Atshan 2012

Diunggah oleh

Thomás LimaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Atshan 2012

Diunggah oleh

Thomás LimaHak Cipta:

Format Tersedia

Journal of Engineering and Development, Vol. 16, No.

2, June 2012 ISSN 1813- 7822

289

Shear Behavior of Self Compacting Concrete

Assistant Lecturer Ali F.Atshan

Al_Mustansirya University

College of Engineering

Department of environmental engineering

ABSTRACT

Twelve self compacting concrete (SCC) beams were cast to investigate the shear behavior

under two concentrated load. All beams have a constant longitudinal steel ratio of

(0.02065) and constant gross section area of (17000)mm

2

. The tested beams were divided

into two group with and without stirrups. The first group contained three beams without

stirrup at different value of compressive strength ( ) with the same value of clear span to

the effective depth ratio (ln/d), while the second group contained nine beams with stirrups.

This group was divided into three series according to the compressive strength ( ) each

series contained three beams at different value of clear span to effective depth ratio(ln/d).I t

was found that the ultimate shear strength predicated from ACI 318-08 is lesser than the

experimental values. The ultimate shear strength for SCC beams with stirrups increase

about 15 . 37 %.30.69 %and 25.633 % when the compressive strength increased from

(29.36 to 49.2 MPa) at clear span to effective ratio (ln/d) 6.164, 5.479 and 5.0 respectively.

The ultimate shear strength for SCC beams without stirrups increased about 31.25% when

the compressive strength increased from (29.36 to 49.2 MPa),the ultimate shear strength of

SCC beams with stirrups increased about 29.966%,38.775%and 37.85% when the clear

span to the effective depth (ln/d) decreased from (6.164 to 5.0) at compressive strength (fc)

29.36, 41.42 and 49.2 MPa respectively, the ultimate shear strength of SCC beams with

stirrups increased about 85.41%, 68.96% and 63.492% as compared with ultimate shear

strength without stirrups at compressive strength 29.36,41.42 and 49.2 MPa respectively.

Key words: shear strength, rectangular section, without stirrups, with stirrups, self

compacting concrete

.

( 0.02065 ( ) 17000 )

2

.

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

290

)(

.)(

)(

.

(318M-08)

,

15.73 % 30.69 % 25.663 % 29.2 /

2

49.2 /

2

6.164 5.79 5.00 .

)( 31.25 %

( 29.2 / )

2

( 49.2 / )

2

,

22.966 % 38.775 % 37.85 %

( 6.164 5.0 ) 29.36 /

2

41.42 /

2

49. /

2

.

)( 85.41 % 68.9 %

63.492 % )(

29.36 /

2

41.42 /

2

49.2 /

2

.

1. Introduction

Self compacting concrete (SCC), is a new kind of high performance concrete (HPC) wi t h

excel l ent def or mabi l i t y and segr egat i on r esi st ance. It is a flowing concrete

without segregation and bleeding, capable of filling spaces in dense reinforcement or

inaccessible voids without hindrance or blockage. The composition of SCC must be

designed in order not to separate and not to excessively bleed. Concrete strength

development is determined not only by the water-to-cement ratio, but also is influenced

by the content of other concrete ingredients like cement replacement material and

admixtures

(1)

.

2. Research significance

Concrete has been used in the construction industry for centuries. Many modification and

developments have been made to improve the performance of concrete, especially in term of

strength and workability. Engineers have found new technology of concrete called self

compacting concrete. The principle objective of the work described in this study to

investigate and to get more information and better understanding of the behavior of shear

strength of self compacting concrete beams .

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

291

3. Test program

3.1 Description of specimens:

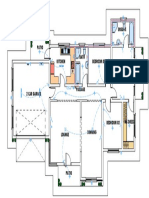

The beams are divided into three groups according to the overall length (1000, 900 and 830

mm). The cross section has overall dimension of 100 mm (width of beams) by 170 mm (total

depth). The longitudinal steel reinforcement consist of six bar (diameter of the bar 8 mm,

with area of 50.265mm

2

) laid in two layer at the bottom and two bar (diameter 4 mm, area of

12.566 mm

2

) laid in one layer at the top. The internal steel stirrups are 4 mm in diameter

(12.566 mm2) at spacing 73 mm center to center as shown in Fig.(1), the test set-up is shown

in Fig. (2) and the total description of the beams which used in this study are listed in Table

(1).

St. 4 mm @ 73 mm c /c

1

4

6

m

m

1

7

0

m

m

Lu

100 mm

1

7

0

m

m

6 8mm

2 4mm

Fjg.(1) Details of specimens all dimensions in mm: (A) elevation ; (B) cross-

section

Fig.(2) Schematic diagram of test set-up

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

292

Table (1): Total description of the tested beams

Clear span to

effective depth

ratio (ln/d)

Effective

depth

(d)mm

Clear span

(ln)mm

Comp.

strength

( )MPa

Beam Group

6.16 146 900 29.39 A10

Beams without

stirrups

6.16 146 900 41.4 B10

6.16 146 900 49.2 C10

6.16 146 900 29.39 A11

Beams with

stirrups

5.47 146 800 29.39 A12

5 146 730 29.39 A13

6.16 146 900 41.4 B11

5.47 146 800 41.4 B12

5 146 730 41.4 B13

6.16 146 900 49.2 C11

5.47 146 800 49.2 C12

5 146 730 49.2 C13

M Ma at te er ri ia al ls s: : 3.2

General description and specification of materials used in the test are listed below, tests are made

in the Materials Laboratory , College of Engineering Al-Mustansiriya University.:

Cement : Ordinary Portland cement Type I produced at northern cement factory (Tasluja-

Bazian) is used throughout this investigation which conforms to the Iraqi specification No.

5/1984

(2)

.

Fine Aggregate: Al-Ukhaider

natural sand is used. which complies with the Iraqi Standard

Specification No.45/1984

(3)

.

Coarse Aggregate: Crushed gravels maximum size 10 mm from Al-Nibaee area are used in

this study. which complies with the Iraqi Standard Specification No.45/1984

(3)

.

Water : Potable water is used throughout this work for both mixing and curing of concrete.

Steel Reinforcement: Deformed longitudinal steel bars with nominal diameter of 8mm and 4mm

were used in this study. Reinforcement were tested to determine the yield stress of 8mm and

4mm and those were 400 and 350 MPa receptively

Limestone Powder: A fine limestone powder (locally named as Al-Gubra) of Jordanian origin

with fineness (3100 gm/cm) is used to avoid excessive heat generation, enhance fluidity and

cohesiveness, improve segregation resistance and increase the amount of fine powder in the mix

(cement and filler). According to EFNARC

[4]

, the fraction less than 0.125 mm will be of most

benefit.

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

293

Superplasticizer : for the production of High-Performance Concrete, a superplasticizer is used

throughout this study. It is known commercially as "GLENIUM51" and it is brought from

Degussa Construction Chemicals. It is a new generation of modified polycarboxylic ether. It is

suitable for the production of SCC. Also, it is free from chlorides and complies with

ASTMC494 types A and F. It is compatible with all Portland cements that meet recognized

international standards

[5]

.

3 3. .2 2. .3 3 M Mi ix x D De es si ig gn n f fo or r S Se el lf f- -c co om mp pa ac ct ti in ng g C Co on nc cr re et te e

Mix proportioning is more critical for SCC than for normal strength concrete (NSC) and high

strength concrete (HSC) . Many trials are carried out on mixes incorporating superplasticizer

by increasing the dosage of the admixture gradually, adjusting the w/c ratio to ensure the self-

compact ability. Tables (2) indicate the mix proportion of SCC mix. For each concrete mix,

three cylinder specimens are taken and tested at 28 days, the test result of fresh concrete

properties are shown in Table (3) these results are within the acceptable criteria for SCC

given by ACI committee-363

(6)

,and indicate excellent deformability without blocking .

Table (2): mix design of SCC mixes by weight

Group

Cube

Strength

( )(MPa)

Cylinder

Strength

( (MPa)

W

/

C

R

a

t

i

o

Mix proportions (kg/m

3

)

L /m

3

C

e

m

e

n

t

L

s

p

T

o

t

a

l

p

o

w

d

e

r

S

a

n

d

G

r

a

v

e

l

W

a

t

e

r

G

l

e

n

i

u

m

5

1

A 36.3 29.36 0.55 346 204 550 743 833 190 6.6

B 51.74 41.42 0.55 474 105.3 357.3 758.4 833 180 8.1

C 59.2 49.2 0.38 535 64 599 814 833 155 18

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

294

Table (3): Results of Testing fresh SCC property in experimental work

Mix symbol

Slump flow

(mm)

T50

Sec.

L-box

(H2/H1)

T20

Sec.

T40

Sec.

A 750 2.6 0.96 1.8 3.5

B 715 3.8 0.90 2.1 3.9

C 685 4.9 0.88 2.3 4.2

[7]

compacted concrete (SCC) - Acceptance criteria for Self

NO. Method Unit

Typical range of values

Minimum Maximum

1 Slump flow mm 650 800

2 T50 Sec 2 5

3 L-Box (H2/H1) 0.8 1

4. Shear strength of beam in CODE provision:

:

) 5 (

) of beam as follows n 08 calculate the nominal shear capacity (V - ACI 318

s c n

V V V . Eq. (1)

d b

f

V

w

c

c

6

...Eq. (2)

d/7 )b d/M wV 120 + f ( V

w u u c c

.... Eq. (3)

S d f Av V

y s

/ . Eq. (4)

Where:-

Vc and Vs are shear transfer capacity of concrete and shear reinforcement respectively; Mu and

Vud are factored moment and shear force; w = As/bwd is the longitudinal bottom reinforcement

ratio; As is the longitudinal bottom reinforcement area; bw is the width of the web; d is the

effective depth; Av is the vertical shear reinforcement area, S is the spacing between the vertical

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

295

stirrups reinforcement; is the compressive strength of concrete and

y

f the yield strength of

shear reinforcement

According to clear span to effective depth ratio (ln/d) the main variable in this research , Eq.(3)

will be used since the shear stress at cracking will depend on the bending moment and shear

force at critical section ratio (Vud/Mu)and the longitudinal steel ratio (w) that lead to reduced

the shear crack and improved the ultimate strength.

Table (4) compared the ultimate shear strength obtained from tested of SCC beams with that

obtained by using the ACI 318-08 provisions, by the inspection of Table (4) shown below it can

be noted that the ultimate shear strength predicated from ACI 318-08 is lesser than the

experimental values because of the SCC will improved durability, and increased bond

strength

[7]

.

Table (4) comparisons of tested results

n V / tested u V

ratio

Nominal shear

kN) n strength (V

ACI

Ultimate shear strength

tested kN) u (V

Beam

1.457 16.469 24 A10

1.306 34.6 44.5 A11

1.482 34.6 50.5 A12

1.658 34.6 56.5 A13

1.560 18.588 29 B10

1.354 36.181 49 B11

1.768 36.181 64 B12

1.879 36.181 68 B13

1.591 19.798 31.5 C10

1.377 37.391 51.5 C11

1.765 37.391 66 C12

1.898 37.391 71 C13

5. Results

Carrying capacity of the tested beams 5.1 Load

The relationship between the applied load and the deflection for the tested beams is shown in

Fig.(3) to Fig.(6). At every stage of loading ,the deflection at mid-span is obtained by dial

gage at mid span, it can be noticed that :

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

296

During the early stage of loading no interface slip is recorded and this continue until the

applied load is equal to first crack load approximately, Beyond the first crack loading

each beams behaved in a different manner.

The ultimate shear strength of SCC beams with stirrups increased when the compressive

strength increased as shown Fig.(7). The ultimate shear strength increase about

15.73%.30.69%and 25.663% when the compressive strength increased from (29.36 to

49.2 MPa) at clear span to effective ratio (ln/d) 6.164, 5.479 and 5.0 respectively as shown

in table (5) .

The ultimate strength of SCC beams without stirrups increased when the compressive

strength increased as shown in Fig.(8), the ultimate shear strength increased about 31.25%

when the compressive strength increased from (29.36 to 49.2 MPa).

The clear span to the effective depth ratio (ln/d) has a significant influence on the ultimate

shear strength as shown in fig (9), the ultimate shear strength of SCC beams increased

about 30%,39%and 38% when the clear span to the effective depth (ln/d) decreased from

(6.164 to 5.0) at compressive strength (fc) 29.36, 41.42 and 49.2 Mpa respectively as

shown in table (6)

The ultimate shear strength of SCC beams with stirrups is greater than SCC beams

without stirrups as shown in Fig.(10),the ultimate shear strength of SCC beams with

stirrups increased about 85.41%, 68.96% and 63.492% as compared with ultimate shear

strength without stirrups at compressive strength 29.36,41.42 and 49.2 Mpa respectively,

as shown in Table (7).

5.2 Failure mode

As was expected, all the tested beams failed in shear as shown in Fig.(11),the diagonal crack

form independently. The beams remain stable after such cracking. Further increase in shear

force will cause the diagonal crack to penetrate into the compression zone at the loading

point, until eventually crushing failure of concrete occurs there

[9]

.

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

297

Fig. (4) Load deflection curve for SCC beams with stirrups at compressive

strength ( ) =41.42 Mpa.

Fig. (3) Load deflection curve for SCC beams with stirrups at

compressive strength ( )=29.36 Mpa.

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

298

Fig. (5) Load deflection curve for SCC beams with stirrups at compressive

strength ( ) =49.2 Mpa.

Fig. (6) Load deflection curve for SCC beams without stirrups at clear span to effective

depth ratio (ln/d)=6.164.

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

299

Fig. (7) Effect of compressive strength ( ) for SCC beams with stirrups on the

ultimate shear strength.

Fig. (8) Effect of compressive strength ( ) for SCC beams without stirrups on the ultimate

shear strength.

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

300

Fig. (9) Effect of clear span to the effective depth ratio (ln/d) on the ultimate

shear strength.

Fig. (10) Effect of absence of stirrups on the ultimate shear strength.

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

301

Table (5) effect of compressive strength ( ) on the percentage increased in the

ultimate shear strength.

Percentage of

increased in

shear capacity

%

Ultimate shear

) u capacity (V

kN

Compressive

) c f strength (

MPa

Clear span to

effective depth

ratio (ln/d)

Group

------- 24 29.36

6.164 Without stirrups 20.833 29 41.42

31.250 31.5 49.2

------- 44.5 29.36

6.164

With stirrups

10.110 49 41.42

15.730 51.5 49.2

------- 50.5 29.36

5.479 26.732 64 41.42

30.69 66 49.2

------- 56.5 29.36

5.0 20.353 68 41.42

25.663 71 49.2

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

302

Table (6) effect of clear span to effective depth ratio (ln/d) on the percentage

increased in the ultimate shear strength.

Percentage of

increased in

shear capacity

%

Ultimate shear

capacity (Vu)

kN

Clear span to

effective depth

ratio (ln/d)

Compressive

strength ( )

MPa

Group

------- 44.5 6.164

29.36

With stirrups

13.483 50.5 5.479

26.966 56.5 5.0

------- 49 6.164

41.42

29.612 64 5.479

38.775 68 5.0

------- 51.5 6.164

49.42 28.155 66 5.479

37.86 71 5.0

Table (7) effect of absence of stirrups on the percentage increased in the

ultimate shear strength.

Percentage of

increased in shear

capacity %

Ultimate shear

capacity (Vu)kN

Compressive

strength ( )Mpa

Beams

------- 24 29.36 A10

85.41 44.5 29.36 A11

------- 29 41.42 B10

68.96 49 41.42 B11

------- 31.5 49.2 C10

63.492 51.5 49.2 C11

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

303

6. Conclusion

Base on the results of this experimental investigation , the following conclusions are drawn:

1. The ultimate shear strength predicated from ACI 318-08 equations is lesser than the

experimental values of the present work.

2. The clear span to the effective depth ratio (ln/d) has a significant influence on the ultimate

shear strength, the ultimate shear strength of SCC beams increased about

29.966%,38.775%and 37.85% when the clear span to the effective depth (ln/d) decreased

from (.61.6 to 5.0) at compressive strength ( ) 29.36, 41.42 and 49.2 Mpa respectively .

3. The ultimate shear strength of SCC beams with stirrups increased at decreased rate when

the compressive strength ( ) increased, The ultimate shear strength increase about

15.73%.30.69%and 25.663% when the compressive strength( ) increased from (29.36

to 49.2 Mpa) at clear span to effective ratio (ln/d) 6.164, 5.479 and 5.0 respectively.

4. The ultimate shear strength of SCC beams without stirrups increased when the

compressive strength increased, the ultimate shear strength increased about 31.25% when

the compressive strength increased from 29.36 to 49.2 Mpa.

5. The ultimate shear strength of SCC beams with stirrups is greater than SCC beams

without stirrups, the ultimate shear strength of SCC beams with stirrups increased about

85.41%, 68.96% and 63.492% as compared with ultimate shear strength without stirrups

at compressive strength 29.36, 41.42 and 49.2 Mpa respectively6

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

304

Fig (11) crack pattern of SCC beams

Journal of Engineering and Development, Vol. 16, No.2, June 2012 ISSN 1813- 7822

305

7. References

[1]Bin MUDA,M.F "The Properties And Flexural Behavior OF self Compacting

Concrete Using Rice Husk Ash And Admixture", M.Sc. Thesis, University of

Technology. Malaysia,2009

] 2 [ 5 " , "

1896 , 9 6

] 3 [ 65 1896 , (

( 5 - 22 6)

[4]EFNARC, "Specification and Guidelines for Self-Compacting Concrete", February

2002, p.32, www.efnarce

[5]ACI Committee 318" Building Code Requirements for Structural Concrete and

Commentary (ACI 318M-08)/ ACI 318 RM-02)", American Concrete Institute,

Detroite, 2008.

[6]ACI Committee 363 Guide to Quality Control and Testing of High Strength

Concrete (ACI- 363, 2R-98), American Concrete Institute, Detroit, 1998.

[7]" The European Guidelines for Self-Compacting Concrete Specification", production

and use, May 2005, www.efca.info or www.efnarc.org, pp.68.

[8]Krieg, W. " Self _ Compacting Concrete : Definition, Development, and

Applications", A technical Paper Presented in the Meeting of the ACI, Saudi Arbia

Chapter, Eastern Province, October, 2003.

[9]Abdel-Razzak A.A, The Effect of Low Shear Span Ratio on the Shear Strength of

RC Beams, M.Sc. Thesis, University of Technology, Baghdad, 2001.

Anda mungkin juga menyukai

- How Do Steel Fibers Improve The Shear Capacity of Reinforced Concrete Beams Without Stirrups?Dokumen16 halamanHow Do Steel Fibers Improve The Shear Capacity of Reinforced Concrete Beams Without Stirrups?Thomás LimaBelum ada peringkat

- Lorenz - Tese de Doutorado (2014) PDFDokumen143 halamanLorenz - Tese de Doutorado (2014) PDFThomás LimaBelum ada peringkat

- Cucchiara (2004) PDFDokumen10 halamanCucchiara (2004) PDFThomás LimaBelum ada peringkat

- Cadoni (2004) PDFDokumen13 halamanCadoni (2004) PDFThomás LimaBelum ada peringkat

- Behavior of High-Strength Concrete Under Biaxial StressesDokumen11 halamanBehavior of High-Strength Concrete Under Biaxial StressesThomás LimaBelum ada peringkat

- Fisker (2016)Dokumen12 halamanFisker (2016)Thomás LimaBelum ada peringkat

- SALMAN e JARALLAH PDFDokumen22 halamanSALMAN e JARALLAH PDFThomás LimaBelum ada peringkat

- SL PICO Jurnal 3 Blok 7 TA 2018Dokumen7 halamanSL PICO Jurnal 3 Blok 7 TA 2018PutrianiBelum ada peringkat

- FPZ HilleborgDokumen9 halamanFPZ HilleborgThomás LimaBelum ada peringkat

- Nonlinear Creep and Cracking of Concrete Under CompressionDokumen11 halamanNonlinear Creep and Cracking of Concrete Under CompressionThomás LimaBelum ada peringkat

- Shear Transfer Strength Evaluation For UHPFRCDokumen5 halamanShear Transfer Strength Evaluation For UHPFRCThomás LimaBelum ada peringkat

- Influence of Shear Parameters On Mixed-Mode Fracture of ConcreteDokumen27 halamanInfluence of Shear Parameters On Mixed-Mode Fracture of ConcreteThomás LimaBelum ada peringkat

- Evaluation of Minimum Shear Reinforcement in Reinforced Concrete BeamsDokumen8 halamanEvaluation of Minimum Shear Reinforcement in Reinforced Concrete BeamsThomás LimaBelum ada peringkat

- Shear Strength Components in RC MembersDokumen16 halamanShear Strength Components in RC MembersThomás LimaBelum ada peringkat

- Size Effect in Diagonal Shear Failure: Influence of Aggregate Size and StirrupsDokumen14 halamanSize Effect in Diagonal Shear Failure: Influence of Aggregate Size and StirrupsThomás LimaBelum ada peringkat

- Shear ACI-DAfStb DatabaseDokumen47 halamanShear ACI-DAfStb DatabaseThomás Lima100% (1)

- Statistical Prediction of Fracture Parameters of Concrete and Implications For Choice of Testing StandardDokumen28 halamanStatistical Prediction of Fracture Parameters of Concrete and Implications For Choice of Testing StandardThomás LimaBelum ada peringkat

- Investigation of The Shear Behavior of RC Beams On The Basis of Measured Crack KinematicsDokumen18 halamanInvestigation of The Shear Behavior of RC Beams On The Basis of Measured Crack KinematicsThomás LimaBelum ada peringkat

- Effective Shear Stiffness of Diagonally Cracked Reinforced Concrete BeamsDokumen9 halamanEffective Shear Stiffness of Diagonally Cracked Reinforced Concrete BeamsThomás LimaBelum ada peringkat

- Yuguang Yang Thesis DigitalDokumen370 halamanYuguang Yang Thesis Digitalmixel123Belum ada peringkat

- Shear Behavior of Self Compacting R.C. I-BeamsDokumen16 halamanShear Behavior of Self Compacting R.C. I-BeamsThomás LimaBelum ada peringkat

- Beygi Et Al - 2008Dokumen15 halamanBeygi Et Al - 2008Thomás LimaBelum ada peringkat

- Aziz 2012Dokumen15 halamanAziz 2012Thomás LimaBelum ada peringkat

- Beygi Et Al - 2008Dokumen15 halamanBeygi Et Al - 2008Thomás LimaBelum ada peringkat

- Beygi Et Al - 2008Dokumen15 halamanBeygi Et Al - 2008Thomás LimaBelum ada peringkat

- Beygi Et Al - 2008Dokumen15 halamanBeygi Et Al - 2008Thomás LimaBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- HRSG HydrotestDokumen7 halamanHRSG Hydrotestshubham raj bhawsarBelum ada peringkat

- Fosroc Bridge BrochureDokumen13 halamanFosroc Bridge Brochureahmedmido14Belum ada peringkat

- Vanke CenterDokumen30 halamanVanke CenterSahil KaradBelum ada peringkat

- Study of Reinforced Concrete Beam-Column JointDokumen4 halamanStudy of Reinforced Concrete Beam-Column JointChua ZhenyuBelum ada peringkat

- Triaxial Permeability 2023Dokumen3 halamanTriaxial Permeability 2023Kim Yuen WongBelum ada peringkat

- Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Dokumen11 halamanReinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Cris BandaBelum ada peringkat

- Nitobond AR STD.: Constructive SolutionsDokumen4 halamanNitobond AR STD.: Constructive SolutionsVarun GuggilamBelum ada peringkat

- Norhouse - Constructions LGSDokumen18 halamanNorhouse - Constructions LGSPinkBelum ada peringkat

- Ammendment To R2 BEPDokumen13 halamanAmmendment To R2 BEPpratikBelum ada peringkat

- Marine StructuresDokumen24 halamanMarine Structuresmanu_696100% (1)

- Hydraulic Fluid Shear Stability: Technical TopicDokumen2 halamanHydraulic Fluid Shear Stability: Technical TopicJahmia CoralieBelum ada peringkat

- Sir Micheal HopkinsDokumen13 halamanSir Micheal HopkinsVarunBelum ada peringkat

- Effect of Reinforcement Particle Size and Volume Fraction On Wear Behaviour of Metal Matrix CompositesDokumen6 halamanEffect of Reinforcement Particle Size and Volume Fraction On Wear Behaviour of Metal Matrix Compositesyash pradhanBelum ada peringkat

- Soil Dynamics and Earthquake Engineering: Professor D.E. BESKOSDokumen1 halamanSoil Dynamics and Earthquake Engineering: Professor D.E. BESKOSbertinBelum ada peringkat

- 5% Slope 5% Slope: Typical Doghouse Detail For Cold Water Pipe Typical Doghouse Detail For Fire Fighting PipeDokumen1 halaman5% Slope 5% Slope: Typical Doghouse Detail For Cold Water Pipe Typical Doghouse Detail For Fire Fighting PipeNitin BuZz100% (1)

- ASCE 7-05 Minimum Design Loads For Buildings and Other Struc 159Dokumen1 halamanASCE 7-05 Minimum Design Loads For Buildings and Other Struc 159v pavan33% (3)

- Valtek MaxfloDokumen8 halamanValtek Maxflosan21Belum ada peringkat

- Use of Industrial Waste Such As Plastic and Crumb Rubber in PavementDokumen9 halamanUse of Industrial Waste Such As Plastic and Crumb Rubber in PavementShreyasBelum ada peringkat

- Design of Piled FoundationDokumen62 halamanDesign of Piled FoundationMaanvir SatyaBelum ada peringkat

- RCC Principles - Construction ProcessDokumen44 halamanRCC Principles - Construction ProcessDharatiSote100% (1)

- STRL02EDokumen2 halamanSTRL02ESusan LingonBelum ada peringkat

- Piled Raft FoundationDokumen13 halamanPiled Raft FoundationArmando FarfanBelum ada peringkat

- Belt Selection CalculationDokumen4 halamanBelt Selection CalculationAkhil AjithBelum ada peringkat

- Plumbing Checklist: Project Name: Project Address: Application NumberDokumen12 halamanPlumbing Checklist: Project Name: Project Address: Application NumberAhmed El MorsyBelum ada peringkat

- Geotechnical FormulasDokumen15 halamanGeotechnical FormulasDavid King100% (1)

- Válvula Anti-Retorno Rexroth - S10A1Dokumen8 halamanVálvula Anti-Retorno Rexroth - S10A1vinícius josé zortéa merinoBelum ada peringkat

- Fosroc PPFDokumen2 halamanFosroc PPFNabeel AL-HakeemBelum ada peringkat

- Novel Application of Post-Tensioning Solves High-Rise Design ChallengesDokumen6 halamanNovel Application of Post-Tensioning Solves High-Rise Design ChallengesephremBelum ada peringkat

- w0167 PreDokumen1 halamanw0167 PreKandeke DaviesBelum ada peringkat

- 7000 PLUMBING CODE SET B Answer Key CorrectionDokumen1 halaman7000 PLUMBING CODE SET B Answer Key CorrectionJay ElBelum ada peringkat