The Kinetics of CO2 Gasification of Coal Chars Hungary 2013

Diunggah oleh

KrozeDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

The Kinetics of CO2 Gasification of Coal Chars Hungary 2013

Diunggah oleh

KrozeHak Cipta:

Format Tersedia

The kinetics of CO

2

gasication of coal chars

Martyna Tomaszewicz

Grzegorz abojko

Grzegorz Tomaszewicz

Michalina Kotyczka-Moran ska

Received: 31 October 2012 / Accepted: 4 January 2013

Akademiai Kiado, Budapest, Hungary 2013

Abstract The gasication reactivities of three char sam-

ples derived from coals of varying ranks (Turow lignite,

Piast, and Wieczorek sub-bituminous coals) toward

CO

2

were investigated isothermally using thermogravimet-

ric analysis. Kinetic behavior was studied at temperatures of

900, 950, and 1,000 C under atmospheric pressure. Con-

ditions for the chemical-controlled regime were established

at these temperatures and pressure. In this paper, four kinetic

models were applied to describe the varying conversion rate:

volumetric model, grain model, modied volumetric model,

and random pore model. From these models, only the ran-

dom pore and the volumetric models positively corre-

sponded to nearly the entire range of experimental results.

Calculated values of activation energy for study samples

were in the range of 180250 kJ mol

-1

, which is in accor-

dance with other reported data. Moreover, the obtained

results conrmed the signicant impact of parent coal rank

on its char reactivity, offering possibilities in the approxi-

mation of coal char kinetic behavior after further more

detailed studies with a larger number of samples.

Keywords Reactivity Gasication CO

2

Kinetics

Coal char TG

List of symbols

Variables

a Empirical constant in modied volumetric model ()

A Pre-exponential factor (min

-1

)

A Ash content (wt %)

b Empirical constant in modied volumetric

model ()

C Carbon content (wt %)

E Activation energy (kJ mol

-1

)

e Porosity per unit volume of sample (cm

3

cm

-3

)

H Enthalpy (kJ mol

-1

)

k Kinetic constant (min

-1

)

k

MVM

Mean value of kinetic constant of modied

volumetric model (min

-1

)

L Pore length per unit volume of sample (cm cm

-3

)

m Mass (mg)

M Moisture content (wt %)

R Universal gas constant (kJ mol

-1

K

-1

)

R

2

Determination coefcient ()

R

0

Mean random reectance of vitrinite (%)

S Surface area per unit volume of sample

(cm

2

cm

-3

)

T Absolute temperature (K)

t Time (min)

W Structural parameter in random pore model ()

V Volatile matter content (wt %)

X Fractional conversion degree of solid ()

Subscripts

T Total

A Relates to mineral matter

C Relates to combustible matter

d Calculated by difference

max Maximal

0 Refers to initial state

Superscripts

ar As-received basis

ad Air-dried basis

d Dry basis

daf Dry and ash-free basis

M. Tomaszewicz (&) G. abojko G. Tomaszewicz

M. Kotyczka-Moranska

Institute for Chemical Processing of Coal, Zamkowa 1,

41-803 Zabrze, Poland

e-mail: mtomaszewicz@ichpw.zabrze.pl

1 3

J Therm Anal Calorim

DOI 10.1007/s10973-013-2961-2

Introduction

Carbon dioxide is regarded as a chief contributor to the

purported greenhouse gas effect that is driving global cli-

mate change. To meet emission limitations, novel tech-

nologies for fossil fuel processing must be developed and

implemented. Gasication technology, which refers to a

series of processes producing synthesis gas, i.e., H

2

and CO

from carbonaceous materials, is found to be promising for

dealing with the commercial-scale release of CO

2

[1]. Over

the past several years, the concept of polygeneration gas-

ication technology, which combines the power generation

and chemicals production from syngas, has generated a

considerable amount of attention. Recently, most of the

research has been oriented toward the increase of gasi-

cation process performance. As has been presented else-

where, the pressurized CO

2

-enriched gasication of coal is

considered a competitive alternative to conventional gasi-

cation technology [2]. The process of gasication of a

solid fuel begins with a rapid devolatilization, leaving a

char that is mainly composed of carbon and ash. The

second stage is the gasication of a nascent char; this stage

is a rate-controlling step because the reaction rate is much

lower than that of pyrolysis. The char reaction rate,

therefore, has a strong inuence on the conversion ef-

ciency that can be attained under selected process condi-

tions [3, 4]. Consequently, char reactivity is a decisive

factor in coal conversion processes and is greatly inu-

enced by the rank and characteristics of parent coal [58],

conditions during the devolatilization [4, 7], structural

evolution and morphological changes [911], and content

of inorganic matter [7, 12]. In CO

2

-enriched gasication

technology, the Boudouard reaction (1) has a critical role

due to its low reaction rate in comparison to other heter-

ogeneous gasication reactions with oxygen and steam.

C CO

2

2 CO DH 172:5 kJ mol

1

298 K

1

A detailed understanding of char reactivity toward

CO

2

and the reaction kinetics is considered essential for the

mathematical and process modeling of gasiers. A com-

prehensive kinetic model should be developed to facilitate

the application of this knowledge to practical systems.

Generally, there are numerous publications concerning the

CO

2

-gasication kinetics of chars derived from coals of

different rank and pyrolysis conditions [13, 14]. Numerous

models have been established for describing the Boudouard

reaction rate [8, 14]. Some kinetic models, such as the

volumetric and grain models, do not consider the structural

changes that solids undergo [8, 10, 15, 16]. Other models

incorporate the structural effects in addition to rates, such

as the random pore model (RPM) [1517]. The main

objective of this study was to determine the kinetic

behavior of chars derived from variously ranked coals by

means of thermogravimetric (TG) analysis. Thermogravi-

metric analysis is the most widely used technique for

analysis of gasication reaction [18]. The second objective

was to nd a suitable kinetic model to explain the variation

of char reactivity and its changes with the progress of the

CO

2

-gasication reaction. The calculations of the kinetic

parameters (e.g., activation energy and pre-exponential

factor) based on four kinetic models are the primary aim

of the study, including the comparison between results

obtained with the particular model.

The results presented herein are considered as a con-

tinuation of research on kinetics of CO

2

gasication of

solid fuels and reactivity, presented in detail elsewhere

[19, 20].

Materials and methods

For this study, three coal samples were selected: lignite

coal from Turow mine and two sub-bituminous coals

from Piast and Wieczorek mines. All mineelds are

located in Poland. Samples were characterized according to

many indices representing rank, ash content and compo-

sition, and maceral composition. The complete results are

given in Table 1.

As seen in Table 1, the samples notably differ according

to rank. The lowest degree of alteration (metamorphism) is

observed for lignite coal, Turow, followed by Piast

and Wieczorek sub-bituminous coals. Moreover, both of

the sub-bituminous coals can be distinguished by rank as

less or more metamorphosed: Piast and Wieczorek,

respectively, in Table 2.

To reduce the impact of the devolatilization conditions

on the kinetic characteristics of chars, the coal samples

were pyrolyzed in a similar manner. The coals were sub-

jected to pyrolysis in an own-designed xed-bed tubular

reactor of 75 mm internal diameter heated by an electric

furnace under inert atmosphere of nitrogen. For the dev-

olatilization, coal particles ranging from 1 to 4 mm were

chosen. The pyrolysis conditions were as follows: heating

rate of 5 K min

-1

up to 1,000 C and a 30-min holding

time. After pyrolysis, chars were cooled to ambient tem-

perature under owing nitrogen. Subsequently, char sam-

ples were ground and sieved; particle sizes less than

200 lm were selected for TG analysis.

Kinetic measurements were performed isothermally in a

Netzsch STA 409 PG Luxx thermogravimetric analyzer.

Experiments were conducted at three temperatures: 900,

950 and 1,000 C. A weighted char sample (5 mg) was

placed on an alumina crucible inside the furnace and

heated under an argon stream of 25 ml min

-1

up to

M. Tomaszewicz et al.

1 3

reaction temperature with a heating rate of 25 K min

-1

.

Once the desired temperature was reached, the isothermal

gasication reaction of the char sample was initiated by

switching on the CO

2

with a ow rate of 100 ml min

-1

.

The system recorded the weight loss by a highly sensitive

analytical balance located in a casing of apparatus with a

resolution of 10

-3

mg. Thermocouples measuring the

sample temperatures were connected to the bottom portion

of the crucible, precisely underneath the sample layer. The

TG experimental results, obtained as mass loss versus time

data, were converted according to conversion (X) versus

time proles (on ash-free basis) using Eq. (2):

X

m

0

m

m

0

m

ash

2

where m is the instantaneous mass of the sample, m

0

is the

initial mass, and m

ash

is the remaining mass, corresponding

to ash content. The apparent reaction rate was calculated as

a differential of conversion degree versus time, denoted as

dX

dt

. The calculations made with Eq. (2) are found valid

based on the assumption that no reactions of mineral matter

with CO

2

occur during gasication.

Many different models have been proposed to describe

coal char gasication reactions with CO

2

. For kinetic

analysis, four models, which assume the one-step reaction,

were selected. The change in apparent reaction rate can be

expressed as follows:

dX

dt

k T f X 3

where k is the rate constant, dependent on temperature, T, and

f(X), whichhas a structural meaningand corresponds tochosen

nth-order expressions. The kinetic constant is a function of

temperature according to Arrhenius relationship (4):

k T Aexp

E

RT

4

where A and E are pre-exponential factor and activation

energy, respectively, and T is the absolute temperature.

In this study, four nth-order kinetic models were

employed to describe the course of reaction: the volumetric

model (VM), the modied volumetric model (MVM), the

grain model (GM), and the RPM. All models provide dif-

ferent expressions for the term f(X).

The VM is the simplest model, assuming a uniform gas

diffusion within the entire particle and, in consequence,

simplies the reaction by assuming that gas is reacting with

the char in a homogenous manner [8, 15, 16, 19]. The kinetic

expression for the reaction rate is represented by Eq. (5)

dX

dt

k

VM

1 X 5

or in the integrated form by Eq. (6):

ln 1 X k

VM

t 6

The MVM was rst introduced by Kasaoka et al. [22] as

a modication of the VM. However, it assumes that the rate

Table 1 Properties of Turow, Piast, and Wieczorek parent

coals

Coal sample Turow Piast Wieczorek

Proximate analysis/wt %

M

t

ar

44.2 14.4 9.0

M

ad

3.9 4.7 2.6

AC

d

8.1 21.1 17.1

V

daf

59.14 39.10 37.82

Ultimate analysis/wt %

C

T

ad

62.3 59.3 67.8

H

T

ad

5.48 3.83 4.14

N

ad

0.61 0.91 1.16

S

T

ad

1.02 1.09 0.48

S

A

ad

0.28 0.20 0.26

S

C

ad

0.74 0.89 0.22

O

d

ad

19.17 10.27 7.38

Cl

ad

0.009 0.399 0.320

Chemical composition of ash/wt %

SiO

2

32.7 51.42 52.07

Al

2

O

3

24.5 27.03 21.77

Fe

2

O

3

11.4 7.23 9.00

CaO 4.10 2.71 5.04

MgO 6.24 3.30 4.48

TiO

2

1.86 1.04 0.73

Na

2

O 6.76 2.06 1.46

K

2

O NDA 2.40 2.27

Petrographic composition and reectance/%

Vitrinite 73 54 50

Liptinite 17 10 8

Inertinite 6 23 27

R

0

0.23 0.58 0.78

Table 2 Results of the proximate and ultimate analysis of Turow,

Piast, and Wieczorek coal chars

Char sample Turow Piast Wieczorek

Proximate analysis/wt %

M

ad

2.2 1.1 0.7

AC

d

13.7 25.4 25.8

V

daf

0.77 0.47 0.47

Ultimate analysis/wt %

C

T

ad

84.8 72.9 72.2

H

T

ad

0.28 0.32 0.34

N

ad

0.98 1.08 1.09

O

ad

2.05 0.98 0.75

The kinetics of CO

2

-gasication of coal chars

1 3

constant is changing with conversion of solid (X) as the

reaction proceeds [3, 16, 21]. The reaction rate can be

expressed by means of Eq. (7) and the change in

conversion degree with Eq. (8):

dX

dt

k

MVM

X 1 X 7

ln 1 X at

b

8

where k

MVM

(X) is the model-corresponding kinetic

constant, and a and b are empirical parameters with no

physical meaning. The rate constant k

MVM

can be

calculated using Eq. (9):

k

MVM

X a

1

b

b ln 1 X

b1

b

9

The above expression can be integrated to obtain the mean

value of the rate constant, which can be useful in obtaining the

kinetic parameters by means of Eq. (4) and comparing other

constants derived from the analysis of kinetic expressions.

The formulation for the integration is given by Eq. (10):

k

MVM

Z

1

0

k

MVM

X dX 10

The GM assumes that the reaction occurs at the external

surface of the char particle [8, 10, 15, 21, 24]. As the

reaction gradually moves inside the particle, only the ash

layer remains. At the intermediate conversion of a sample

particle, there is a shrinking core of the unreacted solid,

which diminishes with the course of the reaction. The

model is given by Eq. (11) and in an integrated form by

Eq. (12):

dX

dt

k

GM

1 X

2

3

11

3 1 1 X

1

3

h i

k

GM

t 12

The RPM which was developed by Bhatia and Perlmutter

[25] assumes that there is random overlapping of the pore

surface during the extent of the reaction [8, 1517, 2325].

Hence, the surface area available for reaction is also

changing. Those changes are expressed with the structural

parameter, W, which is characteristic for this model. The

RPM, in contrast with the VM, the MVM, and the GM, can

predict the occurrence of maximal rate in the course of the

reaction. The W parameter can be calculated according to

Eq. (13) when initial porosity, e

0

, surface area, S

0

, and pore

length, L

0

, of the solid are known:

W

4pL

0

1 e

0

S

2

0

13

Additionally, the structural parameter can be calculated

by means of maximal conversion degree of solid, X

max

, for

0

0.2

0.4

0.6

0.8

1

0 10 20 30 40 50 60

t/min.

Turw char

(a)

0

0.2

0.4

0.6

0.8

1

Piast char

(b)

0

0.2

0.4

0.6

0.8

1

0 50 100 150 200

Wieczorek char

900 C

950 C

1000 C

(c)

t/min.

X

/

X

/

X

/

900 C

950 C

1000 C

900 C

950 C

1000 C

0 50 100 150 200

t/min.

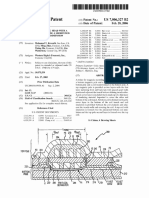

Fig. 1 Effect of temperature on conversion degree of studied char

samples: Turow (a), Piast (b), and Wieczorek (c)

0

0.2

0.4

0.6

0.8

1

0 30 60 90 120 150

X

/

Turw char

Piast char

Wieczorek char

t/min.

Fig. 2 Effect of coal rank on the carbon conversion of studied char

samples at a temperature of 950 C

M. Tomaszewicz et al.

1 3

l n ( 1 X )

V

o

l

u

m

e

t

r

i

c

M

o

d

e

l

,

V

M

G

r

a

i

n

M

o

d

e

l

,

G

M

R

a

n

d

o

m

P

o

r

e

M

o

d

e

l

,

R

P

M

M

o

d

i

f

i

e

d

V

o

l

u

m

e

t

r

i

c

M

o

d

e

l

,

M

V

M

T u r w c h a r

P i a s t c h a r

W i e c z o r e k c h a r

0 1 2 3 4 5 6 7 8

0

2

0

4

0

6

0

8

0

t

/

m

i

n

.

t

/

m

i

n

.

t

/

m

i

n

.

t

/

m

i

n

.

t

/

m

i

n

.

t

/

m

i

n

.

t

/

m

i

n

.

t

/

m

i

n

.

t

/

m

i

n

.

t

/

m

i

n

.

t

/

m

i

n

.

t

/

m

i

n

.

9

0

0

C

9

5

0

C

1

0

0

0

C

0

0

.

5 1

1

.

5 2

2

.

5 3

3

.

5

0

2

0

4

0

6

0

3 ( 1 ( 1 X )

1 / 3

)

9

0

0

C

9

5

0

C

1

0

0

0

C

0

0

.

5 1

1

.

5 2

2

.

5 3

0

2

0

4

0

6

0

( 2 / ) ( ( 1 l n ( 1 X ) )

1 / 2

1 )

9

0

0

C

9

5

0

C

1

0

0

0

C

0 1 2 3 4 5 6 7 8

0

2

0

4

0

6

0

8

0

9

0

0

C

9

5

0

C

1

0

0

0

C

0 1 2 3 4 5 6 7 8

0

5

0

1

0

0

1

5

0

2

0

0

9

0

0

C

9

5

0

C

1

0

0

0

C

0

0

.

5 1

1

.

5 2

2

.

5 3

0

5

0

1

0

0

1

5

0

2

0

0

9

0

0

C

9

5

0

C

1

0

0

0

C

0

0

.

5 1

1

.

5 2

2

.

5

0

5

0

1

0

0

1

5

0

2

0

0

9

0

0

C

9

5

0

C

1

0

0

0

C

0 1 2 3 4 5 6 7 8

0

5

0

1

0

0

1

5

0

2

0

0

2

5

0

9

0

0

C

9

5

0

C

1

0

0

0

C

0 1 2 3 4 5 6 7 8

0

5

0

1

0

0

1

5

0

2

0

0

9

0

0

C

9

5

0

C

1

0

0

0

C

0

0

.

5 1

1

.

5 2

2

.

5 3

3

.

5

0

5

0

1

0

0

1

5

0

2

0

0

9

0

0

C

9

5

0

C

1

0

0

0

C

0

0

.

5 1

1

.

5 2

2

.

5 3

0

5

0

1

0

0

1

5

0

2

0

0

9

0

0

C

9

5

0

C

1

0

0

0

C

0 1 2 3 4 5 6 7 8

0

5

0

1

0

0

1

5

0

2

0

0

9

0

0

C

9

5

0

C

1

0

0

0

C

l n ( 1 X ) l n ( 1 X )

3 ( 1 ( 1 X )

1 / 3

)3 ( 1 ( 1 X )

1 / 3

)

( 2 / ) ( ( 1 l n ( 1 X ) )

1 / 2

1 )

( 2 / ) ( ( 1 l n ( 1 X ) )

1 / 2

1 )

l n ( 1 X ) l n ( 1 X ) l n ( 1

l n ( 1 X ) l n ( 1

F

i

g

.

3

P

l

o

t

s

t

t

i

n

g

t

h

e

V

M

,

t

h

e

G

M

,

t

h

e

R

P

M

,

a

n

d

t

h

e

M

V

M

t

o

t

h

e

e

x

p

e

r

i

m

e

n

t

a

l

d

a

t

a

f

o

r

g

a

s

i

c

a

t

i

o

n

o

f

t

h

e

T

u

r

o

w

P

i

a

s

t

,

a

n

d

W

i

e

c

z

o

r

e

k

c

h

a

r

s

a

t

t

e

m

p

e

r

a

t

u

r

e

s

o

f

9

0

0

,

9

5

0

,

a

n

d

1

,

0

0

0

C

The kinetics of CO

2

-gasication of coal chars

1 3

which maximal reaction rate is observed. The formulation

is given by differentiation of the basic kinetic expression

(14):

dX

dt

1 X

1 Wln 1 X

p

14

After that operation, the value of W can be estimated

according to relation (15) [24]:

W

2

2 ln 1 X

max

1

15

For the evaluation of the rate constant, the integrated

form of relation (14) gives

2

W

1 Wln 1 X

p

1

k

RPM

t 16

Results and discussion

Figure 1 presents the variation of the conversion degree

with time of gasication reaction. It has been shown that

increasing the temperature leads to the shortening gasi-

cation time. This is an expected relationship due to the fact

that the Boudouard reaction is an endothermic one. The

relations presented in Fig. 1 show that the conversion

degree intensively increases from the beginning of the

reaction until a conversion degree of approximately 0.9 is

reached. Subsequently, the reaction proceeds very slowly

until complete conversion. The initial, rapid increase of

conversion can be directly related to the rapid evolution of

the surface area, which proceeds until the pores collapse.

In the case, the reaction surface is decreasing and the rate

is decreasing as well.

The effect of coal rank is shown in Fig. 2. The gure

shows the conversion degree versus time proles measured

at 950 C for the three coal chars with the parent coal rank

ranging from lignite to sub-bituminous. It can be seen that

reactivity decreases with increasing parent coal rank. The

Wieczorek sub-bituminous coal char is the least reac-

tive, whereas the Turow lignite char has a 3 times faster

reaction rate than the other chars. Similarly, small differ-

ences in rank between the Piast and Wieczorek parent

coals can also be seen in terms of their reactivity because

the gasication proles are alike.

The effect of coal rank can be associated with three

major phenomena. First, the higher reactivity observed for

low-rank chars is consistent with the higher concentration

of active sites. Second, the low-rank coal chars have higher

porosity. Hence, the probability of participation of active

sites located in micropores is also higher. Finally, low-rank

coal chars represent higher degrees of dispersion of active

components of mineral matter that are likely to catalyze the

Boudouard reaction.

Table 3 Summarized kinetic and empirical parameters for the VM, the GM, the RPM, and the MVM kinetic models for Turow, Piast, and

Wieczorek gasied at 900, 950, and 1,000 C

Sample Temp./ C VM GM RPM MVM

k

VM

/min

-1

R

2

/- k

GM

/min

-1

R

2

/- W/- k

RPM

/min

-1

R

2

/- a/- b/-

k

MVM

/min

-1

R

2

/-

Turow 900 0.0931 0.8821 0.0514 0.9989 2.87 0.0413 0.9923 0.0053 1.78 0.0823 0.9732

950 0.2146 0.9819 0.1086 0.9497 3.29 0.0885 0.9761 0.0976 1.26 0.1750 0.9941

1000 0.4630 0.9548 0.2326 0.9846 3.39 0.1829 0.9982 0.1485 1.50 0.3720 0.9957

Piast 900 0.0166 0.9497 0.0113 0.9979 3.53 0.0082 0.9996 0.0017 1.46 0.0159 0.9985

950 0.0499 0.9310 0.0277 0.9928 3.21 0.0215 0.9970 0.0197 1.19 0.0402 0.9958

1000 0.1084 0.9237 0.0605 0.9943 3.84 0.0441 0.9971 0.0253 1.39 0.0878 0.9976

Wieczorek 900 0.0128 0.9921 0.0097 0.9955 2.40 0.0078 0.9908 0.0062 1.15 0.0115 1.0000

950 0.0371 0.9657 0.0206 0.9557 2.54 0.0174 0.9807 0.0102 1.28 0.0322 0.9871

1000 0.0931 0.9586 0.0517 0.9718 4.48 0.0355 0.9818 0.0225 1.39 0.0802 0.9837

Table 4 Comparison of the kinetic parameters of the Turow, Piast, and Wieczorek coal chars obtained through analysis of the VM, the

GM, the RPM, and the MVM

Model Turow Char Piast Char Wieczorek Char

E/kJ mol

-1

A/min

-1

E/kJ mol

-1

A/min

-1

E/kJ mol

-1

A/min

-1

VM 199.14 6.87 9 10

7

233.37 4.27 9 10

8

246.44 1.22 9 10

9

GM 187.30 1.11 9 10

7

208.38 2.17 9 10

7

207.34 1.60 9 10

7

RPM 184.70 6.91 9 10

6

209.15 1.74 9 10

7

188.18 1.88 9 10

6

MVM 187.17 1.76 9 10

7

212.07 4.48 9 10

7

240.69 6.10 9 10

8

M. Tomaszewicz et al.

1 3

To study the applicability of selected kinetic models and

predict the kinetic behavior of the studied samples, the

models were tted to experimental data. The reaction rate

constants can be calculated from the slopes of the linearized

relationships expressed by Eqs. (6), (11), and (16), based on

the experimental outcomes by means of linear regression, for

the VM, the GM, and the RPM, respectively. The estimation

of the empirical parameters a and b of the MVM was per-

formed according to a non-linear curve t with the least-

squares method according to Eq. (8). The illustrated

application of the studied models used to describe the

experimental data obtained at different temperatures for

the Turow, Piast, and Wieczorek chars is shown in

Fig. 3. For these studies, the whole range of conversion was

taken into account. The analysis of the data, presented in

Fig. 3, revealed that the VMcannot be sufciently applied to

the experimental results because it does not t the data for

conversions higher than 0.95. Only for the Wieczorek char

sample gasied at 900 C, for which complete conversion

has not been reached, does the model give very good line-

arity. In the case of the GM, improved tting can be

observed. However, differences between the experimental

data and the model can be observed for higher conversion

degrees, indicating that the GM cannot be considered valid

for conversion degrees greater than 0.98. Considering the

RPM, very good linearity was observed, with pronounced

impact of surface area on reactivity for all studied coal chars

toward CO

2

. For the semi-empirical MVM, satisfactory

representation of experimental results was also observed.

The MVM represents the sigmoidal characteristic of the

-ln(1 - X) versus time relationship. Therefore, the MVM

better ts the experimental data than the VM. Small incon-

sistencies can be observed for conversion degrees higher

than 0.99, particularly for temperatures of 950 and 1,000 C.

However, this nding can be considered negligible until the

MVM covers nearly the entire range of conversion degrees.

The reaction rate constants were derived from the slopes

of the graphical representations of expressions (6), (11),

and (16) and experimental data for the VM, the GM, and

the RPM, respectively. The summarized results are listed in

y = 23952x +18.046

R =1

y = 22528x +16.225

R = 0.9992

y = 22215x +15.748

R = 0.9999

y = 22513x +16.686

R = 0.9994

3.5

3

2.5

2

1.5

1

0.5

0.00078 0.0008 0.00082 0.00084 0.00086

l

n

k

i

Reciprocal temperature/ K

1

ln k VM

ln k GM

ln k RPM

ln k MVM

(a)

y = 28070x +19.871

R = 0.9942

y = 25064x +16.892

R = 0.9997

y = 25157x +16.671

R = 0.9963

y = 25507x +17.617

R = 0.9993

5

4.5

4

3.5

3

2.5

2

0.00078 0.0008 0.00082 0.00084 0.00086

l

n

k

i

ln k VM

ln k GM

ln k RPM

ln k MVM

(b)

y = 29642x +20.922

R = 0.9997

y = 24939x +16.587

R = 0.9934

y = 22634x +14.447

R = 0.9999

y = 28950x +20.228

R = 0.9997

5

4.5

4

3.5

3

2.5

2

0.00078 0.0008 0.00082 0.00084 0.00086

l

n

k

i

ln k VM

ln k GM

ln k RPM

ln k MVM

(c)

Reciprocal temperature/ K

1

Reciprocal temperature/ K

1

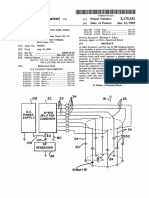

Fig. 4 Arrhenius relationships obtained for the Turow (a), Piast (b),

and Wieczorek (c) coal chars

170

190

210

230

250

0 0.1 0.2 0.3 0.4

E

M

V

M

/

k

J

m

o

l

1

O/C in parent coal/

170

190

210

230

250

0 0.2 0.4 0.6 0.8 1

R

o

, random vitrinite reflectance/%

E

M

V

M

/

k

J

m

o

l

1

(a) (b)

Fig. 5 Relations between

values of activation energy

obtained using the MVM and

the atomic ratio O/C (a) and the

random vitrinite reectance R

0

(b); both quantities are

representing the rank of parent

coals

The kinetics of CO

2

-gasication of coal chars

1 3

Table 3, along with model-corresponding rate coefcients

and the RPM structural parameter, W. The values obtained

with the MVM, the estimated empirical parameters a and b,

mean kinetic rate constants for this model, and the deter-

mination coefcients are also included in Table 3.

To evaluate the kinetic parameters by means of the

Arrhenius relationship [Eq. (4)], the reciprocal relationship

between the logarithm of the rate constant and the absolute

temperature (1/T) of the reaction obtained by each model at

the studied temperature range was analyzed. The Arrhenius

plots for the Turow, Piast, and Wieczorek chars are

presented in Fig. 4. Very satisfactory ttings were found

for all samples and models as illustrated.

As seen in Fig. 4, no noticeable change in the slopes

of the Arrhenius relations was observed, proving that

increasing temperature does not shift the reaction from

chemically controlled to diffusion controlled. The slopes of

the relationships obtained for the GM and the RPM are

nearly parallel lines providing similar slopes and indicating

similar activation energy values calculated with these

models. In turn, the slopes of the Arrhenius relations for

the VM are steeper for all samples. This result could be

associated with poor tting of the models to the experi-

mental data, shown for VM in Fig. 3. Concerning the

relationship obtained for the MVM, the slope is similar to

those evaluated for the GM and the RPM in the cases of

the Turow and Piast coal chars, while for the

Wieczorek coal char, the slope is more similar to the

VM. On the basis of the slope and the intersection values,

the activation energy E and pre-exponential factor A were

obtained for all studied models, as summarized in Table 4.

The activation energies appear in a similar range as in

previous research works [3, 14, 26]. However, due to the

different slope values observed for the Arrhenius plots, the

values of A and E differ signicantly with the employed

kinetic models. The VM always gives a higher activation

energy. The activation energies estimated by the GM, the

RPM, and the MVM are in the range of 184188 and

208212 kJ mol

-1

for the Turow and Piast coal

chars, respectively. In the case of the Wieczorek coal

char, the calculated activation energy values differ signif-

icantly depending upon the model used to obtain them.

Such changes can be associated with incomplete conver-

sion observed for this sample during gasication at the

lowest temperature of 900 C, which could lead to inac-

curate or false values of kinetic rate constants. Taking into

account the rank of the Wieczorek parent coal and the

fact that the MVM is considered valid for predicting

reactivity of other samples, the activation energy value of

approximately 241 kJ mol

-1

is reliable.

To develop a comprehensive empirical kinetic model for

the char-CO

2

reaction taking into account parent coal

characteristics, the activation energies and the selected

parameters representing parent coal rank were correlated.

From the parent coal characteristics, the atomic ratio O/C

and mean random vitrinite reectance, R

o

, were chosen as

parameters expressing the alteration degree. In Fig. 5,

relations are shown between the activation energy obtained

with the MVM and the O/C ratio and between the rst and

R

o

. With increasing metamorphism degree, oxygen content

decreases and carbon content increases. As a result, the

value of the ratio between contents of these two elements

also decreases. As the O/C ratio of the parent coal rises,

the reactivity (activation energy) of the char diminishes, as

seen in Fig. 5. Likewise, in the case of vitrinite reectance,

which is high for higher-rank coals, the activation energy

increases with increasing value of this parameter. Both

relations can be expressed with simple functions, i.e.,

logarithmic and linear for atomic ratio and R

o

, respectively.

The relations described above once more conrm the

signicant impact of the parent coal rank on the reactivity

of its char. These ndings suggest that more studies should

be performed with a much larger number of samples

varying widely with their rank in order to nd a relation

which could roughly estimate the char reactivity on the

basis of the parent coal characteristics, without additional

information on the kinetic behavior during the gasication

process. Such an approach has been taken by other

researchers, and the results of correlations with petro-

graphic data [27] and the carbon content [11, 28] are

considered sufciently satisfactory.

Conclusions

A kinetic study, using TG analysis, of the CO

2

-gasication

reaction of chars derived from three coal samples of dif-

ferent ranks, one lignite and two sub-bituminous, was

performed over the temperature range of 9001,000 C at

atmospheric pressure. It was established that the char

gasication reactions were carried out under chemical

control for all temperatures studied. Furthermore, it was

observed that increases in the temperature lead to short-

ening of the gasication time due to a higher reaction rate.

This study also evaluated widely used kinetic models

(volumetric, grain, random pore, and modied volumetric)

in prediction of changes in the conversion rates during the

course of the reaction. Of the analyzed models, only the

VM can be discarded due to the poor tting of the exper-

imental data. The other models can be regarded as suitable.

A particularly satisfactory performance was given by the

RPM and the MVM, which incorporate additional param-

eters in their kinetic expressions. Kinetic rate constants and

corresponding values of activation energy and pre-expo-

nential factors were calculated. For the studied char sam-

ples, the activation energy values obtained were 180 and

M. Tomaszewicz et al.

1 3

240 kJ mol

-1

, which are in good agreement with data

reported by other researchers. Moreover, the reactivity of

the coal chars is signicantly affected by the parent coal

rank, which was shown by the activation energy and the

dependency on the atomic ratio O/C and mean random

vitrinite reectance, R

o

.

Acknowledgements The research results presented herein were

obtained during the course of the project Development of coal

gasication technology for high-efciency production of fuels and

energy, Task No. 3 of the Strategic Program for Research and

Development: Advanced energy generation technologies funded by

the Polish National Centre for Research and Development. M. Tom-

aszewicz has received a scholarship under the project Doktoris

Scholarship Programme for the Innovative Silesia, co-nanced by

the European Union in the frame of the European Social Fund.

References

1. Higman C, van der Burgt MJ. Gasication. 2nd ed. New York:

Elsevier; 2008.

2. Chmielniak T, S

cia _ zko M, Tomaszewicz G, Tomaszewicz M.

Pressurized CO

2

-gasication of coal. 5th International Freiberg

Conference on IGCC & XtL Technologies, 2124 May 2012,

Leipzig, Germany.

3. Wu Sh, Gu J, Zhang X, Wu Y, Gao J. Variation of carbon crystalline

structures and CO

2

gasication reactivity of Shenfu coal chars at

elevated temperatures. Energy Fuels. 2008;22:199206.

4. Li Ch, Zhao J, Fang Y, Wang Y. Pressurized fast-pyrolysis

characteristics of typical Chinese coals with different ranks.

Energy Fuels. 2009;23:5099105.

5. Miura K, Hashimoto K, Silveston P. Factors affecting the reac-

tivity of coal chars during gasication, and indices representing

reactivity. Fuel. 1989;68:146175.

6. Kwon T-W, Kim SD, Fung DPC. Reaction kinetics of char-CO

2

gasication. Fuel. 1988;67:5305.

7. van Heek KH, Muhlen H-J. Effect of coal and char properties on

gasication. Fuel Process Technol. 1987;15:11533.

8. Molina A, Mondragon F. Reactivity of coal gasication with

steam and CO

2

. Fuel. 1998;77:18319.

9. Hurt RH, Sarom AF, Logwell JP. The role of microporous

surface area in the gasication of chars from a sub-bituminous

coal. Fuel. 1991;70:107982.

10. Zou JH, Zhou ZJ, Wanf FCh, Zhang W, Dai ZH, Liu HF, Yu ZH.

Modeling reaction kinetics of petroleum coke gasication with

CO

2

. Chem Eng Process. 2007;46:6306.

11. Adschiri T, Furusawa T. Relation between CO

2

-reactivity of coal

char and BET surface area. Fuel. 1986;65:92731.

12. Huttinger KJ, Nattermann C. Correlations between coal reactivity

and inorganic matter content for pressure gasication with steam

and carbon dioxide. Fuel. 1994;73:16824.

13. Liu G-S, Niksa S. Coal conversion submodels for design appli-

cations at elevated pressures. Part II. Char gasication. Prog

Energy Combust Sci. 2004;30:679717.

14. Irfan MF, Usman MR, Kusakabe K. Coal gasication in CO

2

atmosphere and its kinetics since 1948: a brief review. Energy.

2011;36:1240.

15. Fermoso J, Stevanov C, Moghtaderi B, Arias B, Pevida C, Plaza

MG, Rubiera F, Pis JJ. High-pressure gasication reactivity of

biomass chars produced at different temperatures. J Anal Appl

Pyrol. 2009;85:28793.

16. Murillo R, Navarro MV, Lopez JM, Aylon E, Callen MS, Garcia

T, Mastral AM. Kinetic model comparison for waste tire char

reaction with CO

2

. Ind Eng Chem Res. 2004;43:776873.

17. Liu H, Luo Ch, Kaneko M, Kato Sh, Kojima T. Unication if

gasication kinetics of char in CO

2

at elevated temperatures with

a modied random pore model. Energy Fuels. 2003;17:96170.

18. Feng B, Bhatia SK. On the validity of thermogravimetric deter-

mination of carbon gasication kinetics. Chem Eng Sci. 2002;

57:290720.

19. Mianowski A, Robak Z, Tomaszewicz M, Stelmach S. The

Boudouard-Bell reaction analysis under high-pressure conditions.

J Therm Anal Calorim. 2012;110:93102.

20. abojko G, Kotyczka-Moranska M, Plis A, S

cia _ zko M. Kinetic

study of polish hard coal and its char gasication using carbon

dioxide. Thermochim Acta. 2012;549:15865.

21. Nowicki L, Antecka A, Bedyk T, Stolarek P, Ledakowicz S. The

kinetics of gasication of char derived from sewage sludge.

J Therm Anal Calorim. 2011;104:693700.

22. Kasaoka S, Sakata Y, Tong C. Kinetic evaluation of the reactivity

of various coal chars for gasication with carbon dioxide in

comparison with steam. Int Chem Eng. 1985;25:16075.

23. Wu Y, Wu Sh, Gao J. A study on the applicability of kinetic

models for Shenfu coal char gasication with CO

2

at elevated

temperatures. Energies. 2009;2:54555.

24. Ochoa J, Cassanello MC, Bonelli PR, Cukierman AL. CO

2

gas-

ication of Argentinean coal chars: a kinetic characterization.

Fuel Process Technol. 2001;74:16176.

25. Bhatia SK, Perlmutter DD. A random pore model for uid-solid

reactions: I. Isothermal, kinetic control. AIChE J. 1986;72:

797803.

26. Liu G, Tate AG, Bryant GW, Wall TF. Mathematical modeling of

coal char reactivity with CO

2

at high pressures and temperatures.

Fuel. 2000;79:114554.

27. Furimsky E, Palmer AD, Kalkreuth WD, Cameron AR, Kovacik

G. Prediction of coal reactivity during combustion and gasica-

tion by using petrographic data. Fuel Process Technol. 1990;25:

13551.

28. Adschiri T, Shiraha T, Kojima T, Furusawa T. Prediction of CO

2

gasication rate of char in uidized bed gasier. Fuel. 1986;65:

168893.

The kinetics of CO

2

-gasication of coal chars

1 3

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- United States Patent (19) : Kaye Oct. 15, 1996Dokumen44 halamanUnited States Patent (19) : Kaye Oct. 15, 1996KrozeBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Us 6250486Dokumen14 halamanUs 6250486KrozeBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Us 3616264Dokumen4 halamanUs 3616264KrozeBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Us8608097 PDFDokumen10 halamanUs8608097 PDFKrozeBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Aug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitDokumen6 halamanAug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitKrozeBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Us 3376803Dokumen26 halamanUs 3376803KrozeBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- United States Patent: (21) Appl. N0.: 13/226,109 (Continued)Dokumen17 halamanUnited States Patent: (21) Appl. N0.: 13/226,109 (Continued)KrozeBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- United States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000Dokumen18 halamanUnited States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000KrozeBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- United States Patent (19) : Nºzizi EDokumen11 halamanUnited States Patent (19) : Nºzizi EKrozeBelum ada peringkat

- Us 3195038Dokumen10 halamanUs 3195038KrozeBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Us 6633161Dokumen21 halamanUs 6633161KrozeBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Us 7006327Dokumen11 halamanUs 7006327KrozeBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Dec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964Dokumen4 halamanDec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964KrozeBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- United States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000Dokumen18 halamanUnited States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000KrozeBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- United States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000Dokumen18 halamanUnited States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000KrozeBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Us 5818319Dokumen30 halamanUs 5818319KrozeBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- United States Patent (19) : (45) Date of Patent: Oct. 12, 1999Dokumen17 halamanUnited States Patent (19) : (45) Date of Patent: Oct. 12, 1999KrozeBelum ada peringkat

- United States PatentDokumen14 halamanUnited States PatentKrozeBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- United States Patent (19) (11) Patent Number: 5,179,332Dokumen14 halamanUnited States Patent (19) (11) Patent Number: 5,179,332KrozeBelum ada peringkat

- Us 6577888Dokumen12 halamanUs 6577888KrozeBelum ada peringkat

- United States Patent (19) : Nºzizi EDokumen11 halamanUnited States Patent (19) : Nºzizi EKrozeBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- United States Patent (19) : Sinclair Et AlDokumen21 halamanUnited States Patent (19) : Sinclair Et AlKrozeBelum ada peringkat

- Us 4774914Dokumen25 halamanUs 4774914KrozeBelum ada peringkat

- United States Patent (19) (11) Patent Number: 5,207,074Dokumen18 halamanUnited States Patent (19) (11) Patent Number: 5,207,074KrozeBelum ada peringkat

- Us 4866424Dokumen14 halamanUs 4866424KrozeBelum ada peringkat

- United States PatentDokumen15 halamanUnited States PatentKrozeBelum ada peringkat

- United States PatentDokumen25 halamanUnited States PatentKrozeBelum ada peringkat

- Us 5379832Dokumen16 halamanUs 5379832KrozeBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- United States PatentDokumen15 halamanUnited States PatentKrozeBelum ada peringkat

- United States Patent (19) : 16 VoltageDokumen12 halamanUnited States Patent (19) : 16 VoltageKrozeBelum ada peringkat

- Masonry: Construction Method and Project ManagementDokumen43 halamanMasonry: Construction Method and Project ManagementJQBelum ada peringkat

- Stoichiometry: Previous Eamcet BitsDokumen7 halamanStoichiometry: Previous Eamcet BitswdwdwdwdwBelum ada peringkat

- Eset 211 Lab 08 InverterDokumen3 halamanEset 211 Lab 08 InverterPhan HiếuBelum ada peringkat

- AMIE Sample Paper 2Dokumen3 halamanAMIE Sample Paper 2skannan1980Belum ada peringkat

- GIZ Manual On IHWM IndexDokumen42 halamanGIZ Manual On IHWM IndexAlberto CamachoBelum ada peringkat

- Tilting Pad Thrust BearingDokumen6 halamanTilting Pad Thrust BearingChristopher GarciaBelum ada peringkat

- Mod 1Dokumen39 halamanMod 1Aitesham JamadarBelum ada peringkat

- Project Proposal (Urban Gardening)Dokumen2 halamanProject Proposal (Urban Gardening)Geanne Antoinette BasilioBelum ada peringkat

- Impact of Green Supply Chain Management Practices On Firms' Performance: An Empirical Study From The Perspective of PakistanDokumen17 halamanImpact of Green Supply Chain Management Practices On Firms' Performance: An Empirical Study From The Perspective of PakistanMaia NovitasariBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Ibrahiiiiim Rep. Conradson Carbon ResidueDokumen7 halamanIbrahiiiiim Rep. Conradson Carbon ResidueIbrahim Dewali100% (2)

- Wasco Brochure 2012Dokumen31 halamanWasco Brochure 2012Amir Asyraf SuhailiBelum ada peringkat

- Keyhole Welding With CF-TIG (Cathode Focussed GTA) : Research PaperDokumen7 halamanKeyhole Welding With CF-TIG (Cathode Focussed GTA) : Research PaperMatija BušićBelum ada peringkat

- Emergency LightDokumen4 halamanEmergency LightNahitha100% (1)

- Clay Treatment of Fuel White PaperDokumen3 halamanClay Treatment of Fuel White PaperGiuliano Castellani CiodaroBelum ada peringkat

- FlorosparticDokumen3 halamanFlorosparticCarlos Rojas HandalBelum ada peringkat

- ETD 2004 CircularDokumen2 halamanETD 2004 Circularagarwalabhay3_991072Belum ada peringkat

- m3018 en - 2008 08Dokumen16 halamanm3018 en - 2008 08Ronaldo Rodrigues100% (1)

- Towards 4.0: The Smelter of The FutureDokumen4 halamanTowards 4.0: The Smelter of The FutureShyamal VermaBelum ada peringkat

- Construction of A Low Cost Drip Irrigation System For ProductionDokumen4 halamanConstruction of A Low Cost Drip Irrigation System For ProductionBaba shehu Abba kyariBelum ada peringkat

- Canon Parts ListDokumen14 halamanCanon Parts ListbishoppyrcBelum ada peringkat

- Batching Plant CalculationDokumen3 halamanBatching Plant CalculationSarinBelum ada peringkat

- Coagulants For Water TreatmentDokumen48 halamanCoagulants For Water TreatmentClauwie Ganoy BuenavistaBelum ada peringkat

- Interseal 670HS: Surface Tolerant EpoxyDokumen4 halamanInterseal 670HS: Surface Tolerant Epoxyhvdb72Belum ada peringkat

- FINAL-ITP For Concreting Work Rev.2 25-Oct-2014Dokumen12 halamanFINAL-ITP For Concreting Work Rev.2 25-Oct-2014Mohammed MujahidBelum ada peringkat

- Ipc TM 650 Test Methods ManualDokumen3 halamanIpc TM 650 Test Methods ManualPiere Salas HerreraBelum ada peringkat

- Basalt FiberDokumen19 halamanBasalt FiberHitesh Shah100% (1)

- Preparation of Methylene Chloride (Greene 1879)Dokumen2 halamanPreparation of Methylene Chloride (Greene 1879)j9cr4zrdxxBelum ada peringkat

- 09highly Coupled Dist SystDokumen19 halaman09highly Coupled Dist SystJohn YuBelum ada peringkat

- Service Manual: Chassis & Mast MC/FCDokumen57 halamanService Manual: Chassis & Mast MC/FCnicolas0% (2)

- MECN 4110 - Mechanisms Design - Fall 2012 - Lecture 01Dokumen59 halamanMECN 4110 - Mechanisms Design - Fall 2012 - Lecture 01florenceprasadBelum ada peringkat

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDari EverandSodium Bicarbonate: Nature's Unique First Aid RemedyPenilaian: 5 dari 5 bintang5/5 (21)

- Process Plant Equipment: Operation, Control, and ReliabilityDari EverandProcess Plant Equipment: Operation, Control, and ReliabilityPenilaian: 5 dari 5 bintang5/5 (1)

- A New Approach to HAZOP of Complex Chemical ProcessesDari EverandA New Approach to HAZOP of Complex Chemical ProcessesBelum ada peringkat

- Guidelines for Chemical Process Quantitative Risk AnalysisDari EverandGuidelines for Chemical Process Quantitative Risk AnalysisPenilaian: 5 dari 5 bintang5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDari EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsBelum ada peringkat

- Physical and Chemical Equilibrium for Chemical EngineersDari EverandPhysical and Chemical Equilibrium for Chemical EngineersPenilaian: 5 dari 5 bintang5/5 (1)