Risk Asses 41-Blasting and Painting Control

Diunggah oleh

Rochdi Bahiri100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

1K tayangan3 halamanHak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

1K tayangan3 halamanRisk Asses 41-Blasting and Painting Control

Diunggah oleh

Rochdi BahiriHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

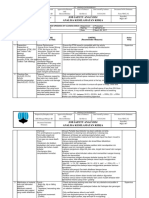

RISK ASSESSMENT FORM

Location: Terga Date of Assessment: 17-01-2010 Assessment No: 041

Assessor(s): FRIDI.ALI System/Activity: BALASTING AND PAINTING CONTROL

P

r

o

b

a

b

i

l

i

t

y

&

F

r

e

q

u

e

n

c

y

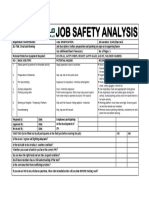

Definite 5 5 10 15 20

High 4 4 8 12 16

Moderate 3 3 6 9 12

Low 2 2 4 6 8

Negligable 1 1 2 3 4

1 2 3 4

Minor Serious Major Catastrophic

Severity

Key to Priorities

Medium Priority (5 days) High Priority (2-3 days) Immediate

Hazards Identified (include the exposed groups)

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date Action

Completed

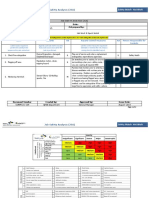

Collapse of Material:

Compressor

reversal of the machine

Injury following the bursting of a supply hose

or the explosion of the air tank.

Projected hose or fitting loose or in poor

condition

Projections by flushing air in the purge.

4 3 12 Control the good function of the sand blast

machine

Put the machine on flat soil

Check that equipment is good condition

before the work begins, especially fittings

and hoses

Purge hoses before connecting to the tool.

To ensure that nobody is on the path of the

blast.

Close the air supply before connecting or

disconnecting the hose

Calibrate the right pressure to the specific

tack of blasting (6-8 bars)

Drain the tank after each return to work to

avoid condensation

2 2 4

Electrocution 4 3 12 Verification of electric cables before the start

of work by an electrician

2 2 4

RISK ASSESSMENT FORM

Hazards Identified (include the exposed groups)

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date Action

Completed

Lance projection

Burst of piping

4 3 12

check before start of the operation the state

of the pipe and fitting quality fittings by the

operator and regular maintenance should be

scheduled

Provide and verify the connection of the pipe

before the operation

2 2 4

Fire extinguisher 3 3 9 Site emergency plan to be followed in event

fire or explosion.

All personnel to be inducted and aware of

emergency procedures.

Installation of fire extinguishers near

electrical installations.

2 3 6

Release of dust and flying particles 3 3 9 Provide protections eye, mouthwash, eye,

breathing mask with cartridge and dry suit

prohibit the movement of people around the

activities

2 3 6

Projection of fragments of material in the eye 3 3 9 All personnel to wear appropriate PPE at all

time

Use suitable break system protection to

avoid risk silicosis

2 3 6

Eyes and ear protection 3 3 9 eyewear protection 2 3 6

risk of joint injuries of the elbow and wrist

associated with the vibration of the machine

3 3 9 Do not work continuously with the device. It

is better to take turns to reduce exposure to

noise and vibration

2 3 6

noise 3 3 9 It is essential that the operator is equipped

with hearing protection mitigating noise and

co-workers nearby

2 3 6

Waste management

Environment pollution from waste material

and leakage

2 4 8 Waste and debris must be collected at the

As and evacuated

2 2 4

RISK ASSESSMENT FORM

Hazards Identified (include the exposed groups)

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date Action

Completed

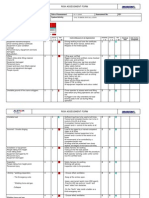

Painting

Attack by chemical agents

Contact with the skin (irritation, burning)

Inhaling

Screening

4 4 16 protection of the operator with appropriate

PPE:

Drysuit and gloves

Breathing mask with cartridge protective

against gas or vapor and dust hood

supplied air

Goggles or visor

2 3 6

Spray equipment under high pressure 4 3 12 Before use check the proper functioning of

the device

2 2 4

Compressor:

Exhaust (CO)

Risk of electrocution: static electricity

produced by the movement of the paint

4 3 12

The compressor must be in an open

space

Verifying a grounding before beginning

the work of all components of the device

and the container of paint

Verification of Electrical son before

operating the device

2 3 6

Flexible:

Destruction or burst hoses

4 3 12

Check before beginning work for the

proper functioning of the manometer

The hose must be adapted to the

chemical component of paint and

pressure spray equipment

2 2 4

Pistol:

Risk of perforation of the skin by

painting at high pressure

Risk of jamming of the nozzle with

fingers

4 4 16 The pistol must be equipped with:

System blocking the trigger

Avoid all contact of the hand with the

nozzle

2 2 4

Assessor Print : Sign: Date:

Anda mungkin juga menyukai

- Risk Asses 65-Piping Fabricated and Assembly - H03Dokumen11 halamanRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriBelum ada peringkat

- Risk Assessment For Sand BlastingDokumen8 halamanRisk Assessment For Sand BlastingRochdi Bahiri71% (17)

- Manual Tig Welding (RRC) - Job ProcedureDokumen3 halamanManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Jsa Grinding Welding Gas CuttingDokumen3 halamanJsa Grinding Welding Gas CuttingRyanBelum ada peringkat

- Risk Assesment For Sand Blasting and PaintingDokumen6 halamanRisk Assesment For Sand Blasting and PaintingRochdi Bahiri100% (10)

- Jsa For Ut TestDokumen2 halamanJsa For Ut Testnasar_mahsood50% (2)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDokumen2 halamanJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelBelum ada peringkat

- JSA For Painting Works-Hazards ControlDokumen4 halamanJSA For Painting Works-Hazards Controlkaleem0% (2)

- Visitors Safety InductionDokumen1 halamanVisitors Safety InductionCaptain100% (1)

- Jsa Confined SpaceDokumen4 halamanJsa Confined Spacearunmiranda100% (4)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Dokumen6 halamanJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganBelum ada peringkat

- JSA FOR Concerate PlacementDokumen1 halamanJSA FOR Concerate Placementwahyu nugrohoBelum ada peringkat

- Jsa For Cutting, Grinding and Welding For GulfconDokumen3 halamanJsa For Cutting, Grinding and Welding For GulfconOgunwa Emmanuel100% (1)

- #15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsDokumen14 halaman#15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsSathish Insmile100% (1)

- Bgps H Jsa 008 Jsa Confined SpaceDokumen4 halamanBgps H Jsa 008 Jsa Confined SpaceBuddy EkoBelum ada peringkat

- Job Safety Analysis: Job Title: Installing Pneumatic Rubber FenderDokumen3 halamanJob Safety Analysis: Job Title: Installing Pneumatic Rubber FenderIhwan AsrulBelum ada peringkat

- JSA Earthpit Construction GeneralDokumen4 halamanJSA Earthpit Construction Generalmukka88Belum ada peringkat

- JSA Machinal PipingDokumen7 halamanJSA Machinal PipingNaitik Desai48100% (1)

- 4..pipe Spool Air Blowing & Cleaning JSA 04Dokumen2 halaman4..pipe Spool Air Blowing & Cleaning JSA 04Francis Vinoj100% (1)

- HIRA - Night Work Hazard ControlDokumen3 halamanHIRA - Night Work Hazard ControlHiralal PattanayakBelum ada peringkat

- JSA of Glass FixingDokumen5 halamanJSA of Glass FixingPAVANKUMAR50% (2)

- Copy (2) of JSA For Removal of MS Sheet For E&P ShedDokumen12 halamanCopy (2) of JSA For Removal of MS Sheet For E&P Shedmidozoty50% (2)

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDokumen2 halamanJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- MTA2018-JHA-012 Air Compressor OperationDokumen10 halamanMTA2018-JHA-012 Air Compressor OperationKelvin TanBelum ada peringkat

- JSA Demolition Wall B#3Dokumen2 halamanJSA Demolition Wall B#3tit somm100% (3)

- JSA PaintingDokumen1 halamanJSA PaintingjonesBelum ada peringkat

- ULSADO-JSA - Installation of Temporary Fence GateDokumen2 halamanULSADO-JSA - Installation of Temporary Fence GateKelvin TanBelum ada peringkat

- Job Safety Analysis MDC Cylinder ReplacementDokumen2 halamanJob Safety Analysis MDC Cylinder ReplacementMaxi Pro100% (2)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDokumen5 halamanJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANBelum ada peringkat

- Safra PineDokumen3 halamanSafra PineTanzeel Liaqat100% (4)

- Jsa For Drilling.Dokumen3 halamanJsa For Drilling.Belsyah Nofriyan75% (4)

- 005 HIRARC Hollow Core Slab InstallationDokumen5 halaman005 HIRARC Hollow Core Slab Installationbdiey100% (4)

- Ultratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSADokumen5 halamanUltratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSATFattah100% (1)

- Barbending HiracDokumen2 halamanBarbending HiracJohn Ha71% (7)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDokumen4 halamanJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Job Safety Analysis Sheet: FacilityDokumen1 halamanJob Safety Analysis Sheet: Facilitywahyu nugrohoBelum ada peringkat

- JHA For Blasting Painting Works FinalDokumen7 halamanJHA For Blasting Painting Works Finalrosevelvet50% (10)

- 30 - Turfing WorksDokumen1 halaman30 - Turfing WorksRafee Pie100% (1)

- Jsa For Civil Confined Space EntryDokumen11 halamanJsa For Civil Confined Space EntryKhuda BukshBelum ada peringkat

- JHA For Installation of Boiler AccessoriesDokumen2 halamanJHA For Installation of Boiler Accessoriesperquino oasan100% (3)

- Jsa Grit BlastingDokumen2 halamanJsa Grit BlastingHenryOdoh100% (3)

- SOP Excavation and PermittingDokumen4 halamanSOP Excavation and PermittingTengku & Wan ResourcesBelum ada peringkat

- Jsa Welding Cutting and Grinding at Closing AreaDokumen7 halamanJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (2)

- Manual Excavation JSADokumen1 halamanManual Excavation JSATausif Khan100% (2)

- JHA PlumberDokumen3 halamanJHA PlumberEko Susanto100% (1)

- JHA 08 On Erection of Roofing SheetsDokumen3 halamanJHA 08 On Erection of Roofing SheetsAkhilesh KumarBelum ada peringkat

- Jsa For Piping and Erection RevisedDokumen1 halamanJsa For Piping and Erection RevisedDr AnwarBelum ada peringkat

- Method Statement For Hot WorkDokumen1 halamanMethod Statement For Hot WorkDark FantasyBelum ada peringkat

- Fencing, Installation and Repair.: Activity DescriptionDokumen6 halamanFencing, Installation and Repair.: Activity DescriptionVictorBelum ada peringkat

- JOB SAFETY ANALYSIS - Structural PaintingDokumen1 halamanJOB SAFETY ANALYSIS - Structural PaintingSajith C PauloseBelum ada peringkat

- RMDJV Pj74 Hiradc Misc 01 (Housekeeping)Dokumen2 halamanRMDJV Pj74 Hiradc Misc 01 (Housekeeping)myn maliQueBelum ada peringkat

- JSA-020-Safety Watch-Hot WorkDokumen2 halamanJSA-020-Safety Watch-Hot WorkNishad MuhammedBelum ada peringkat

- Job Safety AnalysisDokumen4 halamanJob Safety AnalysisDedi Apriadi71% (7)

- Vehicular Movement Job Safety Analysis (JSA)Dokumen2 halamanVehicular Movement Job Safety Analysis (JSA)sudam kumar raut100% (2)

- 01 JSA For Earthworks at Corridor ADokumen32 halaman01 JSA For Earthworks at Corridor AHilbrecht De Pedro100% (1)

- Risk Asses 53-GPR Fitting AssemblyDokumen6 halamanRisk Asses 53-GPR Fitting AssemblyRochdi BahiriBelum ada peringkat

- Assessment No 47 Demolition Basin E40Dokumen4 halamanAssessment No 47 Demolition Basin E40Rochdi Bahiri0% (1)

- RISK ASSES-82 - Installation of Condenser Unit 2Dokumen8 halamanRISK ASSES-82 - Installation of Condenser Unit 2Rochdi BahiriBelum ada peringkat

- Jsa 2Dokumen5 halamanJsa 2Muddassir Baig MirzaBelum ada peringkat

- RISK ASSE 110 - Fire Fighting System - F03Dokumen8 halamanRISK ASSE 110 - Fire Fighting System - F03Rochdi BahiriBelum ada peringkat

- Risk Asses23 - Generator RotorDokumen3 halamanRisk Asses23 - Generator RotorRochdi BahiriBelum ada peringkat

- Hawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsDokumen4 halamanHawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsRochdi BahiriBelum ada peringkat

- Audit of Power Purchase AgreementsDokumen6 halamanAudit of Power Purchase AgreementsRochdi BahiriBelum ada peringkat

- TSA Appendices State - 16 09 2014 - WPDokumen24.221 halamanTSA Appendices State - 16 09 2014 - WPRochdi BahiriBelum ada peringkat

- Wmu 2013 - PPT - FinalDokumen103 halamanWmu 2013 - PPT - FinalRochdi BahiriBelum ada peringkat

- Risk Asses23 - Generator RotorDokumen3 halamanRisk Asses23 - Generator RotorRochdi BahiriBelum ada peringkat

- Risk Assesment 16 - Pre - Assembly and Erection ofDokumen7 halamanRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriBelum ada peringkat

- RISK ASSES-106-Erection of Steel Structure BuildinDokumen4 halamanRISK ASSES-106-Erection of Steel Structure BuildinRochdi Bahiri50% (2)

- Risk Asses 21-Gaz Turbine InstallationDokumen6 halamanRisk Asses 21-Gaz Turbine InstallationRochdi Bahiri100% (1)

- Risk Assess - 98-Installation Fuel Oil ConditioniDokumen4 halamanRisk Assess - 98-Installation Fuel Oil ConditioniRochdi BahiriBelum ada peringkat

- Risk Asses23 - Generator RotorDokumen3 halamanRisk Asses23 - Generator RotorRochdi BahiriBelum ada peringkat

- Dagupan SDRMPDokumen34 halamanDagupan SDRMPJohn Clyde Andres CagaananBelum ada peringkat

- Determination of Modification Factor R For Seismic Design of Pressure Vessels Using ASME and EurocodesDokumen11 halamanDetermination of Modification Factor R For Seismic Design of Pressure Vessels Using ASME and Eurocodesoscargon19Belum ada peringkat

- Seismic Retrofitting of Existing StructuresDokumen111 halamanSeismic Retrofitting of Existing StructuresrealchicBelum ada peringkat

- Public Safety InteroperabilityDokumen4 halamanPublic Safety InteroperabilityCoCo Communications Corp.Belum ada peringkat

- El Nino-La NinaDokumen63 halamanEl Nino-La NinaHimangshu BoraBelum ada peringkat

- English - DPP Haor Risk Management Main PartDokumen10 halamanEnglish - DPP Haor Risk Management Main PartShadman ShakibBelum ada peringkat

- Risk Assessment and Forecast MumbaiDokumen8 halamanRisk Assessment and Forecast MumbaihariluvsuBelum ada peringkat

- The Humid Subtropical ClimateDokumen9 halamanThe Humid Subtropical ClimatearrozpolloBelum ada peringkat

- IMO - Guide To Recovery Techniques (MSC 1 Circ 1182) 31 May 2006 PDFDokumen21 halamanIMO - Guide To Recovery Techniques (MSC 1 Circ 1182) 31 May 2006 PDFalonso_rBelum ada peringkat

- NHA HousingDokumen95 halamanNHA HousingGarry Yan DiazBelum ada peringkat

- Final Exam (DRRR)Dokumen1 halamanFinal Exam (DRRR)Angelica RivamonteBelum ada peringkat

- Đề thi học kì 2 lớp 9 môn Tiếng AnhDokumen4 halamanĐề thi học kì 2 lớp 9 môn Tiếng AnhMin MinBelum ada peringkat

- Precautionary Meas.& Proper Procedures - FireDokumen22 halamanPrecautionary Meas.& Proper Procedures - FireLouisa ReyesBelum ada peringkat

- Oferta Ortodoncia Sep1 Actual DDokumen7 halamanOferta Ortodoncia Sep1 Actual DEdwin Nicko EspinoBelum ada peringkat

- MT Olive - Nov. FinalDokumen56 halamanMT Olive - Nov. Finaljoe9783Belum ada peringkat

- Jose Cangco: Topic: (Common Carriers - in General-Nature and Basis of Liability - Article 1733) (Cruz, Anton)Dokumen65 halamanJose Cangco: Topic: (Common Carriers - in General-Nature and Basis of Liability - Article 1733) (Cruz, Anton)Jovanni BajanBelum ada peringkat

- SCS - Emergency Prepardness HandbookDokumen48 halamanSCS - Emergency Prepardness HandbookAllen SavageBelum ada peringkat

- 1 s2.0 S0278431921002188 MainDokumen11 halaman1 s2.0 S0278431921002188 MainKhushi KapoorBelum ada peringkat

- Sun Tzu QuotesDokumen5 halamanSun Tzu Quotesrlraja74Belum ada peringkat

- To Whom It May Concern: This Is To Certify That, of Legal Age Filipino, Married and A BonifideDokumen2 halamanTo Whom It May Concern: This Is To Certify That, of Legal Age Filipino, Married and A BonifideKathleen Shei Dela CruzBelum ada peringkat

- ESF4 Reference Guide 07-2014 FinalDokumen160 halamanESF4 Reference Guide 07-2014 FinalSoCal SmithBelum ada peringkat

- Is 13920Dokumen47 halamanIs 13920Ravinder KumarBelum ada peringkat

- Calculation of Blast Loads For Application To Structural ComponentsDokumen58 halamanCalculation of Blast Loads For Application To Structural ComponentsPatran60% (5)

- Gujarat Technological UniversityDokumen1 halamanGujarat Technological UniversityGhantalBelum ada peringkat

- DRRR Q1-Module-16-Signs-of-Impending-Volcanic-Eruption-08082020Dokumen39 halamanDRRR Q1-Module-16-Signs-of-Impending-Volcanic-Eruption-08082020Aubrey Capolinas88% (26)

- T8 B2 FAA NY Center Martin Fournier FDR - Handwritten NotesDokumen13 halamanT8 B2 FAA NY Center Martin Fournier FDR - Handwritten Notes9/11 Document ArchiveBelum ada peringkat

- 1-Abdul Khaliq Khan-HEAD RACE TUNNEL PDFDokumen22 halaman1-Abdul Khaliq Khan-HEAD RACE TUNNEL PDFKukuh Prasetyo Pangudi Utomo0% (1)

- Fukushima Nuclear Disaster - ScriptDokumen2 halamanFukushima Nuclear Disaster - ScriptRosa SeijasBelum ada peringkat

- Eurocode 8 - General Rules and Seismic Actions PDFDokumen22 halamanEurocode 8 - General Rules and Seismic Actions PDFmarineugenBelum ada peringkat

- Department of Education: 2021 Brigada Eskwela Steering CommitteeDokumen4 halamanDepartment of Education: 2021 Brigada Eskwela Steering CommitteeErnesto Mayo Fogata50% (2)