Mech UCO Lect 06 Using APDL 1

Diunggah oleh

Percy Romero Murillo0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

184 tayangan39 halamanUsing APDL in Mechanical 1 will demonstrate how to use APDL commands. Using "Commands" objects in the Geometry, Remote Points, and Connections branches will be explored. "Solver Units: Manual" allows the user to specify the unit system for the Mechanical APDL solver.

Deskripsi Asli:

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniUsing APDL in Mechanical 1 will demonstrate how to use APDL commands. Using "Commands" objects in the Geometry, Remote Points, and Connections branches will be explored. "Solver Units: Manual" allows the user to specify the unit system for the Mechanical APDL solver.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

184 tayangan39 halamanMech UCO Lect 06 Using APDL 1

Diunggah oleh

Percy Romero MurilloUsing APDL in Mechanical 1 will demonstrate how to use APDL commands. Using "Commands" objects in the Geometry, Remote Points, and Connections branches will be explored. "Solver Units: Manual" allows the user to specify the unit system for the Mechanical APDL solver.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 39

Chapter 6 Chapter 6

Using APDL in Mechanical 1

ANSYS Mechanical Advanced

(Using Command Objects)

6-1

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

( g j )

Using APDL in Mechanical 1

Training Manual

Overview

Using an understanding of Mechanical APDL acquired from the

previous chapters, this section will demonstrate how to use APDL

commands to access advanced functionality within Mechanical.

Consider the APDL commands as a scripting language to:

Manipulate the mesh directly

Access advanced solver functionality

Access advanced postprocessing capabilities

In this chapter, using Commands objects in the Geometry, Remote In this chapter, using Commands objects in the Geometry, Remote

Points, and Connections branches will be explored.

6-2

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

A. Preliminaries

Before diving into the details of using Commands objects in

Mechanical, some general topics will be reviewed:

Solver unit system

Saving the Mechanical APDL database

Creating/deleting elements and other entities

Branches in the Outline Tree applicable to Commands objects

6-3

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Unit System

APDL commands may involve the input of values that are unit-

dependent, such as piezoelectric coefficients. Because Commands

objects are general, there is no mechanism to convert entered

f f arguments of APDL commands if a user decides to change the active

unit system from the Units menu.

Consequently, it is strongly recommended to manually specify the

l i i h D il i f h A l i S i solver unit system in the Details view of the Analysis Settings

branch. Solver Units: Manual allows the user to specify the unit

system for the Mechanical APDL solver

B tti S l U it M l ith S l By setting Solver Units: Manual with Solver

Unit System set appropriately, the user-specified

unit system will always by used by the

Mechanical APDL solver, regardless of what , g

the active unit system is in Mechanical

This ensures that, if another user obtains the

Workbench project, their solution will be in the

i

6-4

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

correct unit system

Using APDL in Mechanical 1

Training Manual

Saving the Mechanical APDL database

Mechanical uses the file.rst result file for postprocessing. Most

postprocessing operations can be done in Mechanical using User

Results, dicussed later. However, there may be unforeseen

circumstances where a user may wish to postprocess results in

Mechanical APDL

Postprocessing in Mechanical APDL was covered in an earlier chapter

Because of this reason, it is highly recommended to save the

Mechanical APDL database (file.db).

In the Details view of the Analysis Settings

b h t S ANSYS db Y branch, set Save ANSYS db: Yes

The default is not to save file.db, so this must

be specified by the user

6-5

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Creating/Deleting Elements

When elements or nodes are created or deleting using APDL

commands, please note that Mechanical will not be aware of these

changes to the mesh.

If elements/nodes need to be created using APDL commands in a

Commands branch, postprocessing of these elements must be done

inside of Mechanical APDL

If possible avoid deleting elements via APDL commands Consider If possible, avoid deleting elements via APDL commands. Consider

modifying the geometry/mesh to omit regions that are not of interest

6-6

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Inserting Commands Objects

The following branches in the Outline tree allow

users to insert Commands objects:

Any Body under a Geometry branch

Any Remote Point under a Remote Points branch

Any Contact Region under Connections branch

Any Spot Weld under Connections branch

Any Joint under Connections branch

Any Spring under Connections branch

Any Beam under Connections branch

Directly under any analysis branch

Directly under the Solution branch

The details of each of these options will be covered

in this chapter

6-7

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Supplementary Branches

Two branches that do not use Commands objects

directly but are quite helpful are the Coordinate

Systems and the Named Selections branches

As will be discussed later, a Coordinate System can be

assigned a manual coordinate system ID number,

which can be used in APDL commands. For example,

this is useful for selecting a node near a coordinate this is useful for selecting a node near a coordinate

system or transforming results in a particular

coordinate system in Mechanical APDL.

Named Selections will appear as nodal or element pp

components in Mechanical APDL, where a

component is a group of nodes or elements. This

allows users to conveniently reference entities without

having to worry about geometry node/element ID having to worry about geometry, node/element ID

number, etc., and this method can be used for updated

geometry as well.

6-8

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Other Branches

Other branches, such as Construction Geometry,

Virtual Topology, Symmetry, Mesh, and

Solution Combination branches, are not applicable

C to APDL commands, so Commands objects are

not inserted under those branches.

6-9

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

B. Geometry Branch

A Commands object may be inserted under a

Body under the Geometry branch

Note that a Commands object cannot be inserted

directly under the Geometry branch or directly

under a multibody part. It can only be inserted under

a particular body

Point Masses are also not applicable for Commands Point Masses are also not applicable for Commands

objects

The below lists some reasons to use a Commands The below lists some reasons to use a Commands

object associated with a Body:

Definition of composite materials

Solving other types of physics not native to Solving other types of physics not native to

Mechanical

Adding nonlinear material models, such as creep or

viscoelasticity or anisotropic hyperelasticity

6-10

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

y p yp y

Using APDL in Mechanical 1

Training Manual

Geometry Branch

Once a Commands object is inserted, APDL commands can be

pasted or typed into the text area.

The Commands object inserted under a Body can be used to

change the following element attributes for that Body:

Element type

Material Properties

Real Constants/Section Properties

Element Coordinate System

Use the APDL parameter MATID to reference the element type, p yp

material property, real constant, or section property ID number.

The Element Coordinate System ID will typically be 0 (default) unless a

Coordinate System has been associated with that body

6-11

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Geometry Branch: Element Type

As discussed in a previous chapter, changing element types is done

via the following two commands:

ET,MATID,

KEYOPT,MATID,

Changing the element type allows a user to solve different physics or

use a specialized element. However, the nodal connectivity must be

the same between the original and target element type

The Mesh branch controls whether the element will be higher- or lower-

order. The Mesh Method also dictates what the element shape will be

( h h d l t t h d l) (e.g., hexahedral, tetrahedral)

If any element-specific options (keyoptions) need to be set, use the

KEYOPT command

6-12

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Geometry Branch: Element Type

Caution concerning pyramid elements:

Note that while most higher-order elements have a pyramid shape, not all

lower-order elements have a pyramid shape. Hence, check the Elements

R f t th t th l t d l t t t id Reference to ensure that the selected element type supports pyramids.

For example, the structural 8-node p

brick element SOLID185 does not

show a pyramid form, so a user

should not attempt to use this

element if pyramids are present

Pyramids appear when a Mesh Method of Hex-Dominant Meshing or

MultiZone (with Free Mesh Type set) is used

element if pyramids are present

MultiZone (with Free Mesh Type set) is used.

When pyramids are present, this also typically means that tetrahedrons are

present as well. Mechanical will generate tetrahedrons as a 10-node tet while

pyramids and wedges are degenerate 20-node hex elements. Hence, in these

ill t th 10 d t t l t hil 1 ill f t

6-13

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

case, MATID will represent the 10-node tet elements while MATID+1 will refer to

the 20-node hex element type ID.

Using APDL in Mechanical 1

Training Manual

Geometry Branch: Element Type

Note about Element Control:

In the Details view of the Geometry branch,

the user can change Element Control

By default, this is set to Program Controlled,

where the Mechanical APDL solver may change

keyoptions automatically prior to solution

Currently applicable to structural elements y pp

APDL Command is ETCONTROL

See the Commands Reference for ETCONTROL

for additional details

6-14

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Geometry Branch: Element Type

Note about Element Control (continued):

During solution, the following will be printed in the Solution Information

branch:

If automatic resetting of keyoptions is not desired, be sure to set Element

Control: Manual in the Details view of the Geometry branch

Notice that certain keyoptions

have been automatically reset by

Mechanical APDL.

Alth h th t ti tti f Although the automatic setting of

options is meant to aid the user in

selecting appropriate element

formulations, etc., the

k l d bl t t knowledgeable user may not want

keyoptions automatically

overridden. In this case, set

Element Control: Manual prior

t l ti

6-15

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

to solution.

Using APDL in Mechanical 1

Training Manual

Geometry Branch: Material Properties

Deleting all existing material properties for the particular body is

done via the following commands:

MPDELE,Label,MATID

TBDELE,Label,MATID

As a review, defining linear elastic material properties:

MP,Label,MATID, (constant materials)

MPTEMP, and MPDATA,Label,MATID, (temperature-dependent)

To define nonlinear material properties, use:

TB,Label,MATID, to activate a particular material table , , , p

TBTEMP, and TBDATA, or TBPT, to define the parameters

In all of the above cases Label refers to the material property name In all of the above cases, Label refers to the material property name.

See the MP or TB help in the Commands Reference for details.

6-16

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Geometry Branch: Material Properties

Material Properties are the only element attribute which allows

superimposing multiple definitions.

For example, to define density and elastic modulus, one would repeat

the MP command as follows:

MP,EX,MATID,10e6

MP,DENS,MATID,0.1/386.1

To define bilinear isotropic plasticity and creep, one would do the

following:

MP,EX,MATID,200e3

Defines linear elastic properties

MP,NUXY,MATID,0.3

TB,BISO,MATID,1

TBDATA,1,300,2e3

Defines linear elastic properties

Defines bilinear plasticity constants

TB,CREEP,MATID,1,3,10

TBDATA,1,3.125E-14,5,0

For nonlinear structural material combinations, see Section 2.6

Defines creep law and its coefficients

6-17

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

o o ea st uctu a ate a co b at o s, see Sect o 6

Material Model Combinations in the Elements Reference for details

Using APDL in Mechanical 1

Training Manual

Geometry Branch: Material Properties

Points to keep in mind:

When adding creep material properties via TB,CREEP,MATID, note that

Mechanical, by default, will not request creep strains to be saved. By

ddi O S C i C d bj t d th l i adding OUTRES,EPCR,ALL in a Commands object under the analysis

branch (discussed later), one can ensure that creep strains are stored for

postprocessing. (Note that, in the specific case of creep, RATE,ON must

also be added in the Commands object under the analysis branch.) j y )

For user-defined materials with TB,USER,MATID or user-defined creep

with TB,CREEP,MATID,,,100, state variables are often defined via

TB,STATE,MATID. As with the above case, the user should add

i C d bj t d th l i b h t OUTRES,SVAR,ALL in a Commands object under the analysis branch to

ensure that state variables are stored in the result file for postprocessing.

6-18

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Geometry Branch: Section Properties

The Elements Reference in the Mechanical APDL help system

describes whether a particular element uses real constants or section

properties

In either case, the APDL scalar parameter MATID can be used to reference

the real constant and section property ID number of that particular Body.

Deleting existing real constants or section properties:

RDELE,MATID

SDELETE,MATID

Recall the definition of a new real constant or section property:

R,ID,

SECTYPE,ID, and SECDATA,

Modification of a real constant:

RMODIF,ID,

(No equivalent functionality is present for sections. One must delete an

existing section and define a new section instead.)

6-19

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Geometry Branch: Section Properties

Tip for composite (layered) elements:

Composite elements define the material properties for each layer via real

constants or section properties. There is no need to redefine or modify

th t i l ID b i t d ith th B d the material ID number associated with the Body.

Note, however, that structural damping (MP,DAMP) and reference temperature

for thermal strains (MP,REFT) are defined via the material ID number, not per

layer. y

For composite elements, one must define the material ID numbers used

in each layer within the Commands object

Use material ID numbers that are larger than the number of parts present when

d fi i th t i l ID b f h l defining the material ID number for each layer

The actual material property definition used in layers only needs to be

performed once in the event that multiple bodies have composite definition

From the Workbench Project Schematic, link the Model to a From the Workbench Project Schematic, link the Model to a

Mechanical APDL system. Then, verify the composite definition inside

of Mechanical APDL using /ESHAPE,1 to visualize the 3D cross-section,

including layeres.

6-20

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

C. Remote Points

Remote Points are an integral part of many features

in Mechanical:

Point Mass

Joints

Springs

Moment

Remote Force

Remote Displacement

Each Remote Point has an (x, y, z) location and is ( y )

scoped to a geometric entity. One can think of

Remote Points as tying nodes on a geometric

entity to the remote point location, either with a

deformable or rigid behavior.

Understanding how Remote Points work allows

users to take advantage of them with Commands

6-21

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

objects

Using APDL in Mechanical 1

Training Manual

Uses for Remote Points

The below are some reasons why one may wish to use Commands

objects with Remote Points:

Reduce the interface nodes for creation of CMS superelements for more

efficient system-level analyses

Define monitor locations, such as the average deformation of a given

surface

C t MNF fil f ith Ad /Fl

Create an MNF file for use with Adams/Flex

6-22

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Adams is developed by and is a registered trademark of MSC Software

Using APDL in Mechanical 1

Training Manual

Remote Point Representation

A Remote Point consists of contact and target elements

The target element is a 1-node element, representing the remote point

location

The contact elements are associated with the vertex, edge, or surface that

is scoped in the Remote Point Definition

This is an example of surface-based constraints using contact elements.

For details see Chapter 9 of the Contact Technology Guide For details, see Chapter 9 of the Contact Technology Guide.

TARGE170 Element (circled)

6-23

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

CONTA174 Elements (purple)

Using APDL in Mechanical 1

Training Manual

Remote Point Behavior

To better understand the deformable and rigid behavior, consider

the simple 2D plate with a remote force (via remote point) applied to

the center hole:

Deformable behavior: circle does not retain shape p

6-24

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Rigid behavior: circle maintains shape

Using APDL in Mechanical 1

Training Manual

Remote Points

Insert a Commands object under a Remote Point:

The parameter _npilot reflects the node ID number. One can define a

new parameter to keep track of this node ID number for later use, such as

d fi i t DOF defining master DOF:

MY_INTERFACE_NODE = _npilot

m,MY_INTERFACE_NODE,all

The parameter TID is the target elements element type ID number For The parameter TID is the target element s element type ID number. For

example, if one may wish to constrain only UX and UY DOF rather than all

6 (or all 3, if 2D), one can use the following command:

keyopt,TID,4,11

6-25

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Remote Points

Tips on using APDL with Remote Points:

Keep in mind that APDL parameters are persistent throughout the

Mechanical APDL run. Hence, per the previous slide, the parameter

C O ill h th l f th d ID b d MY_INTERFACE_NODE will have the value of the node ID number and can

be used in postprocessing as well.

Most functionality with regards to Remote Points, such as load

application postprocessing displacements or reaction forces application, postprocessing displacements or reaction forces,

spring/joint definition, are already built into the Mechanical GUI. Hence,

prior to using Commands objects with Remote Points, consider

whether or not the sought capability already exists within Mechanical.

6-26

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

D. Contact Regions

Commands objects may also be inserted

under any Contact Region

There are many situations where APDL

commands can access advanced controls:

Definition of debonding/delamination with CZM

Use of fluid pressure-penetration loading

Near-field contact radiation and convection

Definition of multiphysics contact (coupled

thermal-electric-structural) with frictional heat

ti generation

Inclusion of orthotropic friction or dynamic

coefficient of friction, along with cohesion

Changing contact detection locations Changing contact detection locations

other options available as well!

6-27

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Contact Regions

Most of the commonly-used contact options are present in the

Mechanical GUI.

However, ANSYS contact elements have a plethora of options to

allow users to simulate many different scenarios

To understand the various contact capabilities that are available, p ,

refer to the following sections in the Help documentation:

Contact Technology Guide > Chapter 3: Surface-to-Surface Contact

Contact Technology Guide > Chapter 7: Multiphysics Contact gy p p y

Contact Technology Guide > Chapter 12: Debonding

6-28

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Contact Regions

Insert a Commands object of the Contact Region of interest:

The parameters CID and TID are used to refer to the contact and target

element type IDs, respectively.

To apply fluid pressure-penetration loading where pressure loading

occurs when a contact status opens, use the following:

esel,s,type,,CID

sfe all 1 pres 120 sfe,all,1,pres,,120

allsel,all

To change the contact detection type to normal from target, use

keyopt,CID,4,2 keyopt,CID,4,2

6-29

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Contact Regions

Tips on Contact Regions and APDL:

Because Contact Regions are not included in Named Selections, to

reference a contact region for later use, use either of the following:

Define a parameter(s) with the CID (and TID) values

Create an element component (group) for later use via ESEL and CM commands

Understand the situations where symmetric and asymmetric contact

pairs exist If Behavior: Symmetric is set for Pure Penalty or pairs exist. If Behavior: Symmetric is set for Pure Penalty or

Augmented Lagrange algorithms, ensure that any change real

constants or material properties are reflected for both CID and TID.

6-30

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

E. Joints

Typical uses of Commands objects inserted

for Joints include the following:

Definition of Screw Joints and other joints not

available in the Mechanical GUI

Incorporation of nonlinear stiffness, nonlinear

damping, and/or Coulomb friction

1

Obt i i d t il d t l j i t Obtaining more detailed control over joint

behavior, such as applying rotational stops and

locks on a General Joint

6-31

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

1

Note that, at release 12.0, the hysteretic friction capability of Joints

(MPC184) has been removed in favor of the Coulomb friction model.

Using APDL in Mechanical 1

Training Manual

Joints

Many sophisticated joint functionality are present in Mechanical:

Torsional stiffness and damping for Cylindrical and Revolute Joints

Bushing Joint, which can be thought of as a General Joint where a user

may input stiffness and damping relationships between all 6 relative DOF

Joint stops and locks for many joint types

Prior to implementing Commands objects for Joints, review the

Help system to ensure that the capability is not already present:

Mechanical (formerly Simulation) > Using the Mechanical Application

Features > Geometry in the Mechanical Application > Joints

6-32

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Joints

If it is deemed necessary to include a Commands object to access

functionality via APDL commands, review the following Help manual:

Multibody Analysis Guide > Chapter 2. Modeling in a Multibody

Simulation > Section 2.3 Connecting Multibody Components with Joint

Elements

Elements Reference > Element Library > MPC184

The element type used for joints is MPC184. Note that the joint

(MPC184 element) is connected to the solid model via Remote Points.

If the connection between the joint and solid part needs to be modified,

define a Remote Point with a Commands object, as discussed in an

earlier section of this chapter.

Only insert a Commands object under a Joint branch if the joint Only insert a Commands object under a Joint branch if the joint

property will be modified. This includes constraining relative DOF,

adding stops/locks, or defining joint material properties

6-33

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Joints

The APDL parameter _jid refers to the element type, material, real

constant, and section ID number of the MPC184 element:

To define nonlinear stiffness for a Translational Joint:

tb,join,_JID,1,4,jnsa

tbpt,,U1,F1

repeat (Each TBPT command defines pair of displacements U

i

and forces F

i

)

T dd t ti l t f l ti Z t ti f G l J i t b t To add a rotational stop for relative Z-rotation for a General Joint between

-45 and 45:

secstop,6,-acos(-1)/2,acos(-1)/2

(Notice input is in radians, and 6 refers to relative DOF 6 or ROTZ) (Notice input is in radians, and 6 refers to relative DOF 6 or ROTZ)

6-34

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Joints

Tips on using APDL commands with Joints:

The SECTYPE command is required to define the joint behavior and is

typically defined by Mechanical. Hence, to add stops/locks, one should

t th S C d if it l d d fi d b M h i l b t not use the SECTYPE command if it already defined by Mechanical, but

one can just add SECLOCK and SECSTOP commands, as the particular joint

ID will already be active.

Not all Joints support stops locks and joint material definition Not all Joints support stops, locks, and joint material definition

(friction, stiffness, damping) for example, the Spherical Joint supports

neither. Consult the Elements Reference for details on each Joint type

prior to using APDL commands to ensure that the feature is available for

that joint type

Modifying the local coordinate system which defines the orientation of

the relative joint DOF is highly discouraged since Mechanical will

incorrectly report results for that joint incorrectly report results for that joint.

The DJ command applies joint constraints while the FJ command applies

loading to the joints. However, when possible, use of Joint Loads in

Mechanical is recommended over using APDL commands, as the former

6-35

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

g ,

is much easier to implement.

Using APDL in Mechanical 1

Training Manual

F. Springs and Beams

In addition to Contact Regions and Joints, the

Connections branch allows use of Springs

and Beams

Springs are longitudinal springs and/or

dampers with preload capabilities

Beams have circular cross-sections and are

meant to represent structural connections that meant to represent structural connections that

carry bending loads

As with Joints, Springs and Beams are

connected to 2D or 3D bodies via Remote connected to 2D or 3D bodies via Remote

Points

If a Remote Point is not explicitly used, the

underlying finite element representation is still underlying finite element representation is still

using surface-based constraints of contact and

target elements, as elaborated in the Remote

Points section of this chapter

6-36

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Springs and Beams

A Spring is represented with a COMBIN14 element, and a Beam is

modeled with a single BEAM188 element.

Line Bodies are also represented with BEAM188 elements, and the two

should not be confused with each other.

When modeling beam structures, use line bodies (number of beam elements

per line body is controlled via Mesh Sizing).

To model a connection that can carry bending loads a Beam connection may To model a connection that can carry bending loads, a Beam connection may

be applicable.

Using Commands objects for Springs and Beams is not as

common as its usage in other branches, although a few reasons for g , g

doing so are listed below:

Changing the longitudinal Spring to a torsional one via keyoption

Replacing the Beam with a rigid beam (MPC184)

Replacing the Spring with nonlinear or other types of spring elements

6-37

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Using APDL in Mechanical 1

Training Manual

Springs and Beams

For Springs, after inserting a Commands object, use the parameter

_sid to reference the springs element type, material, and real

constant ID number

Example of changing to a torsional spring:

keyopt,_SID,3,1

Note that stiffness and force will refer to torsional stiffness and

moment

Springs do not use a section ID, so the section ID number will be 1

For Beams, the parameter _bid refers to the beams element type,

material, real constant, and section ID number

To replace the deformable beam with a rigid one, use the following:

mpdele,all,_BID

et,_BID,184,1,0

Note that the Beam has material properties, so density and thermal

expansion may be used, if present. To prevent these materials from

being used MPDELE is included in the above example to delete the

6-38

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

being used, MPDELE is included in the above example to delete the

material definition for _BID (beams material ID).

Using APDL in Mechanical 1

Training Manual

Springs and Beams

1D springs may be required for an analysis, where the stiffness in a

particular direction is known beforehand.

1D springs should be modeled with COMBIN14 and KEYOPT(2)=1 through

6. The best practice is to model 1D springs with coincident nodes.

Because Springs in Mechanical are longitudinal springs, they must have

finite length. Hence, Springs should not be converted to 1D springs.

T t 1D i b t b di d fi 2 R t P i t t th To create 1D springs between bodies, define 2 Remote Points at the same

location but scoped to the 2 bodies geometric entities. Add

Commands objects under both Remote Points to record the pilot node

ID number as parameters. Using Commands object in the analysis p g j y

branch (described shortly), 1D spring(s) can be defined using the two

pilot node locations.

Springs operate in the nodal coordinate system. Hence, if Remote Points

d th t th f d di t t th are used, ensure that the referenced coordinate systems are the same.

6-39

ANSYS, Inc. Proprietary

2009 ANSYS, Inc. All rights reserved.

June 2009

Inventory #002669

Anda mungkin juga menyukai

- Tutorial Week 10 - Internal Bone RemodellingDokumen13 halamanTutorial Week 10 - Internal Bone RemodellingHussam El'SheikhBelum ada peringkat

- Ansys Applications OverviewDokumen113 halamanAnsys Applications OverviewaymanganoBelum ada peringkat

- Mech-UCO 120 WS-05 LaminateDokumen39 halamanMech-UCO 120 WS-05 LaminateamBelum ada peringkat

- The 10 Coolest New FeaturDokumen8 halamanThe 10 Coolest New FeaturJaydip VyasBelum ada peringkat

- ELS 6 New FeaturesDokumen2 halamanELS 6 New FeaturesMakenson MuscadinBelum ada peringkat

- Tutorial 2 (Basic) : Pin/Lug Assembly: 5Dplq5LdklDokumen11 halamanTutorial 2 (Basic) : Pin/Lug Assembly: 5Dplq5LdklIbnu RiswanBelum ada peringkat

- ANSYS Mechanical Advances (Using Command Objects)Dokumen31 halamanANSYS Mechanical Advances (Using Command Objects)Dong LIBelum ada peringkat

- InterIIT Low PrepDokumen5 halamanInterIIT Low PrepJARVIS 31Belum ada peringkat

- 20131022-Additive Manufacturing & Allied Technologies, PuneDokumen56 halaman20131022-Additive Manufacturing & Allied Technologies, Puneprakush_prakushBelum ada peringkat

- Etap Spel1 PDFDokumen45 halamanEtap Spel1 PDFbhagyarajBelum ada peringkat

- Configuration Manual Lantek Expert CutDokumen194 halamanConfiguration Manual Lantek Expert Cutmolior100% (1)

- Webinar N°6 Tips and Tricks in RobotDokumen53 halamanWebinar N°6 Tips and Tricks in RobotSrdjan KosoricBelum ada peringkat

- Ab Initio - Parameter Kung Fu: Remediator CommentsDokumen2 halamanAb Initio - Parameter Kung Fu: Remediator CommentsSravya ReddyBelum ada peringkat

- Design of Controller Board For A Lunar Rover: Electronic Basic ThesisDokumen24 halamanDesign of Controller Board For A Lunar Rover: Electronic Basic ThesisMuhammad AhsanBelum ada peringkat

- Raining Uide: UMC-750-O R - F & C 5 ADokumen50 halamanRaining Uide: UMC-750-O R - F & C 5 AsingourBelum ada peringkat

- Autodyn BasicsDokumen32 halamanAutodyn Basicsdarklord338100% (1)

- Mekatronik Sistem Tasarımı SlaytDokumen33 halamanMekatronik Sistem Tasarımı SlaytM Kasım YılmazBelum ada peringkat

- Introduction To ANSYS MechanicalDokumen253 halamanIntroduction To ANSYS Mechanicalabdul khader100% (1)

- The 2nd Assessment ProblemDokumen4 halamanThe 2nd Assessment ProblemrisirarocksBelum ada peringkat

- ASCP Item Attribute Simulation SetsDokumen9 halamanASCP Item Attribute Simulation SetsDavide AllegrettiBelum ada peringkat

- ROBOTICSDokumen3 halamanROBOTICSSaima NishatBelum ada peringkat

- Pvsyst Tutorial v7 Grid Connected 4 enDokumen14 halamanPvsyst Tutorial v7 Grid Connected 4 enjyhsolarBelum ada peringkat

- Ansys Mechanical TrainingDokumen54 halamanAnsys Mechanical TrainingAbhijeet Gandage100% (3)

- WBv12.1 Emag Tutorial4 Transformer PDFDokumen38 halamanWBv12.1 Emag Tutorial4 Transformer PDFAraz SBelum ada peringkat

- Abap Objects 1ooDokumen149 halamanAbap Objects 1ooSwapna KuntamukkalaBelum ada peringkat

- ANSYS Explicit Dynamics 120 Workshop 02Dokumen37 halamanANSYS Explicit Dynamics 120 Workshop 02avinashj18Belum ada peringkat

- Lecture 8 - Post Buckling and Impact AnalysesDokumen22 halamanLecture 8 - Post Buckling and Impact AnalysesSencu RazvanBelum ada peringkat

- 20 APDL Commands Every ANSYS Mechanical User Should Know - PADT, Inc. - The Blog PDFDokumen19 halaman20 APDL Commands Every ANSYS Mechanical User Should Know - PADT, Inc. - The Blog PDFakshayBelum ada peringkat

- New Microsoft Word DocumentDokumen10 halamanNew Microsoft Word DocumentTejas KadamBelum ada peringkat

- Explicit STR and Autodyn PT I 14.5 WS09 RC DropDokumen25 halamanExplicit STR and Autodyn PT I 14.5 WS09 RC DroprzsoltBelum ada peringkat

- ADINA System 9.0Dokumen56 halamanADINA System 9.0hamidBelum ada peringkat

- SolidCAM 2015 Imachining Misc Features PDFDokumen45 halamanSolidCAM 2015 Imachining Misc Features PDFhed_panBelum ada peringkat

- Robot MillingDokumen20 halamanRobot MillingGauravBelum ada peringkat

- ASCP Item Attribute Simulation SetsDokumen10 halamanASCP Item Attribute Simulation SetsRahul KulkarniBelum ada peringkat

- MOKABUG-2010-Creating AppWorx Chains From Banner Processes and Reports-LorettaSampsonDokumen48 halamanMOKABUG-2010-Creating AppWorx Chains From Banner Processes and Reports-LorettaSampsonHari KrishnaBelum ada peringkat

- Catia - Generative Part Stress AnalysisDokumen154 halamanCatia - Generative Part Stress AnalysisconqurerBelum ada peringkat

- Engg Sol ManualDokumen133 halamanEngg Sol Manualmiddieman147100% (6)

- Api I C1Dokumen54 halamanApi I C1mihai37Belum ada peringkat

- Reflector Antenna System DesignDokumen35 halamanReflector Antenna System DesignAyyem Pillai VBelum ada peringkat

- 18BT030203 - Abhishek (A&R Lab)Dokumen23 halaman18BT030203 - Abhishek (A&R Lab)abhishek bhardwajBelum ada peringkat

- 1111 PR Reflector Antenna System Design PDFDokumen35 halaman1111 PR Reflector Antenna System Design PDFAyyem Pillai VBelum ada peringkat

- Mechanical-Nonlin - 13.0 - App6A - Creep Curve Fitting in MAPDLDokumen17 halamanMechanical-Nonlin - 13.0 - App6A - Creep Curve Fitting in MAPDLShaheen S. Ratnani100% (2)

- Powertrain Tasks - : Sub-Juniors Practice TasksDokumen6 halamanPowertrain Tasks - : Sub-Juniors Practice TasksAriana FrappeBelum ada peringkat

- A PLC System: CPU Module (Left) and An I/O Rack (Right) (Allen Bradley PLC-5)Dokumen71 halamanA PLC System: CPU Module (Left) and An I/O Rack (Right) (Allen Bradley PLC-5)vismaywalle1Belum ada peringkat

- Sloshing in A Tank Modelled Using SPH As An Example in AbaqusDokumen11 halamanSloshing in A Tank Modelled Using SPH As An Example in AbaqusPravinkumarGhodake100% (1)

- From Design To Implementation: Linear ControllersDokumen22 halamanFrom Design To Implementation: Linear Controllersสหายดิว ลูกพระอาทิตย์Belum ada peringkat

- Release Notes - READDokumen3 halamanRelease Notes - READHari KurniadiBelum ada peringkat

- Linear ControlDokumen22 halamanLinear ControlElvis YuBelum ada peringkat

- ANSYSDokumen13 halamanANSYSnalanth76Belum ada peringkat

- Characterization and Modeling of A Dynamixel ServoDokumen38 halamanCharacterization and Modeling of A Dynamixel Servogimmegmailemail100% (1)

- SAT File To RevitDokumen7 halamanSAT File To RevitNaassom VazBelum ada peringkat

- ADS Tutorial: A Beginners Tutorial: Modes of OperationDokumen22 halamanADS Tutorial: A Beginners Tutorial: Modes of OperationFredCamoneBelum ada peringkat

- Chapter 2Dokumen2 halamanChapter 2BouregaBelum ada peringkat

- Optimizing Image Analysis For SpeedDokumen7 halamanOptimizing Image Analysis For Speedvlp_bkBelum ada peringkat

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsDari EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsBelum ada peringkat

- Finite Element Analysis for Design Engineers, Second EditionDari EverandFinite Element Analysis for Design Engineers, Second EditionBelum ada peringkat

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsDari EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsPenilaian: 5 dari 5 bintang5/5 (1)

- A Classification System to Describe Workpieces: DefinitionsDari EverandA Classification System to Describe Workpieces: DefinitionsW. R. MacconnellBelum ada peringkat

- Intro To ANSYS Ncode DL 14.5 L01 IntroductionDokumen11 halamanIntro To ANSYS Ncode DL 14.5 L01 IntroductionGanesh R Navad100% (1)

- MAPDL Intro 13.0 L11 PostprocessingDokumen31 halamanMAPDL Intro 13.0 L11 PostprocessingPercy Romero MurilloBelum ada peringkat

- Ansys Ls-Dyna Mapdl 14.5 Ws01 Fan Blade ContainmentDokumen5 halamanAnsys Ls-Dyna Mapdl 14.5 Ws01 Fan Blade ContainmentPercy Romero MurilloBelum ada peringkat

- AACTx R160 L-01 Introduction To AcousticsDokumen77 halamanAACTx R160 L-01 Introduction To AcousticsPercy Romero Murillo0% (1)

- Ext Acoustics ReadMe R145 v8Dokumen1 halamanExt Acoustics ReadMe R145 v8Percy Romero MurilloBelum ada peringkat

- A Normal and Tangential Elastic Foundation in Workbench MechanicalDokumen6 halamanA Normal and Tangential Elastic Foundation in Workbench MechanicalPercy Romero MurilloBelum ada peringkat

- Prod Docu 14.0 Ans AdvDokumen380 halamanProd Docu 14.0 Ans AdvShaheen S. RatnaniBelum ada peringkat

- Non Linear Spring R15.0 v1Dokumen5 halamanNon Linear Spring R15.0 v1Percy Romero MurilloBelum ada peringkat

- Non Linear Spring R15.0 v1Dokumen5 halamanNon Linear Spring R15.0 v1Percy Romero MurilloBelum ada peringkat

- ACT Beam End Release R150 v1Dokumen7 halamanACT Beam End Release R150 v1Percy Romero MurilloBelum ada peringkat

- Acoustics AACTx R150 L06 AppendixDokumen26 halamanAcoustics AACTx R150 L06 AppendixPercy Romero MurilloBelum ada peringkat

- ACT Pressure Vessels Automatic Path Creation R150 v3Dokumen14 halamanACT Pressure Vessels Automatic Path Creation R150 v3Percy Romero MurilloBelum ada peringkat

- ACT Distributed Mass Manual R150 v3Dokumen6 halamanACT Distributed Mass Manual R150 v3Percy Romero MurilloBelum ada peringkat

- Mech Dynamics 14.5 L01 IntroDokumen18 halamanMech Dynamics 14.5 L01 IntroPercy Romero MurilloBelum ada peringkat

- Mech Ac 160 l05 MapdlDokumen32 halamanMech Ac 160 l05 MapdlPercy Romero MurilloBelum ada peringkat

- Mech ANL 16.0 L05 ViscoelasticityDokumen30 halamanMech ANL 16.0 L05 ViscoelasticityPercy Romero MurilloBelum ada peringkat

- AACTx - R160 - L-05 - Response Spectrum & Random Vibration AnalysesDokumen24 halamanAACTx - R160 - L-05 - Response Spectrum & Random Vibration AnalysesPercy Romero Murillo100% (1)

- Mech SNL 16.0 L01 OverviewDokumen17 halamanMech SNL 16.0 L01 OverviewPercy Romero MurilloBelum ada peringkat

- AACTx R160 L-06 Advanced ApplicationsDokumen19 halamanAACTx R160 L-06 Advanced ApplicationsPercy Romero MurilloBelum ada peringkat

- Acoustics AACTx R150 L01 Introduction To AcousticsDokumen71 halamanAcoustics AACTx R150 L01 Introduction To AcousticsPercy Romero MurilloBelum ada peringkat

- Mech AC 160 L03-Bolt PretensionDokumen24 halamanMech AC 160 L03-Bolt PretensionPercy Romero MurilloBelum ada peringkat

- Intro To ANSYS NCode DL 14 5 L09 Stress Life Pt1Dokumen29 halamanIntro To ANSYS NCode DL 14 5 L09 Stress Life Pt1Percy Romero MurilloBelum ada peringkat

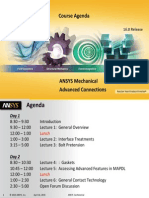

- Mech AC 160 AgendaDokumen2 halamanMech AC 160 AgendaPercy Romero MurilloBelum ada peringkat

- Mech AC 160 L00 IntroDokumen4 halamanMech AC 160 L00 IntroPercy Romero MurilloBelum ada peringkat

- ACGIHDokumen5 halamanACGIHvigneshBelum ada peringkat

- Design of Cold Storage Structure For Thousand PDFDokumen8 halamanDesign of Cold Storage Structure For Thousand PDFzhyhhBelum ada peringkat

- Partially Aerated Bubble Column: 10.1 Problem DescriptionDokumen14 halamanPartially Aerated Bubble Column: 10.1 Problem DescriptionS_ELBEHERYBelum ada peringkat

- CIP13 Concrete BlistersDokumen2 halamanCIP13 Concrete Blisters7774R105Belum ada peringkat

- Inkformation 4 en 02Dokumen28 halamanInkformation 4 en 02MohammadAlAmeenBelum ada peringkat

- Dirac Notation PM r4Dokumen19 halamanDirac Notation PM r4Andrea BucciBelum ada peringkat

- Discussion Between Essar Power & FAG Bearings India LTDDokumen2 halamanDiscussion Between Essar Power & FAG Bearings India LTDJay Rameshbhai ParikhBelum ada peringkat

- Biotecnologia de Microalgas (1988 R) - (De La Noue and de Pauw) - The Potential of Microalgal Biotechnology A Review of Production and Uses of MicroalgaeDokumen46 halamanBiotecnologia de Microalgas (1988 R) - (De La Noue and de Pauw) - The Potential of Microalgal Biotechnology A Review of Production and Uses of MicroalgaeAlexsandro ClaudinoBelum ada peringkat

- Sheet Metal Worker Level 2: Rev. September 2009Dokumen16 halamanSheet Metal Worker Level 2: Rev. September 2009Brennen WilsonBelum ada peringkat

- Isolation and Alkaline Hydrolysis of The Protein GlutenDokumen5 halamanIsolation and Alkaline Hydrolysis of The Protein GlutenTiffany EspirituBelum ada peringkat

- Banthia - Fibre-Reinforced Concrete PDFDokumen29 halamanBanthia - Fibre-Reinforced Concrete PDFPriyanka BasuBelum ada peringkat

- Clay Brick MakingDokumen9 halamanClay Brick MakingapihanasBelum ada peringkat

- ABB Raw Mix Preparation PDFDokumen8 halamanABB Raw Mix Preparation PDFrudye kardun100% (1)

- VGScienta Pressure MeasurementDokumen16 halamanVGScienta Pressure Measurementdeaanggraeni_9345Belum ada peringkat

- JBT GreenDokumen3 halamanJBT GreenRagu VenkatBelum ada peringkat

- Lysol Brand III Disinfectant All Purpose Cleaner 4 in 1 US EnglishDokumen7 halamanLysol Brand III Disinfectant All Purpose Cleaner 4 in 1 US EnglishpatelpiyushbBelum ada peringkat

- Wiper Seal Data Sheet A02 B 11782 1 enDokumen2 halamanWiper Seal Data Sheet A02 B 11782 1 enghanBelum ada peringkat

- Annex 2 - 20-Sample Template For EMoPDokumen2 halamanAnnex 2 - 20-Sample Template For EMoPHercie Jean Golfo50% (2)

- Free Particle PropagatorDokumen2 halamanFree Particle PropagatorstephenbankesBelum ada peringkat

- Syllabus Diploma ElectricalDokumen136 halamanSyllabus Diploma Electricalrjpatil19Belum ada peringkat

- Refrigeration Unit Lab Report FKKDokumen28 halamanRefrigeration Unit Lab Report FKKKicauan KataBelum ada peringkat

- Microwave Level SwitchDokumen3 halamanMicrowave Level SwitchDidinAndresIIBelum ada peringkat

- Soil Report MSI 14 041Dokumen41 halamanSoil Report MSI 14 041frog15Belum ada peringkat

- Spider SilkDokumen5 halamanSpider SilkimranBelum ada peringkat

- Corrosion Under InsulationDokumen25 halamanCorrosion Under InsulationNaqib Nordin33% (3)

- Liquid Viscosity: 5.1. Trial ObjectivesDokumen5 halamanLiquid Viscosity: 5.1. Trial ObjectivesririnBelum ada peringkat

- Chemicals Zetag MSDS LDP Zetag 3940 (US) - 1010Dokumen6 halamanChemicals Zetag MSDS LDP Zetag 3940 (US) - 1010PromagEnviro.comBelum ada peringkat

- Failure Analysis of Structural Steel Subjected To Long Term ExposureDokumen13 halamanFailure Analysis of Structural Steel Subjected To Long Term ExposureDeepak wadgeBelum ada peringkat

- Aggregates Lab Report PDFDokumen5 halamanAggregates Lab Report PDFcharishma takkallapalliBelum ada peringkat

- Author's Accepted Manuscript: Nano EnergyDokumen52 halamanAuthor's Accepted Manuscript: Nano EnergySteven KmiecBelum ada peringkat