of meshing, and contact

and stress analysis of face-milled format generated spiral

bevel gears. Mechanism and Machine Theory2002,

21:775-786.

[10] CATIA Web-based Learning Solutions Version V5

Release 18 Windows, Dassault Systemes, 2007.

[11] CATIA Solutions Version V5 Release 18 English

Documentation, Dassault Systemes, 2007.

[12] Karam F., Kleismit C.: Using Catia V5, Thomson

Learning, 2004.

[13] Amirouche, F.: Principles of Computer-Aided Design and

Manufacturing, 2nd edition, Prentice Hall, Upper Saddle

River, New J ersey, 2004.

Anda mungkin juga menyukai

- Download 12,000 Shed PlansDokumen27 halamanDownload 12,000 Shed PlansRadu_IS100% (2)

- Indian ChronologyDokumen467 halamanIndian ChronologyModa Sattva100% (4)

- 2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFDokumen12 halaman2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFvlad lupasteanuBelum ada peringkat

- Ppt02-TypesOfProjectionSheet BBDokumen27 halamanPpt02-TypesOfProjectionSheet BBMinh NguyenBelum ada peringkat

- Disappearance of Madeleine McCannDokumen36 halamanDisappearance of Madeleine McCannCopernicBelum ada peringkat

- Non-Linear Static Analysis of Multi-Storied BuildingDokumen5 halamanNon-Linear Static Analysis of Multi-Storied Buildingseventhsensegroup100% (1)

- Differences ASME and ISO GD&TDokumen2 halamanDifferences ASME and ISO GD&TKeith AdminBelum ada peringkat

- Tnea 2022 Round 4 Voc + Gen + 7 5 Grand Analysis Ashwin RDokumen44 halamanTnea 2022 Round 4 Voc + Gen + 7 5 Grand Analysis Ashwin RSai DhanushBelum ada peringkat

- Fatigue Life Assessment of Welded Bridge Details Using Structural Hot Spot Stress MethodDokumen134 halamanFatigue Life Assessment of Welded Bridge Details Using Structural Hot Spot Stress MethodThong NguyenBelum ada peringkat

- Design-II, 2016 Bevel Gear Design ProcedureDokumen1 halamanDesign-II, 2016 Bevel Gear Design ProcedureenggsantuBelum ada peringkat

- Pressure Vessel Inspection ReportDokumen33 halamanPressure Vessel Inspection ReportJinlong SuBelum ada peringkat

- Bond-Slip Model For Detailed Finite-Element AnalysisDokumen10 halamanBond-Slip Model For Detailed Finite-Element AnalysisSilver rayleighBelum ada peringkat

- Bevel GearDokumen17 halamanBevel Gearparesh09Belum ada peringkat

- Subroutine For Cohesive ElementDokumen41 halamanSubroutine For Cohesive ElementBhushanRaj100% (1)

- Bevel ExplanationDokumen4 halamanBevel ExplanationVarun VaidyaBelum ada peringkat

- CohesiveZoneModels PDFDokumen31 halamanCohesiveZoneModels PDFGopal KondaguntaBelum ada peringkat

- Finite Element Analysis of Spur Gear Set PDFDokumen85 halamanFinite Element Analysis of Spur Gear Set PDFCan CemreBelum ada peringkat

- Major Project ShredderDokumen12 halamanMajor Project Shredderaman kumarBelum ada peringkat

- Deflection Calculation Due To Imposed Load On Corridor JoistDokumen14 halamanDeflection Calculation Due To Imposed Load On Corridor JoistranjitBelum ada peringkat

- List of PEGA Interview Questions and AnswersDokumen33 halamanList of PEGA Interview Questions and Answersknagender100% (1)

- Engineering Drawing Lecture 2Dokumen34 halamanEngineering Drawing Lecture 2Sadia AzamBelum ada peringkat

- Designing Parametric Bevel Gears With Catia V5: 1 Sources, Credits and LinksDokumen10 halamanDesigning Parametric Bevel Gears With Catia V5: 1 Sources, Credits and Linksimrans04Belum ada peringkat

- Machine Design Project ReportDokumen11 halamanMachine Design Project ReportMuhammad Abdullah100% (1)

- OM - Rieter - UNIMix A76Dokumen321 halamanOM - Rieter - UNIMix A76Phineas FerbBelum ada peringkat

- 3 D Toler AncingDokumen19 halaman3 D Toler AncingErnesto MorettorresBelum ada peringkat

- Fulltext01 PDFDokumen108 halamanFulltext01 PDFNGÔ THÁI NGỌ THẦYBelum ada peringkat

- CH 3 Fa2018Dokumen89 halamanCH 3 Fa2018Hassan AliBelum ada peringkat

- The Pathogenic Basis of Malaria: InsightDokumen7 halamanThe Pathogenic Basis of Malaria: InsightRaena SepryanaBelum ada peringkat

- Horizontal Machining Centers: No.40 Spindle TaperDokumen8 halamanHorizontal Machining Centers: No.40 Spindle TaperMax Litvin100% (1)

- Surface Coating ProcessesDokumen7 halamanSurface Coating ProcessesSailabala ChoudhuryBelum ada peringkat

- MESYS Shaft CalculationDokumen51 halamanMESYS Shaft Calculationdd hhBelum ada peringkat

- FEA Report PDFDokumen24 halamanFEA Report PDFDanish JavedBelum ada peringkat

- Contact Pattern Analysis Training ProgramDokumen4 halamanContact Pattern Analysis Training ProgramRAJIV GandhiBelum ada peringkat

- MESYS Shaft Calculation GuideDokumen28 halamanMESYS Shaft Calculation GuideZoebairBelum ada peringkat

- Fea Project ReportDokumen58 halamanFea Project ReportAvnish DubeyBelum ada peringkat

- ME-109 Engineering DrawingDokumen40 halamanME-109 Engineering DrawingHaadin ZamanBelum ada peringkat

- Deep Drawing Analysis by Using Explicit Dynamics in Ansys WorkbenchDokumen8 halamanDeep Drawing Analysis by Using Explicit Dynamics in Ansys Workbenchsunhell1611Belum ada peringkat

- 13 - Chapter - 3 - Kinematics of Backhoe PDFDokumen36 halaman13 - Chapter - 3 - Kinematics of Backhoe PDFKetul ShahBelum ada peringkat

- 226 - Shaking Table Testing of A Steel Framce Structure...Dokumen9 halaman226 - Shaking Table Testing of A Steel Framce Structure...Ing Jaime Espinoza SkinfieldBelum ada peringkat

- Cad Assignment 1Dokumen14 halamanCad Assignment 1Gursewak SinghBelum ada peringkat

- Catalogo Holders TungaloyDokumen156 halamanCatalogo Holders Tungaloyabsalon_jarvBelum ada peringkat

- Short Question Bank CADDokumen3 halamanShort Question Bank CADnravin5Belum ada peringkat

- CAD important questions and tipsDokumen5 halamanCAD important questions and tipsjeroldscdBelum ada peringkat

- AbaqusDokumen4 halamanAbaquscarl_zaissBelum ada peringkat

- 07 Axisymmetric Finite Element ModelingDokumen14 halaman07 Axisymmetric Finite Element ModelingSchubertDeierlein100% (1)

- Features Located To A PatternDokumen4 halamanFeatures Located To A PatternJuan Posada GBelum ada peringkat

- Design For Precision: Current Status and Trends: KeywordsDokumen30 halamanDesign For Precision: Current Status and Trends: KeywordsBrunoBelum ada peringkat

- Thesis Mochammad Rizky DiprasetyaDokumen125 halamanThesis Mochammad Rizky DiprasetyaRizky DsBelum ada peringkat

- 01-Architecture & PlanningDokumen29 halaman01-Architecture & PlanningpragatinareshBelum ada peringkat

- ME8651 Notes Design of Transmission SystemsDokumen71 halamanME8651 Notes Design of Transmission SystemsAslam AhamedBelum ada peringkat

- Design and Optimization Formula SAE DrivetrainDokumen21 halamanDesign and Optimization Formula SAE DrivetrainIJRASETPublicationsBelum ada peringkat

- Cadcam Geometric ModelingDokumen31 halamanCadcam Geometric ModelingPankaj ChhabraBelum ada peringkat

- BITSF110 Course HandoutDokumen3 halamanBITSF110 Course HandoutultimateBelum ada peringkat

- Iso5455 79Dokumen4 halamanIso5455 79Sebastian PopBelum ada peringkat

- Lecture 2A Macro Mechanics Stress Strain Relations For Material TypesDokumen15 halamanLecture 2A Macro Mechanics Stress Strain Relations For Material TypesHarish ShridharamurthyBelum ada peringkat

- Technical Drawing StandardsDokumen11 halamanTechnical Drawing StandardsSeunBelum ada peringkat

- Tolerance Analysis Methods, Platforms and Trends - Comprehensive OverviewDokumen7 halamanTolerance Analysis Methods, Platforms and Trends - Comprehensive Overviewnagmech07Belum ada peringkat

- Cost Reduction and Light Weighting (BIW)Dokumen25 halamanCost Reduction and Light Weighting (BIW)tran hungBelum ada peringkat

- Contact Stress Analysis of Spur Gear Teeth Pair PDFDokumen6 halamanContact Stress Analysis of Spur Gear Teeth Pair PDFCan CemreBelum ada peringkat

- Trends in Machinetools PDFDokumen6 halamanTrends in Machinetools PDFmohan SRBelum ada peringkat

- Submitted By: Structural Analysis of Modified Bumper of Car With Honeycomb Structure Using AnsysDokumen18 halamanSubmitted By: Structural Analysis of Modified Bumper of Car With Honeycomb Structure Using AnsysAlex Pandian SBelum ada peringkat

- Spiral Springs PDFDokumen18 halamanSpiral Springs PDFEngr Eze Chuklet ChukwumaBelum ada peringkat

- Surface FinishDokumen27 halamanSurface Finishykc38Belum ada peringkat

- Design of Spur Gear - Fundamentals - 1Dokumen19 halamanDesign of Spur Gear - Fundamentals - 1Dhyan PatelBelum ada peringkat

- Involute Gear ProfileDokumen8 halamanInvolute Gear ProfiledressfeetBelum ada peringkat

- 2 Gear BasicsDokumen6 halaman2 Gear BasicsMohamed Adel RizkBelum ada peringkat

- Cad Lab Report 5Dokumen11 halamanCad Lab Report 5Areeba MujtabaBelum ada peringkat

- Optimal Search Results Over Cloud With A Novel Ranking ApproachDokumen5 halamanOptimal Search Results Over Cloud With A Novel Ranking ApproachseventhsensegroupBelum ada peringkat

- FPGA Based Design and Implementation of Image Edge Detection Using Xilinx System GeneratorDokumen4 halamanFPGA Based Design and Implementation of Image Edge Detection Using Xilinx System GeneratorseventhsensegroupBelum ada peringkat

- Comparison of The Effects of Monochloramine and Glutaraldehyde (Biocides) Against Biofilm Microorganisms in Produced WaterDokumen8 halamanComparison of The Effects of Monochloramine and Glutaraldehyde (Biocides) Against Biofilm Microorganisms in Produced WaterseventhsensegroupBelum ada peringkat

- Experimental Investigation On Performance, Combustion Characteristics of Diesel Engine by Using Cotton Seed OilDokumen7 halamanExperimental Investigation On Performance, Combustion Characteristics of Diesel Engine by Using Cotton Seed OilseventhsensegroupBelum ada peringkat

- High Speed Architecture Design of Viterbi Decoder Using Verilog HDLDokumen7 halamanHigh Speed Architecture Design of Viterbi Decoder Using Verilog HDLseventhsensegroupBelum ada peringkat

- Application of Sparse Matrix Converter For Microturbine-Permanent Magnet Synchronous Generator Output Voltage Quality EnhancementDokumen8 halamanApplication of Sparse Matrix Converter For Microturbine-Permanent Magnet Synchronous Generator Output Voltage Quality EnhancementseventhsensegroupBelum ada peringkat

- An Efficient Model of Detection and Filtering Technique Over Malicious and Spam E-MailsDokumen4 halamanAn Efficient Model of Detection and Filtering Technique Over Malicious and Spam E-MailsseventhsensegroupBelum ada peringkat

- Fabrication of High Speed Indication and Automatic Pneumatic Braking SystemDokumen7 halamanFabrication of High Speed Indication and Automatic Pneumatic Braking Systemseventhsensegroup0% (1)

- Extended Kalman Filter Based State Estimation of Wind TurbineDokumen5 halamanExtended Kalman Filter Based State Estimation of Wind TurbineseventhsensegroupBelum ada peringkat

- A Multi-Level Storage Tank Gauging and Monitoring System Using A Nanosecond PulseDokumen8 halamanA Multi-Level Storage Tank Gauging and Monitoring System Using A Nanosecond PulseseventhsensegroupBelum ada peringkat

- Color Constancy For Light SourcesDokumen6 halamanColor Constancy For Light SourcesseventhsensegroupBelum ada peringkat

- An Efficient and Empirical Model of Distributed ClusteringDokumen5 halamanAn Efficient and Empirical Model of Distributed ClusteringseventhsensegroupBelum ada peringkat

- Comparison of The Regression Equations in Different Places Using Total StationDokumen4 halamanComparison of The Regression Equations in Different Places Using Total StationseventhsensegroupBelum ada peringkat

- Design, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)Dokumen7 halamanDesign, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)seventhsensegroupBelum ada peringkat

- Implementation of Single Stage Three Level Power Factor Correction AC-DC Converter With Phase Shift ModulationDokumen6 halamanImplementation of Single Stage Three Level Power Factor Correction AC-DC Converter With Phase Shift ModulationseventhsensegroupBelum ada peringkat

- Ijett V5N1P103Dokumen4 halamanIjett V5N1P103Yosy NanaBelum ada peringkat

- Design and Implementation of Height Adjustable Sine (Has) Window-Based Fir Filter For Removing Powerline Noise in ECG SignalDokumen5 halamanDesign and Implementation of Height Adjustable Sine (Has) Window-Based Fir Filter For Removing Powerline Noise in ECG SignalseventhsensegroupBelum ada peringkat

- The Utilization of Underbalanced Drilling Technology May Minimize Tight Gas Reservoir Formation Damage: A Review StudyDokumen3 halamanThe Utilization of Underbalanced Drilling Technology May Minimize Tight Gas Reservoir Formation Damage: A Review StudyseventhsensegroupBelum ada peringkat

- Study On Fly Ash Based Geo-Polymer Concrete Using AdmixturesDokumen4 halamanStudy On Fly Ash Based Geo-Polymer Concrete Using AdmixturesseventhsensegroupBelum ada peringkat

- Separation Of, , & Activities in EEG To Measure The Depth of Sleep and Mental StatusDokumen6 halamanSeparation Of, , & Activities in EEG To Measure The Depth of Sleep and Mental StatusseventhsensegroupBelum ada peringkat

- An Efficient Expert System For Diabetes by Naïve Bayesian ClassifierDokumen6 halamanAn Efficient Expert System For Diabetes by Naïve Bayesian ClassifierseventhsensegroupBelum ada peringkat

- An Efficient Encrypted Data Searching Over Out Sourced DataDokumen5 halamanAn Efficient Encrypted Data Searching Over Out Sourced DataseventhsensegroupBelum ada peringkat

- Review On Different Types of Router Architecture and Flow ControlDokumen4 halamanReview On Different Types of Router Architecture and Flow ControlseventhsensegroupBelum ada peringkat

- Ijett V4i10p158Dokumen6 halamanIjett V4i10p158pradeepjoshi007Belum ada peringkat

- Key Drivers For Building Quality in Design PhaseDokumen6 halamanKey Drivers For Building Quality in Design PhaseseventhsensegroupBelum ada peringkat

- Free Vibration Characteristics of Edge Cracked Functionally Graded Beams by Using Finite Element MethodDokumen8 halamanFree Vibration Characteristics of Edge Cracked Functionally Graded Beams by Using Finite Element MethodseventhsensegroupBelum ada peringkat

- A Review On Energy Efficient Secure Routing For Data Aggregation in Wireless Sensor NetworksDokumen5 halamanA Review On Energy Efficient Secure Routing For Data Aggregation in Wireless Sensor NetworksseventhsensegroupBelum ada peringkat

- A Comparative Study of Impulse Noise Reduction in Digital Images For Classical and Fuzzy FiltersDokumen6 halamanA Comparative Study of Impulse Noise Reduction in Digital Images For Classical and Fuzzy FiltersseventhsensegroupBelum ada peringkat

- Performance and Emissions Characteristics of Diesel Engine Fuelled With Rice Bran OilDokumen5 halamanPerformance and Emissions Characteristics of Diesel Engine Fuelled With Rice Bran OilseventhsensegroupBelum ada peringkat

- L P 10Dokumen13 halamanL P 10Bình Minh HoàngBelum ada peringkat

- Snorkeling: A Brief History and Guide to This Underwater AdventureDokumen3 halamanSnorkeling: A Brief History and Guide to This Underwater AdventureBernadette PerezBelum ada peringkat

- Turabian Sample PaperDokumen9 halamanTurabian Sample Paperemme_lopez908133% (3)

- Magnets Catalog 2001Dokumen20 halamanMagnets Catalog 2001geckx100% (2)

- 2.7.3 Lab Use Steganography To Hide Data Answer KeyDokumen3 halaman2.7.3 Lab Use Steganography To Hide Data Answer KeyVivek GaonkarBelum ada peringkat

- GuideDokumen2 halamanGuideMaissyBelum ada peringkat

- Process of Producting High Carbon Ferro ChromeDokumen5 halamanProcess of Producting High Carbon Ferro ChromeSantosh Kumar MahtoBelum ada peringkat

- A. Hardened Concrete (Non-Destructive Tests) : The SAC Programme Is Managed by Enterprise SingaporeDokumen2 halamanA. Hardened Concrete (Non-Destructive Tests) : The SAC Programme Is Managed by Enterprise Singaporeng chee yongBelum ada peringkat

- 740 (Q50, V40, Awa 4Dokumen10 halaman740 (Q50, V40, Awa 4rawat2583Belum ada peringkat

- HUMAN RIGHTS, RATIONALITY, AND SENTIMENTALITYDokumen13 halamanHUMAN RIGHTS, RATIONALITY, AND SENTIMENTALITYJohn HunterBelum ada peringkat

- Administrations whose CoCs are accepted for CECDokumen1 halamanAdministrations whose CoCs are accepted for CECGonçalo CruzeiroBelum ada peringkat

- Electronics Foundations - Basic CircuitsDokumen20 halamanElectronics Foundations - Basic Circuitsccorp0089Belum ada peringkat

- Strata KT Office OpportunityDokumen41 halamanStrata KT Office OpportunitySanskar SurekaBelum ada peringkat

- Rock Laboratory PricelistDokumen1 halamanRock Laboratory PricelistHerbakti Dimas PerdanaBelum ada peringkat

- ManuscriptDokumen2 halamanManuscriptVanya QuistoBelum ada peringkat

- 4D - Yulianti Viviana - Exercise 9Dokumen7 halaman4D - Yulianti Viviana - Exercise 9Uli JennerBelum ada peringkat

- PPM To Percent Conversion Calculator Number ConversionDokumen1 halamanPPM To Percent Conversion Calculator Number ConversionSata ChaimongkolsupBelum ada peringkat

- Occupant Load CalculationsDokumen60 halamanOccupant Load CalculationsKAIVALYA TIWATNEBelum ada peringkat

- Grade 4 DLL Quarter 2 Week 2 Sir Bien CruzDokumen47 halamanGrade 4 DLL Quarter 2 Week 2 Sir Bien CruzRonel Fillomena0% (1)

- Salford Care Organisation Job Description & Person SpecificationDokumen14 halamanSalford Care Organisation Job Description & Person SpecificationAyesha EhsanBelum ada peringkat

- GEHC DICOM Conformance CentricityRadiologyRA600 V6 1 DCM 1030 001 Rev6 1 1Dokumen73 halamanGEHC DICOM Conformance CentricityRadiologyRA600 V6 1 DCM 1030 001 Rev6 1 1mrzdravko15Belum ada peringkat

- Lab Report AcetaminophenDokumen5 halamanLab Report Acetaminophenapi-487596846Belum ada peringkat