QGX and QCS

Diunggah oleh

Raed Naim Khammash0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

483 tayangan41 halamanTec hni p today is a Worldwide leader in engineering, project management and technologies, serving the oil and gas industry for more than 50 years. In 2009 revenue: EUR6. Billion a long term solid partner.

Deskripsi Asli:

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniTec hni p today is a Worldwide leader in engineering, project management and technologies, serving the oil and gas industry for more than 50 years. In 2009 revenue: EUR6. Billion a long term solid partner.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

483 tayangan41 halamanQGX and QCS

Diunggah oleh

Raed Naim KhammashTec hni p today is a Worldwide leader in engineering, project management and technologies, serving the oil and gas industry for more than 50 years. In 2009 revenue: EUR6. Billion a long term solid partner.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 41

Dfis, difficults et succs

des grands projets. des grands projets.

Le dfi GNL au Qatar Le dfi GNL au Qatar

Stephane LAGRANGE Step a e G G

Directeur de Projet

T h i T d Technip Today

Qatar, a Key Player in the LNG World

Ras Laffan Industrial City and the 3 Mega LNG Projects

Challenges of Qatar Mega LNG Projects

New technologies

Worldwide work locations

Human factors

Security/safety

Camps p

Logistics

Construction

Start-up Sta t up

1

Tec hni p Today

Worldwide leader in engineering project management and technologies Worldwide leader in engineering, project management and technologies,

serving the oil & gas industry for more than 50 years

A regular workforce of 23,000 in 48 countries

Industrial assets on all continents a fleet of 17 operational vessels (19 vessels by Industrial assets on all continents, a fleet of 17 operational vessels (19 vessels by

2011)

2009 revenue: 6.4 billion

A long term solid partner

Tec hni p del i ver ed maj or ener gy pr oj ec t s i n 2009 / 2010

250

300

l

l

i

o

n

s

)

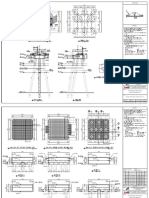

QGX

QCS

200

h

o

u

s

(

M

i

RGX

100

150

t

i

o

n

m

a

n

h

Yemen

LNG

Khursaniyah

50

C

o

n

s

t

r

u

c

t

Millau

Viaduct

Yansab

Ethylene

3

0

C

Ethylene

T h i T d Technip Today

Qatar, a Key Player in the LNG World

Ras Laffan Industrial City and the 3 Mega LNG Projects

Challenges of Qatar Mega LNG Projects

New technologies

Worldwide work locations

Human factors

Security/safety

Camps p

Logistics

Construction

Start-up Sta t up

4

Rec or d LNG TRAI N CAPACI TY (ex i st i ng or under c onst r uc t i on)

Mt/y

7

8

9

Qatar mega

Trains

Mt/y

5

6

7

2

3

4

Yemen

0

1

2

1960 1965 1970 1975 1980 1985 1990 1995 2000 2005 2010 2015 1960 1965 1970 1975 1980 1985 1990 1995 2000 2005 2010 2015

5

Est i mat ed Wor l d l i quef ac t i on c apac i t y (Mt /y)

77 Mt/y

0 20 40 60 80 100

Malaysia

Qat ar

Indonesia

77 Mt/y

Egypt

Aust ralia

Trinidad & Tobago

Nigeria

Algeria

Libya

Unit ed Stat es

Abu Dhabi

Brunei

Oman

In operation

Feb, 2010

Under construction Future projects

Iran

Eq Guinea

Norway

Russia

Yemen

Qatar The largest LNG

producer since 2008

6

Peru

Angola

producer since 2008

T h i T d Technip Today

Qatar, a Key Player in the LNG World

Ras Laffan Industrial City and the 3 Mega LNG Projects

Challenges of Qatar Mega LNG Projects

New technologies

Worldwide work locations

Human factors

Security/safety

Logistics g

Construction

Start-up

7

Qat ar Mega LNG Pr oj ec t s - si t e of Ras Laf f an -

IRAN

South Pars

Gas Field

Oil Field

Umm

Al Irsham

N h Fi ld

QATAR

Ras Laffan

Maydan

Mahzan

Idd El Shargi

Halul Is.

North Field

Dolphin Gas Pipeline Project

Q

DOHA

Al

Wakrah

Dukhan

A Structure

(North)

Bunduq

Idd El Shargi

(South Dome)

Bul

Hanine

dd S a g

(North Dome)

8

Messaied A Structure

(South)

(North)

Bunduq

Ras Laf f an I ndust r i al Ci t y

1

North Field

Exports through RL Port Exports through RL Port

LNG trains LNG

GTL products

GTL plants

Ras Laffan Industrial City: 250 km2

gas

Condensate

DSC LSC PC

R

Condensate

Refinery

Refined products

Naphtha, Gasoil, Kerosene

Export

IPP1&2

Oryx

Local

Gas projects

Naphtha, Diesel, LO, Paraffins

GTL plants

DSC, LSC, PC

Sulfur

Raw gas

pipeline

Sulfur

Ethane

Petrochemicals

Crackers

LPG

LPG

C3, C4

IPP1&2

Fuel gas

Lean gas

pipeline

Ethane

pipeline

Petrochemicals

Polyethylene, glycols

PE units

Ethylene

pipeline

p p

Lean gas

export line

EXPORT

9

MESSAIED

INDUSTRIAL CITY

Ras Laf f an Si t e Vi ew - East si de -

5 LNG Storage tanks

Qatargas II (QP/ExxonMobil/Total)

5 LNG Storage tanks

Qatargas II (QP/ExxonMobil/Total)

2 trains of 7.8 Mta LNG

APCI AP-X

EPC Contract signed Q4/2004

Qatargas III (QP / ConocoPhillips) Q g (Q p )

Qatargas IV (QP / Shell)

2 trains of 7.8 Mta LNG

APCI AP-X

EPC Contract signed Q4/2005

2.5 km 2.5 km

Al Khaleej Gas Phase 2 (AKG-2)

RasGas III QP/Exxon Mobil

2 trains of 7.8 Mta LNG

APCI AP-X

EPC Contract signed Q3/2005

j ( )

RasGas, on behalf of ExxonMobil

1.25 Bscfd sales gas

Ethane recovery

EPC Contract signed Q2/2006

10

ORYX GTL

The l ar gest LNG t r ai ns and t he l ar gest LNG t er mi nal i n t he w or l d

CLP - Common LNG Storage

QGII RGIII QGIII/IV

New process APCI AP-X

QGII; RGIII; QGIII/IV

5+2 x 140 000 m3 tanks

6 BOG compressors

3 new berths

New process, APCI AP X

6 trains: 7.8 Mta - very large train capacity

99% C3+ recovery

New compressor drivers (GE Fr 9)

Large utilities and offsites

14 000 m3/h/berth

2 x 36 lines/berth

Simultaneous loading to 2 berths 11

g

Large, integrated electrical system

T h i T d Technip Today

Qatar, a Key Player in the LNG World

Ras Laffan Industrial City and the 3 Mega LNG Projects

Challenges of Qatar Mega LNG Projects

New technologies

Worldwide work locations

Human factors

Security/safety

Camps p

Logistics

Construction

Start-up Sta t up

12

New Ai r Pr oduc t s AP-X Pr oc ess

3 refrigerant cycles

each

with GE Frame 9E

driver

C3 Refrigerant

string

All exchangers in C3/Pre-cooling section

13

Mixed

Refrigerant

string

Nitrogen

Refrigerant

string

with Technip /Wieland PB tubes

New GE Fr ame 9E i n Mec hani c al Dr i ve

Frame 9E Incentives

High Power - 100 MW site rating (49

o

C day)

3000 RPM - better compressor speed match

Fl t LNG d ti

Customized for LNG

Flat LNG production

Frame 9E

130 MW ISO

Service

Speed range 96%-102%

Continuous duty, base load

Extended maintenance

intervals

210,000 kg package

50,000 kg rotor

intervals

Meets Qatar Environmental

requirements using DLN1

Motor/Generator

45MW

60MW during peak

C3 & N2 send power to MR

275 MW Total Refrigeration

Power Required

3 GE Fr 9 GTs per train

14

T h i T d Technip Today

Qatar, a Key Player in the LNG World

Ras Laffan Industrial City and the 3 Mega LNG Projects

Challenges of Qatar Mega LNG Projects

New technologies

Worldwide work locations

Human factors

Security/safety

Logistics g

Construction

Start-up

15

Chal l enges of Qat ar mega LNG Pr oj ec t

CTJV Yokohama Office

Overall Project

Paris,

France

Worldwide work locations

& Technip Abu Dhabi Chennai

Overall Project

Management and

Implementation

Engineering for

Process Area

CTJV Paris Office

Engineering for Common,

Utilities, Offsite and a part of

Process Areas

Yokohama

, Japan

& Technip Abu Dhabi, Chennai,

Chiyoda Milano, Philippines

And all our suppliers around the

World

Overall Procurement

Management and

Execution

Ras

CTJV SITE Office Qatar -

All Construction and Site Prefabrication Work

Pre-mechanical Completion Work

CTJV Doha Office

Administrative Work

Interface with National and Local

Doha,

Qatar

Ras

Laffan,

Qatar

Pre mechanical Completion Work

Field Engineering

Procurement Services in Qatar and Other Surrounding

Gulf Countries

Customs Clearance Coordination at Ras Laffan Port

Government Authorities

Customs Clearance Coordination at

Doha Port and Logistics

Coordination

Qatar

16

Customs Clearance Coordination at Ras Laffan Port

T h i T d Technip Today

Qatar, a Key Player in the LNG World

Ras Laffan Industrial City and the 3 Mega LNG Projects

Challenges of Qatar Mega LNG Projects

New technologies

Worldwide work locations

Human factors

Security/safety

Camps p

Logistics

Construction

Start-up Sta t up

17

Chal l enges of Qat ar mega LNG Pr oj ec t

People : A mosaic of cultures and religions People : A mosaic of cultures and religions

Some Illustrating Key Figures

More than 200 000 persons who have worked on one of the 3 Qatar Mega LNG Project

Sites

More than 75 000 persons mobilized together at the peak

86 Nationalities

A mosaic of cultures and religions

For each different culture a different perception and behaviors For each different culture, a different perception and behaviors

TECHNIPs approach: understand

Assessing the expectations of the different cultural or religious groups

Identifying the common elements between the different groups and the elements that can y g g p

potentially cause issues

There is a real need to uncover and deal with the differences during the project start-up

process and to continuously or periodically take account these matters during the project

implementation.

18

T h i T d Technip Today

Qatar, a Key Player in the LNG World

Ras Laffan Industrial City and the 3 Mega LNG Projects

Challenges of Qatar Mega LNG Projects

New technologies

Worldwide work locations

Human factors

Security/safety

Logistics g

Construction

Start-up

19

Chal l enges of Qat ar mega LNG Pr oj ec t

S i h d d di d Security : approach and dedicated measures

Each stage of project presents different risks

Mobilization phase: set up of security measures

Various construction phases: increase of the risks with number Various construction phases: increase of the risks with number

of workers and equipment on site, riots,

Commissioning phase: increasing sensitive areas on site, with specific needs

Demobilization phase: Ensure people leave the site voluntarily and smoothly.

Specificity of the 3 Qatar LNG Mega projects:

Due to such extraordinary mass of workforce (75000 persons

at peak and 86 nationalities), Technip had implemented a p )

specific security system on site including:

- a staff of security personnel (300 persons at peak)

- Implementation of the Joint Operation Center (JOC) with Client and

Contractor in charge to coordinate any Emergency Response Plan

22

Chal l enges of Qat ar mega LNG Pr oj ec t

S f / i i f W kf Safety / training of Workforce

Safety level on a construction site depends on the

behaviors of your workers, so it is directly depends on

the skill level of the manpower and their safety the skill level of the manpower and their safety

awareness.

So maintaining an high level of safety performance has been

a real challenge.

Global ratio of 1 safety personnel for 50 workers

Intensive training program in 14 different languages:

More than 200 000 HSE induction trainings

More than 27 000 Training sessions including various safety

Training, Work at height, H2S, etc and craft trainings

High level of Safety equipment provided to the workforce

As result an overall outstanding safety performances in regards

12 21

As result, an overall outstanding safety performances in regards

to the size of the construction sites and number of people

T h i T d Technip Today

Qatar, a Key Player in the LNG World

Ras Laffan Industrial City and the 3 Mega LNG Projects

Challenges of Qatar Mega LNG Projects

New technologies

Worldwide work locations

Human factors

Security/safety

Camps p

Logistics

Construction

Start-up Sta t up

22

Fr om t he deser t t o c amps f ac i l i t i es f or 60 000 per sons

Number Capacity Contractor Capacity Subcontractors Number

of Camps

Capacity Contractor

Camps

p y

Camps

QGX 4 1311 21194

QCS 4 1146 16114

RGX/AKG2 6 1706 21370

Nov 2004

RGX/AKG2 6 1706 21370

Total 14 4163 58678

Camps Utilities

Jan 2006

Average Water Consumption :

350 liters/Day/Person

Average Power Peak:

Camps Utilities

Average Power Peak:

1.8 kW/person

Average Sewage Disposal:

340 liters / day / person

March 2008: Trees have grown up

23

T h i T d Technip Today

Qatar, a Key Player in the LNG World

Ras Laffan Industrial City and the 3 Mega LNG Projects

Challenges of Qatar Mega LNG Projects

New technologies

Worldwide work locations

Human factors

Security/safety

Camps p

Logistics

Construction

Start-up Sta t up

24

Chal l enges of Qat ar mega LNG Pr oj ec t

A h ld l j i f f i h Among the worlds largest projects in terms of freight movements

to a single place

A i ti 3 Milli F i ht T f i t d t i l i d i Q t Approximative 3 Millions Freight Tons of equipments and material received in Qatar

Ports, without major incidents or issue

More than 20 000 TEUs (Twenty feet equivalent unit) containers received and delivered

through Doha Port through Doha Port

Main Challenges:

Congested schedule of Ras Laffan Port operations

Heavy flow of air shipment against limited capacity of Doha Airport

Shortage of container storage capacity in Doha Sea Port

Other regional main ports congestions and delays

25

Shortage of feeder vessels from Mother ports to Doha Port

Shi p ar r i val f or 3 LNG Mega Pr oj ec t s

20

25

Nb of Vessels

15

20

5

10

0

450 vessels in 43 months

Upto almost one vessel per day at peak

26

T h i T d Technip Today

Qatar, a Key Player in the LNG World

Ras Laffan Industrial City and the 3 Mega LNG Projects

Challenges of Qatar Mega LNG Projects

New technologies

Worldwide work locations

Human factors

Security/safety

Camps p

Logistics

Construction

Start-up Sta t up

27

Chal l enges of Qat ar mega LNG Pr oj ec t s

C i Construction

Huge quantity of materials & equipment

700 000 m3 of concrete

137 000 t f t l f k (14 ti Eiff l t ) 137 000 tons of steel framework (14 times Eiffel tower)

270 000 tons of machinery (950 Airbus A380 planes)

180 000 tons of piping

20 000 km of electrical and instrumentation cable

The highest flares are 200 meter high

500 000 m2 (66 soccer fields) for each of the 3 projects

75 000 people at peak 75 000 people at peak

700 million construction man-hours

Sheer size required new construction methods

28

At c onst r uc t i on peak : about 5300 equi pment on si t e

35

Transit

Mixers

62

Tower

cranes

682

Crawler &

Mobile

cranes cranes

3646

Welding

machines

79

E t

29

797

Buses

Excavators

Qat ar gas I I - Manuf ac t ur e of AGRU Absor ber , Mar 2006

Qat ar gas I I - Er ec t i on of AGRU Absor ber , Feb 2007

1 absorber per train,

6 in total

1,450 Tons each

Height = 45 7m Height = 45.7m

Diameter = 7.4m

Lifted with Platform Ringer

Crane, Capacity 2,000T

Fr esh w at er c l osed l oop c ool ed w i t h sea w at er

Fr esh w at er c l osed l oop c ool ed w i t h sea w at er

Fr esh w at er c l osed l oop c ool ed w i t h sea w at er

32

Qatargas II- Fresh cooling water loop piping (114 in)

Chal l enges of Qat ar mega LNG Pr oj ec t s

B t l But also.

Shortage of resources in Qatar and in the Gulf: specialized manpower,

supervision

Construction subcontractors low productivity

Shortage of raw material (cement, washed sand, argon gas, diesel ...)

For the Argon Gas, TECHNIP has developed in partnership with a Gas supplier, a Argon

Gas Station to supply all the 3 LNG projects and Ethylene Projects Gas Station to supply all the 3 LNG projects and Ethylene Projects

Aggressive schedules and simultaneity of 4 mega projects

inter-project dependencies

Infrastructure limitation:

Port congestion, Road traffic congestion in RLIC, supply of water at risk

33

World wide raw material, equipments and manpower price increase

T h i T d Technip Today

Qatar, a Key Player in the LNG World

Ras Laffan Industrial City and the 3 Mega LNG Projects

Challenges of Qatar Mega LNG Projects

New technologies

Worldwide work locations

Human factors

Security/safety

Camps p

Logistics

Construction

Start-up Sta t up

34

St ar t -up: t he c hal l enges of t he Wor l ds Lar gest LGN t r ai n

I t i f ti f t i l / i t d i th l t ti Intensive program of preservation of material /equipment during the long construction

phase with a dedicated team

Protection of the valves

Protection of all rotating equipment

Implementation of High Pressure Leak test with Helium Leak Detection (HLD) :

The Helium Detection process when combined with nitrogen as the pressurization medium can identify leaks

to the order of 0.1 standard cubit feet of gas per year.

1. This helps to save lost production, time and costs compared to repairing leaks after start up.

2. This ensure a safe start up and operation with the Sour feed Gas

High velocity in Gas lines:

Due to the exceptional size of the plant, the flare design

is about 3500 t/h !

This required to adopt advanced method of sizing

of the flare system

35

of the flare system

TODAY

4 Trains in full operation in Qatargas and Rasgas

1 Train on Qatargas 3: in start up phase

The last Train of Qatargas 4 will be in operation by end of 2010

Qatar will celebrate the 77 MT/y

of LNG Capacity production of LNG Capacity production

on Dec 13, 2010

in presence of The Emir of Qatar in presence of The Emir of Qatar

36

Qat ar gas I I Vi ew f r om Fl ar e st ac k 24t h May 2007

Qatargas View as of mid 2009

Qatargas II View from Flare stack 24th May 2007

37

QATARGAS LNG Pr oj ec t s TECHNI P St af f Oc t ober 2009 Q G S G j c s C S Oc 009

Le dfi GNL au Qatar

38

Questions ?

Le dfi GNL au Qatar

39

Thank you! Thank you!

Anda mungkin juga menyukai

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12Dari EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12Belum ada peringkat

- CCC Excellence Awards Bulletin Recognizes Top PerformersDokumen38 halamanCCC Excellence Awards Bulletin Recognizes Top PerformersamalBelum ada peringkat

- Giignl 2015 Annual ReportDokumen29 halamanGiignl 2015 Annual ReportElena0% (1)

- Mumbai Trans Harbour Link Package 1 Sewri Interchange Pavement DesignDokumen9 halamanMumbai Trans Harbour Link Package 1 Sewri Interchange Pavement Designasif_22ukBelum ada peringkat

- MEmaco N 907 - Al ZourDokumen1 halamanMEmaco N 907 - Al Zouraruncg2Belum ada peringkat

- Bfi Urea Export Jetty Pile Drive Report Sheet: 1.Date/Hour 2.Date/HourDokumen1 halamanBfi Urea Export Jetty Pile Drive Report Sheet: 1.Date/Hour 2.Date/Hour唐亮Belum ada peringkat

- LRT3 Cable Approval for Construction ProjectDokumen4 halamanLRT3 Cable Approval for Construction ProjectHafiz NurahimBelum ada peringkat

- Engineering & Marine StructuresDokumen13 halamanEngineering & Marine Structuresامين الزريقيBelum ada peringkat

- Mk2+ Dual Wallform To Retaining Wall: Shade CorporationDokumen15 halamanMk2+ Dual Wallform To Retaining Wall: Shade CorporationJuan Dela CruzBelum ada peringkat

- 2023 02 09 - IWP A03 WP5.3 000 FI LC 101 CV01 101 - Rev1Dokumen16 halaman2023 02 09 - IWP A03 WP5.3 000 FI LC 101 CV01 101 - Rev1Priyanshu UpadhyayBelum ada peringkat

- Load-Out, Transportation and Installation Design Basis: 7. StructureDokumen1 halamanLoad-Out, Transportation and Installation Design Basis: 7. StructurefructoraBelum ada peringkat

- ARCHIRODON PETROJET INSPECTION PLANDokumen2 halamanARCHIRODON PETROJET INSPECTION PLANBelal hassanBelum ada peringkat

- CCCC Harbour Bureau 2: Bridge Girder LauncherDokumen1 halamanCCCC Harbour Bureau 2: Bridge Girder LauncherBudi MaryantoBelum ada peringkat

- Fuel Oil Transit Terminal Situbondo: Preliminary StudyDokumen17 halamanFuel Oil Transit Terminal Situbondo: Preliminary StudyDoni AndreanaBelum ada peringkat

- PDFDokumen129 halamanPDFSatt PaingBelum ada peringkat

- Liquefied Natural Gas Terminals: Services and SolutionsDokumen7 halamanLiquefied Natural Gas Terminals: Services and SolutionsJohnBelum ada peringkat

- 4차 Technical Proposal 견적 기준Dokumen40 halaman4차 Technical Proposal 견적 기준m khaeronBelum ada peringkat

- TBD-TJ-W8-SD-DR-4028 - B - Code B - Stairway Plan and SectionsDokumen5 halamanTBD-TJ-W8-SD-DR-4028 - B - Code B - Stairway Plan and SectionsGeta Oisis Arya PutraBelum ada peringkat

- T 14.419.003 SH1 AA - CEF - Signed PDFDokumen33 halamanT 14.419.003 SH1 AA - CEF - Signed PDF이상기Belum ada peringkat

- Calculo Impacto DefensasDokumen22 halamanCalculo Impacto DefensasRuben Bartolome GarciaBelum ada peringkat

- GASLOG Singapore GA DWG - Appendix 10Dokumen2 halamanGASLOG Singapore GA DWG - Appendix 10karthikaBelum ada peringkat

- SPCC T CV Cal 0001 R1Dokumen10 halamanSPCC T CV Cal 0001 R1Panha PorBelum ada peringkat

- Trestle PiperackDokumen10 halamanTrestle PiperackCong PhamBelum ada peringkat

- DSISPP TS - MS - 004 Tendon Stressing Without JSEA& RD 20.04.21Dokumen56 halamanDSISPP TS - MS - 004 Tendon Stressing Without JSEA& RD 20.04.21Panha PorBelum ada peringkat

- Accropode Brochure 2014Dokumen4 halamanAccropode Brochure 2014Pn EkanayakaBelum ada peringkat

- Feasibility Study for Industrial Infrastructure ConstructionDokumen28 halamanFeasibility Study for Industrial Infrastructure ConstructionYongSun ChoBelum ada peringkat

- MLA Data Sheet - LNG - RevaDokumen6 halamanMLA Data Sheet - LNG - RevaLuis Gonzalez0% (1)

- Villa 5 PDFDokumen20 halamanVilla 5 PDFBookun SkyyBelum ada peringkat

- Tripod Breasting Dolphin - Detail 1 PDFDokumen1 halamanTripod Breasting Dolphin - Detail 1 PDFToniBelum ada peringkat

- Method Statement For Navigation Aid C02 EditedDokumen40 halamanMethod Statement For Navigation Aid C02 EditedOlugbemiga James OlalekanBelum ada peringkat

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDokumen10 halamanWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195Belum ada peringkat

- New Bridge Drawing ListDokumen1 halamanNew Bridge Drawing Listacidrisamuel2656Belum ada peringkat

- CV Eng. Issam JABER - PMDokumen6 halamanCV Eng. Issam JABER - PMissamjaberBelum ada peringkat

- Breasting Dolphin Jetty PDFDokumen157 halamanBreasting Dolphin Jetty PDFPriodeep ChowdhuryBelum ada peringkat

- 01 FST Bs 300 Trans Top-1Dokumen8 halaman01 FST Bs 300 Trans Top-1avt premiumBelum ada peringkat

- Freeport LNG Terminal Operations ManualDokumen60 halamanFreeport LNG Terminal Operations Manualjesusgameboy100% (1)

- Mooring & Breasting Jetty IIDokumen12 halamanMooring & Breasting Jetty IIDwiki AdriyantoBelum ada peringkat

- 2B 100 1 1 V Et 0001 PDFDokumen13 halaman2B 100 1 1 V Et 0001 PDFLuis GonzalezBelum ada peringkat

- Mooring & Breasting Jetty IVDokumen16 halamanMooring & Breasting Jetty IVDwiki AdriyantoBelum ada peringkat

- Binder 1Dokumen19 halamanBinder 1sharath devadigaBelum ada peringkat

- Gina GasketDokumen14 halamanGina GasketA_ValsamisBelum ada peringkat

- 2014 NLNG Facts and Figures Part 1Dokumen50 halaman2014 NLNG Facts and Figures Part 1John Nen BiniBelum ada peringkat

- POM DH1820 MF T 0860 Method Statement PDFDokumen30 halamanPOM DH1820 MF T 0860 Method Statement PDFHafiz NurahimBelum ada peringkat

- OKYC Terminal InfoDokumen57 halamanOKYC Terminal InfotuyenbsrBelum ada peringkat

- PDFDokumen376 halamanPDFAna Castro100% (1)

- 5 Supplimetary Information ReportDokumen39 halaman5 Supplimetary Information ReportANIL KUMARBelum ada peringkat

- Ipp-Gsf-Civ-Gen-005 - 1 of 10 - Rev e PDFDokumen1 halamanIpp-Gsf-Civ-Gen-005 - 1 of 10 - Rev e PDFYosuaBelum ada peringkat

- Idn27943 - SCN1200 F2.5 - Ga+alDokumen2 halamanIdn27943 - SCN1200 F2.5 - Ga+alAbdul JabbarBelum ada peringkat

- Core Loc WaterfrontDokumen12 halamanCore Loc WaterfrontricardoBelum ada peringkat

- QGX T CS CCS 00353Dokumen22 halamanQGX T CS CCS 00353Omar TocmoBelum ada peringkat

- Adani House, NR Mithakhali Circle, Navrangpura, Ahmedabad 380 009, Gujarat, IndiaDokumen34 halamanAdani House, NR Mithakhali Circle, Navrangpura, Ahmedabad 380 009, Gujarat, IndiaphanikrishnabBelum ada peringkat

- 02-MAIN-VILLA-MID UNIT-final Price-19-12-2019Dokumen18 halaman02-MAIN-VILLA-MID UNIT-final Price-19-12-2019jatinBelum ada peringkat

- Jetty공사과정Dokumen47 halamanJetty공사과정choyongsunBelum ada peringkat

- LGC Ycc RB STR VD 25+797 Sup - 301 - R2Dokumen10 halamanLGC Ycc RB STR VD 25+797 Sup - 301 - R2gYANBelum ada peringkat

- Johanes AgusDokumen41 halamanJohanes AgusGerry Dwi PutraBelum ada peringkat

- FSD Ship Loader Telescopic Spout DesignDokumen8 halamanFSD Ship Loader Telescopic Spout DesignRestuBelum ada peringkat

- Data Jetty MaumereDokumen2 halamanData Jetty MaumereAlvinBurhani0% (1)

- A ESIA Yemen Section 3 Revision 1Dokumen42 halamanA ESIA Yemen Section 3 Revision 1Denstar Ricardo SilalahiBelum ada peringkat

- Execution of LNG Mega TrainsDokumen8 halamanExecution of LNG Mega TrainsMelvin MagbanuaBelum ada peringkat

- Abbas - Bilgrami CNG Transportation Trans CanadaDokumen48 halamanAbbas - Bilgrami CNG Transportation Trans CanadaMustafa100% (1)

- VSL (1897) PDFDokumen2 halamanVSL (1897) PDFRaed Naim KhammashBelum ada peringkat

- ProdSpecsDoc144 PDFDokumen20 halamanProdSpecsDoc144 PDFRaed Naim KhammashBelum ada peringkat

- Islamic Law Document on InheritanceDokumen3 halamanIslamic Law Document on InheritanceRaed Naim KhammashBelum ada peringkat

- Design of Water Retaining Structures To ECDokumen44 halamanDesign of Water Retaining Structures To ECVincent Teng100% (4)

- KhayatOct92012V2 PDFDokumen89 halamanKhayatOct92012V2 PDFRaed Naim KhammashBelum ada peringkat

- Epc PDFDokumen20 halamanEpc PDFAnu Mali50% (2)

- 152 Dampers Control Vibrations on World's Highest Cable-Stayed BridgeDokumen1 halaman152 Dampers Control Vibrations on World's Highest Cable-Stayed BridgeRaed Naim KhammashBelum ada peringkat

- Ciria 108 Pressure AnalysisDokumen4 halamanCiria 108 Pressure AnalysisRaed Naim KhammashBelum ada peringkat

- Wocomplexity Analysis PDFDokumen185 halamanWocomplexity Analysis PDFRaed Naim KhammashBelum ada peringkat

- PM1561Dokumen4 halamanPM1561Raed Naim KhammashBelum ada peringkat

- Master Thesis-Andreas Winge PDFDokumen86 halamanMaster Thesis-Andreas Winge PDFRaed Naim KhammashBelum ada peringkat

- Unified Facilities Criteria - Piers and WharvesDokumen175 halamanUnified Facilities Criteria - Piers and WharvesRoda CadizBelum ada peringkat

- RS Means Estimating Cost Ch4Dokumen33 halamanRS Means Estimating Cost Ch4Krish DoodnauthBelum ada peringkat

- Driven Piles for Marine Jetty ConstructionDokumen1 halamanDriven Piles for Marine Jetty ConstructionRaed Naim KhammashBelum ada peringkat

- AFCONS DahejDokumen37 halamanAFCONS DahejRaed Naim KhammashBelum ada peringkat

- LNG Import Terminal Cost and Schedule BasicsDokumen23 halamanLNG Import Terminal Cost and Schedule Basicsjomafeba100% (3)

- Bontang Future 3rd LNG-LPG - A Design Which Achieves Very High Levels of Flexibility, Safety and ReliabilityDokumen25 halamanBontang Future 3rd LNG-LPG - A Design Which Achieves Very High Levels of Flexibility, Safety and Reliabilitywebwormcpt100% (1)

- Design of Concrete TanksDokumen198 halamanDesign of Concrete Tankssuman33100% (1)

- Understanding Met Forces for LNG HandlingDokumen40 halamanUnderstanding Met Forces for LNG HandlingjomaferreiroBelum ada peringkat

- 1 GasTankersAdvanceCourseDokumen105 halaman1 GasTankersAdvanceCourseValerian Strat100% (1)

- Nitocote AP35: Constructive SolutionsDokumen44 halamanNitocote AP35: Constructive SolutionsRaed Naim KhammashBelum ada peringkat

- Drivability of Steel Sheet PilesDokumen3 halamanDrivability of Steel Sheet PilesRaed Naim Khammash100% (1)

- View from Twyford Village HDD Method StatementDokumen17 halamanView from Twyford Village HDD Method StatementRaed Naim KhammashBelum ada peringkat

- Annex 1 HDDDokumen6 halamanAnnex 1 HDDRaed Naim KhammashBelum ada peringkat

- Eco-friendly protective coatingDokumen2 halamanEco-friendly protective coatingRaed Naim KhammashBelum ada peringkat

- 2Dokumen66 halaman2Raed Naim KhammashBelum ada peringkat

- Trust BoringDokumen8 halamanTrust BoringazamshafiqBelum ada peringkat

- View from Twyford Village HDD Method StatementDokumen17 halamanView from Twyford Village HDD Method StatementRaed Naim KhammashBelum ada peringkat

- Construction Method StatementDokumen35 halamanConstruction Method StatementRaed Naim KhammashBelum ada peringkat

- W GC Final 00139Dokumen31 halamanW GC Final 00139Pawan Chaturvedi0% (1)

- Aplicaciones de Membrana para La Gestión Del Agua en El Petróleo e Industria de GasDokumen16 halamanAplicaciones de Membrana para La Gestión Del Agua en El Petróleo e Industria de GasLina TorresBelum ada peringkat

- LNG Compatibility Document Full PDFDokumen28 halamanLNG Compatibility Document Full PDFreliableplacementBelum ada peringkat

- HSBC - Global LNG - On The Cusp of A New Boom (2019 02 14)Dokumen44 halamanHSBC - Global LNG - On The Cusp of A New Boom (2019 02 14)Andre d'AlvaBelum ada peringkat

- Air Products' Experience:: Leadership in Mid-Scale To Large LNG Plant ProjectsDokumen2 halamanAir Products' Experience:: Leadership in Mid-Scale To Large LNG Plant ProjectsDineshBelum ada peringkat

- GVC 202205 e 1Dokumen22 halamanGVC 202205 e 1RoozbehotecBelum ada peringkat

- f9b87e7e-45f5-47a0-8d3e-978c1801ce2eDokumen6 halamanf9b87e7e-45f5-47a0-8d3e-978c1801ce2esasikalaBelum ada peringkat

- LNG and Oil & Gas Equipment Installation Projects 2013-2007Dokumen18 halamanLNG and Oil & Gas Equipment Installation Projects 2013-2007amir moniriBelum ada peringkat

- Human Factor SpecDokumen84 halamanHuman Factor Specmurugn08Belum ada peringkat

- Resilient Qatar's Natural Gas Development Policy and Energy Situation Under Its CrisisDokumen4 halamanResilient Qatar's Natural Gas Development Policy and Energy Situation Under Its Crisisعلي حميد زغير صحنBelum ada peringkat

- Project Construction Professional Seeking New OpportunityDokumen11 halamanProject Construction Professional Seeking New OpportunityRavi YadavBelum ada peringkat

- Polskie - LNG Regas TerminalDokumen7 halamanPolskie - LNG Regas TerminalbranudayBelum ada peringkat

- BU48A02B00 00E N - 007 (ProSafe ProjRef)Dokumen12 halamanBU48A02B00 00E N - 007 (ProSafe ProjRef)Broken WindowBelum ada peringkat

- DieselFacts 2008-1 PDFDokumen16 halamanDieselFacts 2008-1 PDFAsh Kai100% (1)

- LNG Daily: Asia LNG: Prices Rise On Early Concerns of Suez Canal Situation, Off-Peak DemandDokumen16 halamanLNG Daily: Asia LNG: Prices Rise On Early Concerns of Suez Canal Situation, Off-Peak DemandSaputra Manalu100% (1)

- Fundamental of The GlobalDokumen164 halamanFundamental of The GlobalDeepak GoyalBelum ada peringkat

- 071 Ras Gas 12Dokumen39 halaman071 Ras Gas 12xtrooz abiBelum ada peringkat

- Latest Job Vacancy at Qatar Gas - Welcome To Job Pro WorldDokumen19 halamanLatest Job Vacancy at Qatar Gas - Welcome To Job Pro WorldbalaBelum ada peringkat

- Bic - 2017-09Dokumen22 halamanBic - 2017-09Edwin CandoBelum ada peringkat

- Valerus Team Joins Kentz GroupDokumen17 halamanValerus Team Joins Kentz GroupLopez Gardo0% (1)

- Cygnus Energy LNG News Weekly 07th May 2021Dokumen14 halamanCygnus Energy LNG News Weekly 07th May 2021Sandesh Tukaram GhandatBelum ada peringkat

- Pakistan's Growing LNG Market OutlookDokumen26 halamanPakistan's Growing LNG Market OutlookRASHID AHMED SHAIKHBelum ada peringkat

- Hiring For Qatar Gas - Indonesia Project.Dokumen45 halamanHiring For Qatar Gas - Indonesia Project.cheros soccerBelum ada peringkat

- SENTRO Technologies Online Chemical Cleaning PresentationDokumen8 halamanSENTRO Technologies Online Chemical Cleaning Presentation조기현Belum ada peringkat

- Qatargas Leads Major Environmental Project to Recover Flared GasDokumen4 halamanQatargas Leads Major Environmental Project to Recover Flared Gasrvkumar61Belum ada peringkat

- Liquefied Natural Gas: Trust The Industry's Longest-Serving Turnkey ContractorDokumen12 halamanLiquefied Natural Gas: Trust The Industry's Longest-Serving Turnkey Contractorvignesh100% (1)

- Expanding Globally and Maximizing Qatar's Energy ResourcesDokumen113 halamanExpanding Globally and Maximizing Qatar's Energy ResourcesxsupermanBelum ada peringkat

- Qatar Liquified Gas Company Limited (II) : QG2, The Designs and Technologies For A 7.8 MTPA TrainDokumen16 halamanQatar Liquified Gas Company Limited (II) : QG2, The Designs and Technologies For A 7.8 MTPA TrainweldsvBelum ada peringkat

- Shell JDDokumen3 halamanShell JDpmnasimBelum ada peringkat

- 1 MergedDokumen43 halaman1 MergedAmitesh Mathematics Smart ClassesBelum ada peringkat