NASA Clean Room Checklist

Diunggah oleh

viorelu990 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

276 tayangan6 halamanCLEAN ROOM AUDIT CHECKLIST

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOC, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniCLEAN ROOM AUDIT CHECKLIST

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

276 tayangan6 halamanNASA Clean Room Checklist

Diunggah oleh

viorelu99CLEAN ROOM AUDIT CHECKLIST

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 6

NASAs

Test and Certification for Clean Rooms, Benches, and Controlled

Environments, Rev. 1, Ref. JPL oc! "#$%$

Process A&dit Chec'list, Rev. A

Supplier Audited:________________________________________________________________

Audit Date:___________________________________________________________________

Auditor(s):__________________________________________________________________

Reviewed by: Approved by:

<original signature on file> <original signature on file>

_______________________________ _______________________________

SME Olga Ceritelli

Title Procurement Quality Aurance !ead

"uly# $%%& "uly# $%%&

Prepared by:

<original signature on file> <original signature on file>

_____________________________ _____________________________

Tony 'utierre( )arrel *+ Cren,aw

Procurement Quality Aurance - QE 'roup Supervior# Procurement Quality Aurance

"uly# $%%& "uly# $%%&

#.( RE)*!RE+ENTS

#.1 Certification re,&irements for Clean Rooms

2.1

Contamination Control Laboratory personnel shall

perform Laminar Flow Clean Room, Clean Bench and

Controlled Environment Certification for the JL

comm!nity per the "#$%&"# 1'('')2 * 1++, -E. #tandard

-available thro!/h http*%%standards.nasa./ov%..

0erify that certification

re1!irements have been performed

per "#$%&"# 1'('')2 *1++,

#tandard.

2.1.1

2he Contamination Control #ervices Laboratory shall

maintain the certification, 3i/h Efficiency artic!late 4ir

Filter -3E4.%5ltra Low enetration 4ir Filter -5L4.,

and pre)filter replacement stat!s for all of these sites in

order to comply with the doc!mentation re1!irements of

"#$.

Re1!est to see the filter replacement

lo/ or database and verifty the stat!s

on fre1!ency replacement of filters.

2.2

2he Classification of the Clean 4reas shall be

doc!mented per the "#$ 1'('')1 standard -available

thro!/h http*%%standards.nasa./ov%..

Ens!re that the lo/ or database

identifies the classification of the

Clean 4reas.

2.6

2he "#$ 1'('')1 tests shall incl!de b!t are not limited to

airborne partic!late co!ntin/ and si7in/, air velocity

testin/, and differential press!re testin/.

#elect random samples and verify

that tests are performed per "#$

standard above.

2.8

2he Controlled Environment areas -9 class 1::,:::. shall

re1!ire only partic!late testin/ !nless otherwise re1!ested

by the c!stomer.

0erify records that partic!late

testin/ has been performed on Clean

Rooms Class 1::,::: or /reater.

%.( RE)*!RE TEST!N-

6.1

Contamination Control personnel shall meas!re the

s1!are foota/e of each Clean Room or Controlled

Environment to establish the n!mber of samples to be

ta;en in the area.

0erify testin/ records show evidence

that the s1!are foota/e has been

meas!red and recorded.

6.2

2he Contamination Control personnel shall ta;e the

proper n!mber of samples at each location as defined by

the "#$ 1'('')1 4nne< B #ection B.'.1.1 !sin/ a -&C.

Calibrated particle co!nter -Calibrated within 1,: days

desi/nated to co!nt the re1!ired particle si7es for the area

which will determine the classification of the clean area.

#elect a ramdom sample of test

res!lts and verify that the

appropriate n!mber of samples were

ta;en per the "#$ standard.

6.6

Contamination Control personnel shall perform a velocity

test in the clean area.

Ens!re that the velocity test was

performed.

6.'

2he n!mber of tests performed shall be based on the

s1!are foota/e of the area.

0erify that the n!mber of tests

coincide with s1!are foota/e of the

area.

6.8

2estin/ information shall be recorded on the certification

data or memo to the c!stomer.

Review the certification doc!ment

and verify that testin/ information is

incl!ded.

6.(

Contamination Control personnel shall determine if the

flow is ade1!ate for the specified area and ma;e

recommendations to the c!stomer in writin/ where the

flow is deemed to be low or o!t of specification.

#ee; evidence that recommendations

have been made in writin/ by

reviewin/ test records.

6.=

&ifferential press!re readin/s shall be performed in all

clean areas to determine the e<istence of positive

press!re.

Ens!re that differential press!re test

was performed and the res!ltin/ data

was provided to the c!sotmer.

6.1:

2he Contamination Control personnel shall perform a

vis!al cleanliness s!rvey of the Clean 4rea to be tested

!nder the "#$ standard.

Note :

This visual cleanliness survey shall be conducted per

the SN-C-0005 Contamination Control Requirements

for the Space Shuttle (Section !"# for visual

cleanliness!

Ens!re that a vis!al for cleanliness

has been performed per specification

and recorded and filed.

6.11

2he Contamination Control Laboratory shall perform

Low)0olatile Resid!e samplin/ by providin/ a clean

sample plate -for airborne collection. or -wipe samples.

for prod!ct testin/ if re1!ired by the c!stomer.

Note :

The follo$in% testin% shall be optional!

>hen re1!ired by the c!stomer,

ens!re that the Low)0olatile Resid!e

samplin/ has been performed.

The Contamination Control &ab can provide

particulate fallout plates to determine the

lar%er si'e particulates that may be enterin% the

clean area!

Tapelift samples can be provided for testin%

hard$are cleanliness( cleanliness of the $alls (

floors or any equipment in the clean area!

".( -AR+ENT RE)*!RE+ENTS

'.1

?inim!m @arment Re1!irements for Clean Rooms,

Controlled Environments and >or; #tations.

2able 1 -below. shall be !sed as the minim!m

re1!irements for clean rooms, controlled environments,

and wor;stations -as specified in 4#2? E2682):',

available thro!/h http*%%standards.nasa./ov%.

Review the specification and verify

that the re1!irements listed in 2able

1 have been met as a minim!m.

..( /*TS!E C/NTRACT/R CLEAN R//+

CERT!0!CAT!/NS AN RE)*!RE+ENTS

8.1

Contractors who perform wor; on JL clean rooms shall

comply with all the applicable re1!irements set forth in

the "#$ 1'('')1 and "#$%&"# 1'('')2 * 1++, -E.

controllin/ doc!ments.

Refer to "#$ doc!ments referenced

and ens!re re1!irements have been

complied with.

8.6

2he contractor shall s!pply to the JL Contamination

Control Laboratory a doc!mentation pac;a/e that

certifies the wor; complies with all the "#$ standard

re1!irements, and specifies the type of wor; performed,

and any optional tests performed.

Ens!re that the contractor satisfies

this re1!irement and verify that it is

per "#$.

8.'

2he contractor shall b!ild the new Clean Room facility in

accordance to the "#$ 1'('' doc!ments and s!pply the

JL Contamination Control Laboratory doc!mentation

which shall incl!de all tests in accordance with that

doc!ment, and si7es, part n!mber of man!fact!rer

n!mber, and statement that the filters were not tested with

&ioctylphthalate -&$., plastici7er test materials or other

non)approved JL test methods with a CAC for the 3E4

or 5L4 filter installation.

Review the doc!ments s!pplied to

the JL Contamination Control

Laboratory doc!mentation and verify

that re1!irements in "#$ have been

met.

$.( 1EPA2*LPA AN RELATE 0!LTER

REPLACE+ENTS

(.1

3E4 filters that are over the man!fac!t!rerBs

recommended life e<pectancy of 8 years shall be tested for

lar/e partic!late by deployin/ witness plates in the clean

room area to determine if the 3E4 filter is de/radin/.

Note:

The )*+,-.&+, filters have a life e/pectancy of 0-5

years in accordance $ith the manufacturer1s

recommendations! Typically the filters at 2+& require

replancement in 3-4 years! There are some filters that

have been purchased by 2+& that hve a life e/pectancy

of 0 years( $arranted by the manufacturer( at

additional costs!

5nder s!ch condition, verify that

filter de/radation has been tested

and recorded.

(.2

2he Contamination Control personnel shall determine by

the tests performed in the certification process when the

filter re1!ire replacement based on the airflow or the

differential press!re drop of the filter.

Ens!re that Contamination Control

certification incl!des tests performed

to determine when filter replacement

is re1!ired.

(.'

4ll 3E4 filters older than = years old shall be replaced.

Notes:

5aivers for filters older than 4 years shall be revie$ed

on an individual basis!

Clean rooms that have fitlers older than 4 years shall be

put in non-compliance!

Review filter lo/%records and verify

that these fitlers have been replaced

at the =

th

year of !se or before.

3.( CERT!0!CAT!/N CLASS LE4ELS

=.1

2he Clean Room, Controlled Environment or Clean

Bench shall have a desi/nated class level n!mber A

which corresponds to the "#$ 1'('')1 2able 2 cleanliness

classes.

0erify that the desi/nated area is

mar;ed with the class n!mber.

=.=

Re)certification tests shall be performed on the clean

rooms at specific intervals to demonstrate compliance

with "#$ 1'('')1 accordin/ to the classification of the

installation.

#elect a sample of records and verify

that re)certification tests were

performed at specific intervals.

5.( CERT!0!CAT!/N LABEL

,.2

2his label shall identify the location, -A4#4 ".&. C on

clean benches or clean tents. Classification, &ate of

Certification, the ne<t Certification date and other tests

performed.

Ens!re that the label identifyin/ the

location has all the proper

information.

1(.( REC/R 6EEP!N-

1:.2

2he certification or non)compliance tests data shall be

entered into the comp!ter database.

Note:

The data shall include the certification classification or

non-compliance data of the clean room( clean bench or

controlled environment( the date of the test( re-

certification date( the standard to $hich the test $as

performed( the location and identification code or

N,S, property number!

Re1!est to see the database

information and verify it.

1:.'

4n "nter)$ffice ?emo shall be initiated with the

classification, differential press!re and velocity data,

c!stomerBs name, char/e n!mber, location of the wor;

performed and the calibration date of the particle co!nter.

Re1!est a copy of the memo and

verify all the pertinent information

has been incl!ded.

11.( REP/RT!N- T/ T1E C*ST/+ER

11.1

2he Contamination Control Laboratory shall provide the

c!stomer with all the data related to the c!stomerBs clean

room, controlled environment or clean bench for

compliance with the "#$ standards in a memo form.

Ens!re that the c!stomer has been

informed of clean room compliance

to "#$.

Anda mungkin juga menyukai

- Clean Room ValidationDokumen15 halamanClean Room ValidationSaifulIslam100% (2)

- Clean Room Qualification and MonitoringDokumen1 halamanClean Room Qualification and MonitoringMuqeet KazmiBelum ada peringkat

- AirlocksDokumen75 halamanAirlocksmarkieboy3650% (2)

- Apparel Considerations For Clean ManufacturingDokumen2 halamanApparel Considerations For Clean ManufacturingGaurav ShakyaBelum ada peringkat

- Good Distribution Practice A Complete Guide - 2021 EditionDari EverandGood Distribution Practice A Complete Guide - 2021 EditionBelum ada peringkat

- Clean RoomDokumen23 halamanClean RoomHumaid Shaikh100% (1)

- Environmental Monitoring and Control A Complete GuideDari EverandEnvironmental Monitoring and Control A Complete GuideBelum ada peringkat

- What Is A Cleanroom - Cleanroom ClassificationsDokumen2 halamanWhat Is A Cleanroom - Cleanroom ClassificationsMai Phuong Phan TranBelum ada peringkat

- Principles and Practices of Contamination Control and CleanroomsDari EverandPrinciples and Practices of Contamination Control and CleanroomsBelum ada peringkat

- Facilities & Equipment GMP UCM456370Dokumen95 halamanFacilities & Equipment GMP UCM456370rajeshkumardasari100% (1)

- EM50Dokumen94 halamanEM50Prasenjit Das100% (1)

- Cleanroom A Complete Guide - 2021 EditionDari EverandCleanroom A Complete Guide - 2021 EditionPenilaian: 5 dari 5 bintang5/5 (2)

- EU GMP Annex 1 - Sterile Medicinal Product - 2008Dokumen16 halamanEU GMP Annex 1 - Sterile Medicinal Product - 2008tungquacert100% (1)

- Guidelines For Routine Environmental Cleaning of The Operating RoomDokumen13 halamanGuidelines For Routine Environmental Cleaning of The Operating RoomYnaffit Alteza UntalBelum ada peringkat

- Basic Cleanroom ProtocolDokumen33 halamanBasic Cleanroom Protocolsid_calayag100% (2)

- CLEAN ROOM PresentationDokumen54 halamanCLEAN ROOM PresentationSanjay Gade100% (1)

- Comprehensive Clean RoomDokumen4 halamanComprehensive Clean RoomLucila Figueroa GalloBelum ada peringkat

- 8.4 Performance Qualification Protocol For Dispensing BoothDokumen13 halaman8.4 Performance Qualification Protocol For Dispensing BoothArej Ibrahim AbulailBelum ada peringkat

- INSWABU - Check List - Sparkling PET - 20190619Dokumen136 halamanINSWABU - Check List - Sparkling PET - 20190619YogiBelum ada peringkat

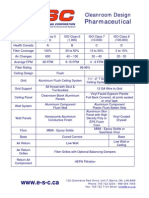

- Cleanroom Design Criteria PharmaceuticalDokumen1 halamanCleanroom Design Criteria PharmaceuticalNabil RamBelum ada peringkat

- Clean Room StandardsDokumen12 halamanClean Room StandardslakshminarayananBelum ada peringkat

- Cleanroom Airlock Performance and Beyond: Column Ieq ApplicationsDokumen6 halamanCleanroom Airlock Performance and Beyond: Column Ieq ApplicationsGuilhermeValadaresBelum ada peringkat

- Microbiology Clean Room Design SpecificationDokumen2 halamanMicrobiology Clean Room Design SpecificationMHNADBelum ada peringkat

- Validation Part2Dokumen48 halamanValidation Part2gvasBelum ada peringkat

- P Assurance Manuals and Validation Procedures - GmpsopDokumen38 halamanP Assurance Manuals and Validation Procedures - GmpsopDeepakBelum ada peringkat

- 2 Understanding Cleanroom Classification PDFDokumen22 halaman2 Understanding Cleanroom Classification PDFTECHNO DATEBelum ada peringkat

- 7 Iso14644Dokumen84 halaman7 Iso14644mgvtertv100% (2)

- ISO 14644 Parts 1 & 2 - ChangesDokumen38 halamanISO 14644 Parts 1 & 2 - ChangesSiva Sankara Narayanan SubramanianBelum ada peringkat

- Cleanroom Design That Terra Recommends: Cost vs. Coverage: Evaluating FFU PlacementDokumen3 halamanCleanroom Design That Terra Recommends: Cost vs. Coverage: Evaluating FFU PlacementdesignselvaBelum ada peringkat

- Sterlization TechniqueDokumen32 halamanSterlization TechniquenehadewasiBelum ada peringkat

- GMP Food Manufacturing Audit Checklist - SafetyCultureDokumen22 halamanGMP Food Manufacturing Audit Checklist - SafetyCultureNaeema100% (1)

- Basic Requirements For Clean RoomDokumen6 halamanBasic Requirements For Clean Roomsamuel debebeBelum ada peringkat

- EPA Quality GuidelineDokumen144 halamanEPA Quality GuidelineEder ApazaBelum ada peringkat

- EUGMP Annex 1 Update 2008 Particle CountingDokumen7 halamanEUGMP Annex 1 Update 2008 Particle CountingKye Hwan KimBelum ada peringkat

- Cleaning and CleanroomsDokumen7 halamanCleaning and CleanroomsTim SandleBelum ada peringkat

- Design of Containemt IsolatorsDokumen72 halamanDesign of Containemt IsolatorsSweekar Borkar50% (2)

- Federal Standard 209e For Cleanroom - An Obsolete Document!Dokumen15 halamanFederal Standard 209e For Cleanroom - An Obsolete Document!Լուսինե ՀովսեփյանBelum ada peringkat

- Aero BiologyDokumen8 halamanAero BiologyFlavio ChipanaBelum ada peringkat

- Clean Rooms L Essentiel 3Dokumen4 halamanClean Rooms L Essentiel 3Sweekar BorkarBelum ada peringkat

- Asseptic Process PharmaDokumen116 halamanAsseptic Process PharmaSandy PiccoloBelum ada peringkat

- Methods For Testing Cleanroom GarmentsDokumen7 halamanMethods For Testing Cleanroom GarmentsMINGZILABelum ada peringkat

- Testing Compressed Air Lines For Microbiological ContaminationDokumen8 halamanTesting Compressed Air Lines For Microbiological Contaminationmuzammil21_adBelum ada peringkat

- Clean Room PharmaDokumen39 halamanClean Room PharmadurbcomsonoBelum ada peringkat

- CIP Cycle Development Sep04Dokumen7 halamanCIP Cycle Development Sep04John HigginsBelum ada peringkat

- Clean Room Training 2023Dokumen17 halamanClean Room Training 2023LoraBelum ada peringkat

- Presentation - NEBBDokumen7 halamanPresentation - NEBBBhavik Thakar100% (1)

- Cleanroom Air ChangeDokumen2 halamanCleanroom Air ChangeFlu PlantBelum ada peringkat

- Application Note: Successful Wetting For Filter Integrity Testing in Volume-Restricted SystemsDokumen13 halamanApplication Note: Successful Wetting For Filter Integrity Testing in Volume-Restricted SystemsSlavaBelum ada peringkat

- Design Economics For Usp Purified Water SystemsDokumen4 halamanDesign Economics For Usp Purified Water SystemsJuan Fernando Juez CastilloBelum ada peringkat

- Phuong - DryheatDokumen5 halamanPhuong - DryheatqhpuongBelum ada peringkat

- Cleanroom GuideDokumen68 halamanCleanroom GuidefluplantBelum ada peringkat

- Food Safety Director or Quality Assurance Manager or Quality AssDokumen3 halamanFood Safety Director or Quality Assurance Manager or Quality Assapi-121348480Belum ada peringkat

- Particle Monitoring Requirements in Pharmaceutical CleanroomsDokumen7 halamanParticle Monitoring Requirements in Pharmaceutical CleanroomsananthBelum ada peringkat

- Blades Manufacturing of Main Rotor PDFDokumen29 halamanBlades Manufacturing of Main Rotor PDFviorelu990% (1)

- Reducing Blood Pressure NaturallyDokumen2 halamanReducing Blood Pressure Naturallyviorelu99Belum ada peringkat

- Sound Proofing Light Aircraft (And Other Stuff Too!)Dokumen13 halamanSound Proofing Light Aircraft (And Other Stuff Too!)viorelu99100% (1)

- Fusion of Eight Psychic Channels - Opening and Sealing Psychic Channels PDFDokumen48 halamanFusion of Eight Psychic Channels - Opening and Sealing Psychic Channels PDFAlexandra Ioana Niculescu100% (2)

- The Procrastination MatrixDokumen33 halamanThe Procrastination Matrixviorelu99Belum ada peringkat

- AT3 Manual 4Dokumen9 halamanAT3 Manual 4viorelu99Belum ada peringkat

- 5 PerformancesDokumen14 halaman5 Performancesviorelu99Belum ada peringkat

- Thermoform Design GuideDokumen74 halamanThermoform Design Guideviorelu99100% (1)

- AT3 Manual 1Dokumen9 halamanAT3 Manual 1viorelu99Belum ada peringkat

- THE ALPHA-NETICS RAPID READING PROGRAM - Owen D (1) SkousenDokumen114 halamanTHE ALPHA-NETICS RAPID READING PROGRAM - Owen D (1) Skousenfreeplump3100% (8)

- The Mysterious Life and Death of DR ReichDokumen6 halamanThe Mysterious Life and Death of DR Reichviorelu99Belum ada peringkat

- Aerospace StandardsDokumen4 halamanAerospace Standardsviorelu99100% (2)

- WhitePaper - Laser Tracker TechnologyDokumen4 halamanWhitePaper - Laser Tracker Technologyviorelu99Belum ada peringkat

- Design For Manufacturability For CNC MachiningDokumen4 halamanDesign For Manufacturability For CNC Machiningviorelu99Belum ada peringkat

- Nishi Jap.Dokumen8 halamanNishi Jap.viorelu99Belum ada peringkat

- Assembly Part Handling.Dokumen3 halamanAssembly Part Handling.anuradhaBelum ada peringkat

- Air Jacketed Steri-Cycle CO2 IncubatorDokumen8 halamanAir Jacketed Steri-Cycle CO2 IncubatorLEO AROKYA DASSBelum ada peringkat

- AAF Astrocel II HepaDokumen2 halamanAAF Astrocel II HepaPH LimBelum ada peringkat

- MANUAL ESTUFA DE CULTIVO CELULAR - Thermo Scientific Forma® Steri-Cult® CO2 IncubatorsDokumen8 halamanMANUAL ESTUFA DE CULTIVO CELULAR - Thermo Scientific Forma® Steri-Cult® CO2 IncubatorsAsesoria tecnica Azul DiagnosticBelum ada peringkat

- 2005, Badal, L.,The Importance of ISO Cleanliness CodesDokumen4 halaman2005, Badal, L.,The Importance of ISO Cleanliness CodesVelibor KaranovićBelum ada peringkat

- Lubretec Flyer LowresDokumen2 halamanLubretec Flyer Lowressinter-musicBelum ada peringkat

- Clean Room StandardsDokumen12 halamanClean Room StandardslakshminarayananBelum ada peringkat

- Clean Rooms, Clean Air and Contamination Control: Tim SandleDokumen44 halamanClean Rooms, Clean Air and Contamination Control: Tim SandleZeyad A AbdullahBelum ada peringkat

- AAF Astrocel II HepaDokumen2 halamanAAF Astrocel II HepaPH LimBelum ada peringkat

- Particle Counting TrainingDokumen38 halamanParticle Counting Traininglulalala8888Belum ada peringkat

- Contamination Control - Essential To A Condition Based Maintenance ProgramDokumen10 halamanContamination Control - Essential To A Condition Based Maintenance ProgramJHON ANGEL VARGAS HUAHUASONCCOBelum ada peringkat

- Development of CCSDokumen54 halamanDevelopment of CCSDiana Oldani100% (2)

- Iso and RP Parallel Docs 013108 - AllthreeDokumen3 halamanIso and RP Parallel Docs 013108 - AllthreedesignhvacBelum ada peringkat

- JGXP - 2011 - v15n4 - Contamination Control in The Compliance Program PDFDokumen7 halamanJGXP - 2011 - v15n4 - Contamination Control in The Compliance Program PDFNelson Alejandro FierroBelum ada peringkat

- Smoke Study Article 1Dokumen15 halamanSmoke Study Article 1JAGADISH PHARMACEUTICALSBelum ada peringkat

- Consistency Training: Contamination ControlDokumen67 halamanConsistency Training: Contamination ControlMaerks KevinBelum ada peringkat

- Publications by Tim Sandle (3rd Revision)Dokumen42 halamanPublications by Tim Sandle (3rd Revision)Tim SandleBelum ada peringkat

- Cleanroom MicrobiologyDokumen14 halamanCleanroom MicrobiologyKraken UrBelum ada peringkat

- MSFC STD 246eDokumen91 halamanMSFC STD 246eJoseph DavidBelum ada peringkat

- Basic Requirements For Clean RoomDokumen6 halamanBasic Requirements For Clean Roomsamuel debebeBelum ada peringkat

- EU GMP Annex 1 Guide For Cleanroom Garments 2023 enDokumen15 halamanEU GMP Annex 1 Guide For Cleanroom Garments 2023 enbertBelum ada peringkat

- Feature Advantage Benefit (CelCulture CO2 Incubator Range)Dokumen4 halamanFeature Advantage Benefit (CelCulture CO2 Incubator Range)Michael G. BasaBelum ada peringkat

- NASA Clean Room ChecklistDokumen6 halamanNASA Clean Room Checklistviorelu99Belum ada peringkat

- Microbial OOS InvestigationsDokumen12 halamanMicrobial OOS InvestigationsSairam EdupugantiBelum ada peringkat

- ECA Task Force CCS GuidelineDokumen54 halamanECA Task Force CCS Guidelineto van trung100% (3)

- Airflow Visualisation in An Aseptic FacilityDokumen4 halamanAirflow Visualisation in An Aseptic FacilityTorres XiaBelum ada peringkat

- Filtration Handbook Filtration and Flushing StrategyDokumen28 halamanFiltration Handbook Filtration and Flushing StrategyFuchsbau100% (1)

- Repair Manual Cummins ISX QSX15Dokumen16 halamanRepair Manual Cummins ISX QSX15angel017100% (2)

- Characterization of Airflow Patterns, Identification of Barrier System Design Flaws, and Cleanroom/Barrier System Integration MistakesDokumen43 halamanCharacterization of Airflow Patterns, Identification of Barrier System Design Flaws, and Cleanroom/Barrier System Integration MistakesUsama Sayed100% (2)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDari EverandArizona, Utah & New Mexico: A Guide to the State & National ParksPenilaian: 4 dari 5 bintang4/5 (1)

- Best Dives West Hemisphere ExcerptDari EverandBest Dives West Hemisphere ExcerptPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDari EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensBelum ada peringkat

- The Bahamas a Taste of the Islands ExcerptDari EverandThe Bahamas a Taste of the Islands ExcerptPenilaian: 4 dari 5 bintang4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoDari EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoPenilaian: 5 dari 5 bintang5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptDari EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptPenilaian: 5 dari 5 bintang5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksDari EverandNew York & New Jersey: A Guide to the State & National ParksBelum ada peringkat