Electric Welding

Diunggah oleh

dimpesh silarpruiyaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Electric Welding

Diunggah oleh

dimpesh silarpruiyaHak Cipta:

Format Tersedia

WORKING

Electric Welding

Electric Welding is done by creating an arc between the base metal (the metal

being welded) and the filler metal. The arc melts the base metal and filler metal,

combining them into one material to join the bas Electric welding is the joining of

metal using an electrical arc and a filler metal (stick electrode or wiree metals. The

filler metal is consumed in the process.

Use of Electrical Welding

We use electrical welding for welding of L angles and plates witch are use at the

base and head side. This structure will support the column and the whole

machine.The upper head contain motor and pulley arengment at the top. The motor

pullley is conneted to the shaft pulley through a belt .

: Flux cored welding (FCAW) works like MIG welding, except flux cored welding

does not require an external cylinder full of shielding gas .

Types of Electric Welding Processes

There a number of different electric welding processes. While most of the

processes work with steel, no one process works with every type of metal. The

following table indicates which process is recommended for which type of metal.

The different types of welding processes will be discussed in detail in the next

section of this module.

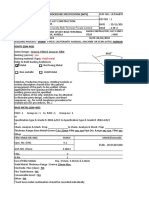

Metal Type Electric Welding Process

Stick MIG

Flux

Wire

AC-TIG DC-TIG Resistance Spot

Steel X X X X X

Stainless Steel X X X X X

Aluminum X X X

Cast Iron X

Copper/Brass X

Magnesium Alloys X

Titanium X

Skill Level Moderate Low Low High High Low

TIG Welding (Tungsten Inert Gas, also known as GTAW or

Gas Tungsten Arc welding)

TIG Welding (also called GTAW or Gas Tungsten Arc Welding) joins metals by

heating them with an arc formed between the tungsten electrode and the base

metal. (The tungsten electrode, unlike a stick electrode, does not become part of

the completed weld). Filler metal is sometimes used and Argon inert gas or inert

gas mixtures are used for shielding.

The advantages of TIG welding include:

AC TIG welds aluminum and magnesium alloys

DC TIG welds brass, copper, steel, stainless steel, and titanium

Provides the highest quality and most precise welds

Ability to weld thin materials

The disadvantages of TIG welding include:

Requires more skill and experience than any other method

USE TIG OF PROCESS

The TIG process is used for welding of the ss shaft . Fins are welded with the ss

shaft by TIG welding .

Milling machine

Milling machines are tools designeer to machine metal, wood, and other

solid materials. Often automated, milling machines can be positioned in

either vertical or horizontal orientation to carve out materials based on a

pre-existing design. These designs are often CAD directed, and many

milling machines are CNC-operated, although manually and traditionally-

automated milling devices are also common. Milling machines are capable

of dynamic movement, both of the tool and the workpiece, and many

milling machines can perform multi-axis machining.

Because of variations in orientation, operation and application, milling

machines have varying functions and different operating principles.

Designing of pulley

For making of pulley we use firstly use boring operation .In boring operation

we take inner dia of 14mm for main shaft and 10mm for motor shaft .Outer

diameter is taken as 40mm for both the pulley. Both the pulley are made of

cast iron.

We make the pulley as per the belt use so we use pulley with normal

grooves.

The grooves are made with the 45 degree angle.

Metal Polishing & Buffing

Virtually any metal can be buffed to a mirror-like shine. Aluminum, brass,

copper, pot metal, steel and stainless steel can all be buffed to a high shine

using the high-quality buffing compounds, wheels, and other supplies

available from Eastwood's automotive accessories shop.

PRINCIPLES OF BUFFING

The Difference Between "Polishing" and "Buffing"

"Polishing" a piece of metal removes a moderate amount of metal from the

piece, using coarse to medium abrasives in stages. The piece will have a

"brushed" look and you will not be able to see any reflections in it. Polishing

removes scratches and minor surface imperfections which are too deep for

buffing compounds to remove efficiently. If you run your fingernail over a

scratch and it gets caught, then the piece should be polished before

buffing. The key to uccess in polishing is to remove just enough

material to make the surface even and no more.

SHAPER MACHINE

A shaper is a type of machine tool that uses linear relative motion between the

workpiece and a single-point cutting tool to machine a linear toolpath. Its cut is

analogous to that of a lathe, except that it is (archetypally) linear instead of helical.

(Adding axes of motion can yield helical toolpaths, as also done in helical planing.)

A shaper is analogous to a planer, but smaller, and with the cutter riding a ram that

moves above a stationary workpiece, rather than the entire workpiece moving

beneath the cutter. The ram is moved back and forth typically by a crank inside the

column; hydraulically actuated shapers also exist.

Stainless Steel - Grade 304

Chemical Formula

Fe, <0.08% C, 17.5-20% Cr, 8-11% Ni, <2% Mn, <1% Si, <0.045% P, <0.03% S

Grade 304 is the standard "18/8" stainless; it is the most versatile and most widely

used stainless steel, available in a wider range of products, forms and finishes than

any other. It has excellent forming and welding characteristics. The balanced

austenitic structure of Grade 304 enables it to be severely deep drawn without

intermediate annealing, which has made this grade dominant in the manufacture of

drawn stainless parts such as sinks, hollow-ware and saucepans.

Composition

Typical compositional ranges for grade 304 stainless steels are given in table

Table 1. Composition ranges for 304 grade stainless steel

Grade C Mn Si P S Cr Mo Ni N

304

min.

max.

-

0.08

-

2.0

-

0.75

-

0.045

-

0.030

18.0

20.0

-

8.0

10.5

-

0.10

304L

min.

max.

-

0.030

-

2.0

-

0.75

-

0.045

-

0.030

18.0

20.0

-

8.0

12.0

-

0.10

304H

min.

max.

0.04

0.10

-

2.0

-

0.75

-

0.045

-

0.030

18.0

20.0

-

8.0

10.5

-

Possible Alternative Grades

Possible alternative grades to grade 304 stainless steels are given in table 5.

Table Possible alternative grades to 304 grade stainless steel

Grade Why it might be chosen instead of 304

301L

A higher work hardening rate grade is required for certain roll formed

or stretch formed components.

302HQ

Lower work hardening rate is needed for cold forging of screws, bolts

and rivets.

303

Higher machinability needed, and the lower corrosion resistance,

formability and weldability are acceptable.

316

Higher resistance to pitting and crevice corrosion is required, in

chloride environments

321

Better resistance to temperatures of around 600-900C is

needed321 has higher hot strength.

3CR12

A lower cost is required, and the reduced corrosion resistance and

resulting discolouration are acceptable.

430

A lower cost is required, and the reduced corrosion resistance and

fabrication characteristics are acceptable.

OTHER PROPERTIES

Corrosion Resistance

Excellent in a wide range of atmospheric environments and many corrosive

media. Subject to pitting and crevice corrosion in warm chloride

environments, and to stress corrosion cracking above about 60C.

Considered resistant to potable water with up to about 200mg/L chlorides at

ambient temperatures, reducing to about 150mg/L at 60C.

Heat Resistance

Good oxidation resistance in intermittent service to 870C and in continuous

service to 925C. Continuous use of 304 in the 425-860C range is not

recommended if subsequent aqueous corrosion resistance is important. Grade 304L

is more resistant to carbide precipitation and can be heated into the above

temperature range.

Grade 304H has higher strength at elevated temperatures so is often used for

structural and pressure-containing applications at temperatures above about 500C

and up to about 800C. 304H will become sensitised in the temperature range of

425-860C; this is not a problem for high temperature applications, but will result

in reduced aqueous corrosion resistance.

Heat Treatment

Solution Treatment (Annealing) - Heat to 1010-1120C and cool rapidly. These

grades cannot be hardened by thermal treatment.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Presentation 1Dokumen13 halamanPresentation 1dimpesh silarpruiyaBelum ada peringkat

- Mechanical Failure of Materials 9789814560375-c2Dokumen23 halamanMechanical Failure of Materials 9789814560375-c2Recep Vatansever0% (1)

- Design and Calculation For KersDokumen5 halamanDesign and Calculation For Kersdimpesh silarpruiyaBelum ada peringkat

- Experiment No.4 AutomobileDokumen4 halamanExperiment No.4 Automobiledimpesh silarpruiyaBelum ada peringkat

- Mechanical Failure of Materials 9789814560375-c2Dokumen23 halamanMechanical Failure of Materials 9789814560375-c2Recep Vatansever0% (1)

- Experiment No 1 AutomobileDokumen4 halamanExperiment No 1 Automobiledimpesh silarpruiyaBelum ada peringkat

- Assignment-I ME-704 Automobile EngineeringDokumen1 halamanAssignment-I ME-704 Automobile Engineeringdimpesh silarpruiyaBelum ada peringkat

- Chapter 6 AvailabilityDokumen6 halamanChapter 6 Availabilitygovind4ever5Belum ada peringkat

- UntitledDokumen6 halamanUntitleddimpesh silarpruiyaBelum ada peringkat

- UntitledDokumen3 halamanUntitleddimpesh silarpruiyaBelum ada peringkat

- UntitledDokumen2 halamanUntitleddimpesh silarpruiyaBelum ada peringkat

- UntitledDokumen1 halamanUntitleddimpesh silarpruiyaBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- GL DrilTec Catalogue Last VersionDokumen32 halamanGL DrilTec Catalogue Last Versiontoxicity23Belum ada peringkat

- Laboratory 5Dokumen10 halamanLaboratory 5Andy BirdieBelum ada peringkat

- Afrox Product CatalogueDokumen92 halamanAfrox Product CataloguedhurushaBelum ada peringkat

- Welder Performance Qualification ProcedureDokumen25 halamanWelder Performance Qualification ProceduresajiBelum ada peringkat

- Doclib 4677 Autocraft 316lsi DatasheetDokumen1 halamanDoclib 4677 Autocraft 316lsi Datasheetamir moniriBelum ada peringkat

- Lesson 3 - Covered Electrodes For Welding Mild Steels PDFDokumen1 halamanLesson 3 - Covered Electrodes For Welding Mild Steels PDFMelissa MurrayBelum ada peringkat

- 16 Welding ConsumablesDokumen63 halaman16 Welding ConsumablesJawed AkhterBelum ada peringkat

- LJ Welding, 2017 V.2 WebDokumen32 halamanLJ Welding, 2017 V.2 WebNick LirovBelum ada peringkat

- Multi-Function Welding Machine ManualDokumen16 halamanMulti-Function Welding Machine ManualMiguel Lalangui DomíngezBelum ada peringkat

- Welding Electrodes: Profile No.: 235 NIC Code:27102Dokumen12 halamanWelding Electrodes: Profile No.: 235 NIC Code:27102ram prasad100% (1)

- MISON AR Shielding Gas135 99117Dokumen4 halamanMISON AR Shielding Gas135 99117camelod555Belum ada peringkat

- SS Weld Reference PhotosDokumen19 halamanSS Weld Reference PhotosfizanlaminBelum ada peringkat

- Stainless Steel Welding by Weld RealityDokumen50 halamanStainless Steel Welding by Weld RealitylightwinterdayBelum ada peringkat

- Guidelines For Welding: ZERON 100 Super Duplex Stainless SteelDokumen16 halamanGuidelines For Welding: ZERON 100 Super Duplex Stainless SteelHrishikesanBelum ada peringkat

- Managers Guide For Welding PDFDokumen115 halamanManagers Guide For Welding PDFsuraji100% (1)

- Weld Joint 1Dokumen81 halamanWeld Joint 1rajibali27100% (1)

- Flux-Cored Arc WeldingDokumen30 halamanFlux-Cored Arc Weldinganon_795652448Belum ada peringkat

- Manufacturing ScienceDokumen89 halamanManufacturing ScienceVokBelum ada peringkat

- Specification For Low-Alloy Steel Electrodes and Rods For Gas Shielded Arc WeldingDokumen9 halamanSpecification For Low-Alloy Steel Electrodes and Rods For Gas Shielded Arc WeldingSilvanaBelum ada peringkat

- Part III ISO and ASME DevelopmentsDokumen7 halamanPart III ISO and ASME Developmentsروشان فاطمة روشانBelum ada peringkat

- A5 Product Guide Manual Welding Low ResDokumen19 halamanA5 Product Guide Manual Welding Low ResMartinez HernandezBelum ada peringkat

- List of ANBs Approved To Develop Education, Training and Qualification ActivitiesDokumen5 halamanList of ANBs Approved To Develop Education, Training and Qualification ActivitiesJBKBelum ada peringkat

- PQR Amp WPQ Standard Testing Parameter WorksheetDokumen4 halamanPQR Amp WPQ Standard Testing Parameter WorksheetvinodBelum ada peringkat

- Parweld Pez 400Dokumen1 halamanParweld Pez 400pablotorres_cBelum ada peringkat

- 3SS NW00 00007 PDFDokumen10 halaman3SS NW00 00007 PDFKarthikBelum ada peringkat

- Weld Description Sheets and Weld MapsDokumen13 halamanWeld Description Sheets and Weld MapsMohammad MushtaqBelum ada peringkat

- p9 1 GuidelineDokumen11 halamanp9 1 GuidelineSHARAD SHAHBelum ada peringkat

- TRGS 528Dokumen66 halamanTRGS 528Marcus BragaBelum ada peringkat

- ASMEDokumen20 halamanASMENorazzah AbdullahBelum ada peringkat

- Wps For Akbtpl E-6013 - ModifiedDokumen13 halamanWps For Akbtpl E-6013 - ModifiedvinayBelum ada peringkat