Rotalk 28

Diunggah oleh

Iñaki EseberriDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Rotalk 28

Diunggah oleh

Iñaki EseberriHak Cipta:

Format Tersedia

INDUSTRY LEADING VALVE ACTUATION NEWS FROM THE WORLD OF ROTORK

28

Celebrating

50 Years

in Control

YEARS

1957 - 2007

Rotork is Business of the Year SW

Excellence Award Winner

Company News

The latest news from Rotork

Focus on Gearboxes

Spotlight on Rotork Site Services

Inside:

COVER STORY:

Celebrating 50 Years in control.............. 3

COMPANY NEWS:

The latest company news....................... 4

CONTRACT NEWS:

The latest Rotork

contract success stories.............. 5 & 15

FEATURES:

Skilmatic update..................................... 9

Spotlight on Site Services.................... 10

Site Services news................................ 12

Product news........................................ 13

Focus on Gearboxes.............................. 14

PEOPLE NEWS:

Personnel news..................................... 16

28

INDUSTRY LEADING VALVE ACTUATION

NEWS FROM THE WORLD OF ROTORK

[

2

]

Front cover montage:

Rotorks complete history of the electric actuator dating from

the 100A Actuator in 1957 to the IQ Pro introduced in 2006

[3]

28

COVER STORY

For more information on ROTALK articles and features contact Nicky Skinner at ROTORK Bath: +44(0)1225 733200 email: nichola.skinner@rotork.co.uk

Above: Alastair Spurr - Operations

Director (centre), with Tim Eggington

- Production Manager (left) and

shopfloor staff at the Brassmill

Lane factory.

Right: Rotork headquarters,

Brassmill Lane, Bath, UK.

Celebrating Fifty Years in Control

As Rotork celebrates its fiftieth

birthday, another landmark is

reached with the opening of the

companys first manufacturing

plant in China.

The new factory, in Shanghai, is

building Rotork Gears IW Range

secondary gearboxes for both the

local and export markets. Fifty years

YEARS

1957 - 2007

ago, when the first Rotork actuators

were being assembled at Jeremy

Frys Widcombe Manor home, this

would have been hard to imagine.

The first purpose-built Rotork

factory began life on a greenfield

site at Brassmill Lane in Bath in

1962. Today, the dramatically

expanded Brassmill Lane facility is

still the companys headquarters and

primary factory for the manufacture

of electric actuators.

By the end of the 1970s the

manufacture of electric and

fluid power actuators had been

established in the USA as well as the

UK and the manufacture of electric

actuators for the domestic market in

India had began in Mumbai.

During the last twenty years the

pace of expansion has continued to

increase, driven by the penetration

of new markets, innovative product

developments and acquisitions.

Further manufacturing plants in

the UK, USA, The Netherlands, Italy,

Germany, Malaysia and now China

have increased the total number to

ten. Between them, these plants

produce the most comprehensive

offering of electric, electro-hydraulic,

hydraulic, pneumatic, high pressure

gas and gas-over-oil actuators,

control systems, gearboxes and

accessories available from any single

manufacturer, giving Rotork its

unrivalled one-stop-shop capability.

AWT electric actuator test rigs at the Malaysian Factory A and K electric actuators at Chennai, India Fluid Systems factory at Lucca, Italy

IQ electric actuators at Rotork Inc., Rochester USA Gearbox production at Rotork Shanghai Jordan electric actuators at Jordan Controls Inc., USA

[

4

]

COMPANY NEWS

Rotork Group company news from around the world

Rotork successfully defends

Intellectual Property

Rights in Europe

In a legal judgement on 11th April 2007, the Court of

The Hague, Netherlands, found Shanghai Autork Digital

Apparatus Co. Ltd guilty of slavish imitation, breach of

copyright and violation of design rights relating to Rotorks

award winning IQ and IQT series of actuators.

In addition Autork was found guilty

of infringing Rotorks internationally

recognised trademark.

In a wide ranging judgement,

Autork was ordered by the Court,

with immediate effect, to stop

infringing Rotorks proprietary

rights throughout the whole of the

expanded European Community.

The Court further instructed Autork

to remove infringing product from

storage addresses, distribution points

and customers. Autork, based in

Mid-Yunnan Road, Shanghai, PRC is

a trading organisation very closely

affiliated to Tefulong Group Co.

Ltd (formerly known as Zhejiang

Tefulong Machinery Co. Ltd) who

also trade as Wenzhou Greatork

Apparatus Co. Ltd. The President,

principal shareholder and legal

representative of these businesses

is the Wenzhou businessman and

property developer Mr Baoping Fang.

Further action against Tefulong,

its affiliated companies and legal

representative is ongoing with

Shanghai Peoples Court of China.

Rotork, currently celebrating its 50th

anniversary, has been responsible for

introducing many innovations within

valve automation and its products

are the result of extensive research

and development.

Rotork urges its customers and

users to be vigilant and wary of

inferior imitations of its products

and components that have not been

subjected to the same level of third

party approvals and certifications.

If in any doubt, customers are

requested to contact their nearest

official Rotork representative.

Rotork, currently celebrating its 50th anniversary, has

been responsible for introducing many innovations

within valve automation and its products are the

result of extensive research and development.

Centre of Excellence for

Fluid Systems opens in Spain

Rotorks premises in Spain have

been selected to be the tenth

Centre of Excellence for the Rotork

Fluid Systems Divisions pneumatic

and hydraulic actuation business.

Rotork Fluid Systems manufactures

a comprehensive range of valve

actuators, controls and associated

equipment, serving the oil and gas

exploration and transportation,

water and waste treatment, power

generation, chemical and processing

industries. Manufacturing plants

in Italy, Germany and the USA are

supported by a growing number of

Centres of Excellence, strategically

located around the world to meet

the needs of local markets.

Each centre holds stocks, provides

application engineering and the

packaging of control components

as well as the full range of sales,

contract, service, installation and

commissioning activities. Fluid

power actuation specialists at

the centres are able to provide

solutions to virtually any application

requirement.

The new facility in Spain joins

Centres of Excellence in Australia,

Canada, Germany, Italy, the UK, USA

(3) and Singapore, which

have opened in recent years as

Rotork Fluid Systems international

business has experienced

unprecedented growth.

Rotork is the outright winner

of the 2007 West of England

Business of the Year Award, a

prestigious annual event now

in its twentieth year, organised

by the international accounting

and consulting firm Price

Waterhouse Coopers.

The award recognises a companys

achievements and performance

across a broad range of aspects

including innovation, business

management, future outlook,

employee development and training,

health and safety, commitment to

the community and environmental

responsibility.

The rigorous selection procedure,

performed by a judging panel

comprised of leading figures

from industrial, financial and

business sectors, embraces the

submission of an extensive written

review of the business including

performance figures for the past five

years, followed by a detailed and

penetrative visit to the companys

premises.

Competition for the award was

fierce. In addition to Rotork the

six finalists consisted of eminent

companies in the construction,

property maintenance and business

management sectors and the

National Trust.

In the final analysis, however,

the Rotork package of business

achievement and innovation won

through, proving once again that

at the age of 50 the company

can still outperform the toughest

challengers.

Research and Development Director

Graham Ogden led Rotorks award

winning campaign, which follows

closely on last years success in

winning a 2006 Innovation and

Design Excellence Award.

Rotork wins Prestigious

Business of the Year Award

Rotork directors at the award ceremony

For more information on ROTALK articles and features contact Nicky Skinner at ROTORK Bath: +44(0)1225 733200 email: nichola.skinner@rotork.co.uk [

5

]

CONTRACT NEWS

Rotork Group contract news from around the world

28

Wessex Waters first

formal framework

agreement for electric

valve actuators has been

awarded to Rotork in

the face of substantial

competition from

European manufacturers.

The agreement, which will run for

three years from the beginning of

2007, encompasses the supply of

electric actuators, control systems

and associated services including

the retrofitting of new actuators

on existing valves, service and

maintenance. Rotork has been a

supplier of valve actuators on water

and waste treatment plants now

owned by Wessex Water throughout

virtually all of its history. Generally,

Wessex Water installations now

utilise IQ and IQT Pro intelligent

electric actuators, featuring

market-leading non-intrusive

commissioning and information

transfer technologies which

combined with comprehensive

data logging abilities optimise plant

performance and facilitate predictive

maintenance by recording historical

valve operating data.

As a key control element in the

automated operation of modern

water and waste treatment plants,

the Rotork actuators proven and

reliable connectivity with the

industry-preferred Profibus open

control protocol has also made

an important contribution to the

framework selection decision.

The benefit of Rotorks Profibus

Highway Termination Module,

enabling actuator disconnection/

reconnection without disrupting

A Rotork engineer testing an IQ actuator on site at Highbridge

Wessex Water first for Rotork

High speed actuator

deliveries help to get

the gas moving in Egypt

Rotork Fluid Systems has

successfully completed a fast-

track valve actuation contract

for a new strategic natural gas

distribution pipeline in Egypt.

The contract involved the

manufacture of specialised gas-

over-oil actuators for main line

isolating valves on the 135 kilometre

Shoukaur to Hurghada pipeline.

Eleven actuators were required on

a fourteen week delivery schedule

within the period including

Christmas and New Year.

Built at Rotork Fluid Systems factory

in Lucca, Italy, the scotch-yoke RFS

Model GO 130 actuators will operate

24 inch Class 600 ball valves

manufactured by Egyptian

valvemaker Evaco. Rotork gas-over-

oil actuators are specifically adapted

for valve control in the remote

locations traversed by pipelines by

using the pressure of the gas in

the pipeline itself to operate the

valve. In addition to the standard

gas-over-oil specification, actuators

for this contract were fitted with

valvemaker requested options

comprising torque limiting devices

to protect valve stems and integral

back-up accumulators with a

stand-alone capacity of four valves

strokes.The Shoukaur to Hurghada

pipeline is owned by the Egyptian

gas transportation company GASCO,

who are organising engineering,

procurement, construction

supervision, commissioning and

start-up. Construction of the USD 60

million project which commenced

in May 2006 and will be completed

by mid 2007 is being performed

by Egyptian engineering contractor

Petrojet. The completed pipeline

will supply natural gas at the rate

of up to 5 MMSCMD (5 million

standard cubic metres per day) to

the Egyptian provinces of Shoukaur

and Hurghada. Rotork Fluid

Systems performance in securing

the successful completion of this

important contract was applauded by

GASCO Materials General Manager

Mr. Karem Mahmoud during a recent

visit to the Lucca factory.

Mr. Karem Mahmoud is pictured (right) at the Lucca factory with Fluid Systems

General Manager Sales, Vittorio Stefani.

communication to other devices

on the highway, was especially

appreciated. Wessex Water Contracts

Manager Russell Day commented: In

addition to a track record of reliability

and low cost of ownership, Wessex

Water has been impressed by Rotorks

performance with after sales service

and technical support. Price stability

and value for money were also taken

into account during our decision

process with regard to this important

item of equipment for Wessex Water.

RFS Model GO 130

actuators will operate

24 inch Class 600 ball

valves manufactured

by Egyptian

valvemaker Evaco.

[

6

]

In the latest of several similar contracts in the Middle

East, Rotork electric, hydraulic and pneumatic actuators

have been ordered for two major new gas developments

in the United Arab Emirates.

Single source capability and local support

earns multi-technology actuator contracts

Rotork is a single-source supplier of electric multi-turn (top left), hydraulic linear (top

right) and pneumatic quarter-turn valve actuators for the OGD3 and AGD2 projects.

AGD2 overall project manager is

Foster Wheeler and completion is

scheduled for the first quarter of

2008. Rotorks actuator contracts

have been placed by Bechtel in

the USA and UK, Snamprogetti

and the National Petroleum

Construction Company.

The Habshan Onshore Gas

Development Phase 3 (OGD3) and

Asab Gas Development Phase 2

(AGD2) will provide a huge resource

of natural gas to liquids (NGL)

and condensate for the refinery at

Ruwais to assist with the expansion

of the petrochemical industry in

Abu Dhabi. In addition both projects

will generate substantial volumes of

liquid gas which will be re-injected

into the oil fields for pressure

stabilisation.

Rotork IQ intelligent electric

actuators have been ordered

throughout the $2,300 million

projects, which involve the

construction of NGL and

condensate recovery facilities at

the Habshan onshore field and a

110 kilometre pipeline to Ruwais,

where new storage tanks are also

being constructed. Six hundred

IQ actuators have been ordered,

together with up to sixteen Rotork

Pakscan two-wire digital control

systems. In addition, approximately

one hundred quarter-turn

pneumatic and linear hydraulic

actuators are being supplied,

providing a single source for multi-

technology actuation products that

simplifies the contractual route

for the four contractors involved.

Contractual negotiations have

been further assisted by Rotorks

increased commitment to the area,

as demonstrated by the presence of

a Rotork Middle East Regional Office

in Abu Dhabi.

For the OGD3 and AGD2 projects,

regular meetings with the three

end-user clients GASCO, ADCO and

TAKREER resulted in Rotork being

awarded all five of the actuator

packages on offer. The OGD3/

CONTRACT NEWS

Rotork Group contract news from around the world

The Italian Jobs

Rotork Italy has won an exclusive

framework agreement with Kuwait

Petroleum Italy for the supply of

electric actuators at the giant Naples

tank farm. The agreement covers the

motorisation of 175 manual wedge

gate valves with IQ actuators in a

contract that will be completed in

February 2008.

In recent years more than 100 IQ

actuators have been installed on the

site and thanks to the high technology

of the design and the on-site service

provided by Rotork the customers

Technical Direction team has decided

to standardise on the product. The

new contract is Rotork Italys second

framework agreement with the Italian

fuel distribution industry. The first was

signed in 2001 with API (Anonima

Petrol Italiana) for the Ancona Refinery,

where more than 400 IQ actuators

and six Pakscan loop control systems

are now in operation. Rotork Italy is

also busy with the power generation

industry in the country, where more

than 1200 IQ actuators have been

installed since 2000 as a result of new

energy production laws. Torrevaldaliga

the largest power station in Italy has

been refurbished in two stages, in 2003

and 2006, resulting in the installation

of approximately 450 IQ actuators with

Profibus connectivity in the two parts of

the site, Torre Nord and Torre Sud.

Rotork received most of the orders from

ENEL, who had overall responsibility for

the refurbishment of both parts and

had been using IQ actuators at another

plant at La Casella since 2000. Further

orders were received for the boiler areas

from Ansaldo Caldaie, who specified a

preference for the IQ actuator, and from

damper manufacturers Stejasa in Spain

and Damper Technology in the UK.

Following actuator installation Rotork

engineers attended the site in order to

assist and train DCS technicians from

ABB on Torre Nord and Siemens on

Torre Sud.

For more information on ROTALK articles and features contact Nicky Skinner at ROTORK Bath: +44(0)1225 733200 email: nichola.skinner@rotork.co.uk [

7

]

28

CONTRACT NEWS

Rotork Group contract news from around the world

Rotork Fluid Systems has received an order valued in

excess of one million Euros for the actuation of valves

in the feed gas preparation area of the Pearl GTL (Gas to

Liquids) project in Qatar, the largest plant of its type in

the world, due for completion by the end of the decade.

The order has been placed by

Orton Industrial Valves in Italy and

involves the supply of a total of

180 GP and CP range pneumatic

actuators for the operation of

butterfly valves in sizes ranging

between 8 and 24 inches.

Built by Chiyoda of Japan, the

Pearl feed gas preparation plant

comprises two trains of processing

units with a total capacity of 1600

MSCFD (million standard cubic feet

per day) of natural gas, equivalent

to 8 MMTPA (million tonnes per

annum) of LPG. The plant will

supply feed gas to the GTL core

unit for the production of 140,000

barrels per day of clean, high quality

fuels and products.

Negotiations for the Rotork

contract have been assisted by

close co-ordination between

Rotork Fluid Systems area offices

in the Middle East and Korea as

well as the factory at Lucca in Italy,

where the sales support team

has been on hand to ensure the

best possible support to Chiyoda

and the valvemakers involved

throughout the bidding process.

The Pearl GTL project is being

developed by Qatar Petroleum

and Qatar Shell GTL Limited under

a Development and Production

Sharing Agreement with the

government of the State of Qatar

signed in 2004. The project

is expected to produce three

billion barrels of oil equivalent

wellhead gas over the period of

the agreement. A total of USD

10 billion of contracts have been

awarded to-date, including all the

major engineering, procurement

and construction contracts.

This photograph, taken at the premises of Orton in Italy when the Rotork contract was

signed, shows (from left to right): Christian Ferdenzi - Area Sales Manager, Rotork Fluid

Systems. Enrico Vitale - Area Sales Manager, Orton. Peter France - Managing Director,

Rotork Fluid Systems. Enzo Stendardo - Marketing Manager, Orton. Alberto Aliani -

Managing Director, Orton. Vittorio Stefani - General Manager Sales, Rotork Fluid Systems.

The completion of the new

Reliance refinery at Jamnagar

on the west coast of India

scheduled for the end of

2008 will create what is

being described as the largest

refinery complex in the world.

The new refinery is under

construction on an area adjacent to

the existing refinery, tank farm, export

facility and power station, a giant

project in itself which was completed

in the late 1990s. At both sites,

Rotork IQ intelligent electric valve

actuators have been widely specified,

generating an installed quantity of

several thousand motorised valves.

More than 2500 IQ actuators are now

in operation at the original refinery,

which has a daily production capacity

of 660,000 barrels. The new plant,

which will require a similar number

of IQ actuators, will nearly double

this capacity, producing mostly

diesel, petrol and jet fuel. Bechtel is

responsible for detailed engineering,

project management, site support

and construction supervisory services.

Rotork is currently receiving orders

from valvemakers including Metso

More actuators specified for

Giant Refinery Expansion

Automation and Tyco Valves &

Controls. As with the existing refinery,

many of the new actuators will be

controlled by the Rotork Pakscan two-

wire digital control system, radically

reducing the cabling costs involved

in linking large numbers of field units

over long distances to Distributed

Control System equipment housed

in centralised control rooms. The

site will be amongst the first to

be equipped with Rotorks third

generation P3 version of Pakscan,

featuring increased information

capacity and improved user-

friendliness. The P3s enhanced

specification includes Ethernet

connectivity, a built-in secure web

server and the logging of host

messages, field unit commands

and status changes with time

synchronisation capability.

A new master station HMI (Human

Machine Interface) screen replaces

the text-only predecessor with clear,

easy-to-read icons to facilitate the

navigation of screen menus for

configuration of controls, alarms and

diagnostics. The new IQ actuators also

incorporate enhanced functionality

features as standard for improved

long term asset management. For

example, an integral data logger

stores historical operating data,

including the sequence of valve

torque profiles. This information can

be downloaded and analysed with

Rotorks PC-based IQ-Insight

software to establish predictive

maintenance schedules or identify

potential problems.

Valve actuation contract at

Worlds Largest Gas to Liquids Project

Instrument engineers from Reliance photographed during factory acceptance tests on

the first consignment of Pakscan P3 master stations to be shipped from Rotork Bath.

[

8

]

CONTRACT NEWS

Rotork Group contract news from around the world

Rotork Fluid System heavy duty pneumatic valve actuators have

been ordered for the first next generation upgrading plant for

the processing of bitumen and heavy oils.

Next generation

heavy oil upgrading

plant chooses Rotork

Customised solution at

the Copper Mine

Kennecott Utah Copper

has the largest open

pit copper mine in the

world, from where ore

containing just 0.6%

copper is blasted out,

crushed, concentrated,

smelted and refined to

produce 99.99% pure

copper metal.

Within this rugged industrial

process a number of existing

linear actuators were causing

problems with maintenance

and production in the

flotation cell area, where

the ore is mixed with water,

chemicals and air to produce

the 28% copper concentrate

which then goes on to be

smelted.

Rotork worked closely with

Kennecott Copper and

Industrial Solutions of Utah

to successfully replace the

problematic actuators with

custom-designed Rotork

linear pneumatic units, three

of which are pictured here.

Bitumen, which is obtained

from oil sands, and heavy oils

comprise the bulk of raw material

resources for the Canadian oil and

petroleum industries. They are

said to represent the future new or

incremental supply of crude oil for

the world and North America

in particular.

Canada has enormous resources of

these raw materials which are thick,

tar-like and extremely viscous,

making them difficult to transport

by pipeline and refine unless they

are first diluted and then upgraded

to remove contaminates.

Current upgraders in North

America, which are operating at

near-full capacity, use technologies

that are capital intensive and

attract high operating costs

according to BA Energy Inc, who

are constructing the Heartland

Upgrader at Strathcona County,

northeast of Edmonton in Alberta.

Described as a techno-economic

breakthrough, the Heartland

Upgrader utilises next generation

technology to upgrade bitumen

and heavy oil to synthetic crude

oils and other petroleum products

without the need for a hydrogen

production facility.

On the first phase of the project

Rotork is supplying CP and GP

range spring return actuators

mounted on Leusch trunnion

mounted ball valves in sizes up to

30 inches. The actuators will be

fitted on the valves and packaged

with control elements at Rotork

Fluid Systems regional Centre of

Excellence in Calgary.

Duties for the actuated valves

include diluted, desalted and

emulsified bitumen, sour

water, natural and sweep gas,

steam, warm de-aerated water,

asphaltene/water and the

intriguing sounding DRU stripper

bottoms! On completion of

Phase 1 in 2008 the Heartland

Upgrader will have a capacity of

up to 77,500 barrels per day of oil

sands bitumen blend, which will

rise to approximately 260,000

barrels per day when the upgrader

is fully expanded by 2013. The

project is being constructed by the

engineering partnership of Jacobs

Engineering Group Inc and Larsen

& Toubro Ltd.

Rotork enjoys a long association with the Canadian oil sands industry, with thousands

of actuators installed in numerous locations.

For more information on ROTALK articles and features contact Nicky Skinner at ROTORK Bath: +44(0)1225 733200 email: nichola.skinner@rotork.co.uk [

9

]

SKILMATIC UPDATE

Rotork Group contract news from around the world

28

Following the introduction of the SI range of intelligent electro-

hydraulic actuators, the demand for Skilmatic actuators is racing

ahead throughout the world. So much so that significant upgrades

to manufacturing capacity from order entry to final inspection

have been implemented at the UK Skilmatic factory in Leeds.

Strong Sales, Increased Capacity

New staff, including assembly

operators and an additional

contracts/production engineer,

have been employed whilst the

manufacturing facility has moved

to a newly refurbished building

area with more casting washing

and assembly space and segregated

service areas.

In addition, new tooling for the

sub-assembly and assembly areas

has been installed in order to

increase manufacturing capacity.

Finally, computerised function

and cycle testing has also been

introduced in order to reduce final

inspection times.

All in all, says Howard Slack,

Rotork Skilmatic Divisions Director,

we are making the upgrades

in order to achieve immediate

manufacturing improvements and

reductions to our delivery dates for

the Skilmatic SI actuator range.

we are making the upgrades in order

to achieve immediate manufacturing

improvements and reductions to our

delivery dates for the Skilmatic SI

actuator range.

Top: Work in progress on the new Skilmatic manufacturing plant.

Above: Manufacturing underway again

One recent Skilmatic SI contract is helping to improve the supply

of natural gas to the Republic of Ireland. The order, from Bord

Gais, was awarded to Rotorks agent in Ireland, Pegler and Louden

(BSS), who recommended the Skilmatic electro-hydraulic solution

as an improvement to the pneumatic actuators originally used

on the application.

Natural Gas in Ireland

Bord Gais is responsible for

the supply, transmission and

distribution of natural gas in

Ireland, 25% of which enters the

country through four gas metering

lines at the site where the Skilmatic

actuators are now installed.

Each metering line has been

equipped with two failsafe, spring-

return modulating Skilmatic

SIZL actuators, retrofitted on

existing CCI globe control valves.

The valves perform the critical

duty of controlling the gas flow

and pressure, so precise valve

positioning is vital. Each Skilmatic

SI-ZL350 actuator provides an

output torque of 8900 lbf through

a 300mm stroke length, with a

positional accuracy of more than

99.98%.

The actuators are certified for

hazardous area operation to

ATEX ll2G EExd llBT4. Installation

and commissioning was performed

by engineers from Exeeco APS

(Actuators, Projects & Service)

Division.

Two of the completed Skilmatic

actuator installations on the

Bord Gais project.

The actuators are

certified for hazardous

area operation to

ATEX ll2G EExd llBT4.

To further develop Rotorks

services in the areas of

maintenance, management and

upgrading of installed actuation

assets to ensure that we can fully

support and satisfy the increasing

demands from our customers on

a global basis.

Grant Wood - Director of the Site Services Division

[

10

]

SPOTLIGHT ON SITE SERVICES

Rotork Group Features from around the world

Rotork Site Services, the new projects, service and retrofit division,

is now active in 47 service centres in over 20 countries around

the world, with agents providing support services in another

55 countries, bringing the total number of expert technicians

supporting Rotork customers to well over 1,000.

At the launch of the division in 2006, director Grant Wood described

his aspirations for the new service as:

What does it

all mean?

Emergency and Planned Service:

Whatever the type of actuator, in all areas (including hazardous

environments), we will respond to customers requirements. Some

customers require guaranteed emergency response times, others

require planned response for all types of actuator work including:

installation, commissioning, upgrading, connection and installation of

bus communication systems, troubleshooting and repair of damaged or

deteriorating assets

Actuator Overhauls:

After a long service life some customers prefer their actuators to be

completely overhauled rather than replacing them with new ones. In

our workshops we completely strip and rebuild actuators, returning

them to their original state.

Shutdown Outages:

We can support customers in making sure that all their actuators are

fully operational and that they meet tight shutdown deadlines. For

example some power stations look for us to remove and overhaul

in our workshops over 200 actuators when taking a unit out for

maintenance. We do this, reinstall and commission the

actuators and where requested carry out additional actuation projects

simultaneously to ensure that customers make the most of their plant

shutdown time.

Health Checks:

Some customers lack detailed information on their assets, making it

difficult to prioritise maintenance and replacement investment. We

can carry out a detailed and intrusive inspection of the actuators and

combine this with build data from our own databases to give customers

a holistic view of their assets.

Preventative Maintenance:

Regular scheduled maintenance to enhance the integrity of actuators

and their associated valves. This service is typically sought by customers

looking to maximise the uptime of their plant.

Retrofitting actuators to existing valves:

We have a wealth of experience in fitting actuators to valves, penstocks

and dampers that are already installed as part of existing plant.

When asked to elaborate on how the service is actually tailored to meet the specific

needs of customers, Grant provided this comprehensive explanation:

[11] For more information on ROTALK articles and features contact Nicky Skinner at ROTORK Bath: +44(0)1225 733200 email: nichola.skinner@rotork.co.uk

28

Rotork Group Features from around the world

SPOTLIGHT ON SITE SERVICES

Whether customers are replacing obsolete actuators, changing power

sources or motorising manual valves we offer a tailor made solution to

meet customers specific requirements.

Factory fitting of actuators to new valves:

The careful assembly of valve and actuator is critical to ensure that an

automated valve performs correctly and reliably.

Whilst this service is often carried out by valve manufacturers, if there is

a need we can carry this out on a customers behalf.

Extended scope projects:

This is a growing requirement and some of our service teams have the

wide range of skills necessary to offer a one stop shop to automate

part or all of a customers process.

Our capabilities cover all of the installation phases (scoping, design,

procurement, manufacturing, installation, commissioning) on the

broad scopes that typically surround actuation projects.

Site Safety: Remote

Operated Shutoff

Valves (ROSoV)

Safety is one area where Site Services is increasingly active,

following the report into the Buncefield oil depot accident in

the UK at the end of 2005.

One of the immediate actions called for is the installation of

Remote Operated Shutoff Valves (ROSoV) to safeguard similar

sites. Rotork has therefore produced a ROSoV publication to

describe the actuation products and fire protection solutions

that are available for this critical duty through the services of

the Site Services Division.

Contact your nearest Rotork office to obtain a copy or

download it from www.rotork.com.

[

12

]

SITE SERVICES NEWS PRODUCT NEWS

Rotork Group product news from around the world Rotork Group contract news from around the world

When disposed of they blend

into the methane stream from

decomposing matter. Unless

they can be removed they render

the methane unusable for the

engines used in the biogas to

energy plants installed at landfill

and sewage treatment works.

The solution is to install specialised

filtration equipment to remove

these troublesome gases. PPTek,

a UK manufacturer of the filters,

recently supplied a system to

the Severn Trent Stoke Bardolph

Sewage Treatment Works in

Nottinghamshire, where engineers

from Exeeco successfully carried out

the installation. Martin Cheetham,

Exeeco Divisional Director explains:

Without any actuators involved,

this job was unusual for us and

enabled us to demonstrate our

extended capabilities on an

innovative solution to a process

problem that is common across

sewage gas and landfill gas power

generation systems throughout

the world.

Below: The PPTek siloxane removal plant installed by Exeeco at Severn Trent Stoke Bardolph STW.

The performance of Rotork Indonesia throughout

an actuator service contract at a petrochemical

plant has won a top award for Rotork Service

Engineer Dedi Supriadi.

Supervisors Award

for Rotork Indonesia

Siloxane removal -

another first for Exeeco

An unfortunate side effect of the replacement of CFC gases

in cosmetics, deodorants and other consumer products is the

damage to methane powered generating equipment in sewage

treatment plants caused by the Siloxanes that are now in

widespread use in these products.

The PT Chandra Asri plant is

situated at Cilegon in Banton,

approximately 120 kilometres west

of Jakarta. Built in 1997, the plant

is home to many Rotork actuators,

some of which required servicing

during a turn around, or outage, in

November 2006. Rotork Indonesia

received the inspection and service

contract for fourteen A Range

actuators mostly 70As installed

on Class 150 Friatec through-

conduit gate valves in sizes up to

48 inches located in the ethylene

plant. The successful completion of

the contract was marked by Dedis

selection as the best supervisor

from all fifteen maintenance

contracting companies involved in

the turn around, with top marks for

safety and zero lost time injuries.

Rotorks achievement was marked

by the award of a Certificate of

Commendation to Dedi at PT

Chandra Asris Jakarta offices in

February 2007.

Edi Supriadi is pictured at work with one of the actuators at Cilegon and with his

Certificate of Commendation awarded by PT Chandra Asri.

For more information on ROTALK articles and features contact Nicky Skinner at ROTORK Bath: +44(0)1225 733200 email: nichola.skinner@rotork.co.uk [

13

]

28

SITE SERVICES NEWS PRODUCT NEWS

Rotork Group product news from around the world Rotork Group contract news from around the world

Rotork IQPro electric actuators are now available with a Safety

Integrity Level (SIL) option for applications requiring SIL 2 and 3*.

With impending certification by TV, the SIL option can be

specified with any new IQ or IQT actuator or retrofitted to

existing actuators supplied since 2000.

SIL option for IQPro - TV approval imminent

Reliability has always been the

overriding priority for Rotork

electric actuator design and

manufacture, earning a reputation

that is unrivalled in the industry.

With the advent of standards to

quantify and achieve functional

safety in hazardous processes, the

reliability of equipment to perform

the required safety function must

now be ensured and defined with

auditable data.

Rotork has combined the inherent

design excellence of the IQ actuator

with the design and analysis

demands of IEC 61508 and IEC

61511 Standards to produce the

SIL option.

The Rotork SIL safety PCB

assembly monitors the standard

IQ/IQT control board and provides

diagnostic coverage and redundant

control in order to carry out the

desired safety function if an invalid

command signal is generated and/

or if the standard actuator control

system fails.

A safety function status relay

provides indication of the actuator

availability and redundant safety

function operation, with the same

status duplicated locally on the

actuator display.

Two safety functions

are available:

The Stayput function prevents

movement on a detected failure,

the actuator staying in its current

position. This is applicable to IQ

and IQT actuators.

The ESD (Emergency Shut Down)

function is selectable to move

fully closed, fully open or stayput.

This is applicable to IQ actuators

only. For more information or a

comprehensive description of SIL

options for Rotork electric or fluid

power actuators, contact

pete.hirst@rotork.co.uk.

*Where SIL3 is required, IQ Pro-SIL

may also provide coverage where 1 out

of 2 (1oo2) architecture is employed.

Actuators pass 7 day, 45 metre submersion test

Rotorks standard IP68 electric actuator enclosure is

designed to survive total submersion to a depth of 7

metres (23 feet) for 3 days, but recent test programme

has shown that it is capable of withstanding far worse

conditions for more than twice as long.

Above: Actuators positioned in test

chamber before the lid was attached.

Right: The IQT electrical housing and

terminal compartment, showing no signs

of damage after the test.

The test has confirmed the actuators

ability to survive for seven days whilst

submerged at a depth of 45 metres

(150 feet), conforming to the strict

standards of IPX8.

Performed at Rotorks R & D

department in Bath (no pun

intended!), the IPX8 test was

engineered by Rotork Houston with

the offshore oil platform, floating

production and storage industries

in mind. In these harsh operating

environments there is a risk of

extended periods of total submersion

at considerable depths and it is

important to know that the actuators

will still operate in these conditions.

Rotork IQT electric and Skilmatic

electro-hydraulic units were used in

the test, representing the types of

actuators often specified for electric

isolation and failsafe valve duties in

offshore and marine applications.

During the test the actuators were

remotely operated several times and

both types performed successfully

with no ingress of water into any

electrical housings.

[

14

]

FOCUS ON GEARBOXES

Rotork Group Features from around the world

Spotlight on Manual Gearboxes

Rotork manual gearboxes are

mostly manufactured at the

factory in Losser, which first

opened as Alecto in 1984, was

acquired by Rotork in 1998 and

became Rotork Gears BV in 2002.

The plant is one of five Rotork

Gears manufacturing centres,

the others being in the UK, USA,

Italy and China.

The main product line at Losser is

a range of worm gearboxes with a

maximum output torque of 32,000

Nm. The self-locking quarter-turn

design is suitable for ball, butterfly

and plug valves and manufactured

in a range of materials

encompassing aluminium, cast

iron and stainless steel. Gearboxes

are assembled from standard sub-

assemblies stocked at the factory

which are machined to meet the

In the first significant order of its kind for Rotork Valvekits,

the company is supplying sixty special low temperature duty

gearboxes to Bestobell Valves.

More subsea success

for Rotork Gears

In the latest of several recent

similar successes, Rotork

Gears has won subsea

gearbox orders for the KOC

crude oil export facilities

project in Kuwait.

The ability to meet critical delivery

schedules with top quality products

enabled Rotork Gears to fend off

fierce competition from European

manufacturers and secure the

contract, which is on one of the

largest and most prestigious oil sector

projects in the area.

Rotork Gears was selected by

valvemaker Velan Srl Italy to supply

Model WGS gearboxes. They are

mounted on Velan 56inch forged

steel, fully welded subsea trunnion

mounted full port Class 300 ball

valves.

The gearboxes are equipped with

pressure compensators, high

visibility T position indicators, direct

mounted ROV (remote operating

vehicle) inputs and stainless steel

handwheels with chain and clip for

emergency operation in the event of

ROV failure.

Rotork Valvekits wins LNG project order

The Model AB 1250W hand

operated gearboxes will be fitted

to Bestobell float level isolation

valves on LNG cargo carriers

under construction in Korean

shipyards. Valvekits has worked

closely with Bestobell to ensure

that the specifications and safety

levels demanded by this cryogenic

application have been adhered to

during contract discussions. As a

result of this success, further orders

for the Bestobell valves have now

been received as the ships owners

Qatargas have specified them for

their LNG fleet.

customers specification. Once

assembled, optional extras such

as switchboxes are fitted. Further

options include chainwheels,

square caps, padlocks and

extensions between the valve and

gearbox or between the gearbox

and its handwheel. The modular

approach to manufacture enables

the gear- boxes to be produced

with maximum speed and sold

at economical prices. In addition

to standard products, the factory

is also capable of manufacturing

special designs to meet specific

customer requirements. All

products undergo rigorous testing

and inspection routines prior to

shipment from the factory.

The workshop (below) photograph shows

an example of a large gearbox fitted to a

pneumatically actuated ball valve for a

customer in Germany.

[

15

]

CONTRACT NEWS

For more information on ROTALK articles and features contact Nicky Skinner at ROTORK Bath: +44(0)1225 733200 email: nichola.skinner@rotork.co.uk

Rotork Group contract news from around the world

The City of Fort Worth Water Departments Village Creek Wastewater Treatment

Plant serves more than 880,000 people and numerous industries in twenty-two

communities by treating up to 300 million gallons of wastewater each day.

The future is bright for Rotork at Fort Worth

28

Rotork Fluid Systems at Rochester

has supplied pneumatic and

gas-over-oil actuators to DHV

Industries for a project to build a

new gas pipeline in Vietnam.

The PM3 Ca Mau Pipeline is part

of the Gas Power Fertilizer Co-

ordination Project to supply natural

gas to an integrated power and

fertilizer plant in Ca Mau Province.

Originating on the Bunga Raya-B

(BR-B) platform in the Gulf of

Thailand the pipeline includes a 298

km subsea section, shore crossing

and landfall station, 27 km onshore

section with line block valves, gas

distribution station and supply

pipeline to the power and fertilizer

plant. The completed pipeline

is expected to have a maximum

capacity of 2 BCM (billion cubic

metres) of natural gas per annum.

Actuators for Vietnam pipeline

Rotork Fluid Systems is supplying

CP and GP range pneumatic

actuators for a new gas processing

facility in Egypt.

As part of the contract a HIPPS

(High Integrity Pressure Protection

Systems) test was successfully

performed on the GP actuators,

witnessed by a large contingent

from the valvemaker customer

CCI, including the companys vice

president Mr. Flavio Ricotti. The six

GP actuators subject to the HIPPS

test certification will operate Truflo

ball valves.

The remaining total of 170 GP and CP

actuators, supplied to LCM Italy, will

be installed in the production areas

of the new facility, which will boost

output at the Salam gas plant to 20

million cubic metres per day of gas

along with 66,000 barrels per day

of condensate.

The end user is Khalda Petroleum, a

joint venture between USA company

Apachi and Egyptian national

company EGPC. The plant, which is

being built by Egyptian construction

company Petrojet, is scheduled for

completion in 2008.

Egyptian contract includes HIPPS test

When Tim Allen became the

Departments I & E Manager a few

years ago his aim was to utilise

the best of breed valve actuator

across the district. At the time he

was wrestling with several different

manufacturers products in his

quest to standardise across the

board, so that all future upgrades

and additional processes would

incorporate first rate non-intrusive

technology. Rotorks Chris Carlisle

and Joe Etchegaray from local agent

FloTec worked hard to impress Tim

with the features of the Rotork

design and as a result, at the end

of a thorough technical evaluation

and bidding process, Rotork IQM

actuators were selected to replace a

competitors actuators coupled to

gearboxes on fourteen effluent filter

dump valve and two 96inch slide

gate valves in the contact basin. The

City paid a premium to ensure that

the technology met their demanding

specifications, but according to Jacob

Pena, I & E Supervisor at the plant,

this soon began to pay off during

the straight forward and efficient

installation and commissioning

programme. A team of four electrical

technicians were able to remove the

old actuators, install junction boxes,

rewire, mount and fully commission

nine Rotork actuators in a single

day. Jacob is convinced that he

couldnt have done this with any

other supplier.

Commissioning data was set up using

Rotork Insight software on Jacobs

PDA in his office and transmitted to

the actuators when the installation

work was completed. Jacob was

especially impressed with the ability

to dial in the torque and limit

settings. He also liked the fact that

he could set the number of turns to

close and open, which he says is not

available from other manufacturers.

Both Tim and Jacob agreed that

having reference footprint valve

torque profiles and the ability

to download actuator and valve

operating data on a routine basis

will be used to make preventative

maintenance decisions and

become an integral part of the

plants maintenance management

programme. All in all, the staff is

extremely satisfied with Rotork

technology.

So much so that a competitors

working demonstration unit, which

includes the manufacturers latest

non-intrusive setting and data

extraction features, is to be removed

from the facility and replaced with a

Rotork IQTM.

They say that Rotork Insight software

has no match with its sequential

event management and torque

profiles which provide very useful

data that is easy to interpret. For

the future the plan is to upgrade the

actuators in several more areas with

Rotork IQs, including the rest of the

fitter dump valves, digesters, aeration

basin, sludge valves and offsite pump

stations. The Village Creek facility

alone has more than five hundred

MOVs that will eventually retrofitted

with Rotork actuators as the budgets

become available.

Pneumatic and gas-over-oil actuators bound for Vietnam at the DHV factory.

PEOPLE NEWS

[16]

UK head office

Rotork Controls Limited, Bath

tel 01225 733200

fax 01225 333467

mail@rotork.co.uk

USA head office

Rotork Controls Inc, Rochester

tel (585) 247 2304

fax (585) 247 2308

info@rotork.com

Rotalk is published and printed by

Rotork Controls Ltd. in the UK.

For more information on ROTALK articles and features contact Nicky Skinner at ROTORK Bath: +44(0)1225 733200 email: nichola.skinner@rotork.co.uk

28

Peter France appointed

Group Chief Operating Officer

From 1st October 2007

the Rotork Group will have

a new Chief Operating

Officer in the person of

Peter France. Peter (39) is

currently Managing Director

of Rotork Fluid Systems and

a Director of Rotork p.l.c.

Born in Rotorks home city of Bath,

Peter joined the company in 1989.

His career has encompassed UK

and international sales, service and

management duties for the electric

and fluid power actuator divisions

including the position of Director

and General Manager for South East

Asia during a time of rapid

expansion throughout the area

in the late 1990s.

Pictured on the Larsen & Toubro

stand at ADIPEC, this IQ Pro actuator

and AUDCO ball valve is one of the

many that have been ordered for

the Inter Refinery Pipeline Project,

where Rotork is supplying over 500

of the latest version Pakscan-enabled

IQ actuator with eight Pakscan hot-

standby master stations.

The new pipeline will link the

refineries at Sas-Al-Nakl and Ruwais

in the UAE, eliminating the current

need to transport products between

the sites by marine tankers, easing

shipping congestion in the busy

Umm Al Nar Channel and improving

environmental protection.

Pipeline IQ actuators

These finely honed athletes are a cycle team

sponsored by Rotork for a series of races, who

will raise company and product awareness

throughout the country whilst participating in

a sport that is rapidly growing in South Africa.

The idea was the brainchild of Rotork

salesman Kevin Froneman, who will be

travelling with the team and drumming up

business at the events.

Rotorks Reps get

on their bikes in

South Africa

DHV Industries manufacture gate,

globe, check, ball, wellhead and choke

valves at Bakersfield in California.

Their stand at the 2007 OTC Houston

show featured this trunnion mounted

pipeline ball valve fitted with a Rotork

spring-return pneumatic actuator.

Pictured with the exhibit are (left

to right): Ron Fortner DHV Sales

Manager, Eric Lingle DHV Vice

President and Sam Lingle DHV

Marketing & Sales Director.

At OTC Houston

At the same event the ASME

(American Society of Mechanical

Engineers) Offshore Technology

Golf Tournament has earned the

reputation of being one of the

premier events and has been a

sell-out for several years.

This year Rotork Fluid Systems

teamed up with their new distributor

in the Texas Gulf Coast area,

Equipment Valve & Supply Inc.,

to provide breakfast for the

participating golfers.

Pictured (left to right): Leo LaBorde-RFS,

John Nicholas and Jack Lee from Equipment

Valve & Supply and Charles Reaves RFS.

As the Managing Director of

Rotork Fluid Systems since 2001,

Peter has shaped the extensive

growth of the Division,

which now accounts for a

significant proportion of Rotorks

worldwide sales.

L to R: Candice Da Cunha (Marouns Autos), Kevin

Froneman (Rotork), Mannny Da Costa (Pro United

Contractors), Lorn Swart (One Time Airlines), Gert

Engelbrecht (Paltechnologies)

Rotorks Ashley Watkins is pictured on the exhibition stand with Mr. M. Marriappan,

Manager of Project Sales Europe and Middle East, Larsen & Tubro, India.

Anda mungkin juga menyukai

- Servitization and Physical Asset ManagementDari EverandServitization and Physical Asset ManagementPenilaian: 1 dari 5 bintang1/5 (1)

- Machines, Tools and Methods of Automobile ManufactureDari EverandMachines, Tools and Methods of Automobile ManufacturePenilaian: 4 dari 5 bintang4/5 (1)

- Spotlight On Fluid Systems: Also InsideDokumen16 halamanSpotlight On Fluid Systems: Also InsideIñaki EseberriBelum ada peringkat

- Rotork Controls The Flow at Thames Water's Flagship Project: Also in This Issue..Dokumen16 halamanRotork Controls The Flow at Thames Water's Flagship Project: Also in This Issue..Iñaki EseberriBelum ada peringkat

- Rotork Is One-Stop For Storage Tank Expansion Project: Actuation Shop'Dokumen24 halamanRotork Is One-Stop For Storage Tank Expansion Project: Actuation Shop'Iñaki EseberriBelum ada peringkat

- Introducing:: Pakscan P3 A New Evolution..Dokumen20 halamanIntroducing:: Pakscan P3 A New Evolution..Iñaki EseberriBelum ada peringkat

- Focus On Rotork Site Services: Also InsideDokumen20 halamanFocus On Rotork Site Services: Also InsideIñaki EseberriBelum ada peringkat

- Focus Autumn04Dokumen15 halamanFocus Autumn04seajoemathewBelum ada peringkat

- Also Inside:: Cva Heralds New Age of Electric Actuation For Process Control ValvesDokumen20 halamanAlso Inside:: Cva Heralds New Age of Electric Actuation For Process Control ValvesIñaki EseberriBelum ada peringkat

- Rotork's Complete Global Offering - .Dokumen12 halamanRotork's Complete Global Offering - .Iñaki EseberriBelum ada peringkat

- RolleChim SRL Presentation 2015Dokumen10 halamanRolleChim SRL Presentation 2015Gargiulo AnitaBelum ada peringkat

- Chemical Engineering - 2010-04 (April)Dokumen100 halamanChemical Engineering - 2010-04 (April)Staszek BanachBelum ada peringkat

- HDPE الوسايلDokumen151 halamanHDPE الوسايلMohamed ElarabiBelum ada peringkat

- Rotek 84pgcat FINAL ViewOnly Swing Bearning1Dokumen82 halamanRotek 84pgcat FINAL ViewOnly Swing Bearning1dsnsarmaBelum ada peringkat

- National Oilwell Varco, in - SEC Filing 10KDokumen116 halamanNational Oilwell Varco, in - SEC Filing 10Kcaballero_tigreBelum ada peringkat

- ProjectDokumen84 halamanProjectgnikhilreddy2Belum ada peringkat

- Final Case of Voltas ACDokumen27 halamanFinal Case of Voltas ACMonica Yadav100% (1)

- FEW Industrial Visit ReportDokumen11 halamanFEW Industrial Visit ReportMathew JosephBelum ada peringkat

- Zeeco FlareDokumen70 halamanZeeco Flaredr.c.is.dr.c50% (2)

- April 2013Dokumen86 halamanApril 2013montoyazumaetaBelum ada peringkat

- Score Energy Tech Day: Midas MeterDokumen10 halamanScore Energy Tech Day: Midas MeterisukuruBelum ada peringkat

- b2b Project On Larsen ToubroDokumen31 halamanb2b Project On Larsen ToubroAnand VyasBelum ada peringkat

- About Littelfuse: From Wikipedia, The Free Encyclopedia Littelfuse, IncDokumen9 halamanAbout Littelfuse: From Wikipedia, The Free Encyclopedia Littelfuse, IncSimply AbstractedBelum ada peringkat

- IPIP PresentationDokumen16 halamanIPIP Presentationvioflorex4Belum ada peringkat

- JPT SpeDokumen140 halamanJPT SpeZenga Harsya PrakarsaBelum ada peringkat

- Global Coating Catalogue 2014Dokumen64 halamanGlobal Coating Catalogue 2014Siniša Švoger100% (1)

- 1440 - Magazine Chemical Engineering October 2012Dokumen76 halaman1440 - Magazine Chemical Engineering October 2012gh_ali110Belum ada peringkat

- 1.1 The ProjectDokumen62 halaman1.1 The ProjectDrw ArcyBelum ada peringkat

- Catalogo de Productos GeneralDokumen48 halamanCatalogo de Productos GeneraljosempincBelum ada peringkat

- Hydro Power Solutions Alstom 2012Dokumen20 halamanHydro Power Solutions Alstom 2012MarcWorldBelum ada peringkat

- Tech Universal UK Pre-Qualification UpdatedDokumen60 halamanTech Universal UK Pre-Qualification Updatedalang_businessBelum ada peringkat

- B2B Project On LARSEN & TOUBRO It's All About ImagineeringDokumen28 halamanB2B Project On LARSEN & TOUBRO It's All About ImagineeringlanceklusenerBelum ada peringkat

- Katalog Controls 2005Dokumen474 halamanKatalog Controls 2005mdananic0% (2)

- WP Magazine 1 2016Dokumen19 halamanWP Magazine 1 2016Anonymous M0OEZEKoGiBelum ada peringkat

- Modern Pumping TodayDokumen76 halamanModern Pumping Todayanjangandak2932Belum ada peringkat

- Bhel Mini Pro Report On Turbo Generators 1Dokumen53 halamanBhel Mini Pro Report On Turbo Generators 1Akirakumar100% (1)

- CheIng - June 2010 PDFDokumen68 halamanCheIng - June 2010 PDFErvin WatzlawekBelum ada peringkat

- CTHBDokumen543 halamanCTHBJose AcostaBelum ada peringkat

- Chemical Engineering Plant Cost Index Ei 201102Dokumen6 halamanChemical Engineering Plant Cost Index Ei 201102Ahmad AlbetarBelum ada peringkat

- Focus Autumn2005Dokumen32 halamanFocus Autumn2005seajoemathewBelum ada peringkat

- Wipro Infrastructure EngineeringDokumen9 halamanWipro Infrastructure EngineeringSoumitra Mistified BanerjeeBelum ada peringkat

- b2b Project On Larsen & ToubroDokumen27 halamanb2b Project On Larsen & ToubroGaurav Kumar0% (1)

- Ravi Bhel ReportDokumen33 halamanRavi Bhel ReportPayal SinghBelum ada peringkat

- Fores GroupDokumen5 halamanFores GrouppnaronaBelum ada peringkat

- Hotchkiss Group 2010 BrochureDokumen6 halamanHotchkiss Group 2010 BrochureGiải Pháp Cơ ĐiệnBelum ada peringkat

- CatalogDokumen44 halamanCatalogRibhi HamdanBelum ada peringkat

- Marketing VoltasDokumen31 halamanMarketing VoltasNiraj Kumar100% (1)

- Marine Propeller Shaft PowerDokumen26 halamanMarine Propeller Shaft PowerJuniorJavier Olivo FarreraBelum ada peringkat

- Cryowrap Pyrowrap Catalog 294.compressed 315Dokumen116 halamanCryowrap Pyrowrap Catalog 294.compressed 315pipestressBelum ada peringkat

- SHK ValveDokumen4 halamanSHK ValveMuthu Kumar RBelum ada peringkat

- Sludge Proposal CompleteDokumen97 halamanSludge Proposal CompleteRccg DestinySanctuaryBelum ada peringkat

- HP May 2014Dokumen115 halamanHP May 2014John UrdanetaBelum ada peringkat

- Intelligent Digital Oil and Gas Fields: Concepts, Collaboration, and Right-Time DecisionsDari EverandIntelligent Digital Oil and Gas Fields: Concepts, Collaboration, and Right-Time DecisionsPenilaian: 4.5 dari 5 bintang4.5/5 (5)

- Contracts, Biddings and Tender:Rule of ThumbDari EverandContracts, Biddings and Tender:Rule of ThumbPenilaian: 5 dari 5 bintang5/5 (1)

- ARM-based Microcontroller Projects Using mbedDari EverandARM-based Microcontroller Projects Using mbedPenilaian: 5 dari 5 bintang5/5 (2)

- Business Ecosystems: Constructs, Configurations, and the Nurturing ProcessDari EverandBusiness Ecosystems: Constructs, Configurations, and the Nurturing ProcessBelum ada peringkat

- Project Management For Procurement Management ModuleDari EverandProject Management For Procurement Management ModuleBelum ada peringkat

- Process Intensification: Engineering for Efficiency, Sustainability and FlexibilityDari EverandProcess Intensification: Engineering for Efficiency, Sustainability and FlexibilityBelum ada peringkat

- Engineering Applications: A Project Resource BookDari EverandEngineering Applications: A Project Resource BookPenilaian: 2.5 dari 5 bintang2.5/5 (1)

- Instrumentationandcontrol.netDokumen1 halamanInstrumentationandcontrol.netIñaki EseberriBelum ada peringkat

- Instrumentation Switch ChecklistDokumen9 halamanInstrumentation Switch ChecklistIñaki EseberriBelum ada peringkat

- General Chemical Resistance Guide: Corrosion Test DataDokumen6 halamanGeneral Chemical Resistance Guide: Corrosion Test DataIñaki EseberriBelum ada peringkat

- Example Calculation SheetDokumen1 halamanExample Calculation SheetIñaki EseberriBelum ada peringkat

- 35011501-05 enDokumen1 halaman35011501-05 enIñaki EseberriBelum ada peringkat

- SamsonDokumen2 halamanSamsonIñaki EseberriBelum ada peringkat

- Legal Implications For Companies and Individuals Under "Industrial ManslaughterDokumen2 halamanLegal Implications For Companies and Individuals Under "Industrial ManslaughterIñaki EseberriBelum ada peringkat

- Module 7 Temperature MeasurementDokumen84 halamanModule 7 Temperature MeasurementIñaki EseberriBelum ada peringkat

- Process Safety Concerns Can Arise When Using Refurbished or New-Surplus EquipmentDokumen8 halamanProcess Safety Concerns Can Arise When Using Refurbished or New-Surplus EquipmentIñaki EseberriBelum ada peringkat

- Using PIDokumen4 halamanUsing PIIñaki EseberriBelum ada peringkat

- Certificado Siemens 115Dokumen3 halamanCertificado Siemens 115Iñaki EseberriBelum ada peringkat

- Innovative Flow Control Technologies Assist: Australia's Programme For Clean LNGDokumen24 halamanInnovative Flow Control Technologies Assist: Australia's Programme For Clean LNGIñaki EseberriBelum ada peringkat

- Rotork Invests in The Future: Nuclear Power GenerationDokumen12 halamanRotork Invests in The Future: Nuclear Power GenerationIñaki EseberriBelum ada peringkat

- 1st Quarter 2016 Lesson 5 Powerpoint With Tagalog NotesDokumen25 halaman1st Quarter 2016 Lesson 5 Powerpoint With Tagalog NotesRitchie FamarinBelum ada peringkat

- New York LifeDokumen38 halamanNew York LifeDaniel SineusBelum ada peringkat

- Assignment Brief - Starting A Business and Fundamental of MarketingDokumen7 halamanAssignment Brief - Starting A Business and Fundamental of Marketingmd rahimBelum ada peringkat

- CESC Performance Task Quarter 1Dokumen3 halamanCESC Performance Task Quarter 1MarinaM.CubiaBelum ada peringkat

- Erp FinalDokumen33 halamanErp FinaltenetchatBelum ada peringkat

- UBO - Lecture 07 - Implementing and Managing Organisational ChangeDokumen0 halamanUBO - Lecture 07 - Implementing and Managing Organisational ChangeShahNooraniITBelum ada peringkat

- Active and Inactive Volcano LPDokumen2 halamanActive and Inactive Volcano LPhorace hernandez100% (5)

- Data Sheet For T-8101.RevCDokumen5 halamanData Sheet For T-8101.RevCSuresh SjBelum ada peringkat

- Minuto hd8761Dokumen64 halamanMinuto hd8761Eugen Vicentiu StricatuBelum ada peringkat

- Critical Health Concerns in The 21st CenturyDokumen4 halamanCritical Health Concerns in The 21st CenturykelleybrawnBelum ada peringkat

- MikroekonomiDokumen1 halamanMikroekonomiYudhaPrakosoIIBelum ada peringkat

- SOP For Production DepartmentDokumen5 halamanSOP For Production DepartmentDaniel SusantoBelum ada peringkat

- Compuware DCRUM Intro 2012 Version 12.00Dokumen142 halamanCompuware DCRUM Intro 2012 Version 12.00JanBelum ada peringkat

- Fire and IceDokumen11 halamanFire and IcelatishabasilBelum ada peringkat

- A A ADokumen5 halamanA A ASalvador__DaliBelum ada peringkat

- Pay Scale WorkshopDokumen5 halamanPay Scale WorkshopIbraBelum ada peringkat

- Chapter 7 Integration Testing PDFDokumen74 halamanChapter 7 Integration Testing PDFebrgsrtBelum ada peringkat

- Nursing Care Plan Diabetes Mellitus Type 1Dokumen2 halamanNursing Care Plan Diabetes Mellitus Type 1deric85% (46)

- Adobe Scan 23-Feb-2024Dokumen4 halamanAdobe Scan 23-Feb-2024muzwalimub4104Belum ada peringkat

- Designing The Workplace For CollaborationDokumen17 halamanDesigning The Workplace For Collaborationmas zak danielBelum ada peringkat

- Resume Pet A Sol LanderDokumen3 halamanResume Pet A Sol LanderdreyesfinuliarBelum ada peringkat

- Evelyn Arizpe - Teresa Colomer - Carmen Martínez-Roldán - Visual Journeys Through Wordless Narratives - An International Inquiry With Immigrant Children and The Arrival-Bloomsbury Academic (2014)Dokumen290 halamanEvelyn Arizpe - Teresa Colomer - Carmen Martínez-Roldán - Visual Journeys Through Wordless Narratives - An International Inquiry With Immigrant Children and The Arrival-Bloomsbury Academic (2014)Lucia QuirogaBelum ada peringkat

- Mechatronics MaterialDokumen86 halamanMechatronics MaterialKota Tarun ReddyBelum ada peringkat

- Module 1 Learning PrinciplesDokumen2 halamanModule 1 Learning PrinciplesAngela Agonos100% (1)

- VukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedDokumen19 halamanVukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedputhenkulamBelum ada peringkat

- Theories of GrowthDokumen33 halamanTheories of Growthdr parveen bathlaBelum ada peringkat

- 100 IELTS Essay Topics For IELTS Writing - My IELTS Classroom BlogDokumen16 halaman100 IELTS Essay Topics For IELTS Writing - My IELTS Classroom BlogtestBelum ada peringkat

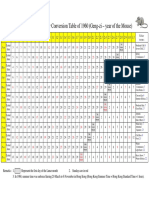

- Gregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Dokumen1 halamanGregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Anomali SahamBelum ada peringkat

- New Arrivals 17 - 08 - 2021Dokumen16 halamanNew Arrivals 17 - 08 - 2021polar necksonBelum ada peringkat

- 0 - Danica Joy v. RallecaDokumen2 halaman0 - Danica Joy v. RallecaRandy Jake Calizo BaluscangBelum ada peringkat