SAIC-L-2014 Rev. 5

Diunggah oleh

Jagadeesh PuppalaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SAIC-L-2014 Rev. 5

Diunggah oleh

Jagadeesh PuppalaHak Cipta:

Format Tersedia

A2

Flange face surface finish meets the requirements of ASME 16.5, 16.47

or API 6A as applicable.

ASME 16.5, 16.47 requirements:

1. Raised Face Flanges: A serrated concentric or serrated spiral finish

having a resultant surface finish from 3.2 to 6.3 m (125 to 250 micro

inch.) average roughness shall be furnished.

2. Ring Joint flanges. The gasket groove finish shall not exceed 1.6 m

(63 micro inch.)

Note: For hydrogen service, flange facing surface finish for raised face

shall not exceed Ra 3.2 micrometers (125 micro inch).

SAES-L-109,

Para. 12.5

A4

The gasket contact areas of the flanges are not coated. (to ensure

proper contact surface for sealing purpose .)

SAES-L-109,

Para. 12.5

C3 Rotational offset: 2.4 mm

SAES-L-350,

Para. 9.5 c

C

Alignment for flanges over 3-inch NPS connected to

machinery/equipment is within the following tolerances:

C2 Horizontal bolt hole offset: 2.4 mm

SAES-L-350,

Para. 9.5 b

C1 Vertical bolt hole offset: 2.4 mm

SAES-L-350,

Para. 9.5 a

B2

The tilt of a flange measured at the periphery across any diameter shall

not exceed 1.6 mm from the square position.

SAES-L-350,

Para. 9.4 d

A3

B1

Rotation of flanges, measured as the offset between elevations of bolt

holes on opposite sides of a flange centerline, shall not exceed 2.4 mm

SAES-L-350,

Para. 9.4 c

B Flange alignment (pipe to pipe) tolerances

The flange facing, particularly the seating area, is clean and no damage

(such as scratches) in excess of the permissible imperfections in

Attachment 2.

(MSS-SP-44, 1/1/96-R 2001, Para. 7.4)

SAEP-351,

Para. 4.3

A1

Type & Pressure rating of the mating flanges conforms with the IFC

drawings & line class for piping. (Refer to Attachment 1 for flange rating

and piping classification. )

SAES-L-350,

Para. 12.2

A

General Information:

Line Class: ________________Schedule___________________

Flanges Type__________________Rating(s)________________

Inspected Flange No. ___________________________________

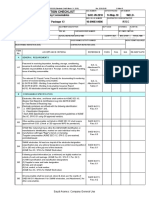

ITEM

No.

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

QUANTITY INSP. MH's SPENT

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

Flange Jts. #:

EQUIPMENT ID NUMBER(S) / LINE NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

INSPECTION OF BOLTED FLANGE JOINT ASSEMBLY SAIC-L-2014 31-Aug-11 PIPING-

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010) Rev 5 31-Aug-10

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

Page 1 of 10

103,104 (BT(01,02) (BT(BT03)

31-05-2013 & 07:00 A.M

11-E2WU/12FEOW SCH:

WN/FF

As per highlighted drawings

INCREASE GAS HANDLING CAPACITY SAMSUNG ENGG / CHELSEA 10-00905-0002

BA-692687-001 0A1

31-05-2013

B-25

YES

SATIP-L-350-01 3.10

H W

D1 Vertical bolt hole offset: (2.4 mm + 30%) = 3.12mm

SAES-L-350,

Para. 9.5 a

SAES-L-350,

Para. 9.5 d

C6 Combination of vertical, horizontal and rotational offset: 3.2 mm

SAES-L-350,

Para. 9.5 f

D

Alignment of Flange Joints with spectacle plate is within the

following tolerances:

C5 Flange face separation: gasket thickness 1.6 mm

SAES-L-350,

Para. 9.5 e

C4

Flange face tilt across diameter: 0.025mm per 25 mm (0.001 inch per

inch) of flange outside diameter up to a maximum of 0.672 mm (0.030

inch), and 0.254mm (0.010 inch) for all flanges with an outside diameter

less than 10 inches.

Page 2 of 10

E3

The identification markings on the spiral wound gaskets (flange size

(NPS), pressure class and the appropriate flange standard (ASME

B16.5 or ASME B16.47) were verified to conform with the flange size

and flange standard and as specified in the IFC Drawing.

Note: Spiral wound gaskets are marked "B16.47A" for use on ASME

B16.47 Series A flanges, and "B16.47B" for use on ASME B16.47

Series B flanges. These are not interchangeable. (ASME B16.20, Para.

3.4.1 g) Not a requirement for gaskets forASME B16.5 flanges.

SAEP-351,

Para. 4.1

E5

Spiral wound gasket:

The filler is flush with the metal windings, not below the metal windings.

(ASME B16.20, Para. 3.2.2)

ASME B16.20,

Para. 3.2.2

E4

Spiral-wound gaskets:

Are marked with a color code, as shown in Attachment 5 (Table 19),

that identifies the windings and filler materials as follows: (ASME

B16.20, Para. 3.4.3)

a. A continuous color around the outer edge of the centering ring

that identifies the winding metal.

b. The color identifying the filler material for NPS 1-1/2" and larger

have four intermittent stripes spaced approximately 90 deg

apart on the outer edge of the centering ring.

c. Smaller size gaskets have a minimum of two stripes 180 deg

apart.

NOTE: Additional color coding may be employed by the construction

agency.

ASME B16.20,

Para. 3.4.3

D3 Rotational offset: (2.4 mm + 30%)= 3.12mm

SAES-L-350,

Para. 9.5 c

D2 Horizontal bolt hole offset: (2.4 mm + 30%)= 3.12mm

SAES-L-350,

Para. 9.5 b

E Gasket Verification

D4 Combination of vertical, horizontal and rotational offset: 3.2 mm

E1

Gasket type was verified to be compatible with the flange facing.

Refer to Attachment 3 for gasket type selection.

SAEP-351,

Para. 4.1

SAES-L-350,

Para. 9.5 f

SAEP-351,

Para. 4.1

E6

Spiral Wound gasket:

Outer rings are required for all pipe sizes. Inner rings are required for

the following flanges:

1. Flanges size 24 and larger;

2. Flange class 900# and above;

3. Spiral wound gaskets with graphite or PTFE filler materials.

NOTE: Inner rings are recommended to be specified for flexible

graphite and other filler materials where experience has

demonstrated inward buckling of the gaskets to be a

problem. (ASME B16.20, Para. 3.2.4)

SAES-L-109,

Para. 12.3.5

E7

Spiral Wound gasket:

The inner and the outer rings material shall be carbon steel. The inner

and outer rings material for gaskets operating in temperatures below

minus 45C shall be type 316 stainless steel material.

SAES-L-109,

Para. 12.3.4

E2

Gaskets are free from any damage particularly in the seating element.

(NOTE: Ensure that spiral wound gaskets are stored flat especially for

large sizes, 24 inches and larger.)

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010) Rev 5 31-Aug-10

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

INSPECTION OF BOLTED FLANGE JOINT ASSEMBLY SAIC-L-2014 31-Aug-11 PIPING-

Page 3 of 10

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010) Rev 5 31-Aug-10

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

INSPECTION OF BOLTED FLANGE JOINT ASSEMBLY SAIC-L-2014 31-Aug-11 PIPING-

SAES-L-109,

Para. 12.6

E11

PIKOTEK or Equivalent Gaskets:

PIKOTEK gaskets shall not be used in refineries and gas plants. The

PIKOTEK gaskets shall not be used in services operating at 280F and

higher

NOTE: For water corrosive services where flange face corrosion is a

concern, Gaskets with Teflon sealed, glass reinforced epoxy laminated

to 316 stainless steel core shall be used

SAES-L-109,

Para. 12.5

E10

The identification markings on the spiral wound gaskets (flange size

(NPS), pressure class and the appropriate flange standard (ASME

B16.5 or ASME B16.47) were verified to conform with the flange size

and flange standard and as specified in the IFC Drawing.

Note: Spiral wound gaskets are marked "B16.47A" for use on ASME

B16.47 Series A flanges, and "B16.47B" for use on ASME B16.47

Series B flanges. These are not interchangeable. (ASME B16.20, Para.

3.4.1 g) Not a requirement for gaskets forASME B16.5 flanges.

SAEP-351,

Para. 4.1

E8

The ring gaskets have the following identification:

a. manufacturer's name or identification trademark

b. gasket number prefixed by the letters R,RX,or BX

followed by the gasket material identification.

c. The gasket is marked with an ASME B 16.20 designation.

(NOTE: Refer to Attachment 4 for Identification Markings )

(ASME B16.20, Para. 2.4)

ASME B16.20,

Para. 2.4

F Bolting

F1 Bolts and nuts have no physical damage to shanks or threads.

SAEP-351,

Para.4.2

E9

The dimension of the ring-joint gasket indicated by letter designation (R,

RX, or BX) stamped on the ring gasket was verified to conform with the

flange size and flange standard where it will be used.

(NOTE: Verification is made with the details on IFC drawing and Tables

3 to 8 of ASME B16.20). { ASME B16.20, Para. 2.5}

ASME B16.20,

Para. 2.5

E12

Insulating Gaskets:

Subject to the limitations given in item E11 above , insulating gaskets,

PIKOTEK gaskets, or approved equal, with isolating sleeves and

washers are used for:

1. Insulating dissimilar metal flanged joints with high potential galvanic

corrosion (i.e., electrical isolation)

2. Insulting joints for cathodic protection.

Page 4 of 10

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010) Rev 5 31-Aug-10

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

INSPECTION OF BOLTED FLANGE JOINT ASSEMBLY SAIC-L-2014 31-Aug-11 PIPING-

G1

SAEP-351 option is chosen for Bolt Tightening of flanges:

A) Inspection approval is obtained

for a "cut and paste" procedure of SAEP-351 .

B) Selected lubricant(s) & Torque values based on the friction factors of

the selected lubricant are included in the procedure.

SAEP-351,

Para. 3.2.1

Tools for bolt tightening have been identified and resolved between

Contractor, SAPMT, Proponent and Inspection prior to commencing the

erection of the piping.

SAEP-351,

Para. 6.1

G3

Approval is obtained for a "Gasket Control Procedure"

Note: The Procedure shall account for every single type of gasket by

use of color coding or other identification system. Critical is that differing

gasket metallurgies are not mixed (controls)

SAEP-351,

Para. 4.1

G4

G2

Bolt tightening procedure in lieu of SAEP-351 is approved by the Piping

Stds Committee Chairman or his rep. (Includes tensioning procedures

such as "Hydratight", etc)

SAES-L-350,

Para. 3.2.1

G Bolt Tightening & Gasket Control Procedure

Stud bolts and nuts have identification markings and verified to be

suitable to the service temperature as follows:

A. Materials for Process and general services:

a. (- 40C to 450C) A193 Gr B7/ A194 Gr 2H

B. Materials for Low Temp Services:

b. LT(-73C to 450C) A320 Gr L7M / A194 Gr 7M

c. LT(-101C to 343C) A320 Gr L7 / A320 Gr 4 or 7

C. Materials for upper intermediate temperature services:

a. t (450C to 645) A193 Gr B16 /A194 Grade 4

D. For Wet sour service, direct exposure or bolts are covered:

a. (- 48C to 450C) A193 Gr B7M/ A194 Gr 2HM

b. (-73C to 450C) A320 Gr L7M/ A194 Gr 7M

Note: Material selection for temperatures and/or services not listed

above shall be approved by the Chairman of Piping Standards

Committee.

F2

SAES-L-109,

Para 13.2

F4

Bolt Length: Bolts extend completely through their nuts (full thread

engagement.).

(NOTE: Thread engagement is adequate if the lack of complete

engagement is not more than one thread. ) (ASME B31.3, Para. 335.2.3)

ASME B 31.3,

Para. 335.2.3

F3

Bolting material installed in aggressive external environment such as

offshore and underground piping are protected using one of the

followings:

a) Ceramic-fluoropolymer coating per 09-SAMSS-107,

b) Using Corrosion-resistant alloys

c) Painting the exposed portions of the bolts and sealing the gap

between flange faces,

d) Encapsulating the bolted flange connection with heat shrinkable

tubing.

SAES-L-109,

Para 13.3

Page 5 of 10

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010) Rev 5 31-Aug-10

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER DATE APPROVED QR NUMBER

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

INSPECTION OF BOLTED FLANGE JOINT ASSEMBLY SAIC-L-2014 31-Aug-11 PIPING-

G5

Contractor personnel crews executing flange assembly work have

proper training & skills to work per SAEP-351.

Note: Verification is by submission of a roster to COMPANY.

SAEP-351,

Para. 3.2.2

NOTE: a) Satisfactory completion and approval of this Checklist allows the performance of Bolt

Tightening for the listed flange joints to proceed.

b) SATR-L-2001 shall be used to document bolt tightening.

REFERENCES:

1. SAES-L-105, Piping Material Specifications, (8 August 2009)

2. SAES-L-109, Selection of Flanges, Stud Bolts and Gaskets, (28 April 2009)

3. SAES-L-350, Construction of Plant Piping, (22 April 2009)

4. SAEP-351, Bolted Flange Joints Assembly, (7 Nov 2006)

5. ASME B31.3, Chemical Plant and Petroleum Refinery Piping, (2006 Edition)

6. ASME B16.20, Metallic Gaskets for Pipe Flanges- Ring-Joint, Spiral-Wound, and Jacketed,

(2001)

7. ASME B16.21, Nonmetallic Flat Gaskets for Pipe Flanges,(2005)

8. ASME B16.5, Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24, (2003)

9. ASME B16.47, Large Diameter Steel Flanges NPS 26 through NPS 60, (2006)

REMARKS:

ATTACHMENTS:

1. Attachment 1 - Line Class and Pressure Rating Equivalent

2. Attachment 2 - PERMISSABLE IMPERFECTIONS IN FLANGE FACING FINISH

3. Attachment 3 - GASKET TYPE SELECTION (SAES-L-109, Sec. 12)

4. Attachment 4 - Ring Gasket Markings

5. Attachment 5 - Color Coding and Abbreviations for Spiral-Wound Gasket Materials

Work / Rework May Proceed

Name, Initials and Date: Name, Initials and Date:

Performed Inspection

Name, Organization,

Initials and Date:

Quality Record Approved: T&I Witnessed QC Record Reviewed

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

T&I Witnessed QC Record Reviewed

Name, Sign and Date:

Work Verified

QC Supervisor Proponent and Others

Work Verified

QC Inspector PID Representative

Construction Representative*

Name, Initials and Date:

Work is Complete and Ready for Inspection:

Name, Initials and Date:

Work Verified

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed

Contractor / Third-Party

Page 6 of 10

NARAYAN.P 30-05-2013

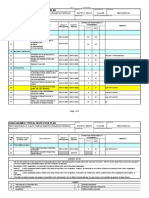

Attachment 1:

Line Class and Pressure Rating Equivalent

(Examples of Line Classes: 1CS1P1, 6CS1P1, 15CS9P)

Attachment 2:

TABLE 11-PERMISSABLE IMPERFECTIONS IN FLANGE FACING FINISH(^)

(MSS-SP-44, 1/1/96-R 2001)

31-Aug-11 PIPING-

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010)

DATE APPROVED QR NUMBER

INSPECTION OF BOLTED FLANGE JOINT ASSEMBLY SAIC-L-2014

Rev 5

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

31-Aug-10

First Field

of Line Class Nominal Pressure Rating , Flange Face

(ASME B16.5/B16.47 Flange Class)

1 150 RF

3 300 RF

6 600 RF

9 900 RJ

15 1500 RJ

25 2500 RJ

(ASME B16.1 Cast Iron Flange Class)

12 125 FF

13 250 RF

(Specific Rating Designations)

80 Non-pressure FF

85 Pressure Class 75/150 RF

90 Class 3000, API 6A, RJ

95 Class 10000, API 6A, RJ

Page 7 of 10

31-Aug-11 PIPING-

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010)

DATE APPROVED QR NUMBER

INSPECTION OF BOLTED FLANGE JOINT ASSEMBLY SAIC-L-2014

Rev 5

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

31-Aug-10

Compressed synthetic fiber with oil resistant binder,1.6mm thick per ASME B16.21.

can be used in non-hazardous services up to a maximum temperature of

230C.(SAES-L-109, Para. 12.8.2)

Octagonal ring joint gaskets Type R, per ASME 16.20 shall be used with API SPEC

6A Type 6B flanges and ASME RTJ flange type. SAES-L-109, Para 12.2.1

4. Class 125 and 150 flat face flanges in

non-hazardous services up to a maximum

temperature of 230C.

NOTE: Gasket selection may also be verified for compatibility with the flanges based on line classification as

detailed in SAES-L-105.

Metal Grooved (Kammprofile) gaskets with graphite sealing facing material and

outer centering ring shall be used as an alternative to spiral wound gaskets in piping

system subjected to pressures and fluctuating conditions, temperature differential

across the flange face and bolt stress relaxation. (SAES-L-109 Para 12.4)

Type of gasket requires approval by the Chairman of Piping Standards Committee in

CSD. (SAES-L-109, Para. 12.8.3)

8. Raised face flanges for most acid services up to

70% concentration and to 65C. For sulfuric acid

above 70% concentration (including oleum), and nitric

acid (all concentrations)

NOTE: The flange finish shall be 3.2 to 6.4

micrometers Ra.

9. Flanges used in other acids

ATTACHMENT 4:

The maximum temperature for spiral wound gaskets using graphite filler material is

limited to 454C.(SAES-L-109, Para. 12.3.2.1)

FLANGE TYPE

2. API Spec 6A, Type B Flange

3. Raised Face Flange in oxidizing environment

1. Ring Joint Flanges

1. Ring-joint gasket materials shall be selected based on suitability for the service

conditions.

2. Rubber coated ring joint gaskets may be used for severely corroded services.

3. Soft iron or low carbon steel may be used for the ring type joint material.

(SAES-L-109, Para 12.2.2 & Para 12,2.3)

3. Raised Face Flange in general hydrocarbons and

process hydrocarbon services including steam.

Spiral wound gaskets with 316 stainless steel winding and high purity flexible

graphite filler shall be used for raised face flanges. per ASME B16.20.

Filler materials that deteriorate at elevated temperatures, e.g. Teflon, shall not be

used in hydrocarbon services.(SAES-L-109, Para. 12.3.2.2 & 12.3.3)

Note: Metal Grooved (Kammprofile) gaskets with graphite sealing facing material

and outer centering ring shall be used as an alternative to spiral wound gaskets in

piping system subjected to pressures and fluctuating conditions, temperature

differential across the flange face and bolt stress relaxation. (SAES-L-109 Para 12.4)

GASKET TYPE SELECTION (SAES-L-109, Sec. 12)

GASKET TYPE

ATTACHMENT 3:

5. Flat face flanges for most acid services up to 70%

concentration and to 65C. For sulfuric acid above

70% concentration (including oleum), and nitric acid

(all concentrations)

Full face ASTM D1418 class FKM elastomer. (SAES-L-109, Para. 12.8.3)

8. Raised face flanges for most acid services up to

70% concentration and to 65C. For sulfuric acid

above 70% concentration (including oleum), and nitric

acid (all concentrations)

NOTE: The flange finish shall be 3.2 to 6.4

micrometers Ra.

PTFE-filled spiral wound Alloy 20 stainless steel with stainless steel inner ring.

(SAES-L-109, Para. 12.8.3)

9. Flanges used in other acids

Type of gasket requires approval by the Chairman of Piping Standards Committee in

CSD. (SAES-L-109, Para. 12.8.3)

Full face gaskets of elastomeric material 3 mm thick with Shore A Durometer

hardness between 50 and 60. (SAES-L-109, Para. 12.8.4)

Full face gasket, 3 mm thick, elastomeric material per ASTM D1418 class CSM.

(SAES-L-109, Para. 12.8.4)

6. Plastic flanges

7. Plastic flanges in wet chlorine and hypochlorite

services

Page 8 of 10

31-Aug-11 PIPING-

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010)

DATE APPROVED QR NUMBER

INSPECTION OF BOLTED FLANGE JOINT ASSEMBLY SAIC-L-2014

Rev 5

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

31-Aug-10

ATTACHMENT 5:

Page 9 of 10

31-Aug-11 PIPING-

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2010)

DATE APPROVED QR NUMBER

INSPECTION OF BOLTED FLANGE JOINT ASSEMBLY SAIC-L-2014

Rev 5

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

31-Aug-10

Page 10 of 10

Anda mungkin juga menyukai

- SAIC-L-2014 Flange Joint Insp PDFDokumen7 halamanSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyBelum ada peringkat

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDokumen12 halamanSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadBelum ada peringkat

- SAIC-A-2009 Rev 2Dokumen5 halamanSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுBelum ada peringkat

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDokumen2 halamanSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Ad 036821 001Dokumen1 halamanAd 036821 001AmolBelum ada peringkat

- SATR-L-2001 Rev. 5Dokumen10 halamanSATR-L-2001 Rev. 5Neelam AhmadBelum ada peringkat

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDokumen12 halamanSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWBelum ada peringkat

- 01 Samss 035Dokumen28 halaman01 Samss 035Cherukunnon Jubu100% (2)

- Materials System SpecificationDokumen9 halamanMaterials System SpecificationFAPM1285Belum ada peringkat

- Saep 351Dokumen19 halamanSaep 351QA QC100% (1)

- SAIC-A-2006 Rev 6Dokumen16 halamanSAIC-A-2006 Rev 6biplabpal2009Belum ada peringkat

- Saic L 2008 PDFDokumen4 halamanSaic L 2008 PDFHesham HelalBelum ada peringkat

- SAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageDokumen8 halamanSAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageMuhammad Farukh Manzoor0% (1)

- SAUDI ARAMCO SHOP FABRICATION INSPECTION PLANDokumen2 halamanSAUDI ARAMCO SHOP FABRICATION INSPECTION PLANskychurch100% (1)

- 175 320300Dokumen1 halaman175 320300sridhar100% (1)

- Pages From NSH-SAOMPP-QCP-PI-021 Hydratight Procedure For Flange Hydraulic Torque TighteningDokumen2 halamanPages From NSH-SAOMPP-QCP-PI-021 Hydratight Procedure For Flange Hydraulic Torque TighteningRajis Rahim100% (1)

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDokumen3 halamanSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidBelum ada peringkat

- 175 012000Dokumen2 halaman175 012000Abu Anas M.SalaheldinBelum ada peringkat

- SAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARDokumen7 halamanSAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARZahidRafiqueBelum ada peringkat

- 1 SATIP-L-350-01 On-Plot Piping - Rev 01Dokumen4 halaman1 SATIP-L-350-01 On-Plot Piping - Rev 01zooplado75% (4)

- Saudi Aramco Inspection ChecklistDokumen2 halamanSaudi Aramco Inspection ChecklistJoni Carino SuniBelum ada peringkat

- SAIC-L-2136 Rev 0Dokumen3 halamanSAIC-L-2136 Rev 0philipyapBelum ada peringkat

- 04-SAMSS-035 ARAMCO General Reuirement For ValvesDokumen18 halaman04-SAMSS-035 ARAMCO General Reuirement For ValvesAhmed100% (4)

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDokumen32 halamanSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- 01-SAMSS-043 2018 ASTM Carbon Steel and Low Alloy Pipes For On-Plot ApplicationsDokumen18 halaman01-SAMSS-043 2018 ASTM Carbon Steel and Low Alloy Pipes For On-Plot ApplicationsWHWEN100% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDokumen2 halamanInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinBelum ada peringkat

- Materials System SpecificationDokumen7 halamanMaterials System Specificationaanouar77Belum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen3 halamanSaudi Aramco Inspection ChecklistAbdul HannanBelum ada peringkat

- Inspection Procedure for Determining Retirement Thickness of PipingDokumen6 halamanInspection Procedure for Determining Retirement Thickness of Pipingmalika_00Belum ada peringkat

- SAIC-A-2008 Rev 0Dokumen3 halamanSAIC-A-2008 Rev 0Kristine Caye DatarioBelum ada peringkat

- 01 Samss 010Dokumen11 halaman01 Samss 010doyenofcastleBelum ada peringkat

- SATIP SAIC SATR IndexDokumen87 halamanSATIP SAIC SATR Indexlhanx2100% (8)

- Saudi Aramco Inspection ChecklistDokumen15 halamanSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- III. Applicable Codes & Standards for Aramco ProjectsDokumen5 halamanIII. Applicable Codes & Standards for Aramco ProjectsZain Ali KidwaiBelum ada peringkat

- 175 043000Dokumen1 halaman175 043000Fahad AhmadBelum ada peringkat

- Saes A 004Dokumen18 halamanSaes A 004emmanuilmoulos6339100% (1)

- Active Doc ListDokumen405 halamanActive Doc Listnadeem UddinBelum ada peringkat

- 175 091300Dokumen2 halaman175 091300Abu Anas M.SalaheldinBelum ada peringkat

- Materials System SpecificationDokumen21 halamanMaterials System Specificationnadeem shaikhBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen5 halamanSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- SAIC-D-2006 Rev 2Dokumen2 halamanSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுBelum ada peringkat

- 175 043600Dokumen2 halaman175 043600Abu Anas M.SalaheldinBelum ada peringkat

- Satip A 004 03Dokumen3 halamanSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- SAIC-A-2016 Rev 0Dokumen2 halamanSAIC-A-2016 Rev 0philipyapBelum ada peringkat

- Inspection Procedure EDRDokumen8 halamanInspection Procedure EDRaamirtec301Belum ada peringkat

- 32 Samss 017Dokumen11 halaman32 Samss 017naruto256Belum ada peringkat

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Dokumen2 halamanSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadBelum ada peringkat

- Saic A 2011Dokumen8 halamanSaic A 2011jerinBelum ada peringkat

- Saudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalDokumen11 halamanSaudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalSasi Head OfficeBelum ada peringkat

- SAIC-L-2035 Rev 6Dokumen2 halamanSAIC-L-2035 Rev 6biplabpal2009Belum ada peringkat

- Saep 324Dokumen13 halamanSaep 324Up WeldBelum ada peringkat

- Saudi Aramco Typical Inspection PlanDokumen2 halamanSaudi Aramco Typical Inspection PlanMAZHARULBelum ada peringkat

- SAIC-L-2015 Rev 7Dokumen7 halamanSAIC-L-2015 Rev 7Jaseel KanhirathingalBelum ada peringkat

- Technical Notes and Specifications Part CDokumen29 halamanTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- SAUDCO INSPECTION CHECKLIST FOR SMALL TANKSDokumen4 halamanSAUDCO INSPECTION CHECKLIST FOR SMALL TANKSAnonymous S9qBDVkyBelum ada peringkat

- Saic L 2015Dokumen8 halamanSaic L 2015Engr IrfanBelum ada peringkat

- Flange Selection GuideDokumen11 halamanFlange Selection GuidebandithaguruBelum ada peringkat

- Process & Piping Design Section Plug Valves Technical SpecificationDokumen14 halamanProcess & Piping Design Section Plug Valves Technical Specificationashish.mathur1100% (1)

- Spec 6a E21 en Add3Dokumen16 halamanSpec 6a E21 en Add3LiLiBelum ada peringkat

- Technical Notes (General Specification) FOR Valves (Gate, Globe, Check, Ball, Plug, Needle, Butterfly & Piston Valves)Dokumen30 halamanTechnical Notes (General Specification) FOR Valves (Gate, Globe, Check, Ball, Plug, Needle, Butterfly & Piston Valves)jayakumar100% (1)

- QP - spc.L.006 R1-Field Applied Fusion Bonded Epoxy Coating For Pipeline Girth Weld JointsDokumen25 halamanQP - spc.L.006 R1-Field Applied Fusion Bonded Epoxy Coating For Pipeline Girth Weld JointsJagadeesh Puppala100% (2)

- QP - spc.L.007 R1-Heat Shrink Sleeves For Corrosion Protection of PipelinDokumen24 halamanQP - spc.L.007 R1-Heat Shrink Sleeves For Corrosion Protection of PipelinJagadeesh PuppalaBelum ada peringkat

- ES.2.13.0002 Rev A - Data Sheet For Diesel Engine Driven GeneratorsDokumen9 halamanES.2.13.0002 Rev A - Data Sheet For Diesel Engine Driven GeneratorsJagadeesh PuppalaBelum ada peringkat

- Is 3025 PART 38 - 1989 Dissolved OxygenDokumen7 halamanIs 3025 PART 38 - 1989 Dissolved OxygenSunil Abdul SalamBelum ada peringkat

- ES.5.06.0001 RA - PressureVesselsDokumen28 halamanES.5.06.0001 RA - PressureVesselsJagadeesh PuppalaBelum ada peringkat

- Is.7634.2.2012 0Dokumen26 halamanIs.7634.2.2012 0Jagadeesh PuppalaBelum ada peringkat

- Is 4984 - 2016 LRDokumen32 halamanIs 4984 - 2016 LRJagadeesh Puppala69% (49)

- Is.7634.2.2012 0Dokumen26 halamanIs.7634.2.2012 0Jagadeesh PuppalaBelum ada peringkat

- Astm D2321 (2000)Dokumen10 halamanAstm D2321 (2000)Jagadeesh PuppalaBelum ada peringkat

- 2555-1!31!0025 Polysterene BoardDokumen19 halaman2555-1!31!0025 Polysterene BoardJagadeesh PuppalaBelum ada peringkat

- Đề Thi Thử THPT 2021 - Tiếng Anh - GV Vũ Thị Mai Phương - Đề 13 - Có Lời GiảiDokumen17 halamanĐề Thi Thử THPT 2021 - Tiếng Anh - GV Vũ Thị Mai Phương - Đề 13 - Có Lời GiảiHanh YenBelum ada peringkat

- Fuck Your LawnDokumen86 halamanFuck Your Lawnhuneebee100% (1)

- Tugas B InggrisDokumen9 halamanTugas B InggrisDellyna AlmaBelum ada peringkat

- Cipac MT 185Dokumen2 halamanCipac MT 185Chemist İnançBelum ada peringkat

- Ucg200 12Dokumen3 halamanUcg200 12ArielBelum ada peringkat

- Role of Family and Society in The Rehabiloitation of Offenders PDFDokumen4 halamanRole of Family and Society in The Rehabiloitation of Offenders PDFDevlika DasBelum ada peringkat

- Indonesia Organic Farming 2011 - IndonesiaDOCDokumen18 halamanIndonesia Organic Farming 2011 - IndonesiaDOCJamal BakarBelum ada peringkat

- PT6 Training ManualDokumen64 halamanPT6 Training ManualAnderson Guimarães100% (2)

- SM RSJ 420 800Dokumen77 halamanSM RSJ 420 800elshan_asgarovBelum ada peringkat

- Valvula de Leve MasterDokumen20 halamanValvula de Leve Masterguillermo trejosBelum ada peringkat

- Workplace Hazard Analysis ProcedureDokumen12 halamanWorkplace Hazard Analysis ProcedureKent Nabz60% (5)

- Pictorial History of AOTADokumen5 halamanPictorial History of AOTAThe American Occupational Therapy Association0% (4)

- Retail Management PPT1Dokumen14 halamanRetail Management PPT1Srilekha GubbalaBelum ada peringkat

- FileDokumen284 halamanFileJesse GarciaBelum ada peringkat

- UNICESS KR Consmetics Maeteria Nunssupjara 01apr23Dokumen44 halamanUNICESS KR Consmetics Maeteria Nunssupjara 01apr23ZB ChuaBelum ada peringkat

- ItilDokumen11 halamanItilNarendar P100% (2)

- InjectorDokumen23 halamanInjectorBac Nguyen100% (1)

- Rudraksha - Scientific FactsDokumen20 halamanRudraksha - Scientific FactsAkash Agarwal100% (3)

- Rreinforcement Pad Leak Test ProcedureDokumen5 halamanRreinforcement Pad Leak Test ProcedureAmin Thabet100% (2)

- Antenna LecDokumen31 halamanAntenna Lecjosesag518Belum ada peringkat

- Solids Level Measurement Application Guide en 78224 PDFDokumen144 halamanSolids Level Measurement Application Guide en 78224 PDFwalcalBelum ada peringkat

- Module A Specimen Questions January2020 PDFDokumen5 halamanModule A Specimen Questions January2020 PDFShashi Bhusan SinghBelum ada peringkat

- Junayed - 19 39800 1Dokumen11 halamanJunayed - 19 39800 1gurujeeBelum ada peringkat

- Comm Part For A320Dokumen1 halamanComm Part For A320ODOSBelum ada peringkat

- Cfm56-3 Engine Regulation by CFMDokumen43 halamanCfm56-3 Engine Regulation by CFMnono92100% (5)

- Practical Examination Marking Guideline Grade 12 Physical Science 2019 PDFDokumen5 halamanPractical Examination Marking Guideline Grade 12 Physical Science 2019 PDFWonder Bee Nzama100% (1)

- Myth and Realism in The Play A Long Day's Journey Into Night of Eugene O'neillDokumen4 halamanMyth and Realism in The Play A Long Day's Journey Into Night of Eugene O'neillFaisal JahangeerBelum ada peringkat

- New930e-4se Ceam031503 930e4se Omm A31937 Up PDFDokumen273 halamanNew930e-4se Ceam031503 930e4se Omm A31937 Up PDFSergelen SakhyabazarBelum ada peringkat

- General Specifications: Detail ADokumen1 halamanGeneral Specifications: Detail AJeniel PascualBelum ada peringkat

- AAR Maintenance 001Dokumen3 halamanAAR Maintenance 001prakash reddyBelum ada peringkat

- University of Chicago Press Fall 2009 CatalogueDari EverandUniversity of Chicago Press Fall 2009 CataloguePenilaian: 5 dari 5 bintang5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesDari EverandUniversity of Chicago Press Fall 2009 Distributed TitlesPenilaian: 1 dari 5 bintang1/5 (1)