Evaluating The Effect of The Space Surrounding The

Diunggah oleh

Ravinder SinghJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Evaluating The Effect of The Space Surrounding The

Diunggah oleh

Ravinder SinghHak Cipta:

Format Tersedia

Evaluating the effect of the space surrounding the

condenser of a household refrigerator

Ramadan Bassiouny*

Dept. of Mech. Power Eng. and Energy, Faculty of Engineering, Minia University, Minia 61111, Egypt

a r t i c l e i n f o

Article history:

Received 4 August 2008

Received in revised form

10 February 2009

Accepted 18 March 2009

Published online 2 April 2009

Keywords:

Domestic refrigerator

Modelling

Simulation

Convection

Air

Air condenser

a b s t r a c t

The paper presents an analytical and computational modeling of the effect of the space

surrounding the condenser of a household refrigerator on the rejected heat. The driving

force for rejecting the heat carried by the refrigerant from the interior of a refrigerator is

the temperature difference between the condenser outer surface and surrounding air. The

variation of this difference, because of having an insufcient space, increasing the room air

temperature, or blocking this space, is of interest to quantify its effect

The results showed that having an enough surrounding space width (s >200 mm) leads

to a decrease in the temperature of the air owing vertically around the condenser coil.

Accordingly, this would signicantly increase the amount of heat rejected. Moreover,

blocking this space retards the buoyant ow up the condenser surface, and hence increases

the air temperature around the condenser. This would also decrease the heat rejected from

the condenser. Predicted temperature contours are displayed to visualize the air plumes

variation surrounding the condenser in all cases.

2009 Elsevier Ltd and IIR. All rights reserved.

Impact de lespace autour du condenseur dun re frige rateur

domestique : e valuation

Mots cles : Re frige rateur domestique ; Mode lisation ; Simulation ; Convection ; Air ; Condenseur a` air

1. Introduction

Household refrigerators are cyclic systems that consume

a reasonable amount of electric energy to fulll a certain job.

The performance of the different components of the refrig-

erator is of interest for many researchers to investigate and

analyze. These refrigerators prove to be durable, reliable,

and provide a satisfactory service for over 15 years (C engel

and Boles, 1999). Improper operation and placement of

a refrigerator would certainly degrade its performance and

durability.

The basic vapor-compression refrigeration cycle remained

more efcient than the absorption refrigeration cycle and the

thermoelectric refrigeration cycle. Fig. 1 shows a general

schematic of a household refrigerator with a wire-and-tube

condenser attached to the back of the refrigerator. The gure

also shows the domain of interest in the present study. The

performance of each component of the refrigerator affects its

* Tel.: 20 16 391 6415; fax: 20 86 2346674.

E-mail address: ramadan9@yahoo.com

www. i i i r . or g

avai l abl e at www. sci encedi r ect . com

j our nal homepage: www. el sevi er . com/ l ocat e/ i j r ef r i g

0140-7007/$ see front matter 2009 Elsevier Ltd and IIR. All rights reserved.

doi:10.1016/j.ijrefrig.2009.03.011

i nt e r na t i o na l j o ur na l o f r e f r i g e r a t i o n 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6

overall performance. The challenge for the designer is to

control noise, vibration, heat rejection, and minimize the

power consumption of the compressor; keeping the system

operates at higher efciencies and capacities.

The condenser is the main component in the refrigerating

system. It is responsible for rejecting the heat, absorbed by the

refrigerant in the evaporator, out of the refrigerator

compartment into its surroundings. It may be cooled by

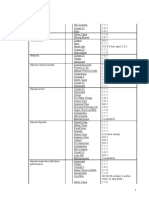

Nomenclature

A area (m

2

)

C

p

air specic heat, J kg

1

K

1

d diameter (m)

g gravitational acceleration (ms

2

)

G ow rate per unit area (kg s

1

m

2

)

Gr Grashof number ()

H condenser height (m)

h heat transfer coefcient (Wm

2

K

1

)

k thermal conductivity (Wm

1

K

1

)

l tube length (m)

_ m mass ow rate, kg s

1

N number of wires ()

p pressure (Nm

2

)

P Pitch (m)

Pr Prandtle number ()

Q heat rejected (W)

Ra Rayleigh number ()

s surrounding gap thickness (m)

T temperature (K)

U overall heat transfer coefcient (Wm

2

K

1

)

u, v velocity (ms

1)

W condenser width (m)

x, y coordinate system (m)

Subscripts

a air

avg average

c condenser, convection

ev evaporator

e element

eq equivalent

i inner, element number

l liquid

o outer

r radiation

R refrigerant

s surface

t tube

v vapor

w wall

Greek letters

a thermal diffusivity (m

2

s

1

)

b coefcient of expansion (K

1

)

N ambient conditions

n kinematic viscosity (m

2

s

1

)

r air density (kg m

3

)

Refrigerator

compartment

Compressor

Refrigerator

condenser

Evaporator

tube

Refrigerator

door

Capillary

tube

Drier

Rubber gasket

H

W

Refrigerator

back-wall

wire

s

Interested parameter

Condenser tube

cross-section

air

current

Fig. 1 A schematic of a household refrigerator and the interested domain.

i nt e r na t i o na l j our na l of r e f r i g e r a t i on 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6 1646

natural draft on freestanding refrigerators and freezers or fan-

cooled on larger models and on models designed for built-in

applications. The natural-draft condenser is attached to the

back wall of the compartment, Fig. 1, and is cooled by natural

air convection under the refrigerator cabinet and up the back.

Mainly a natural-draft condenser consists of a at serpentine

of copper tubes of 4.5 mm outer diameter, and steel wires of

almost 1 mm diameter welded 6 mm apart normal to the

condenser tubes. Generally, one of the most important design

requirements for a condenser includes sufcient heat dissi-

pation at peak-load conditions. Insufcient surrounding air

passage or blocking this passage by a cabinet above the

refrigerator level will degrade the performance of the

condenser and thus the refrigerator (C engel and Boles, 1999).

The refrigerator performance and energy savings are of

great importance for many researchers. Laguerre and Flick

(2004) investigated natural convection inside the refrigerator

compartment. This is important to visualize the cabinet air

movement that will greatly help placing foods in places with

effective heat transfer.

To minimize the radiation effect of the condenser and

compressor surfaces on the interior temperature of refriger-

atorfreezers, a suggestion of covering the refrigerator wall

near the condenser and compressor with an aluminum foil

was studied in Afonso and Matos (2006). The authors

mentioned that putting this aluminum foil reduced the inte-

rior air temperature by 2 K.

The wire-on-tube condensers, used in the R-12 based

refrigerators, were numerically and experimentally studied by

Ameen et al. (2006) when used with R-134a based refrigera-

tors. The authors used the FEM method to analyze free

convection around this type of condensers. They tracked the

refrigerant ow to check the location where condensation

inception occurs. The authors investigated two different

condenser coils with different tube-and-wire pitch, number,

and length. They reported that the two-phase change loca-

tions are shifted downstream with either the increase in the

refrigerant mass owrate or increase in ambient temperature.

Bansal and Chin (2003) presented a useful analysis for the

wire-and-tube condenser. They optimized the condenser

capacity per unit weight by varying wire-and-tube pitches and

diameters. They reached an optimization factor that led to an

improved design with 3% gaining capacity and 6% reduced of

condenser weight. In the same study, the authors reported

that the outer heat transfer resistance contributes to about

80% for single-phase ow and 8395% for two-phase ow.

Further, the dominant heat-transfer mode is by convection,

which contributes to 65% of the total heat transfer.

Bansal and Chin (2002) studied the performance of the hot-

wall condensers, as a replacement of the wire-and-tube

condensers. The authors analyzed the heat transfer charac-

teristics for the condenser. They claimed that a 10% over-

prediction in condenser capacity was attributed to the heat

inltration into the refrigerator compartment, which they did

not consider intheir model. Theyconcludedthat theouter heat

transfer resistance contributes to about 80%and 8395%of the

total heat transfer for single and two-phase ow respectively.

The temperature of the space, in which the refrigerator is

placed, is of importance since it affects the heat dissipation

driving force. Saidur et al. (2002) experimentally studied the

effect of this ambient temperature on energy consumption.

The room temperature was varied from 14

C to 32

C in an

environmentally controlled chamber located in a laboratory.

The authors mentioned that, according to ASHRAE, 6070% of

the total refrigerator load is due to the temperature difference

between the air surrounding the refrigerator and the refrig-

erator interior temperature. The most signicant conclusion

drawn by the authors is that the room temperature has the

highest effect on energy consumption.

The motivation behind this paper was the way a household

refrigerator is placed in a kitchen or a room. In some narrow

places, the refrigerator backside, where the condenser is

attached, is pushed against a wall leaving a very small gap of

air to carry the condenser rejecting heat. Therefore, it was

thought that there should be a sort of optimization through

quantifying the effect of this gap on condenser rejected heat,

compressor consumed power, and accordingly the refriger-

ator performance.

The present analytical model did beneted froma previous

effective model (Bansal and Chin, 2003), but was modied to

serve a different purpose in this study.

2. Problem formulation

The temperature difference between the condenser-surface

temperature, T

s

, and the surrounding air temperature, T

a

, is

the driving force for rejecting the heat librated from the

refrigerators occupants. In most household refrigerators, the

condenser cooling process takes place naturally. Therefore, it

is very necessary to have an enough free space around the

condenser to allow this cooling process to occur effectively.

Being a part of the space in which the refrigerator is placed,

the condenser surrounding air has essentially the same

conditions as this space. Hence, the temperature of the

refrigerator surrounding affects the condenser effectiveness,

and accordingly the refrigerator performance. It is expected

that as the condenser surrounding space is narrowed or

blocked, the air owing through gets hotter. This would

prolong the compressor time of operation to reach an internal

thermostat set point, and would decrease the refrigerator

coefcient of performance as a result.

The physical domain to be studied is shown in Fig. 1. The

air surrounding the condenser is sandwiched between the

refrigerator back wall to which the condenser is attached and

the room wall. Through this width, s, the air temperature

surrounding the condenser importantly varies. Hence, the

driving force to reject the condenser heat into the surrounding

will be affected.

The analysis considered a certain refrigerant temperature,

and a xed refrigerant ow rate. This assumption helps

keeping the compressor working on a xed pressure ratio. The

goal was the effect of moving a refrigerator against a room

wall on the condenser heat rejected driving force.

3. Mathematical formulation

The mathematical analysis of this natural convection process

is based on an elemental energy balance. So, the element

i nt e r na t i o na l j o ur na l o f r e f r i g e r a t i o n 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6 1647

approach with variable conductance and air temperature over

the elements is employed. Fig. 2 shows an element of the

condenser. The element length is equal to the tube length, and

its height equals to the tube pitch, P

t

. Heat is rejected from

tube and wires by both convection and radiation. Therefore,

the heat transfer over an element can be represented by the

following equation:

Q

e

UA

e

_

T

R

T

a;avg

_

(1)

where UA

e

is the conductance, and T

a,avg

is the air average

temperature over the element. It is calculated in a weighting

fashion between the temperature of the air entering the

element, T

ai

, and the temperature of the air leaving the

element, T

ai1

, as follows:

T

a;avg

uT

ai

1 uT

ai1

T

ai1

uT

ai

T

ai1

(2)

where u is a weighting factor that is considered 0.5 in this

study for the sake of equally dividing the contribution of inlet

and exit air temperatures over the element. For heat to ow

from the refrigerant inside the tubes to the ambient air

surrounding the tubes, it should overcome a series of resis-

tances. These resistances are the inner convection resistance,

the conduction resistance, and the outer convection resis-

tance. The resistances are connected between refrigerant

temperature, inner wall temperature, outer-surface equiva-

lent temperature, and the average ambient temperature. The

surrounding air temperature was averaged in a weighted

fashion (eq. (2)) between the inlet and exit air temperatures

over the studied element. In addition, the condenser outer-

surface equivalent temperature was related to both the tube

temperature and wire temperature. The conductance is the

reciprocal of the summation of all these resistances. It can be

written as:

UA

e

1

1

h

i

A

i

lnr

o

=r

i

2pk

w

l

1

h

o

A

o

(3)

The outer area includes the area of the tube and the area of

the wires. It can be written as:

A

o

A

t

A

wire

pd

t

l 2pd

wire

P

t

N

The outer convective heat transfer is required. This coef-

cient represents both convection and radiation so, it can be

written as:

h

o

h

c

h

r

(4)

Knowing that convection and radiation take place from

both tube and wires, it is necessary to dene tube outer

temperature, T

t,o

, and wire temperature, T

wire

. The wires act as

ns, so the n efciency concept is adopted for the case of

nite length. Therefore, the n efciency is given as (Holman,

1981):

h

wire

tanh

mPt

2

_

_

mPt

2

_ ; where m

4h

wire

d

wire

k

wire

(5)

The wire temperature can then be calculated as follows:

T

wire

h

wire

T

t;o

u1 h

wire

T

ai

1 u 1 h

wire

T

ai1

(6)

knowing that h

wire

T

wire

T

a;avg

=T

t;o

T

a;avg

and using

equation (2).

Since the wires are normally welded to the tubes, a contact

resistance exists. Due to the wire small diameter, an equiva-

lent temperature taking into consideration the wire-and-tube

temperatures is proposed in Bansal and Chin (2003) as follows:

T

eq

A

t

T

t;o

A

wire

T

wire

A

o

d

t

lT

t;o

2d

wire

P

t

NT

wire

d

t

l 2d

wire

P

t

N

(7)

Substituting equation (6) into equation (7) gives:

T

eq

d

t

lT

t;o

2d

wire

P

t

NT

wire

d

t

l 2d

wire

P

t

N

a

1

T

t;o

a

2

T

ai

a

3

T

ai1

(8)

where the coefcients are dened as:

a

1

1 2NFh

wire

1 2NF

; a

2

2uNF1 h

wire

1 2NF

;

a

3

21 uNF1 h

wire

1 2NF

and the factor F represents a geometric ratio dened as:

F

_

d

wire

d

t

_ _

P

t

l

_

The outer-radiation heat transfer coefcient, h

r

is calculated

based on the energy balance between the radiation and

analogy to convection. The walls were assumed to have the

same temperature of the air since this free convection and the

air velocities are very small. Therefore, this outer-radiation

heat transfer coefcient, h

r

is calculated using the following

relation:

h

r

3

app

s

T

4

eq

T

4

a;avg

T

eq

T

a;avg

(9)

where 3

app

represents the apparent emissivity, which is an

identication parameter for the heat exchanger. It is taken

0.88 as a reasonable value (Bansal and Chin, 2003). The Stefan

Boltzmann constant, s, is 5.67 10

8

W/m

2

K

4

.

Tagliaco and Tanda (1997) proposed a correlation to

compute the outer convective heat transfer coefcient for the

wire-and-tube condenser. This correlation is given as:

h

c

Nuk

a

H

; where Nu

0:66

_

RaH

d

t;o

_

0:25

_

1

_

1 0:45

_

d

t;o

H

_

0:25

_

e

sw=4

_

(10)

and Ra Gr Pr bgT

t;o

T

N

H

3

=na.

Ta

i

Ta

i+1

P

t

Single

tube

Wires

Tube length

Q

e

Fig. 2 One-element layout for wire-and-tube

conguration.

i nt e r na t i o na l j our na l of r e f r i g e r a t i on 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6 1648

The parameter 4 28:2=H

0:4

sw

0:9

st

1:0

28:2=H

0:8

_

264=

_

T

t;o

T

N

_

0:5

sw

1:5

st

0:5

while swp

wire

d

wire

/d

wire

, and st p

t

d

t

/d

t

.

The solution procedure is presented in the ow chart

shown in Fig. 3. It is not easy to model the process without

setting some assumptions. In this study, the airow was

assumed to be steady state, laminar (Ra <10

9

), and the wires

and tube have constant temperatures. The refrigerant satu-

ration temperature corresponding to the condenser pressure

is dominant over the condenser length. In this analysis,

a degree of superheating and subcooling was assumed to be

5

C. As a result, a theoretical cycle was plotted on the pres-

sureenthalpy diagram of R-12, and an average condenser

temperature was calculated based on the condenser inlet

temperature in the superheated region, the saturation

temperature at P

c

, and the condenser exit temperature in the

compressed liquid region.

The inner convective heat transfer coefcient can be

calculated based on ASHRAE (1997) correlation for condensa-

tion in horizontal tubes. This correlation is in the form of:

hD

k

l

0:026

_

m

l

C

p

k

l

_

1=3

_

DG

eq

m

l

_

0:8

(11)

where G

eq

G

v

r

l

=r

v

0:5

G

l

.

Equation (11) is reported in ASHRAE (1997) (eqn. (13) by

Ackers et al. table (3), chapter 4) for a lm-type condensation

in horizontal tubes. The parameter G is the mass velocity

(mass ow rate/area), i.e. G

v

m

v

/A

v

, and G

l

m

l

/A

l

. Knowing

that m m

v

m

l

or 1 x m

l

=m, and AA

v

A

l

. The mass

No

Yes

No

yes

No

yes

h

wire

= h

o

Correct guessed

T

t,o

y = y + P

t

T

a i

= T

a i+1

Start

Input refrig. Temp., refrig. flow rate, tube and

wire element geometric data, conductivity

Calculate

wire

, T

wire

, T

eq

,

h

r

Update air properties based on T

eq

, and obtain h

c

and h

o

Calculate h

i

, and then Q

e

based on the resistances eq.(1)

Print T

ai

, T

ai+1

, Q

e

Stop

Initial guess of T

t,o

, h

wire

, and T

a i

Calculate T

t,o

, and element exit temp. T

a i+1

|T

t,o

- T

t,o,

g|

< 0.01

| h

o

- h

wire

| < 0.01

First tube and wire element, y = 0, P

t

Is y = condenser

height

Fig. 3 Flow chart of the analytical solution procedure.

i nt e r na t i o na l j o ur na l o f r e f r i g e r a t i o n 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6 1649

velocities can be approximated as: G

v

G, and G

l

(1 x)G for

a certain refrigerant ow rate.

Since heat transfer from the refrigerant to the ambient

equals to heat transfer from the refrigerant to the outer

surface of the condenser in the steady state, the outer tube

temperature can be calculated as:

T

t;o

T

R

Q

e

_

lnr

o

=r

i

2pkl

1

h

i

A

i

_

(12)

The heat rejected by the condenser outer surface is carried

by the airow surrounding the condenser. Hence, the exit air

temperature over an element is obtained through a heat

balance between the amount of heat rejected by convection

and radiation over that element with the air enthalpy change

and given as:

T

a;i1

Q

e

_ m

a

C

p

T

a;i

(12a)

The gap between the condenser and the room opposite wall

was treated as an enclosure of a rectangular cross-section.

Hence, at the condenser bottom this area along with an

assumed very low inlet air velocity and density was used to

estimate the inlet air mass owrate, neglecting the open-ends

effect, as the study focuses on a two-dimensional owand the

ow was assumed upward due to the buoyancy effect.

A FORTRAN program was written, based on the ow chart

shown in Fig. 3, and used the above-mentioned governing

equations to analyze the wire-and-tube condenser behavior.

4. Experimental measurements

Some measurements were carried out on a wire-and-tube

condenser of a real household refrigerator type (Ideal

RC225LF, 125 W) works on 145 g of R-12. The condenser

congurations are as listed below:

- Tube outer diameter 0.0045 m

- Wire diameter 0.001 m

- Tube pitch0.05 m

- Tube length0.45 m

- Condenser height 0.8 m

- No. of wires per side 64

- No. of tube elements 16

The refrigerator was placed against a roomwall leaving the

interested gap to be studied. Thermocouples were placed into

this gap at the condenser bottom, middle and upper levels to

measure the upward air temperatures at different cross-

distances. Thermocouples were soldered to the outer surface

of the tube and their junctions were wrapped to isolate the

junctions from the convection and radiation effect from

surrounding. The condenser temperature was averaged based

on three values at the bottom, middle, and upper portions.

The thermocouple accuracy was 1

C. For a certain internal

load at a setting evaporator temperature, the condenser

average outer-surface temperature was measured for the

three distances (30 mm, 100 mm, and 200 mm) and was found

to be 51

C, 47

C, and 41

C, respectively. These values were

considered in the analytical model to predict the condenser

heat rejected for the three cooling gaps. The refrigerant

temperature was assumed to be one degree above the outer

surface temperature since the tube thickness is small. The

refrigerant ow rate was considered varies from 0.0005 to

0.0007 kg s

1

. The whole cycle was plotted on the R-12 ph

diagram and the condenser heat rejected was found almost

between 120 W and 97 W; as the distance varies from 200 mm

to 30 mm. The cycle coefcient of performance was calculated

and found to be approximately from 2 to 3 for the same

refrigerating effect.

5. Numerical analysis

The computational uid dynamics, CFD, was used as a tool of

numerical visualization to model this buoyancy-driven

problem. Ansys, a commercial nite element program, was

used to predict the ow pattern through the different gap

thicknesses. The ow was assumed to be laminar (Ra <10

9

),

steady, and two-dimensional.

Since the natural ow around the condenser is mainly due

to the buoyancy effect, it is necessary to know the velocity

pattern and temperature variation as a result. This requires

solving for the momentum equations considering the effect of

buoyancy force on the pressure gradient. Then the energy

equation is solved to predict the temperature distribution.

Hence, the considered governing equations are the conser-

vation of mass, conservation of momentum, and conservation

of energy equations. Denitely, there is an order of magnitude

between the u and v values as well as their variation. These

equations, as given in Bejan, 1984 and listed below, predict the

air velocity and temperature variation under different

conditions.

vu

vx

vy

vy

0 (13)

u

vu

vx

y

vu

vy

1

r

vp

vx

nV

2

u (14)

u

vy

vx

y

vy

vy

nV

2

y gbT T

N

(15)

u

vT

vx

y

vT

vy

aV

2

T (16)

The y-momentum equation, eqn. (15), adopts the Boussinesq

approximation for the body force term. The momentum

equations (14) and (15) account for the change of momentum

due to free convection, and due to viscous effect due to the

buoyancy force effect. Equation (16) takes care of the energy

balance between heat dissipated by conduction and

convection.

Fig. 4 shows a schematic for the adopted boundary condi-

tions along the computational domain. No slip conditions

were assumed along the walls: the room wall, the refrigerator

back wall, and the condenser tubes outer surface. The bottom

inlet air to the condenser was assumed to have the same

temperature as the roomair. Avery tiny value of air velocity in

the y-direction, v

in

, was assumed to be a solution trigger. The

i nt e r na t i o na l j our na l of r e f r i g e r a t i on 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6 1650

atmospheric pressure was considered at the top exit boundary

conditions. Radiation cannot be neglected due to the nature of

the surfaces and the expected air low velocity around the

condenser. In the computational analysis, radiation model

was invoked through setting wall emissivities, and

temperatures.

To show grid sensitivity, a gradual mesh renement was

adopted. The solution started with a relatively coarse grid, and

the traverse and vertical air average temperature between

tubes was plotted successively until there was no signicant

variation. This tested the grid independent solution.

Quadrilateral elements with a quadratic approximation of

the shape function were used. The program forms the

element equation based on this selection. Then, elements

assembly to form the global matrix is carried on based on two

criteria: the continuity of the primary variables (velocity and

temperature) and the balance of the secondary variables

(ux). The prescribed boundary conditions are then applied

and the solution process using the tri-diagonal matrix algo-

rithm is carried out. Fig. 5 displays an enlarged portion of the

computational domain of the gap bounded by the refrigerator

back wall, where the condenser is attached, and a room wall.

6. Results and discussion

The heat rejected from the condenser is dependent on the

temperature difference between the condenser-surface

equivalent temperature and the surrounding air temperature.

Therefore, the main goal behind this study was to investigate

the effect of the surrounding gap around the condenser on its

heat rejection under a certain condition of refrigerant ow

rate.

Fig. 5 Enlarged view of the computational domain for the three distances considered.

a b

No kitchen cabinet With kitchen cabinet above.

u = v = 0

T = T

w

u = v = 0

T = T

w

u = v = 0

T = T

w

u = v = 0

T = Teq

u = v = 0

T = Teq

u = 0, v = v

in

, T = T

in

u = 0, v = v

in

, T = T

in

P = p

atm

P = p

atm

u = v = 0

T = T

w

u = v = 0

T = T

w

y

x

Fig. 4 A schematic of the interested domains with the corresponding boundary conditions. (a) No kitchen cabinet, (b) with

kitchen cabinet above.

i nt e r na t i o na l j o ur na l o f r e f r i g e r a t i o n 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6 1651

6.1. Effect of surrounding space

Fig. 6 depicts a qualitative seen for the temperature contours

around the condenser coil for the three-studied distances. A

remarkable difference is shown in terms of the temperature

variation between the three studied gaps. The gure shows

almost a laminar boundary layer around the tubes at the lower

part of the condenser within almost 150 mm from the inlet.

Beyond this point, an intermittent ow disturbance and the

ow wiggle around the tubes. Tagliaco and Tanda (1997)

mentioned that ow around wire-and-tube condensers are of

different regimes depending on the condenser height. More-

over, in the narrow gap (s 30 mm), almost a symmetrical

temperature distribution is noticed around the condenser

tubes with the higher temperature exists around the tubes

surface. As the gap width gets bigger, the symmetry trend is

lost. In addition, it can be seen the decrease in the transverse

air temperature across the gap for the 100 mm width

compared to the case of 30 mm. A further move of the

refrigerator from a room wall improves the rate of heat

rejected from the condenser. This can be attributed to the

enough sink in which the condenser rejects its heat. These

contours can depict the air plumes trapped around the

condenser tubes and room wall. Practically, as the condenser

can effectively reject the heat absorbed from the interior of

the refrigerator, the compressor time of operation can be

saved. This could improve the refrigerator coefcient of

performance as a result.

Quantitatively, the average air-temperature variation

inside the gap surrounding the condenser is presented in Fig. 7

for an ambient air temperature of 30

C, and a condenser

temperature of 50

C. The gure clearly describes the variation

of air average temperature at different gap widths. The gure

indicates that having a sufcient cooling gap around the

condenser (s >200 mm) would absorb the rejected heat, and

hence slightly affecting the surrounding air temperature

along the condenser. This sufcient space decreases the

convective and radiant resistance in front of the rejected heat,

and accordingly improves the overall heat transfer coefcient.

The gure illustrates the steeper boundary layer for the

narrow width (s 30 mm) compared to that is approaching

a atten prole at s >200 mm. It can be quantitatively

concluded that increasing the gap width around the

condenser from 30 mm to 300 mm resulted in almost a 70%

decrease in the air average temperature along the condenser

height, which will accordingly improve the heat transfer rate.

The variation of air average temperature and the corre-

sponding heat rejected is shown in Fig. 8. The gure illustrates

the decrease of the average air-temperature as the condenser

surrounding space gets wider. A signicant linear drop in the

Fig. 6 Air temperature contours along the condenser tubes (T

N

[30 8C).

i nt e r na t i o na l j our na l of r e f r i g e r a t i on 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6 1652

air temperature is shown up to a space width of 300 m, and

then the trend intends to approach an asymptotic behavior

beyond this gap thickness. This trend is under certain oper-

ating conditions of xed: refrigerant ow, condenser capacity

per weight, and cooling capacity. The gure can conclude that

the existence of a sufcient space around the condenser

would improve the heat reject driving force and accordingly,

allow more heat to be rejected from the condenser surface.

It is important to validate the analytical as well as the

numerical predictions through some measurements. Fig. 9

compares the vertical variation of air average temperature at

three different gap widths under the same operating

conditions. All trends are qualitatively similar; however,

there was a numerical overprediction at the lower part of

the condenser and a slight underprediction at the upper

part. This could be a result of a round-off error exists in the

numerical analysis.

6.2. Effect of room air temperature

Masjuki et al. (2001) mentioned that compressor efciency

declines as the ambient temperature rises, and the refriger-

ator consumption of electricity is sensitive to the ambient

temperature. The authors concluded that energy consump-

tionincreases around 40 Wh for a 1

Cincrease in the ambient

temperature. Hence, as the room air around the condenser

gains heat (roominternal loads, the refrigerator is placed close

to a gas stove as in a kitchen, or the refrigerator condenser is

exposed to the sun), the driving force for dissipating the

refrigerator internal load into surrounding decreases. There-

fore, in addition to the space around the condenser, there will

be a problem if the air in the room in which the refrigerator is

placed gains heat before owing up to the condenser tubes.

Fig. 10 presents an analysis for the effect of room air-

temperature increase on the amount of heat rejected by the

condenser. The analysis considered an average condenser

temperature. The gure shows a linear decrease of the heat

rejected with a line slope that is the heat capacity, UA, as the

room air temperature increased that means the decrease of

heat rejected per 1

C decrease of temperature difference

(T

eq

T

a,avg

) for a constant condenser temperature. The gure

also indicates that the resistance in front of the rejected heat

is strongly existed in the narrow gap thickness, s 30 mm.

The results showed that for a constant condenser tempera-

ture, increasing the room air temperature decreases the heat

rejected by almost 65%.

6.3. Effect of air blockage

Blocking the air passage around the condenser would signi-

cantly affect the air behavior and the condenser effectiveness

as a result. An example of blocking the air around the

condenser is having a cabinet with a certain depth and at

a certain distance above the refrigerator. Such a cabinet

existence would affect the natural convection process and the

rate of heat reject as a result. The present study visualized

through the CFD the effect of having such a cabinet (15 cm

above the level of a refrigerator). Fig. 11 quantitatively

compares the average air-temperature variation in both cases.

An increase of almost 6

C in the air temperature can be seen

near the upper part of the condenser, when the cabinet exists.

This increase can be attributed to the accumulation of hot

plumes of air belowthe cabinet surface. This would eventually

decrease the ability of condenser to reject its heat. On the

Air Temperature, C

25 30 35 40 45

V

e

r

t

i

c

a

l

D

i

s

t

a

n

c

e

,

m

0.0

0.2

0.4

0.6

0.8

s = 0.03 m

s = 0.1 m

s = 0.2 m

s = 0.3 m

s = 0.4 m

s = 0.5 m

Fig. 7 Average air temperatures distribution along the

condenser height.

Cooling Gap Thickness, m

0.0 0.2 0.4 0.6 0.8 1.0

H

e

a

t

R

e

j

e

c

t

e

d

,

W

10

20

30

40

50

60

70

80

A

v

e

r

a

g

e

A

i

r

T

e

m

p

e

r

a

t

u

r

e

,

C

30

32

34

36

38

40

42

44

46

(T = 30 C)

Fig. 8 Effect of gap thickness on air average temperature

and condenser heat rejected.

i nt e r na t i o na l j o ur na l o f r e f r i g e r a t i o n 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6 1653

other hand, the effect of the cabinet is not felt at the lower part

of the condenser up to a distance of 0.2 m.

Fig. 12 shows a qualitative numerical visualization of the

air temperature contours for the case of s 100-mm width.

The gure clearly shows the difference when a cabinet is

existed above the refrigerator. The gure depicts the warm

air plumes accumulation near the cabinet due to closing

the vertical passage in front of the buoyant air. This indi-

cates a stratication effect. It can be shown the increase of

air temperature around the condenser tubes as well as

where the upward-owing air is leaving the refrigerator

back wall.

Room Air Temperature, C

15 20 25 30 35 40 45

C

o

n

d

e

n

s

e

r

H

e

a

t

R

e

j

e

c

t

e

d

,

W

0

20

40

60

80

100

120

s = 0.03 m

s = 0.1 m

s = 0.2 m

s = 0.5 m

T

c

= 50 C)

Fig. 10 Effect of room temperature variation on condenser

heat rejected.

Air Average Temperature, C

0 10 20 30 40 50 0 10 20 30 40 50 0 10 20 30 40 50

V

e

r

t

i

c

a

l

D

i

s

t

a

n

c

e

,

m

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

s = 0. 03 m (num.)

s = 0. 03 m (analy.)

s = 0.03 m (Exp.)

Air Average Temeprature, C

V

e

r

t

i

c

a

l

D

i

s

t

a

n

c

e

,

m

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

s = 0.1 m (num.)

s = 0.1 m (analy.)

s = 0.1 m (Exp.)

Air Average Temperature, C

V

e

r

t

i

c

a

l

D

i

s

t

a

n

c

e

,

m

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

s = 0.2 m (num.)

s = 0.2 m (analy.)

s = 0.2 m (Exp.)

Fig. 9 Average air temperature along the cooling gap at the three distances considered.

Average Air Temperature, C

0 10 20 30 40 50

V

e

r

t

i

c

a

l

D

i

s

t

a

n

c

e

,

m

0.0

0.2

0.4

0.6

0.8

No Cabinet

With Cabinet

Fig. 11 Air-temperature variation through the 0.1 m gap

without and with a kitchen cabinet almost 0.15 m above

the level of the refrigerator.

i nt e r na t i o na l j our na l of r e f r i g e r a t i on 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6 1654

7. Conclusions

A household refrigerator placed in a space where insufcient

surrounding air surrounds the condenser would certainly

degrade its performance. The aim of this paper was to

investigate the effect of this surrounding space on the

condenser capacity to reject heat. Some conclusions can be

drawn from the study. The results showed that having an

enough space (s >200 mm) around the condenser increases

the driving force of heat transfer from the condenser. On the

other hand, if the room air temperature increased, even for

an enough space, the amount of heat rejected will decrease.

Blocking the space around the condenser will resist the up-

ow of buoyant air and allow for hot air accumulation close

to the upper part of the condenser. Accordingly this would

decrease the driving force to reject heat out of the condenser

surface.

r e f e r e n c e s

Ameen, Ahmadul, Mollik, S.A., Mahmud, Kizir, Quadir, G.A.,

Seetharamu, K.N., 2006. Numerical analysis and experimental

investigationintotheperformanceof awire-on-tubecondenser

of a retrotted refrigerator. Int. J. Refrigeration 29, 495504.

ASHRAE, 1997. ASHRAE Handbook of Fundamentals. American

Society of Heating; Refrigerating; and Air Conditioning

Engineers, Atlanta, GA (Chapter 4).

Afonso, Clito, Matos, Joaquim, 2006. The effect of radiation

shields around the air condenser and compressor of

a refrigerator on the temperature distribution inside it. Int. J.

Refrigeration 29, 789798.

Bansal, P.K., Chin, T.C., 2002. Design and modelling of hot-wall

condensers in domestic refrigerators. Appl. Therm. Eng. 22,

16011617.

Bansal, P.K., Chin, T.C., 2003. Modelling and optimisation of wire-

and-tube condenser. Int. J. Refrigeration 26, 601613.

Fig. 12 Temperature contours for the 0.1 m gap with and without a kitchen cabinet above the level of the refrigerator

(T

N

[30 8C, T

c

[50 8C). (a) No kitchen cabinet, (b) with a kitchen cabinet.

i nt e r na t i o na l j o ur na l o f r e f r i g e r a t i o n 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6 1655

Bejan, Adrian, 1984. Convection Heat Transfer. John Wiley & Sons

Inc. (Chapters 4 and 7)

C engel, Yunas A., Boles, Michael A., 1999. Thermodynamics, an

Engineering Approach, third ed. McGraw-Hill Co.

Holman, J.P., 1981. Heat Transfer, fth ed. McGraw Hill Co.

Laguerre, O., Flick, D., 2004. Heat transfer by natural convection in

domestic refrigerators. J. Food Eng. 62, 7988.

Masjuki, H.H., Saidur, R., Choudhury, I.A., Mahlia, T.M.I.,

Ghani, A.K., Maleque, M.A., 2001. The applicability of ISO

household refrigeratorfreezer energy test specications in

Malaysia. Energy 26, 723737.

Saidur, R., Masjuki, H.H., Choudhury, J.A., 2002. Role of ambient

temperature, door opening, thermostat setting position and

their combined effect on refrigeratorfreezer energy

consumption. Energy Convers. Manage. 43, 845854.

Tagliaco, L., Tanda, G., 1997. Radiation and natural convection

heat transfer from wire-and-tube heat exchangers in

refrigeration appliances. Int. J. Refrigeration 20, 461469.

i nt e r na t i o na l j our na l of r e f r i g e r a t i on 3 2 ( 2 0 0 9 ) 1 6 4 5 1 6 5 6 1656

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Free Convection On A Refrigerator's CondenserDokumen5 halamanFree Convection On A Refrigerator's CondenserRavinder SinghBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- SP 13 1 Part1 SolutionDokumen6 halamanSP 13 1 Part1 SolutionRavinder SinghBelum ada peringkat

- A Heat Transfer Correlation For Natural Draft Wire-And-tube CondensersDokumen10 halamanA Heat Transfer Correlation For Natural Draft Wire-And-tube CondensersRavinder SinghBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Thermal Resistance of Steam Condensation in Horizontal Tube BundlesDokumen8 halamanThermal Resistance of Steam Condensation in Horizontal Tube BundlesRavinder SinghBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Updates: Dialogue Project Report Due: April 22 Punishment and BiotechnologyDokumen5 halamanUpdates: Dialogue Project Report Due: April 22 Punishment and BiotechnologyRavinder SinghBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Heat Transfer Review QuestionsDokumen8 halamanHeat Transfer Review QuestionsBrittany MorganteBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- MF 6 Kant Mill ReviewDokumen5 halamanMF 6 Kant Mill ReviewRavinder SinghBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- MF 12 Sexual MoralityDokumen5 halamanMF 12 Sexual MoralityRavinder SinghBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- MF 15 Steffen and DavisDokumen6 halamanMF 15 Steffen and DavisRavinder SinghBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- MF 12 Finnis and CorvinoDokumen8 halamanMF 12 Finnis and CorvinoRavinder SinghBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- MF 15 Punishment and DPDokumen7 halamanMF 15 Punishment and DPRavinder SinghBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Lab Assignments - Week 5: Lines and Dimensions Should Be On Different LayersDokumen4 halamanLab Assignments - Week 5: Lines and Dimensions Should Be On Different LayersRavinder SinghBelum ada peringkat

- MF 5Dokumen4 halamanMF 5Ravinder SinghBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- MF 6 Kant Mill ReviewDokumen5 halamanMF 6 Kant Mill ReviewRavinder SinghBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- MF 2 Gandhi IgnatieffDokumen5 halamanMF 2 Gandhi IgnatieffRavinder SinghBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Chapter 3 Review: Chapter 4 Egoism and The Social ContractDokumen5 halamanChapter 3 Review: Chapter 4 Egoism and The Social ContractRavinder SinghBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- MF 5Dokumen4 halamanMF 5Ravinder SinghBelum ada peringkat

- Chapter 1 Review: MetaethicsDokumen5 halamanChapter 1 Review: MetaethicsRavinder SinghBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- MF 3 Pojman and RortyDokumen3 halamanMF 3 Pojman and RortyRavinder SinghBelum ada peringkat

- MF 3 RelativismDokumen5 halamanMF 3 RelativismRavinder SinghBelum ada peringkat

- A P A V S F: CE121: Exam-1 Supporting MaterialDokumen1 halamanA P A V S F: CE121: Exam-1 Supporting MaterialRavinder SinghBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Lalita Oka - Fall 2013 Schedule PDFDokumen1 halamanLalita Oka - Fall 2013 Schedule PDFRavinder SinghBelum ada peringkat

- MF 1Dokumen4 halamanMF 1Ravinder SinghBelum ada peringkat

- Brock Planetary Declination SDokumen6 halamanBrock Planetary Declination SDositheus Seth100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Extrahepatic Biliary Tract Pathology - Cholidolithiasis, Cholidocholithiasis, Cholecystitis and CholangitisDokumen60 halamanExtrahepatic Biliary Tract Pathology - Cholidolithiasis, Cholidocholithiasis, Cholecystitis and CholangitisDarien LiewBelum ada peringkat

- Chapter 5: Sampling Distributions: Solve The ProblemDokumen4 halamanChapter 5: Sampling Distributions: Solve The ProblemEunice WongBelum ada peringkat

- Modern Views Catalogue/Sotheby's BenefitDokumen36 halamanModern Views Catalogue/Sotheby's BenefitStudio AdjayeBelum ada peringkat

- VlsiDokumen79 halamanVlsimdhuq1Belum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Israel StandardDokumen15 halamanIsrael StandardDũng Bùi Đức100% (1)

- Smart Locker - A Sustainable Urban Last-Mile Delivery Solution: Benefits and Challenges in Implementing in VietnamDokumen14 halamanSmart Locker - A Sustainable Urban Last-Mile Delivery Solution: Benefits and Challenges in Implementing in VietnamQuynh LeBelum ada peringkat

- PDFDokumen8 halamanPDFDocBelum ada peringkat

- 1.1 - Selectividad Acti9Dokumen34 halaman1.1 - Selectividad Acti9Bladimir MichelBelum ada peringkat

- VAM Must Sumitomo 1209 PDFDokumen4 halamanVAM Must Sumitomo 1209 PDFnwohapeterBelum ada peringkat

- AdPoe The Hunting of The HareDokumen2 halamanAdPoe The Hunting of The HarePI CubingBelum ada peringkat

- Soal Bahasa Inggris X - XiDokumen6 halamanSoal Bahasa Inggris X - XiBydowie IqbalBelum ada peringkat

- HardikDokumen21 halamanHardikGohil HardikBelum ada peringkat

- Penawaran Pekerjaan Fire Fighting (Upah + Material)Dokumen3 halamanPenawaran Pekerjaan Fire Fighting (Upah + Material)vixer ndi100% (6)

- Deva Surya - 19MF02Dokumen30 halamanDeva Surya - 19MF02SaravananBelum ada peringkat

- 14 WosDokumen6 halaman14 WosATUL KURZEKARBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Chemistry Mid Term Exam 2014Dokumen8 halamanChemistry Mid Term Exam 2014Adham TamerBelum ada peringkat

- Study of Mosquito Larvicidal Effects of (Bitter Gourd) Extracts As NanopowderDokumen3 halamanStudy of Mosquito Larvicidal Effects of (Bitter Gourd) Extracts As NanopowderAnonymous AkoBelum ada peringkat

- Basic Principles of Remote SensingDokumen24 halamanBasic Principles of Remote Sensingfelipe4alfaro4salas100% (1)

- 2003 Nissan Altima 2.5 Serivce Manual RSUDokumen12 halaman2003 Nissan Altima 2.5 Serivce Manual RSUAndy Dellinger100% (1)

- Gcat Threathorizons Full Jan2023Dokumen26 halamanGcat Threathorizons Full Jan2023josbjsBelum ada peringkat

- Afectiuni Si SimptomeDokumen22 halamanAfectiuni Si SimptomeIOANA_ROX_DRBelum ada peringkat

- Civil Engineering Topics V4Dokumen409 halamanCivil Engineering Topics V4Ioannis MitsisBelum ada peringkat

- 1 Name of Work:-Improvement of Epum Road (Northern Side) Connecting With Imphal-Saikul Road I/c Pucca DrainDokumen1 halaman1 Name of Work:-Improvement of Epum Road (Northern Side) Connecting With Imphal-Saikul Road I/c Pucca DrainHemam PrasantaBelum ada peringkat

- PalmistryDokumen116 halamanPalmistrymarinoyogaBelum ada peringkat

- Company Profile: Only Milling Since 1967Dokumen16 halamanCompany Profile: Only Milling Since 1967PavelBelum ada peringkat

- Genie Z45/22Dokumen58 halamanGenie Z45/22jonny david martinez perezBelum ada peringkat

- 2014 An125hkl4Dokumen69 halaman2014 An125hkl4El Turco ChalabeBelum ada peringkat

- Good Stuff Courage, Resilience, Gratitude, Generosity, Forgiveness, and Sacrifice (Akhtar, Salman)Dokumen221 halamanGood Stuff Courage, Resilience, Gratitude, Generosity, Forgiveness, and Sacrifice (Akhtar, Salman)madhugaggar999Belum ada peringkat

- Stokerchapter25lipidmetabolism 160320032037Dokumen29 halamanStokerchapter25lipidmetabolism 160320032037Dawlat SalamaBelum ada peringkat

- Practical Reservoir Engineering and CharacterizationDari EverandPractical Reservoir Engineering and CharacterizationPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataDari EverandPocket Guide to Flanges, Fittings, and Piping DataPenilaian: 3.5 dari 5 bintang3.5/5 (22)