Individual Project Assignment

Diunggah oleh

Yoseph BirruHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Individual Project Assignment

Diunggah oleh

Yoseph BirruHak Cipta:

Format Tersedia

Haul Road Upgrade Project

1 | P a g e

ENTREPRENEURSHIP, COMMERCIALISATION & INNOVATION CENTRE

TECHCOMM5012

APPLIED PROJECT MANAGEMENT

HAUL ROAD UPGRADE PROJECT

Stephen James McKnight

26, May 2012

Haul Road Upgrade Project

2 | P a g e

ENTREPRENEURSHIP, COMMERCIALISATION & INNOVATION CENTRE

TECHCOMM5012

HAUL ROAD UPGRADE PROJECT

CONTENTS

EXECUTIVE SUMMARY10

INTEGRATION...11

SCOPE...12

TIME..16

COST..18

QUALITY20

RISK22

HUMAN RESOURCES24

COMMUNICATIONS.26

PROCUREMENT.28

APPENDIX

Appendix.1 THE MINE MANGEMENT PLAN50

AFE Authorisation For Expenditure Request, OZ Minerals Business Case Submission

Thiess Contract Quote & Rates for requested equipment & resources

Wet Weather delays business case & supporting evidence presentation

LEAN SIX SIGMA DMAIC Business case presentation

Business Improvement Posters & Monthly data progress presentations

Thiess Road Design & Standards Criteria Document

REFERENCES

References....103

Haul Road Upgrade Project

3 | P a g e

The University of Adelaide - TECHCOMM5021

Course Lecturer: John Sing

Major Project:

HAUL ROAD UPGRADE PROJECT

Executive Summary

Up to 10 words description of what the project is.

Upgrade mine roads to an all-weather haul road system

Where is the Project Located?

OZ Minerals, Prominent Hill, South Australia

Who is the Owner and Sponsor

The owner is Dave Way (Deputy Operations Manager, OZ Minerals)

The sponsor is Robert Boyd (Open Pit Manager, OZ Minerals )

The Key Stakeholders are OZ Minerals & Thiess

The name of the Project Manager

Stephen McKnight & also the Expert Road Consultant

Your picture, vision or dream of the projects outcome

A total of 20% of all excavators downtime is attributed to wet weather rainfall events and

subsequent delays. The vision or dream is to minimise this figure by some 25%-50%.

To put this loss into perspective on average each excavator loses some 370 operating hours per

year per digger to wet weather events and subsequent delays, which is equivalent to 480,000

BCMs per excavator per year in lost productivity at $43.00 per BCM, which is some

$20,000,000.00 multiplied by 5 excavators giving $100,000,000.00 in total potential saving costs

on notional EBIDTA values (Earnings Before Interest, Taxes and Amortization).

This project will potentially save $25,000,000.00 up to $50,000,000.00 depending on the

successful implementation of the key deliverables outlined in the Project Management Plan.

Historically, over the last 4 years the Mine has had on average 4 times the predicted annual

rainfall, which has produced a loss of 920 hours of production per year per digger. These rainfall

events typically occur during the months of November to April. Therefore, it is critical to complete

the project before November 2012

The ultimate target is to achieve a minim of 6000 hours production per year per digger. The Haul

Road Upgrade Project will go some way to achieving this target (20%) in conjunction with other

site based initiatives including: a LOM dewatering strategy, blasting increases in pattern size/drill

Haul Road Upgrade Project

4 | P a g e

bit size and a 10% increase in powder factors and hot seat changes in all production equipment,

with staggered fly-in-out days for maximum coverage and finally vertical advance heights of

flitch/bench versus digger movement along wider and deeper benches

The Phase of the project

Due to the fluid and nonlinear nature of such a project we have been pushing every phase possible

at once because of the tight deadline involved, i.e. this project needs to be completed by the next

significant rain events predicted from November 2012 until April 2013.

Therefore, the phase progressions are as follows;

a. Define, identify a problem or opportunity, which has been completed

b. Measure the baseline of the process has been implemented and started January 2012

c. Analyse, identify and validate root causes. A fishbone analysis has been completed,

problem analysis brainstorming completed, root cause prioritisation implemented, 5W

root cause analysis completed, root cause validation established by RTS Friction test

carried out on site to find baseline, a Traffic Light Friction Risk model has been

implemented and various other Project Management Tools have also been implemented,

which will be outlined in the body of this presentation.

d. Improve, find and evaluate best improvements. The best solution was to adopt the use

of a traffic light system for remediation of mine haul roads with some 25 interrelated

criteria across the 3 lights. However, the primary criteria is outlined below;

i. Red light = high priority site requiring immediate remediation with associated

plan and methodology

ii. Amber Light = less intense remediation but significant nonetheless and finally

iii. Green Light = a 200mm wearing course needs to be established to make the road

compliant with the all-weather upgrade specifications

iv. Red Light requires sub-base of up to 1000mm

v. Amber Light requires base of 600mm

vi. Green Light Running surface 200mm

vii. Crossfall of 2% on in pit and mine haul roads

viii. Centre camber with 2% crossfall on dump ramps and roads

ix. Establish significant drainage and run-off sumps

e. Control, execute and maintain improvement.

i. Cost

ii. Schedule

iii. Process Control

iv. SOPS

v. Training

vi. Communications

The project is now in the execution phase

a. All equipment for the project will be on-site by the end of April 2012

b. The T8 supervisors from Thiess have been executing the plan with limited equipment,

resources and material

c. The project is 38% complete to this date regardless the above constraints

Who is the client Representative?

Haul Road Upgrade Project

5 | P a g e

Leidy Alvarado, OZ Minerals Mine Improvement Project Engineer

Who are the Stakeholders?

OZ Minerals Senior Management Team

OZ Minerals Open Cut Management Team

MIT OZ Minerals Project Team

Thiess earth moving contractors

Independent Road Expert Consultant

Purpose of the Project:

Site Description

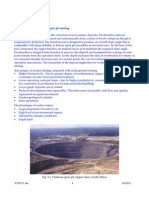

OZ Minerals operates both an open cut and underground copper/gold mine and

processing plant at the Prominent Hill Mine site. Prominent Hill is a remote site

with a FIFO and limited DIDO out workforce supporting the mining, production

and exploration activities. A permanent accommodation village located 3 kms

from the mining operations supports some 1500 workers. Processing of ore

commenced in February 2009. Ore averaging 1.5% Cu and 0.5g/t Au is processed

at a nominal rate of 8Mt per annum to produce copper concentrate via both

Darwin and Port Adelaide by both rail and road

Site Location and Access

The mine site is located 650km north-west of Adelaide, South Australia, some

100km south east of Coober Pedy and 150km north-west of Roxby Downs. The

site is accessible via an unsealed road off the Stuart Highway 100km south of

Copper Pedy. Daily charter flights from Adelaide, Melbourne and Port Augusta

service the FIFO workers

Site Observations

The access ramps are generally in poor condition at higher elevations

recommended by geological element profiles. The majority of access ramps do

not indicate any crossfall. No drainage or facility for run-off from the haul roads

seems to be in place, except for water running along the full length of access

ramps from higher levels to lower levels. This is one of the major causes of

uncontrolled water runoff during major rainfall events. The majority of access

ramps are graded and compacted. The use of inappropriate material selection on

some ramps. There are many cases of wheel rutting on ramp corners due to poor

material selection. Gradients on most active in-pit ramps are between 8%-10%.

Waste dump ramps vary from 5%, 8% and 10% depending on dumping criteria and

poor design. Steely Haematite, Andesite and Dolomite are the best material to

source for the remediation project. Large oversized material has been deposited

on windrows

The existing access ramps make up 3.5km of the total 10km mine haul road

system. The width of ramps are currently 23m being used for 48 haul road trucks,

CAT 793D. Other equipment on-site is made up of some 5 graders CAT 24H,

another 6 Dozers D10T and 4 Liebher 996 excavators with numerous other

ancillary equipment

Some recommendations based on the observations are;

Haul Road Upgrade Project

6 | P a g e

Create a dedicated road maintenance project team

1 x Project Manager

1 x Project Engineer

4 x Various Independent Consultants required during execution phase

and peer review (Expert Road Engineer, Geotechnical Engineer, Friction

Loss Engineer, Surveyor and Peer Review Engineer)

2 x Supervisors (T8)

10 x Operators

Source appropriate equipment

1 x Wheel Loader CAT 992D

2 x Komatsu 785 dump trucks

1 x Grader CAT24H

1 x Komatsu 300 Digger (Contract digger to supplement fleet)

1 x CAT 777 Water Truck

1 x CAT D10 Dozer

And other ancillary equipment as required; Compactors or Impactors

Source appropriate material

Steely Haematite

Haematite

Andesite

Dolomite

Greywacke

Granitites

Engage a dedicated survey team to control and monitor the daily works

supervised by the T8 Thiess operator in charge of implementing the traffic light

system management plan

Purchase the friction testing unit to verify when roads are safe to be driven on

after all rain events

Follow the rain event flow diagram to minimise downtime

The Objectives:

Scope

To address the issue of unsealed roads and the downtime associated with them

during and after rainfall events. This includes, road surfaces, remediation

configurations, floodways, cuts, fills, drainage and mine haul road design, the

identification of unsealed roads and suitable material selection for remediation

including in-pit material and engineered commercially produced material. This

remediation program will include the determination of sub base, base and

wearing course thickness, drainage and erosion protection, environmental

considerations, performance expectations, including surface condition

assessment.

Time

Haul Road Upgrade Project

7 | P a g e

The estimated scheduler for this project is 12 months starting January 2012 until

January 2013

The schedule is broken up into phases which will be elaborated on at a future

date and location in this document

Cost

The estimated cost will be divided between OP EX and CAP EX the expenditure is

in the vicinity of $1.3M CAP EX and $4M OP EX, giving a total of some $5.3M spend

OP EX will pay for the machine, operator utilisation and some occasional day

work nominated activities

CAP EX will pay for material, Consultants and other yet to be identified costs

Requirements to be satisfied:

With the new contract model the Company has accepted the responsibility to upgrade

the haul roads in the open pit to a standard to assist in decreasing the operational delays

and risk involved in friction loss, with respect to the deterioration of the haul roads,

evident during wet weather.

Situation: The mine operates 24/7 365 days per annum. Excavator productivity is now seriously limited

by the fact that the pit is closed off when it starts raining, and then it takes a long time to

reopen the pit after the rain. This is because mine operations wait for roads to be dry again,

to avoid possibility of track slides. Overall wet weather causes circa 370 hours of downtime

per excavator per annum. The mining contract currently states that the contractor is

accountable to maintain all-weather roads.

Complication: The mining contractor is not confident that an all-weather pit is possible at Prominent Hill,

claiming that the quality of the material available on site for road-sheeting. The is no clarity

also on the type of materials to be used, size of materials, current quality of design, use of

reagents, maintenance practices, etc. The road maintenance practices for managing haul

roads before, during and after wet weather events are also not clear and codified (e.g.

scarifying, sheeting, grading, etc.)

Resolution: OZ Minerals is willing to engage an experienced contractor on road design and maintenance

to perform a review of the current haul roads. This will include: design, road sampling, wet

weather performance, dust suppression, material quality & sizes, maintenance practices. The

scope of the report though should primarily be focused on providing OZ Minerals with a

recommendation on how to keep the mining operations running as long as possible during

and after wet weather events. To achieve this scope we would engage a contractor that has

previous experience in such projects and issues, especially in all weather mines or in mines

in tropical areas.

The Roles & Responsibilities

The roles Identified for the project are

Project Manager (Stephen McKnight)

Project Engineer ( Leidy Alvarado)

Haul Road Upgrade Project

8 | P a g e

Road Maintenance Supervisors ( David Kurtzer & Chris Carroll)

2 x 992 Loader Operator

2 x 24H Grader Operators

4 x 785 Truck Operators

2 x 773 Water Cart Operators

1 x Ancillary Operator from independent contractor

The Benefits

What are we trying to achieve

To reduce the wet weather delays associated with Excavator utilisation by at

least 25% representing 370 hours per year for each excavator

Why we should implement the project

This 25% reduction in lost excavator hours represents a potential minimum

$25,000,000.00 EBITA saving to the company annually

The value proposition for the sponsor

At least a 25% EBITA saving per annum representing some $25,000,000.00 saving from a

capital outlay of $5,3000,000.00

Constraints and assumptions

Equipment availability

It has been identified that there is a lack of suitable and available equipment to

implement the project

Material availability

It has been identified that there is not enough suitable or available appropriate

material crushed or screened or stockpiled for the project

Resource availability

Ramping up to the 16 people required for the continuous implementation of the

six month execution phase

Scope, Time & Cost

Even though the project was identified some 1.5 years ago there was no

political will to implement the project due to a lack of consistent direction,

scope, funds and a dedicated champion to drive the project forward.

The implementation strategy including Critical Success Factors (Targets, KPIs and Tolerances)

The project requires completion before the next expected rainfall events, which are

usually expected in November 2012 until April 2013.

Implementation occurred on the 5/12/2011 when the road expert was engaged in

anticipation for the contract change reflecting the haul road upgrade project as a key

strategy for increased productivity of a potential 20% of total Excavator increased

utilisation.

From implementation key actions were identified and progressively introduce; ancillary

equipment, appropriate material, scientific measurement of friction loss and finally

execution of appropriate design criteria for successful completion of the projects targets

mentioned in previous sections of the executive summary.

Risk and treatment

Haul Road Upgrade Project

9 | P a g e

The issue of wet weather delays is very complex and there are no one size fits all solutions

in play. Regardless the fact that there are civil engineering solutions that can and will be

applied; this site has specific requirements for the appropriate solution and outcomes

desired

Lack of basement material or crushed/screened or stockpiled material available when

required

Equipment availability from Thiess

HV & LV, HV & HV interactions during construction/execution phase of project

Resource availability from Thiess for HV requirements

Impact of road maintenance team during construction on production team

Natural disasters

Wet weather rainfall events

How phases can facilitate delivery of future phases (particular design or constructability)

Once the construction/execution phase of the project is completed there will be an

emphasis on maintaining the newly constructed roads on a regular basis so that the

current situation is not revisited during the remaining 6 years of the mines life

The implementation of a road maintenance team will facilitate the continuous upgrade

and improvement of the haul road system without the re-introduction of a sustained

initial haul road upgrade campaign, which is in progress at this time

From the RA all necessary steps have been implemented to negate and mitigate this

phase occurring again in the LOM strategy, this phase is a once off action of the project

leading to a continuous improvement phase

Work Breakdown Structure

Suffice to say that the 5 key areas of the WBS have been defined

Define the situation

Implement/Establish the action plan

Acquire the;

Resources

Material

Equipment

Execute the action plan

Close out the project

The impact of the project on stakeholders

OZ Minerals will have a significant increase in productivity

This will provide increases in share value for stakeholders

The increased productivity will impact the companys bottom line

This will provide extra capital for future project development

Thiess will have multiple benefits

Increased productivity

Reduced wear & tear on equipment

Reduced soft tissue issues for operators

Maintain compliance with the LOM Contract introduced in January 2012

Haul Road Upgrade Project

10 | P a g e

Milestone and an activity schedule

5/12/2011 Independent Road Expert engaged to implement project

5/1/2012 Project needs identified and implemented

5/2/2012 Execution phase begun with limited; resources, equipment and material

5/3/2012 Scientific validation of friction loss assessed and measured

5/4/2012 Resources, Equipment and Material in place and beginning execution phase

5/5/2012 Execution in full swing, all elements on-site and in play

5/6/2012 to 5/11/2012 Haul Road Maintenance Plan following PMBOK project cycles until

conclusion of project in November 2012

Budget

$5.3M have been committed to the Haul Road Upgrade Project

The $5.3M will be divided into CAPEX $1.3M, which includes payment of expert engineers

and surveyors, material all in 75mm for wearing course, friction testing module, uplift of

equipment and any other costs outside the committed OPEX money

OPEX is committed at $4M this pays for equipment hire for the six months of the

execution phase of the project

There is a further contingency fund available, but to this point a final figure has not been

negotiated with the OZ Minerals BI and financial Departments, suffice to say a top end

figure of $1M extra funds could be available if required. However, the current budget is on

track with no need for a contingency to be anticipated

The CAPEX is well within budget with only some $350,000.00 committed thus far,

however the cost of the material (75mm all in) will eat into this fund significantly, some

$1M over the 6 months

The OPEX has an anticipated burn rate of $550,000.00 per month for 6 months coming

in at $3.3M, leaving a $700,000.00 contingency fund if required

Are there Enterprise Environmental Factors or Organisational Process Assets which can be used?

Refer to the body of this document with emphasis on the PMBOK processes

The Management structure of both OZ Minerals Thiess have been utilised in the initial

stages of the projects development, until the project produced its own organisational

chart and resources

All material has been sourced from the PIT

All resources and equipment have been sourced from Thiess

Road design criteria has been sourced from Thiess and previous champions of the project

Further development of the road design criteria have been introduced from the Expert

Road Consultant working in concert with both site based knowledge groups and the

adoption of industry best practise applications to the specific and unique site

requirements

Haul Road Upgrade Project

11 | P a g e

PMBOK MANAGEMENT PLAN

Plans for managing (planning, monitoring & controlling- If Areas not already covered)

Integration

Scope

Time

Cost

Quality

Risk

Human Resources

Communications

Procurement

Haul Road Upgrade Project

12 | P a g e

INTEGRATION

Up to 10 words description of what the project is.

Upgrade mine roads to an all-weather haul road system

Where is the Project Located?

OZ Minerals, Prominent Hill, South Australia

Who is the Owner and Sponsor

The owner is Dave Way (Deputy Operations Manager, OZ Minerals)

The sponsor is Robert Boyd (Open Pit Manager, OZ Minerals )

The Key Stakeholders are OZ Minerals & Thiess

The name of the Project Manager

Stephen McKnight & also the Expert Road Consultant

Your picture, vision or dream of the projects outcome

A total of 20% of all excavators downtime is attributed to wet weather rainfall events and

subsequent delays. The vision or dream is to minimise this figure by some 25%-50%.

To put this loss into perspective on average each excavator loses some 370 operating hours per

year per digger to wet weather events and subsequent delays, which is equivalent to 480,000

BCMs per excavator per year in lost productivity at $43.00 per BCM, which is some

$20,000,000.00 multiplied by 5 excavators giving $100,000,000.00 in total potential saving costs

on notional EBIDTA values (Earnings Before Interest, Taxes and Amortization).

This project will potentially save $25,000,000.00 up to $50,000,000.00 depending on the

successful implementation of the key deliverables outlined in the Project Management Plan.

Haul Road Upgrade Project

13 | P a g e

Historically, over the last 4 years the Mine has had on average 4 times the predicted annual

rainfall, which has produced a loss of 920 hours of production per year per digger. These rainfall

events typically occur during the months of November to April. Therefore, it is critical to complete

the project before November 2012

The ultimate target is to achieve a minim of 6000 hours production per year per digger. The Haul

Road Upgrade Project will go some way to achieving this target (20%) in conjunction with other

site based initiatives including: a LOM dewatering strategy, blasting increases in pattern size/drill

bit size and a 10% increase in powder factors and hot seat changes in all production equipment,

with staggered fly-in-out days for maximum coverage and finally vertical advance heights of

flitch/bench versus digger movement along wider and deeper benches

Site Description

OZ Minerals operates both an open cut and underground copper/gold mine and

processing plant at the Prominent Hill Mine site. Prominent Hill is a remote site

with a FIFO and limited DIDO out workforce supporting the mining, production

and exploration activities. A permanent accommodation village located 3 kms

from the mining operations supports some 1500 workers. Processing of ore

commenced in February 2009. Ore averaging 1.5% Cu and 0.5g/t Au is processed

at a nominal rate of 8Mt per annum to produce copper concentrate via both

Darwin and Port Adelaide by both rail and road

Site Location and Access

The mine site is located 650km north-west of Adelaide, South Australia, some

100km south east of Coober Pedy and 150km north-west of Roxby Downs. The

site is accessible via an unsealed road off the Stuart Highway 100km south of

Copper Pedy. Daily charter flights from Adelaide, Melbourne and Port Augusta

service the FIFO workers

Site Observations

The access ramps are generally in poor condition at higher elevations

recommended by geological element profiles. The majority of access ramps do

not indicate any crossfall. No drainage or facility for run-off from the haul roads

seems to be in place, except for water running along the full length of access

ramps from higher levels to lower levels. This is one of the major causes of

uncontrolled water runoff during major rainfall events. The majority of access

ramps are graded and compacted. The use of inappropriate material selection on

some ramps. There are many cases of wheel rutting on ramp corners due to poor

material selection. Gradients on most active in-pit ramps are between 8%-10%.

Waste dump ramps vary from 5%, 8% and 10% depending on dumping criteria and

poor design. Steely Haematite, Andesite and Dolomite are the best material to

source for the remediation project. Large oversized material has been deposited

on windrows

The existing access ramps make up 3.5km of the total 10km mine haul road

system. The width of ramps are currently 23m being used for 48 haul road trucks,

CAT 793D. Other equipment on-site is made up of some 5 graders CAT 24H,

Haul Road Upgrade Project

14 | P a g e

another 6 Dozers D10T and 4 Liebher 996 excavators with numerous other

ancillary equipment

Some recommendations based on the observations are;

Create a dedicated road maintenance project team

1 x Project Manager

1 x Project Engineer

4 x Various Independent Consultants required during execution phase

and peer review (Expert Road Engineer, Geotechnical Engineer, Friction

Loss Engineer, Surveyor and Peer Review Engineer)

2 x Supervisors (T8)

10 x Operators

Source appropriate equipment

1 x Wheel Loader CAT 992D

2 x Komatsu 785 dump trucks

1 x Grader CAT24H

1 x Komatsu 300 Digger (Contract digger to supplement fleet)

1 x CAT 777 Water Truck

1 x CAT D10 Dozer

And other ancillary equipment as required; Compactors or Impactors

Source appropriate material

Steely Haematite

Haematite

Andesite

Dolomite

Greywacke

Granitites

Engage a dedicated survey team to control and monitor the daily works

supervised by the T8 Thiess operator in charge of implementing the traffic light

system management plan

Purchase the friction testing unit to verify when roads are safe to be driven on

after all rain events

Follow the rain event flow diagram to minimise downtime

Haul Road Upgrade Project

15 | P a g e

SCOPE

To sheet existing haul roads utilising the traffic light system for remediation. This concept has been

previously and briefly explained in both the Executive Summary and Project Management Plan. This form

of remediation identifies 3 different remediation criteria once they are satisfied and competent material is

placed in-situ to design this will facilitate quicker resumption of heavy vehicle activity after wet weather

stoppages. Site based crushing/screened material will be utilised to provide the 3 necessary types of

engineered rock identified in the remediation process. This material will be sourced from in pit basement

material with properties consistent within optimum design tolerances. This material has been successfully

utilised on other in pit ramps (SO8, Beach Ramp, parts of the Western Ring Road, Upper Rom and

Southern Dump access) The new road design has performed better on these areas than on areas yet to

receive the remediation such as ( NO7 ramp, Northern Dump ramp, NO3 running track and Eastern Ring

Road.

In some cases heavy vehicle operations will be able to continue in low level rain events; if the following

factors have been considered and completed; new material in-situ, correct design parameters installed,

such as 2% crossfall, sufficient wearing course, drains and drainage construction all under survey control.

This design veracity will potentially provide in excess of a 25% improvement in digger availability and

utilisation rates during wet weather events. The EDITA data has been outlined in both the Executive

Summary and Project Management Plan. This data will also be available in the cost section of this

document in the PMBOK knowledge area.

In addition, the road maintenance crew lead by the Thiess T8 Supervisor will focus on the design

management with an embedded dedicated survey contractor employed expressly for the project. Their

remit, together is to focus on performance managing the wet weather aspect of the project and its

mitigation. The focus will change after the initial six month construction period to one of daily maintenance

as opposed to daily remediation tasks.

The inclusion of a friction monitoring devise mounted in the T8s vehicle will add some scientific veracity to

the experience based assessment currently being utilised by site personnel. This issue was highlighted in

the flow diagram exercise for determining the wet weather delay process assessment matrix. This

monitoring devise helps to mitigate risk between the differing risk tolerances based on personnel levels of

experience when determining return to work practises after rain events

In Scope: Priority and critical causes of wet weather delays: Poor surface material, insufficient road

maintenance and no crossfall, no drainage.

Project would be considered successful if 25% of delays have been decreased and Extra BCMs have been

produced due to this improvement.

Out of Scope: Other benefits will be achieved simultaneously such as productivity increase, tyres

conservation, HV and machinery maintenance reduction, decrease of uncontrolled vehicles movements,

safer work conditions environment and driver comfort.

Haul Road Upgrade Project

16 | P a g e

SCR ANALYSIS

SITUATION:

Some 20% of total excavator downtime is due to wet weather events. On average each excavator

loses 370 operating hours per year due to wet weather, which is equivalent to 480,000 BCM per

excavator.

COMPLICATION:

To sheet existing haul roads with competent material to enable quicker resumption of heavy

vehicle activity after wet weather stoppages. In addition to sheeting crossfall and drainage also

needs to be included in the remediation process to rain water from the newly constructed roads.

To make this happen there are 3 necessary elements required; Equipment, Material & Resources

RESOLUTION:

Equipment has been ordered to create a dedicated ancillary road maintenance team. Appropriate

material is being stockpiled and crushed and screened as required. The necessary road

maintenance team has been formed to implement the already established Project Management

Plan

STAKEHOLDER COMMENTS

Stephen McKnight: Project Manager & Expert Road Design Engineer

After some considerable background analysis of current designs, requisite rock types, equipment

requirements, resource levels, civil engineered drawings, available material types and rock sizing required;

the project is now at the stage of committing funds and progressing to execution phase. Engineered

drawings have been commissioned. Quotes have been sourced for equipment and material. Human

resourcing levels have been identified and committed to the daily execution of the project. Budgets are

being evaluated and implemented as required. A comprehensive Project Management Plan has been

established and communicated to all the key stakeholders. The plan looks at people, culture, training,

equipment, material and competency based evaluation for driving on remediated haul roads. A traffic light

remediation system that incorporates the necessary design criteria for the identification of the 3 road

mediation types is now in place. A friction analysis of the haul roads has been completed by RTS.

Leidy Alvarado: Project Engineer BI Team

The new approach to tackle Wet Weather Delays is realistic and achievable. The expected improvement

will be guaranteed by completing the 3 proposed project generations. (Road remediation, Road

Maintenance Plan and Rain Management). The project has been re-scoped in order to meet costs, time

and quality requirements of the project deliverables and the stakeholders. In addition, the new contract

has facilitated the communication within both parties and has also enhanced the interest and enthusiasm

of Thiess and Oz projects team by their mutual cooperation. e.g. Quick fixes implemented so far such as

S08 ramp correlates with new roads design and performance tolerances when rain event occur.

Haul Road Upgrade Project

17 | P a g e

The Project implementation stage will be managed by Contract Consultant Engineer (Stephen McKnight)

until completion and it is estimated to be completed within 6 months. It is suggested also to have Road

Maintenance Supervisors (T8s) in order to work in conjunction with Oz Project Engineer. The Road

remediation and Maintenance Plan will be incorporated into 36hrs and Weekly Plan to make sure the

project progress is communicated to all required mine personnel and followed successfully on a daily basis

incorporated into the production planning cycle.

Mitigation steps of Risks identified (see tab 2.1 Risk Mgmt.) within the proposed approach such as Lack of

Equipment and Crushed material have been incorporated into the Implementation Plan.

Haul Road Upgrade Project

18 | P a g e

TIME

WORK BREAKDOWN STRUCTURE

Define the situation

Implement/Establish the action plan

Acquire the;

Resources

Material

Equipment

Execute the action plan

Close out the project

PROJECT MILESTONES

5/12/2011 Independent Road Expert engaged to implement project

5/1/2012 Project needs identified and implemented

5/2/2012 Execution phase begun with limited; resources, equipment and material

5/3/2012 Scientific validation of friction loss assessed and measured

5/4/2012 Resources, Equipment and Material in place and beginning execution phase

5/5/2012 Execution in full swing, all elements on-site and in play

5/6/2012 to 5/11/2012 Haul Road Maintenance Plan following PMBOK project cycles until

conclusion of project in November 2012

PROJECT SCHEDULE

THE 75mm ALL IN SCHEDULE

OZ MINERALS

ALL WEATHER HAUL ROADUPGRADE PROJECT

MATERIAL CRUSHING/SCREENING SCHEDULE

MATERIAL SIZE TOTAL TONNAGE TOTAL VOLUME MONTHLY MATERIAL WEEKLY MATERIAL DAILY MATERIAL DESIREDMATERIAL TYPES TRAFFIC LIGHT SYSTEM DEPTHS

mm t m3 t t t Rock type Colour mm & m

75mm 146,000 67,000 24333 6083 869 Haematite, Andesite, Skarn, Greywacke or Granitoid GREEN 200mm + 2% CROSSFALL

150mm 240,000 109,000 40000 10000 1428 Andesite, Skarn, Greywacke,Sediments or Granitoid AMBER &RED up to 1.5m

300mm 395,000 181,000 65833 16458 2351 Andesite, Skarn, Greywacke, sediments or Granitoid RED up to 2.0m

TOTALS 781,000 357,000 130166 32541 4648

These figures are based on a 6 month crushing/screening schedule

We are assuming a start date of early March 2012 completing August 2012; giving a 2 month buffer before our next "wet weather" window begins from November 2012 to March 2013

Haul Road Upgrade Project

19 | P a g e

COST

Haul Road Upgrade Project

20 | P a g e

QUALITY

Attached are the majority of QAQC documents associated with the project. There are a wide variety of

documents included in this section; ranging from the traffic light design criteria, the actual map of the sites

requiring the traffic light system remediation, correspondence with the world leader in haul road design RJ

Thompson on negative superelevation design, a working haul road assessment document, a flow diagram

on how to mitigate delays in returning to work after wet weather rain events, etc. This section does not go

into the true depth of detail associated with the issues of maintaining quality, but gives a representation of

the thought and knowledge being implied to make the haul road design as robust and relevant to the site.

During the course of this project a number of specific haul road design documents, white papers and books

have been consulted, which can be found in the reference section of this presentation. Suffice to say

quality on this project was identified as one of the most contingent aspects of the projects potential for

success, hence the amount of effort applied to achieve the quality required

THE ALL-WEATHER HAUL ROAD UPGRADE PROJECT (AWHRUP)

TRAFFIC LIGHT SYSTEM

OZ MINERALS PROMINENT HILL JANUARY

2012

DESIGN CRITERIA GREEN AMBER RED

1. Road Design Types Design #1 Design #2 Design #3

200mm wearing

course

200mm wearing

course

200mm wearing

course

passing @ 75mm passing 75mm passing 75mm

400mm Base 600mm Base

passing 150mm passing 150mm

500m Sub Base 1000mm Sub Base

passing 300mm passing 300mm

2. Rock Type Steely Haematite Granitoids Mudstone

Greywacke Andesite Silcrete

Skarn Bulldog Shales

Sedimentary Hornfels Fresh

Weathered

3.MPa (UCS) >81 >47 <20

4. CBR% >80 >60 <15

5. Road Life Span 1 year + 6 months + less than 6 months

6. Rolling Resistance 1% 2% + 3% +

7. Friction >80% >50% <50%

8. Defect Score <64 65 to 139 >140

9. % of Project 50% 20% 30%

Haul Road Upgrade Project

21 | P a g e

10. Definition Green Amber RED

Road Condition Road Condition Road Condition

VERY GOOD FAIR BAD

DAILY INSPECTION WORK REQUIRED IMMEDIATE WORK

DAILY INSPECTION REQUIRED

DAILY INSPECTION

11. Crossfall 2% 3% 4%

12. Crown 2% 3% 4%

13. Drainage .5m .3m >.3m

14. Berms 1.8m 1.5m <1.5m

15. Equipment 2x 992 Digger Anything less Nothing different

3 x 785 Trucks than the wish list than what is on-site

1x 24 Grader Now

1 x 16 Grader

1 x 777 Water Truck

1 x D9 Dozer

1 x 966 FEL

1 x WA900 FEL

HPGPS

LPGPS

1 x 25t Compactor

16. Road Category Permanent Semi-Permanent Semi-Permanent

High Volume Traffic Medium to High Medium to Low

Operating Life 15

years Volume Traffic Volume Traffic

Low Maintenance

Operating Life 10

years

Operating Life <2

years

over design life Regular Maintenance

Maintenance

intensive

Over design life Traffic volume

exceeded

17. Grade Breaks <10% 10% >10%

18. Road widths >30m 30m <30m

19. Tyre Pressure 800kPa >800Kpa >700Kpa

20. Water Truck

Spray 50m on 50m off <50m on 50m off >50m on 50m off

21. Dust Block

Agents Tar/Bitumen Petrol/Polymer Wetting Agents

22. Road

Maintenance

Managed

Maintenance Scheduled Blading Ad-hoc Blading

Haul Road Upgrade Project

22 | P a g e

23. Design Approach Integrated Design Empirical Design Just build a Road

24. Gradients 10% <12.5% >12.5%

Haul Road Upgrade Project

23 | P a g e

Haul Road Upgrade Project

24 | P a g e

Haul Road Upgrade Project

25 | P a g e

Haul Road Upgrade Project

26 | P a g e

Haul Road Upgrade Project

27 | P a g e

Haul Road Upgrade Project

28 | P a g e

Haul Road Upgrade Project

29 | P a g e

Haul Road Upgrade Project

30 | P a g e

Haul Road Upgrade Project

31 | P a g e

Haul Road Upgrade Project

32 | P a g e

Correspondence with Roger J Thompson regarding the issue of introducing negative superelevation to the

road design and QC of the project in relation to crossfall of the in pit haul road design. This situation came

about due to the road design standards Thiess have in their coal operations and as such is in their working

haul road design document, which needed to be addressed so the appropriate run off design could be

implemented in this site specific circumstance.

Excellent Steve, an educational read too. Thank you Rob

From: Stephen McKnight

Sent: Wednesday, 4 J anuary 2012 3:41 PM

To: Robert Boyd; J arrad Dodson; Richard Turnbull; Leidy Alvarado

Cc: David Way

Subject: FW: HAUL ROAD DESIGN

FYI Gents

Steve McKnight

Contract Mining Engineer Mine Improvement Team

OZ Prominent Hill | Respect Integrity Action Results

Ground Floor, 170 Greenhill Road

Parkside, South Australia, 5063, Australia

T 61 8 8672 8148 F 61 8 86728101 M 04 350 29 169

Stephen.McKnight@ozminerals.com

Please consider the environment before printing this e-mail

From: Roger Thompson [mailto:R.Thompson@curtin.edu.au]

Sent: Wednesday, 4 J anuary 2012 3:02 PM

To: Stephen McKnight

Subject: RE: HAUL ROAD DESIGN

Steve

Sounds like a good approach some changes or modifications to designs can have far reaching

effects on operation and maintenance best to explore these before implementation.

Haul Road Upgrade Project

33 | P a g e

Have worked with iron-ore discard roads wearing course material before at a few sites (overseas)

and it tends to make an excellent wearing course if it does not slake (and obviously has no fibrous

material content). Only issue is sometimes too little fine fractions or binder. Bituminous emulsion

treatment also generally an excellent option with this material type, mixed-in if well compacted road

with low void ratio, or spray on IF depth of penetration can be assured (last thing you want is a thin

crust of treatment bit like a sheet of glass on top of a sponge).

Friction/skid resistance testing always good info (Dave Tulloch RTS? excellent for this evaluation

work) but Id also suggest sampling and evaluating the wearing course material at the locations you

do these tests too otherwise you dont have such a good idea of what influence the wearing course

material (as opposed to moisture/rainfall) has on friction supply. Ditto any treatment you

apply. Shave off top 10-20mm max of wearing course where you do the tests and evaluate following

AS1289.

Would be happy to act as your third party peer review and quarterly inspection consultant (haulroad

design aspects safety audits best handled by Damir Vagaja of ARRB). I can run this work through

WASM Consulting who provide liability cover, Admin and invoicing etc. as part of their service. As

and when the work transpires, I can provide a Scope of Works Quote and take it from there.

Regards

Roger

From: Stephen McKnight [mailto:Stephen.McKnight@ozminerals.com]

Sent: Tuesday, 3 J anuary 2012 12:00 PM

To: Roger Thompson

Subject: RE: HAUL ROAD DESIGN

Hi Roger,

First off really appreciate your prompt reply and considered response

Over the last month I have been reading everything you have published to get up to speed with this

project

I am glad you agree with the negative crossfall of 2% with qualifications, of course

We are working with Thiess our Open Pit Hauling Contractor

They have a high turn-over of staff so there are a significant number of newbies on-site at any one

time, hence our difficulties with the fleet working in wet weather, among other reasons

Haul Road Upgrade Project

34 | P a g e

I take on board your central corridor berm idea and will pass it on to the team for discussion

And yes we need to consider drainage in such cases

We are looking at introducing HPGPS & LPGPS systems on both graders and dozers

We are also looking at applying Dust Bloc as well to the wearing course; this is a bitumen type

palliative

The wearing course will be made of steely haematite, MPa >150 passing through up to 75mm @

200mm depth close to or above 80% CBA

With regards friction analysis we are bring in a team to do the whole mine on the 24-26 January, to

establish a baseline

I fully appreciate the negative superelevation on the downward journey into the pit. This will be

and has been discussed with the Thiess team, but will be further enforced

We are constructing a simulation ramp at 10% to begin training the operators

A constructed ramp with a crossfall of 2% appropriate wearing course and drainage

With another ramp with no controls in place

Yes, I totally agree with the civil/geotech analysis and intend to follow your specifications to the

letter

Roger would you consider being our third party peer review and quarterly inspection consultant?

Im not sure if you would be available, but your experience and technical background are second to

none in this field

It would be a privilege and a pleasure if you were interested in assisting our team over the course of

this project

Cheers,

Steve McKnight

Contract Mining Engineer Mine Improvement Team

OZ Prominent Hill | Respect Integrity Action Results

Ground Floor, 170 Greenhill Road

Parkside, South Australia, 5063, Australia

Haul Road Upgrade Project

35 | P a g e

T 61 8 8672 8148 F 61 8 86728101 M 04 350 29 169

Stephen.McKnight@ozminerals.com

Please consider the environment before printing this e-mail

From: Roger Thompson [mailto:R.Thompson@curtin.edu.au]

Sent: Tuesday, 3 J anuary 2012 2:03 PM

To: Stephen McKnight

Subject: RE: HAUL ROAD DESIGN

Steve

In principal, a construction width of 35m for a 30m running surface (4x6.64m body width of 793C)

appears fine. The cross-fall of 2% also typical but would depend on the type of wearing course

(surfacing) material you have too. The only recurrent problem with a constant crossfall is the

potential of trucks to wander across lanes into the direction of on-coming traffic. If you have

operating experience and safety/accident data, it may be worth looking at the type of

accidents/near-misses at the site to see if truck misalignment/skidding, etc. is an issue for whatever

reason. Centre berms have been used in some operations to split traffic lanes, but with a constant

crossfall, this complicates drainage (and road and berm maintenance).

Blading a road with a constant crossfall is also more difficult than a crowned road, with the added

problem of debris, spillage, etc. being pushed to the drain-side where it could cause tyre damage,

etc. Good grading practice should remedy this.

Further, where the road is required to change direction against the cross-fall, care will be needed to

specify speed limits (especially down-grade unladen) since on these curves, the super-elevation will

be in the wrong sense and road surface friction supply needs to be maximised here to prevent

skidding. An incorrect super-elevation may lead to truck instability at speed, and the misalignment

problems outlined above.

This also raises the issue of the wearing course material itself. A good quality material is required,

with a CBR ideally >80%, to help reduce the likelihood of cross-erosion or run-off channels being

Haul Road Upgrade Project

36 | P a g e

eroded from the wearing course on the down-slope edge of the road. The majority of even the best

specified wearing course materials are sensitive to rain, and the road will go down eventually. You

may want to look at adding a stabiliser or other similar treatment to the wearing course to enhance

its ability to shed water as opposed to absorb it. In doing this, youll need to ensure the road

structure is well built and can support a long-lasting surface treatment otherwise youll end up

blading it off the road as you blade the surface due to poor support problems in the structure

itself.

Good starting point would be to sample actual/proposed wearing course materials and get a civil

eng lab to run a road indicator test on them according to AS1289 (grading to 0.075, Atterburg limits,

MDD, OMC and CBR at say 97% Mod AS1289) to see what youve got and what options you have if

you need to fix it up (reduce clay by adding aggregates, increase fine fraction to improve binding,

etc.). Treatment suppliers would also look at this info to determine how and at what rate of

application their product may work.

Let me know if you need more info happy to assist.

Roger

From: Stephen McKnight [mailto:Stephen.McKnight@ozminerals.com]

Sent: Monday, 2 J anuary 2012 4:59 AM

To: Roger Thompson

Subject: HAUL ROAD DESIGN

Hi RJ,

I am currently working on an all-weather haul road upgrade project here in South Australia

I have been applying many of your thoughts, concepts and principles to this project

The project consists of approximately 10kms of road work; in pit haul roads, outer ring roads and

waste dump/ROM pad roads

The projects focus is to reduce the downtime we experience from rainfall events

It has been determined that with rain events between 1mm 5mm we lose up to 80% productivity

due to truck downtime

Some 470 hrs per year per digger, we have 5 Diggers; 996 Liebher

Our aim is to achieve 6000 hrs per digger per year and the all-weather haul road upgrade project has

been put in place to achieve a high percentage of this target

Haul Road Upgrade Project

37 | P a g e

Currently, there are no crossfalls, no road designs or competent material utilised in the construction

of the roads.

I have developed a traffic light system that identifies these conditions and we are working our way

through the work required

However, I require your thoughts on the following situation

We are developing a design for a negative superelevation for the in pit curved roads, which will

spiral down to some 480m at the end of the pits life

We are considering the following ideas;

Up 2% crossfall from the in-pit side of the road out to the highwall side

We will install the drainage on the highwall side of the pit and pump it out from sumps

The width of the total road is 35m

The working surface is up to 30m

We are using 973 Cat Dump Trucks (payload 220t)

My question is related to the negative superelevation

Therefore, what we are proposing, is it safe and feasible or do you have better: thoughts, comments,

ideas or suggestions

We need to make sure the rain water runs off the wearing course into the drains so we do not lose

truck availability

Cheers,

Steve McKnight

Contract Mining Engineer Mine Improvement Team

OZ Prominent Hill | Respect Integrity Action Results

Ground Floor, 170 Greenhill Road

Parkside, South Australia, 5063, Australia

T 61 8 8672 8148 F 61 8 86728101 M 04 350 29 169

Stephen.McKnight@ozminerals.com

Haul Road Upgrade Project

38 | P a g e

Please consider the environment before printing this e-mail

RISK

There were 5 major risk areas identified during the All Weather Upgrade Risk Assessment,

which have been categorised in the below chart The issue of wet weather delays is very

complex and there are no one size fits all solutions in play. Regardless the fact that there

are civil engineering solutions that can and will be applied; this site has specific

requirements for the appropriate solution and outcomes desired

Lack of basement material or crushed/screened or stockpiled material available when

required

Equipment availability from Thiess

HV & LV, HV & HV interactions during construction/execution phase of project

Resource availability from Thiess for HV requirements

Impact of road maintenance team during construction on production team

Natural disasters

Wet weather rainfall events

Risks identified Risk Rating Mitigation Action Risk Rating

Likelihood Conseq. Rating Likelihood Conseq. Rating

1 Possible Major Extreme Unlikely Moderate Moderate

2 Possible Major Extreme Rare Moderate Moderate

3 Unlikely Major High Rare Major Moderate

4 Possible Moderate High Unlikely Moderate Moderate

5 Unlikely Moderate Moderate Unlikely Insignifica

nt

Low

Ongoing stockpiling of Road basement

material and Hire Screening plant

Monitor crew levels, move personnel

between crews, park up digger that do not

ff t th j t

Schedule to be managed by mine planner

(both 36hr plan and weekly plan)and Thiess

Hire Road Maintenance Equipment through

Thiess

Road works completed on shift change

days, alternate routes to be used

Equipment Availabilty

HV contact with LV during road works

Thiess manning level drop below minimum

requirements

Impact on production during road construction,

by the contruction work group

Lack of road basesment or crushed material

when required

Haul Road Upgrade Project

39 | P a g e

These 5 categories have been further calculated in the below risk register matrix

Haul Road Upgrade Project

40 | P a g e

HUMAN RESOURCES

Project Manager: Steve McKnight

Mine Project Engineer: Leidy Alvarado

T8 Supervisors: David Kurtzer / Chris Carroll

Road Crew A & B

2 x CAT 992 Wheel Loader Operators

2 x CAT 16 H Grader Operators

2 x CAT D10 Dozer Operators

4 x KOMATSU 785 Truck Operators

Expert Consultants on an as required basis

(Friction Test Engineer, Geotechnical Engineer, Surveyors & Peer Review Principal Engineer)

Project

Manager

T8 Road

Maintenance

Supervisors

Road Crew A Road Crew B

Project

Engineer

Expert

Consultants

Haul Road Upgrade Project

41 | P a g e

COMMUNICATIONS

Haul Road Upgrade Project

42 | P a g e

PROCUREMENT

Haul Road Upgrade Project

43 | P a g e

APPENDIX.1

THE PROJECT MANAGEMENT PLAN

Haul Road Upgrade Project

44 | P a g e

Haul Road Upgrade Project

45 | P a g e

Haul Road Upgrade Project

46 | P a g e

Haul Road Upgrade Project

47 | P a g e

Haul Road Upgrade Project

48 | P a g e

Haul Road Upgrade Project

49 | P a g e

Haul Road Upgrade Project

50 | P a g e

Haul Road Upgrade Project

51 | P a g e

Haul Road Upgrade Project

52 | P a g e

Haul Road Upgrade Project

53 | P a g e

Haul Road Upgrade Project

54 | P a g e

Haul Road Upgrade Project

55 | P a g e

Haul Road Upgrade Project

56 | P a g e

Haul Road Upgrade Project

57 | P a g e

Haul Road Upgrade Project

58 | P a g e

Haul Road Upgrade Project

59 | P a g e

Haul Road Upgrade Project

60 | P a g e

Haul Road Upgrade Project

61 | P a g e

Haul Road Upgrade Project

62 | P a g e

Haul Road Upgrade Project

63 | P a g e

Haul Road Upgrade Project

64 | P a g e

Haul Road Upgrade Project

65 | P a g e

Haul Road Upgrade Project

66 | P a g e

Haul Road Upgrade Project

67 | P a g e

Haul Road Upgrade Project

68 | P a g e

Haul Road Upgrade Project

69 | P a g e

Haul Road Upgrade Project

70 | P a g e

Haul Road Upgrade Project

71 | P a g e

Haul Road Upgrade Project

72 | P a g e

Haul Road Upgrade Project

73 | P a g e

DESIGN AND

CONSTRUCTION OF

MINE ROADS

1.0 GENERAL .......................................................... 75

2.0 CONTROLS ........................................................ 75

2.1 Road Classification ................................................... 75

2.1.1 Permanent Haulroads ................................................. 75

2.1.2 Pit Haulroads (Short or Medium Term Haulroads) ........... 76

2.1.3 Light Vehicle Roads .................................................... 76

2.2 Mine Road Design & Construction Process ................... 76

2.3 Rolling Resistance .................................................... 78

2.4 Geometric Design Phase ........................................... 79

2.4.1 Stopping Distance ...................................................... 79

2.4.2 Sight Distance ........................................................... 79

2.4.3 Alignment ................................................................. 80

2.4.4 Roadway Width ......................................................... 81

2.4.5 Cross Fall ................................................................. 82

2.4.6 Gradient ................................................................... 83

2.4.7 Super-elevation ......................................................... 84

2.4.8 Road Side Drainage .................................................... 86

2.4.9 Road Shoulders ......................................................... 87

2.4.10 Bundwalls ................................................................. 87

2.4.11 Intersections ............................................................. 89

2.4.12 Intersection Traffic Control .......................................... 93

2.4.13 Runaway Vehicle Control ............................................. 94

2.4.14 Heavy Equipment Go-lines .......................................... 96

2.5 Structural Design Phase ........................................... 99

2.5.1 General Road Construction .......................................... 99

2.5.2 In-situ Surface Preparation ....................................... 100

2.5.3 Sub-base Requirements ............................................ 100

2.5.3 Base Course Requirements ........................................ 101

Haul Road Upgrade Project

74 | P a g e

2.6 Functional Design Phase ......................................... 101

2.6.1 Running Surface Requirements .................................. 102

2.7 Maintenance Design ............................................... 102

2.7.1 General Road Maintenance ........................................ 104

2.7.2 Road Furniture Signs ............................................. 104

2.7.3 Road Furniture Sign Positioning ............................... 105

2.7.4 Road Furniture Delineators ..................................... 106

3.0 MONITORING & REVIEW ................................ 106

4.0 RESPONSIBILITIES ........................................ 107

4.1 Mineworkers ........................................................... 107

4.2 Supervisors ............................................................ 107

4.4 Superintendents / Project Manager ............................ 107

5.0 USEFUL REFERENCES & FORMS ...................... 108

Haul Road Upgrade Project

75 | P a g e

PROCEDURE & INFORMATION

Procedure Information

1.0 General

Mine roads shall be designed and constructed to appropriate specifications

to allow the safe and efficient movement of vehicles around the mine site.

The specifications must have regard to the particular conditions at the mine,

including the following:

The characteristics of the mine vehicles;

The types of materials available for road construction;

The methods of working the mine;

Relevant legislation.

Good design and construction of mine roads will enable:

Safe movement of vehicles;

Optimal haulage cycle times;

Increased tyre life;

Less stress to mechanical components of vehicles;

Less structural damage to vehicle chassis;

Reduced operator fatigue.

PRINTING INFORMATION

Due to the graphics

included within the

body of this document

it must be printed in

high resolution

2.0 Controls

2.1 Road Classification

Mine roads should be designed and constructed to a standard in accordance

with the road classification which is dependent on:

The expected life span of the road;

The primary purpose of the road;

The frequency of usage of the road.

2.1.1 Permanent Haulroads

Permanent haulroads are major arterial roads used by haul trucks and the

majority of mine traffic. The basic criteria for permanent haulroads are as

Haul Road Upgrade Project

76 | P a g e

Procedure Information

follows:

Long term existence;

Used by haul trucks and other mine vehicles;

High frequency usage;

Formed construction profile;

Delineated.

2.1.2 Pit Haulroads (Short or Medium Term Haulroads)

Pit haulroads are roads that are used by haul trucks and other mine traffic

in and around pit areas including, in pit haulroads and ramps, bench roads,

dump roads and ramps, etc. The basic criteria for pit haulroads are as

follows:

Short to long term existence depending on particular road function;

Used by haul trucks and other mine vehicles;

High frequency usage (may be periodic);

Formed or non-formed construction profile;

Delineated.

2.1.3 Light Vehicle Roads

Light vehicle roads are roads that are used by light and medium vehicles for

access around the perimeter of the pit, within pit areas and on the surface.

The basic criteria for light vehicle roads are as follows:

Short to long term existence depending on particular road function;

Used by light and medium vehicles only;

Low to medium frequency usage;

Basic construction profile only;

Delineated on more permanent light vehicle roads.

2.2 Mine Road Design & Construction Process

Haul Road Upgrade Project

77 | P a g e

Procedure Information

Mine road design and construction can be thought of as 4 distinct steps or

phases:

Alignment

Super-elevation

Gradient

Sight Distance, Etc.

General road construction

In-situ surface preparation

Sub-base requirements

Base course requirements

Running surface requirements

Haulroad maintenance

Road furniture signage

Road furniture delineators

Inspections / audits

Design &

Construct

Haul Road Upgrade Project

78 | P a g e

2.3 Rolling Resistance

Rolling resistance is the resistance that occurs when a tyre rolls on a

surface.

Rolling resistance can significantly impact on the efficiency of vehicles

travelling on a mine road and associated haulage costs.

It is caused by any combination of the following:

Deformation of the road (may be at any depth in the road profile)

under the tyre;

Penetration of the tyre into the road surface;

Tyre deformation caused by the road surface resulting in energy

required to lift the vehicle as opposed to propel it forward.

Rolling resistance of a haulroad shall be considered throughout all 4 phases

of the design and construction process to maximise haulage efficiency and

safety.

Poor geometric design resulting in significant

or sharp changes to vehicle direction and

speed may result in deformation of the road,

tyre deformation and/or tyre penetration into

the road surface;

Poor structural design (as a result of poor in-

situ surface, insufficient structural layer

thickness, inappropriate structural material

and/or poorly constructed structural layers)

may result in deformation of the road profile;

Poor functional design (as a result of

inappropriate running surface material and/or

poorly constructed running surface layer) may

result in tyre penetration;

Poor maintenance design (as a result of poor

maintenance practices and/or insufficient

maintenance frequency) may result in an

inability to minimise all types of rolling

resistance.

In order to maximise haulage efficiency rolling resistance should be

minimised where possible.

Refer to AM-PH-HS-IF-

0832.8 Information

Sheet Rolling

Resistance Table

Haul Road Upgrade Project

79 | P a g e

2.4 Geometric Design Phase

The geometric parameters of the mine road shall be designed to ensure the

safe and efficient travel of mine vehicles at normal operating speeds.

2.4.1 Stopping Distance

Mine roads shall be designed to accommodate the stopping distance of the

largest fully laden haul truck regularly using the road (using emergency

braking).

Theoretical stopping distances may be determined from a series of Stopping

Distance Characteristic Graphs developed by the Society of Automotive

Engineers (SAE).

OEMs utilise these standards to design their vehicle brake systems.

Tests carried out by Dawson in 1975 indicate that to preclude brake fade or

failure, 61m braking distance should be considered the minimum allowable

(this is under test conditions). However, adopted stopping distance needs to

accommodate a number of variables (e.g. driver reaction time, road surface

conditions, traction loss, etc) as well as the vehicle braking capability. As a

result, a minimum stopping distance of 100m should be utilised.

Refer to AM-PH-HS-IF-

0832.10 Information

Sheet SAE Stopping

Distance Graphs

2.4.2 Sight Distance

Sight distance is the extent of peripheral area visible to the vehicle

operator, and is dictated by:

The design speed of the road;

The driver eye height of the lowest vehicle using the road;

The stopping distance of the largest vehicle using the mine road in

the worst case driving conditions.

The distance ahead of the driver to an unforeseen hazard shall always be

greater than the distance required to bring the vehicle to a stop.

On hill crests, the sight distance may be restricted by the vertical curve or

crest of the hill, in this instance the crest may need to be flattened.

At horizontal curves or intersections of the road the sight distance may be

restricted by batters, vegetation, signs or other obstructions. Where

possible horizontal curves and intersections should have all sight

restrictions removed or minimised.

Haul Road Upgrade Project

80 | P a g e

2.4.3 Alignment

Road alignment refers to the road direction in both the horizontal and

vertical planes.

The following elements should be considered when designing the mine road

alignment:

All curves (horizontal and vertical) should be designed with the

largest radius possible;

The alignment should be smooth and consistent;

Compound curves (curves where the radius changes) shall not be

used;

Haul Road Upgrade Project

81 | P a g e

Horizontal and vertical alignments should complement each other

and the following should be considered when combining horizontal

and vertical curves:

o Avoid sharp horizontal curves at the crest of vertical curves

as sight distance is generally restricted and it is difficult for

drivers to perceive the curves in such a situation;

o Avoid sharp horizontal curves at the base of ramps or long

sustained downhill grades as vehicles are typically at their

highest speed at these locations;

o If switchbacks are required they should be designed with the

largest radius possible and should be placed on flat sections,

avoid placing them on grade as the inside of the curve may

exceed the design gradient specification.

2.4.4 Roadway Width

Mine roads should be designed and constructed to suit the Operating Width

of the largest vehicle that will be using the road regularly.

The following table summarises the roadway width for various road types:

Straight Single Lane Roadway 2 x Operating Width

Straight Double Lane Roadway 3.5 x Operating Width

Curved Single Lane Roadway 2 x Operating Width x 1.18

Curved Double Lane Roadway 3.5 x Operating Width x 1.18

(1.18 represents an overhang/vehicle tracking multiplier)

Consideration should be given to separate roadways where possible

particularly in high hazard areas (e.g. fog zones). In such circumstances the

roadways should be separated by a median (separation) bund or other

physical barrier. The height of the median bund or physical barrier must be

appropriately selected to ensure that sight distance is not affected (typically

median bundwall height should be restricted to 1m unless otherwise

required for risk control).

In areas where roadway width criteria cannot be met, an assessment of risk

shall be undertaken and appropriate controls put in place.

Straight Double Lane Roadway Schematic

The Roadway of a mine

road refers to the running

surface of the road.

The Operating Width of a

vehicle is the maximum

width of the vehicle during

normal operation. The

measurement must be

taken from outer

extremity (for example

mirrors, tray, rock

deflectors, etc) on one

side to the outer extremity

(for example mirrors, tray,

rock deflectors, etc) on the

other side.

Refer to AM-PH-HS-

TP-0832.6 Template

Site Specification

Sheet (Site Version)

Refer to AM-PH-HS-FO-

0501.6 Job Safety and

Environmental Analysis

Haul Road Upgrade Project

82 | P a g e

Cat Graphics reproduced with permission from Caterpillar Inc.

Straight Separated Double Lane Roadway Schematic

Cat Graphics reproduced with permission from Caterpillar Inc.

Separated Roadways are

treated as two single lane

roadways when

determining roadway

width.

2.4.5 Cross Fall

Cross fall is the cross road gradient perpendicular to the road direction and

Refer to AM-PH-HS-

TP-0832.6 Template

Site Specification

Sheet (Site Version)

Haul Road Upgrade Project

83 | P a g e

should be utilised in order to divert water away from the road surface.

The rate of cross fall should allow rapid water runoff without adversely

affecting the drivers steering control or increasing Position 1 tyre wear.

The degree of cross fall is dependent and directly related to:

Road gradient;

Expected rainfall (during normal weather conditions);

Construction materials used on the running surface.

The following table details typical cross fall for various applications:

Road Gradient

Min Cross fall

Low Rainfall or Smooth

Surface

Max Cross fall

High Rainfall or Rough

Surface

0 to 4% 1 in 25 1.0% 3%

5 to 9% 1 in 11 1.0% 2.5%

10 to 12.5% 1 in 8 0.5% 2%

Refer to AM-PH-HS-IF-

0832.11 Information

Sheet Gradient

Conversion

2.4.6 Gradient

The gradient on a ramp is the grade line profile along the road centre line,

in the vertical plane.

Vertical curves should be utilised to provide smooth transitions from one

grade to another. The vertical curves utilised shall ensure that the sight

distance is sufficient at the design speed for the vehicles using the road.

Gradient should be kept as constant as possible (avoid unnecessary grade

changes) to reduce the tendency of trucks to change through gears (hunt)

on the up-grade hauls. This affects:

Haulage cycle times;

Fuel consumption;

Stress on the mechanical components of the vehicle e.g.

transmissions and torque converters;

Excessive chassis flexing due to uneven surfaces (Racking);

Damage to the road surface.

Gradient should be selected in accordance with manufacturers

specifications to suit the particular vehicle that is expected to utilise the

road.

Both the uphill (rimpull) and downhill (retarding/brake capability) of the

vehicle should be considered when determining the most appropriate grade.

Refer to AM-PH-HS-IF-

0832.11 Information

Sheet Gradient

Conversion

Refer to AM-PH-HS-

TP-0832.6 Template

Site Specification

Sheet (Site Version)

Haul Road Upgrade Project

84 | P a g e

Particular attention needs to be paid to loaded downhill haulage and/or long

sustained downhill grades (for both loaded and unloaded operations) to

ensure that the braking capability of the vehicle is not compromised.

Consideration must also be given to possible mine design impacts when

selecting gradients.

Typically grades up to 10% (1in10) should be utilised on haulage ramps.

An assessment of risk shall be undertaken for grades ranging from 10%

(1in10) to 12.5% (1in8).

Gradients exceeding 12.5% (1in8) shall not be utilised.

Median bundwalls should be utilised to separate traffic where there is a

horizontal curve on grade. Horizontal curves on ramps may increase the

potential for vehicles travelling down the ramp to lose control and slide into

vehicles travelling up the ramp (this is particularly the case when the down

grade curve is to the left).

2.4.7 Super-elevation

Super-elevation is the cross fall applied to switchbacks, corners and curves.

It allows the vehicle taking the corner to counteract the centrifugal forces

by directing the vehicle weight towards the centre of radius of the curve.

All horizontal curves shall be appropriately super-elevated and/or speed

restricted.

The amount of super-elevation on the corner is directly related to the radius

of the corner and the desired vehicle speed through the corner.

Under no circumstance shall negative super-elevation be used.

Typically super-elevation for a normal mine road application is between 3%

and 5%. Super-elevation rates above 5% are not recommended.

The following table details recommended super-elevation rates and proper

curve and speed relationship:

Recommended super-elevation rates in % for given vehicle speeds and curve radii

Curve

Radius

Vehicle Speed (km/hr)

20 30 40 50 60 70

50m 6% - - - - -

Refer to AM-PH-HS-IF-

0832.11 Information

Sheet Gradient

Conversion

Haul Road Upgrade Project

85 | P a g e

75m 4% 9% - - - -

100m 3% 7% - - - -

200m 2% 4% 6% 10% - -

300m 2% 2% 4% 7% 8% -

400m 2% 2% 3% 5% 6% 6%

500m+ 2% 2% 3% 5% 5% 5%

Outside of recommended specification

The portion of the road used to transform a cross slope section into a super-

elevated section is termed the run-out length.

The purpose of the run-out is to assist the driver in the manoeuvring of a

vehicle through the curve.

Run-out lengths vary with the design speed and total change in cross slope.

The following table enables the correct run-out length to be determined and

at what rate the cross slope transitions:

Cross slope change in % for 10m of roadway length

Vehicle Speed (km/hr)

15 20 25 30 35 40 45 50 55

2.5% 2.5% 2.5% 2.1% 1.8% 1.6% 1.4% 1.3% 1.1%

Example:

To illustrate the calculation of run-out assume a vehicle is travelling at

50km/hr. The roadway has a normal cross fall of 3% to the left. The vehicle

encounters a curve to the right that requires a super-elevation of 5% to the

right. The total change in cross slope is 3%+5%=8%. From the above table

the rate of change per 10m of roadway at 50km/hr is 1.3%. Thus the run-

out length required is:

= (8% / 1.3%) x 10m

= 61.54m (use 62m)

Run-out shall be applied such that 1/3 occurs in the curve and 2/3 in the

tangent (straight section).

Application of Super-elevation and Run-out