8-Channel Analog Input Module Power Requirements

Diunggah oleh

mushahid980Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

8-Channel Analog Input Module Power Requirements

Diunggah oleh

mushahid980Hak Cipta:

Format Tersedia

1 - 8 0 0 - 6 3 3 - 0 4 0 5

e6-76

ProgrammableControllers

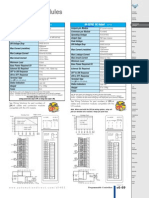

CH1

Voltage Transmitter

See Note 1

CH2

Voltage Transmitter

CH3-6

Not used

CH7

2-wire 4-20mA

Transmitter

CH7

3-wire 4-20mA

Transmitter

Analog Input Modules

F4-08AD 8-Channel Analog Input <--->

Number of Channels 8, single ended (one common)

Input Ranges

0-5V, 0-10V, 1-5V, 5V, 10V

0-20mA, 4-20mA

Channels Individually

Configurable

No. Each channel can be configured for current or

voltage but must be same range.

Resolution 12 bit (1 to 4,096)

Active Low-pass Filtering -3dB at 20Hz, -12 dB per octave

Input Impedance

250 0.1%, 1/2Wcurrent input

>20Mvoltage input

1 Mminimum

Absolute Maximum Ratings

-45mA to + 45mA, current input

-75V to +75V, voltage input

Conversion Time

0.4ms per channel (module conversion)

1 ms per selected channel minimum (CPU)

Linearity Error (End to End) 1 count (0.025% of full scale) max.

Input Stability 1/2 count

Full Scale Calibration Error

(Offset error not included)

12 counts voltage input

12 counts max. @ 20mA current input

Offset Calibration Error

2 counts max., unipolar voltage input

4 counts max., bipolar voltage input,

4 counts max., 4mA current input

PLC Update Rate 1 channel per scan min., 8 per scan, max.

Digital Input Points Required

16 (X) input points (12 binary data bits, 3

active channel bits, 1 bit unused)

Base Power Required 5V 75mA

Terminal Type (included) Removable (D4-16IOCON)

External Power Supply 18-30VDC, 120mA, class 2

Recommended Fuse 0.032 A, Series 217 fast-acting, current inputs

Operating Temperature 32 to 140F (0 to 60C)

Accuracy vs. Temperature

50 ppm/C maximum full scale (including

maximum offset change of 2 counts)

Storage Temperature -4 to 158F (-20 to 70C)

Relative Humidity 5 to 95% (non-condensing)

Environmental Air No corrosive gases permitted

Vibration MIL STD 810C 514.2

Shock MIL STD 810C 516.2

Noise Immunity NEMA ICS3-304

One count in the specification table is equal to one least significant bit of the analog data value (1 in 4096).

NOTE 1: Shields should be grounded at the signal source

NOTE 2: Unused channels should be connected to 0V or have current jumpers installed

More than one external power supply can be used (see channel 8)

A Series 217, 0.032A, fast-acting fuse is recommended for 4-20mA current loops.

If the power supply common of an external power supply is not connected to 0VDC on the module,

then the output of the external transmitter must be isolated. To avoid ground loop errors,

recommended 4-20mA transmitter types are:

2 or 3 wire: Isolation between input signal and power supply.

4 wire: Isolation between input signal, power supply and 4-20mA output.

See Wiring Solutions for part numbers of

ZIPLink cables and connection modules

compatible with this I/O module.

Volume 14

1 - 8 0 0 - 6 3 3 - 0 4 0 5

e6-24

ProgrammableControllers

Volume 14

Verify your power budget

requirements

Your I/O configuration choice can be

affected by the power requirements of the

I/O modules you choose. When deter-

mining the types and quantity of I/O

modules you will be using, it is important

to remember there is a limited amount of

power available from the power supply.

The chart on the opposite page indicates

the power supplied and used by each

DL405 device. The adjacent chart shows

an example of how to calculate the power

used by your particular system. These two

charts should make it easy for you to

determine if the devices you have chosen

fit within the power budget of your system

configuration.

If the I/O you have chosen exceeds the

maximum power available from the power

supply, you can resolve the problem by

shifting some of the modules to an expan-

sion base or remote I/O base (if you are

using remote I/O).

Warning: It is extremely important to calculate the

power budget correctly. If you exceed the power budg-

et, the system may operate in an unpredictable man-

ner which may result in a risk of personal injury or

equipment damage.

Use ZIPLinks to reduce

power requirements

If your application requires a lot of relay

outputs, consider using the ZipLink AC or

DC relay output modules. These modules

can switch high current (10A) loads

without putting a load on your base power

budget. Refer to Wiring System for DL405

PLCs later in this section for more informa-

tion.

This logo is placed next to I/O modules

that are supported by the ZIPLink connec-

tion systems.

See the I/O module specifications at the

end of this section.

Calculating your power

usage

The following example shows how to

calculate the power budget for the DL405

system. The example is constructed around

a single 8-slot base using the devices

shown. It is recommended you construct a

similar table for each base in your system.

Check the Power Budget

DL405 CPU power supply specifications and power requirements

A

Base Number

0

Device Type 5 VDC (mA)

External 24 VDC

Power (mA)

B CURRENT SUPPLIED

CPU/Expansion Unit

/Remote Slave

D4-440 CPU 3700 400

C CURRENT REQUIRED

SLOT 0 D4-16ND2 +150 +0

SLOT 1 D4-16ND2 +150 +0

SLOT 2 F4-04DA +120 +100

SLOT 3 D4-08ND3S +100 +0

SLOT 4 D4-08ND3S +100 +0

SLOT 5 D4-16TD2 +100 +0

SLOT 6 D4-16TD2 +100 +0

SLOT 7 D4-16TR +1000 +0

D OTHER

BASE D4-08B +80 +0

Handheld Programmer D4-HPP +320 +0

E Maximum Current Required 2820 100

F Remaining Current Available 3700-2820=880 400-100=300

1. Using a chart similar to the 3one above, fill in column 2.

2. Using the tables on the opposite page, enter the current supplied and used by each device (columns 3 and 4). Pay special attention to the cur-

rent supplied by the CPU, Expansion Unit, and Remote Slave since they differ. Devices which fall into the "Other" category (Row D) are devices such

as the Base and the Handheld programmer, which also have power requirements, but do not plug directly into the base.

3. Add the current used by the system devices (columns 3 and 4) starting with Slot 0 and put the total in the row labeled "maximum current

required" (Row E).

4. Subtract the row labeled "Maximum current required" (Row E), from the row labeled "Current Supplied" (Row B). Place the difference in the row

labeled "Remaining Current Available" (Row F).

5. If "Maximum Current Required" is greater than "Current Supplied" in either column 3 or 4, the power budget will be exceeded. It will be unsafe to

use this configuration and you will need to restructure your I/O configuration. Note the auxiliary 24 VDC power supply does not need to supply all

the external power. If you need more than the 400mA supplied, you can add an external 24VDC power supply. This will help keep you within your

power budget for external power.

Specification AC Powered Units 24 VDC Powered Units 125 VDC Powered Units

Part Numbers

D4-450, D4-440, D4-430,

D4-EX (expansion base unit),

D4-RS (remote slave unit)

D4-450DC-1, D4-440DC-1,

D4-EXDC (expansion base unit),

D4-RSDC (remote slave unit)

D4-450DC-2

D4-440DC-2

Voltage Withstand (dielectric) 1 minute @ 1,500 VAC between primary, secondary, field ground, and run relay

Insulation Resistance > 10Mat 500VDC

Input Voltage Range

85-132 VAC (110 range) 170-264 VAC (220

range

20-28 VDC (24 VDC)

with less than 10% ripple

90-146 VDC (125 VDC)

with less than 10% ripple

Maximum Inrush Current 20 A 20 A 20 A

Maximum Power 50 VA 38 W 30 W

w w w . a u t o m a t i o n d i r e c t . c o m / d l 4 0 5 ProgrammableControllers

e6-25

Company

Information

Systems

Overview

Programmable

Controllers

Field I/O

Software

C-more &

other HMI

Drives

Soft

Starters

Motors &

Gearbox

Steppers/

Servos

Motor

Controls

Proximity

Sensors

Photo

Sensors

Limit

Switches

Encoders

Current

Sensors

Pressure

Sensors

Temperature

Sensors

Pushbuttons/

Lights

Process

Relays/

Timers

Comm.

Terminal

Blocks &

Wiring

Power

Circuit

Protection

Enclosures

Tools

Pneumatics

Safety

Appendix

Product

Index

Part #

Index

Volume 14

Power Requirements

Power Supplied

CPUs/Remote Units/

Expansion Units

5 VDC Current

Supplied in mA

24V Aux Power

Supplied in mA

CPUs/Remote

Units/Expansion Units

5V Current Supplied

in mA

24VAux. Power

Supplied in mA

D4-430 CPU

D4-440 CPU

D4-440DC-1 CPU

D4-440DC-2 CPU

D4-450 CPU

D4-450DC-1 CPU

D4-450DC-2 CPU

3700

3700

3700

3700

3100

3100

3100

400

400

NONE

NONE

400

NONE

NONE

D4-EX

D4-EXDC

D4-EXDC-2

D4-RS

D4-RSDC

H4-EBC

H4-EBC-F

4000

4000

3700

3700

3700

3470

3300

400

NONE

NONE

400

NONE

400

400

Power Consumed

Power-consuming

Device

5V Current

Consumed

External 24VD

Current Required

Power-consuming

Device

5V Current

Consumed

External 24VDC

Current Required

I/O Bases Analog Modules (continued)

D4-04B-1

D4-06B-1

D4-08B-1

80

80

80

NONE

NONE

NONE

F4-16AD-1

F4-16AD-2

F4-04DA-1

F4-04DA-2

F4-04DAS-1

F4-04DAS-2

F4-08DA-1

F4-08DA-2

F4-16DA-1

F4-16DA-2

F4-08RTD

F4-08THM-n

F4-08THM

75

75

70

90

60

60

90

80

90

80

80

120

110

100

100

75+20per circuit

90

60 per circuit

60 per circuit

100+20 per circuit

150

100+20 per circuit

25 max.

NONE

50

60

DC Input Modules

D4-08ND3S

D4-16ND2

D4-16ND2F

D4-32ND3-1

D4-32ND3-2

D4-64ND2

100

150

150

150

150

300 max.

NONE

NONE

NONE

NONE

NONE

NONE

Remote I/O

H4-ERM

H4-ERM-F

D4-RM

320

450

300

NONE

NONE

NONE

AC Input Modules

D4-08NA

D4-16NA

100

150

NONE

NONE

AC/DC Input Modules

D4-16NE3

F4-08NE3S

150

90

NONE

NONE

Communications and Networking

H4-ECOM100

H4-ECOM-F

D4-DCM

F4-MAS-MB

FA-UNICON

300

670

500

235

NONE

NONE

NONE

NONE

NONE

65

DC Output Modules

D4-08TD1

F4-08TD1S

D4-16TD1

D4-16TD2

D4-32TD1

D4-32TD1-1

D4-32TD2

D4-64TD1

150

295

200

400

250

250

350

800

35

NONE

125

NONE

140

140 (15V)

120 (4A max

including loads)

NONE

CoProcessors

F4-CP128-1 305 NONE

AC Output Modules

D4-08TA

D4-16TA

250

450

NONE

NONE

Specialty Modules

H4-CTRIO

D4-INT

D4-HSC

F4-16PID

F4-8MPI

D4-16SIM

F4-4LTC

400

100

300

160

225

150

280

NONE

NONE

NONE

NONE

170

NONE

75

Relay Output Modules

D4-08TR

F4-08TRS-1

F4-08TRS

D4-16TR

550

575

575

1000

NONE

NONE

NONE

NONE

Analog Modules Programming

F4-04AD

F4-04ADS

F4-08AD

85

270

75

100

120

90

D4-HPP-1 (Handheld Prog.) 320 NONE

Operator Interface

DV-1000 150 NONE

C-more Micro-Graphic 210 NONE

1 - 8 0 0 - 6 3 3 - 0 4 0 5

e6-56

ProgrammableControllers

Volume 14

Wiring Solutions

Wiring Solutions using the ZIPLink

Wiring System

ZIPLinks eliminate the normally tedious process of wiring between

devices by utilizing prewired cables and DIN rail mount connector

modules. It's as simple as plugging in a cable connector at either

end or terminating wires at only one end. Prewired cables keep

installation clean and efficient, using half the space at a fraction

of the cost of standard terminal blocks. There are several wiring

solutions available when using the ZIPLink System ranging from

PLC I/O-to-ZIPLink Connector Modules that are ready for field

termination, options for connecting to third party devices, GS,

DuraPulse and SureServo Drives, and specialty relay, transorb and

communications modules. Pre-printed I/O-specific adhesive label

strips for quick marking of ZIPLink modules are provided with

ZIPLink cables. See the following solutions to help determine the

best ZIPLink system for your application.

Solution 1: DirectLOGIC, CLICK and Productivity3000

I/O Modules to ZIPLink Connector Modules

When looking for quick and easy I/O-to-field termination, a ZIPLink

connector module used in conjunction with a prewired ZIPLink cable,

consisting of an I/O terminal block at one end and a multi-pin

connector at the other end, is the best solution.

Using the PLC I/O Modules to ZIPLink Connector

Modules selector tables located in this section,

1. Locate your I/O module/PLC.

2. Select a ZIPLink Module.

3. Select a correspondingZIPLink Cable.

Solution 3: GS Series and DuraPulse Drives

Communication Cables

Need to communicate via Modbus RTU to a drive or a

network of drives?

ZIPLink cables are available in a wide range of

configurations for connecting to PLCs and SureServo,

SureStep, Stellar Soft Starter and AC drives. Add a ZIPLink

communications module to quickly and easily set up a

multi-device network.

Using the Drives Communication selector tables located in

this section,

1. Locate your Drive and type of communications.

2. Select a ZIPLink cable and other associated hardware.

Solution 2: DirectLOGIC, CLICK and Productivity3000

I/O Modules to 3rd Party Devices

When wanting to connect I/O to another device within close proximity

of the I/O modules, no extra terminal blocks are necessary when using

the ZIPLink Pigtail Cables. ZIPLink Pigtail Cables are prewired to an I/O

terminal block with color-coded pigtail with soldered-tip wires on the

other end.

Using the I/O Modules to 3rd Party Devices selector tables

located in this section,

1. Locate your PLC I/O module.

2. Select a ZIPLink Pigtail Cable that is compatible

with your 3rd party device.

w w w . a u t o m a t i o n d i r e c t . c o m / d l 4 0 5 ProgrammableControllers

e6-57

Company

Information

Systems

Overview

Programmable

Controllers

Field I/O

Software

C-more &

other HMI

Drives

Soft

Starters

Motors &

Gearbox

Steppers/

Servos

Motor

Controls

Proximity

Sensors

Photo

Sensors

Limit

Switches

Encoders

Current

Sensors

Pressure

Sensors

Temperature

Sensors

Pushbuttons/

Lights

Process

Relays/

Timers

Comm.

Terminal

Blocks &

Wiring

Power

Circuit

Protection

Enclosures

Tools

Pneumatics

Safety

Appendix

Product

Index

Part #

Index

Volume 14

Wiring Solutions

Solution 4: Serial Communications Cables

ZIPLink offers communications cables for use with DirectLOGIC, CLICK,

and Productivity3000 CPUs, that can also be used with other communica-

tions devices. Connections include a 6-pin RJ12 or 9-pin, 15-pin and 25-

pin D-sub connectors which can be used in conjunction with the RJ12 or

D-Sub Feedthrough modules.

Using the Serial Communications Cables selector

table located in this section,

1. Locate your connector type

2. Select a cable.

Solution 5: Specialty ZIPLink Modules

For additional application solutions, ZIPLink modules are available in a

variety of configurations including stand-alone relays, 24VDC and

120VAC transorb modules, D-sub and RJ12 feedthrough modules,

communication port adapter and distribution modules, and SureServo

50-pin I/O interface connection.

Using the ZIPLink Specialty Modules selector table

located in this section,

1. Locate the type of application.

2. Select a ZIPLink module.

Solution 6: ZIPLink Connector Modules to 3rd Party

Devices

If you need a way to connect your device to terminal blocks without

all that wiring time, then our pigtail cables with color-coded

soldered-tip wires are a good solution. Used in conjunction with any

compatible ZIPLink Connector Modules, a pigtail cable keeps wiring

clean and easy and reduces troubleshooting time.

Using the Universal Connector Modules and Pigtail

Cables table located in this section,

1. Select module type.

2. Select the number of pins.

3. Select cable.

1 - 8 0 0 - 6 3 3 - 0 4 0 5

e6-58

ProgrammableControllers

Volume 14

PLC I/O Modules to ZIPLink

Connector Modules - DL405

DL405 PLC Input Module ZIPLink Selector

PLC ZIPLink

Input

Module

# of

Terms

Component

Module Part

No.

Cable Part

No.

D4-08ND3S 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

D4-16ND2 20

Feedthrough ZL-RTB20 ZL-D4-CBL20*

Sensor ZL-LTB16-24 ZL-D4-CBL20*

D4-16ND2F 20

Feedthrough ZL-RTB20 ZL-D4-CBL20*

Sensor ZL-LTB16-24 ZL-D4-CBL20*

D4-32ND3-1 40

Feedthrough ZL-RTB40

ZL-D24-CBL40*

ZL-D24-CBL40*X

Sensor ZL-LTB32-24

D4-32ND3-2 40

Feedthrough ZL-RTB40

ZL-D24-CBL40*

ZL-D24-CBL40*X

Sensor ZL-LTB32-24

D4-64ND2 40

Feedthrough ZL-RTB40

ZL-D24-CBL40*

ZL-D24-CBL40*X

Sensor ZL-LTB32-24

D4-08NA 11 See Note 3

D4-16NA 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

D4-16NA-1 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

D4-16NE3 20

Feedthrough ZL-RTB20 ZL-D4-CBL20*

Sensor ZL-LTB16-24 ZL-D4-CBL20*

F4-08NE3S 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

DL405 PLC Analog Module ZIPLink Selector

PLC ZIPLink

Analog

Module

# of Terms Component Module Cable

F4-04AD 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-04ADS 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-08AD 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-16AD-1 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-16AD-2 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-04DA-1 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-04DA-2 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-08DA-1 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-16DA-1 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-08DA-2 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-16DA-2 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-04DAS-1 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-04DAS-2 20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-08THM

T/C Wire Only See Note 3

F4-08THM-n

T/C Wire Only See Note 3

F4-08RTD

T/C Wire Only See Note 3

DL405 PLC Output Module ZIPLink Selector

PLC ZIPLink

Output

Module

# of Terms Component

Module Part

No.

Cable Part

No.

D4-08TD1 11 See Note 3

F4-08TD1S

20 See Note 3

D4-16TD1 20

Feedthrough ZL-RTB20 ZL-D4-CBL20*

Fuse ZL-RFU20

6

ZL-D4-CBL20*

D4-16TD2 20

Feedthrough ZL-RTB20 ZL-D4-CBL20*

Fuse ZL-RFU20

6

ZL-D4-CBL20*

Relay ZL-RRL16-24-2 ZL-D4-CBL20*

D4-32TD1 40

Feedthrough ZL-RTB40

ZL-D24-CBL40*

ZL-D24-CBL40*X

Fuse ZL-RFU40

6

D4-32TD1-1 40

Feedthrough ZL-RTB40

ZL-D24-CBL40*

ZL-D24-CBL40*X

Fuse ZL-RFU40

6

D4-32TD2 40

Feedthrough ZL-RTB40

ZL-D24-CBL40*

ZL-D24-CBL40*X

Fuse ZL-RFU40

6

D4-64TD1

1

40

Feedthrough ZL-RTB40

ZL-D24-CBL40*

ZL-D24-CBL40*X

Fuse ZL-RFU40

6

D4-08TA

11 See Note 3

D4-16TA 20

Feedthrough ZL-RTB20 ZL-D4-CBL20*

Fuse ZL-RFU20

6

ZL-D4-CBL20*

D4-08TR

11 See Note 3

F4-08TRS-1

5

20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

F4-08TRS-2

5

20 Feedthrough ZL-RTB20 ZL-D4-CBL20*

D4-16TR

4

20

Feedthrough ZL-RTB20 ZL-D4-CBL20*

Fuse ZL-RFU20

6

ZL-D4-CBL20*

* Select the cable length by replacing the * with: Blank = 0.5m, -1 = 1.0m,

or -2 = 2.0m.

1

The D4-64ND2 and D4-64TD1 modules have two 32-point connectors and

require two ZIPLink cables and two ZIPLink connector modules.

2

To make a custom cable for the 32 or 64-point modules, use: Ribbon-style

Connector ZL-D24-CON-R, Solder-style 180 connector ZL-D24-CON or Solder-

style 45 connector ZL-D24-CON-X

3

These modules are not supported by the ZIPLink wiring system.

4

Caution: The D4-16TR realy outpus are derated not to exceed 2 Amps per point

and 4 Amps per common when used with the ZIPLink wiring system.

5

The F4-08TRS-1 and F4-08TRS-2 are derated not to exceed 2 Amps per point

and 2 Amps per common when used with the ZIPLink wiring system.

6

Note: Fuses (5 x 20 mm) are not included. See Edison Electronic Fuse section

for (5 x 20 mm) fuse. S500 and GMA electronic circuit protection for fast-acting

maximum protection. S506 and GMC electronic circuit protection for time-

delay performance. Ideal for inductive circuits. To ensure proper operation, do

not exceed the voltage and current rating of ZIPLink module. ZL-RFU20 = 2A

per circuit; ZL-RFU40 = 400 mA per circuit.

NOTE: ZIPLINK CONNECTOR MODULES AND ZIPLINK CABLES

SPECIFICATIONS ARE IN THE ZIPLINK CATALOG SECTION.

Anda mungkin juga menyukai

- GXT2-10000T230 Service ManualDokumen33 halamanGXT2-10000T230 Service ManualMilton Mejia80% (10)

- SP Manual HELIX REV 08 PDFDokumen376 halamanSP Manual HELIX REV 08 PDFConstantin100% (5)

- Gearbox assembly drawing and bill of materialsDokumen1 halamanGearbox assembly drawing and bill of materialsAbhimechBelum ada peringkat

- RLC 1st ManualDokumen141 halamanRLC 1st Manualjaved shaikh chaandBelum ada peringkat

- Polro Two Support Rotary Kiln: Machine Manual en-KP - CPT.001.ADokumen25 halamanPolro Two Support Rotary Kiln: Machine Manual en-KP - CPT.001.ARahmat Hidayat100% (1)

- D 432 ND 31Dokumen6 halamanD 432 ND 31mushahid980Belum ada peringkat

- Programmable Controllers DC Output Module SpecsDokumen6 halamanProgrammable Controllers DC Output Module Specsmushahid980Belum ada peringkat

- AC/DC Input and Simulator ModulesDokumen6 halamanAC/DC Input and Simulator ModulesInamex-fpVeracruzBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen7 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen7 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen7 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen7 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen7 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Power Supplies and Power RequirementsDokumen2 halamanPower Supplies and Power RequirementsKristen CollierBelum ada peringkat

- Elemento de Flujo TVTHILL1Dokumen50 halamanElemento de Flujo TVTHILL1Rafael Martin Anaya FigueroaBelum ada peringkat

- Chapter - 5 Fatek FbsDokumen6 halamanChapter - 5 Fatek Fbstahir204Belum ada peringkat

- A565 Main Menu SpecsDokumen229 halamanA565 Main Menu SpecsSiawPeng Er100% (1)

- GE Power ManagemenDokumen21 halamanGE Power ManagemeningguedezandresBelum ada peringkat

- Analog Servo Drive: Description Power RangeDokumen9 halamanAnalog Servo Drive: Description Power RangeElectromateBelum ada peringkat

- F2-08SIM Input Simulator D2-08NA-1 AC InputDokumen10 halamanF2-08SIM Input Simulator D2-08NA-1 AC InputVladimir Aliro Quezada CidBelum ada peringkat

- 4-20 Ma Analog Input: HE800ADC020 / HE800ADC120 HE-ADC020 / HE-ADC120 12-Bit ResolutionDokumen8 halaman4-20 Ma Analog Input: HE800ADC020 / HE800ADC120 HE-ADC020 / HE-ADC120 12-Bit ResolutionCarlos86Belum ada peringkat

- Description Power Range: Analog Servo DriveDokumen9 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen8 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Amc 12a8 SpecsheetDokumen9 halamanAmc 12a8 SpecsheetElectromateBelum ada peringkat

- Analog Servo Drive: Description Power RangeDokumen9 halamanAnalog Servo Drive: Description Power RangeElectromateBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen9 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen8 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Advanced Motion Controls S100a20Dokumen8 halamanAdvanced Motion Controls S100a20ElectromateBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen9 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Analog Servo Drive: Description Power RangeDokumen7 halamanAnalog Servo Drive: Description Power RangeElectromateBelum ada peringkat

- 3000W Single Output Power Supply: SeriesDokumen7 halaman3000W Single Output Power Supply: SeriesAlexander PekarovskiyBelum ada peringkat

- Analog Servo Drive: Description Power RangeDokumen8 halamanAnalog Servo Drive: Description Power RangeElectromateBelum ada peringkat

- HPS2DN Digital Reduced Voltage Starter-New SerialDokumen51 halamanHPS2DN Digital Reduced Voltage Starter-New Serialasimasim123100% (2)

- Dkg-329 Automatic Transfer Switch With Uninterrupted Transfer and Multiple Genset SupportDokumen43 halamanDkg-329 Automatic Transfer Switch With Uninterrupted Transfer and Multiple Genset SupportLuis Fernando CuaspudBelum ada peringkat

- Analog Servo Drive: Description Power RangeDokumen9 halamanAnalog Servo Drive: Description Power RangeElectromateBelum ada peringkat

- Signal Conditioning & Process Control Equipment: A Brief Introduction To Common ApplicationsDokumen11 halamanSignal Conditioning & Process Control Equipment: A Brief Introduction To Common ApplicationsFeela NazBelum ada peringkat

- Advanced Motion Controls S16a8Dokumen8 halamanAdvanced Motion Controls S16a8ElectromateBelum ada peringkat

- Analog Servo Drive: Description Power RangeDokumen9 halamanAnalog Servo Drive: Description Power RangeElectromateBelum ada peringkat

- Azbh 12 A 8Dokumen8 halamanAzbh 12 A 8ElectromateBelum ada peringkat

- AVR Hardware Design ConsiderationsDokumen14 halamanAVR Hardware Design ConsiderationsAmarnath M Damodaran100% (1)

- Analog Servo Drive: Description Power RangeDokumen9 halamanAnalog Servo Drive: Description Power RangeElectromateBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen8 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen9 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- DCpower SuplyDokumen12 halamanDCpower Suplymm30973097Belum ada peringkat

- RISH Energy Measures AllDokumen8 halamanRISH Energy Measures AllDevin Carlos100% (1)

- Data Sheet Micro 1012Dokumen4 halamanData Sheet Micro 1012HudsOn Silva0% (1)

- DVP-Slim Digitai IO Module Instruction SheetDokumen2 halamanDVP-Slim Digitai IO Module Instruction SheetAgnimuthuBelum ada peringkat

- Analog Servo Drive: Description Power RangeDokumen7 halamanAnalog Servo Drive: Description Power RangeElectromateBelum ada peringkat

- PM130Plus SiesaDokumen2 halamanPM130Plus SiesaDavis MontenegroBelum ada peringkat

- FX2N 2adDokumen8 halamanFX2N 2adpublicdomain197Belum ada peringkat

- DK PC3000 ModulesDokumen11 halamanDK PC3000 ModulessickosatBelum ada peringkat

- 250T Frequency TransmitterDokumen13 halaman250T Frequency Transmitterreality88Belum ada peringkat

- Description Power Range: Analog Servo DriveDokumen7 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- DKG-705 Automatic Mains Failure and Remote Start Unit User ManualDokumen58 halamanDKG-705 Automatic Mains Failure and Remote Start Unit User ManualJefferson VieiraBelum ada peringkat

- 3) Connecting The PLC To External DevicesDokumen8 halaman3) Connecting The PLC To External DevicesAnderson MoraBelum ada peringkat

- NOTIFIER Panel Convencional para Extincion RP-2002Dokumen4 halamanNOTIFIER Panel Convencional para Extincion RP-2002Cristobal HernandezBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen7 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Analog Servo Drive: Description Power RangeDokumen9 halamanAnalog Servo Drive: Description Power RangeElectromateBelum ada peringkat

- Cartafx2n4 AdDokumen8 halamanCartafx2n4 AdRenato AbreuBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen8 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- 25 A 20Dokumen9 halaman25 A 20s_barriosBelum ada peringkat

- Description Power Range: Analog Servo DriveDokumen8 halamanDescription Power Range: Analog Servo DriveElectromateBelum ada peringkat

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142Dari EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142Belum ada peringkat

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Penilaian: 2.5 dari 5 bintang2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- Heat Recovery For Chilled Water Systems - Applications For Condenserless ChillersDokumen20 halamanHeat Recovery For Chilled Water Systems - Applications For Condenserless Chillersfacebook111111100% (2)

- MDM Motor Planning Kit PDFDokumen24 halamanMDM Motor Planning Kit PDFFUCKUBelum ada peringkat

- Selection Guide: Heat Reclaim Benefits at A GlanceDokumen2 halamanSelection Guide: Heat Reclaim Benefits at A Glancemushahid980Belum ada peringkat

- Ylcs - Sa, Ha & Aa Models: Water Cooled Liquid Chiller and Remote Air Cooled ChillerDokumen72 halamanYlcs - Sa, Ha & Aa Models: Water Cooled Liquid Chiller and Remote Air Cooled Chillermushahid980Belum ada peringkat

- API 510 Certification Preparation: Course Length: Cost: InstructorDokumen1 halamanAPI 510 Certification Preparation: Course Length: Cost: Instructormushahid980Belum ada peringkat

- Sandy DavidDokumen2 halamanSandy Davidmushahid980Belum ada peringkat

- Ozone System OZONFILT® OZVbDokumen3 halamanOzone System OZONFILT® OZVbmushahid980Belum ada peringkat

- API 510 Training CourseDokumen5 halamanAPI 510 Training Coursemushahid980Belum ada peringkat

- Sample 1 On 1 EmailDokumen1 halamanSample 1 On 1 Emailmushahid980Belum ada peringkat

- CB-7853 Boiler Room Guide - LR PDFDokumen90 halamanCB-7853 Boiler Room Guide - LR PDFcewaleed2590Belum ada peringkat

- Bedrock Webinar Training Series - Introduction To Open Secure Automation-Part 1-QandADokumen8 halamanBedrock Webinar Training Series - Introduction To Open Secure Automation-Part 1-QandAmushahid980Belum ada peringkat

- Technical Information Levelflex FMP50: Guided Wave RadarDokumen96 halamanTechnical Information Levelflex FMP50: Guided Wave Radarmushahid980Belum ada peringkat

- Open Door Policy LetterDokumen1 halamanOpen Door Policy Lettermushahid980Belum ada peringkat

- Love Letter Template 06Dokumen1 halamanLove Letter Template 06mushahid980Belum ada peringkat

- Open Source Ventilator PakistanDokumen104 halamanOpen Source Ventilator Pakistanmushahid980Belum ada peringkat

- Tracking Credit Card CallsDokumen1 halamanTracking Credit Card Callsmushahid980Belum ada peringkat

- OS Ventilator Overview StatementDokumen4 halamanOS Ventilator Overview Statementmushahid980Belum ada peringkat

- Topnir Crude Project ECOPDokumen15 halamanTopnir Crude Project ECOPmushahid980Belum ada peringkat

- Bedrock Webinar Training Series - Introduction To Open Secure Automation-Part 1-QandADokumen8 halamanBedrock Webinar Training Series - Introduction To Open Secure Automation-Part 1-QandAmushahid980Belum ada peringkat

- Bill of Materials: Item # Quantity Part Ref ValueDokumen3 halamanBill of Materials: Item # Quantity Part Ref Valuemushahid980Belum ada peringkat

- Bedrock Webinar Training Series - Introduction To Open Secure Automation-Part 1-QandADokumen8 halamanBedrock Webinar Training Series - Introduction To Open Secure Automation-Part 1-QandAmushahid980Belum ada peringkat

- Low-cost Ambu-Bag Ventilator DesignDokumen1 halamanLow-cost Ambu-Bag Ventilator Designmushahid980Belum ada peringkat

- App Project Design DocumentDokumen7 halamanApp Project Design Documentmushahid980Belum ada peringkat

- WeddingcostsDokumen1 halamanWeddingcostsmushahid980Belum ada peringkat

- The Pocket Tracker For Tracking Credit Card Calls: Call Date Time Name of Rep. Rep's ID#Dokumen1 halamanThe Pocket Tracker For Tracking Credit Card Calls: Call Date Time Name of Rep. Rep's ID#mushahid980Belum ada peringkat

- How Much Do You Owe?: Credit Card Amount of Debt Apr Monthly Minimum PaymentsDokumen1 halamanHow Much Do You Owe?: Credit Card Amount of Debt Apr Monthly Minimum Paymentsmushahid980Belum ada peringkat

- Team Selection Worksheet: Technical/Task-Related Skills Skill: Experience Needed: Team MemberDokumen5 halamanTeam Selection Worksheet: Technical/Task-Related Skills Skill: Experience Needed: Team Membermushahid980Belum ada peringkat

- Thread SummaryDokumen17 halamanThread Summarymushahid980Belum ada peringkat

- App Project Design DocumentDokumen7 halamanApp Project Design Documentmushahid980Belum ada peringkat

- Thread SummaryDokumen17 halamanThread Summarymushahid980Belum ada peringkat

- Problem Set 6 SolutionsDokumen5 halamanProblem Set 6 SolutionsKrupali ShahBelum ada peringkat

- Replacing MechatronicsDokumen7 halamanReplacing MechatronicsNenad VlašičekBelum ada peringkat

- Electrostatic DischargeDokumen23 halamanElectrostatic DischargeHoucine AkkalBelum ada peringkat

- Gas Ranges: Cooker With 4 Burners, 1 Gas OvenDokumen2 halamanGas Ranges: Cooker With 4 Burners, 1 Gas OvenAm MBelum ada peringkat

- Sulfur Tolerance Kit Installation Instruction QSG12 CM2350 G113 G110 Bulletin 5414618Dokumen9 halamanSulfur Tolerance Kit Installation Instruction QSG12 CM2350 G113 G110 Bulletin 5414618Carlos D RamirezBelum ada peringkat

- Draka Mobile Networks Cables 2010-10Dokumen33 halamanDraka Mobile Networks Cables 2010-10dieters_uaBelum ada peringkat

- Pulleys and Sheaves 1060Dokumen84 halamanPulleys and Sheaves 1060m s sankar raoBelum ada peringkat

- UK 1000 Quick Ref GuideDokumen44 halamanUK 1000 Quick Ref GuiderichardBelum ada peringkat

- Uen R 79440001Dokumen29 halamanUen R 79440001Carlos VillaltaBelum ada peringkat

- Sec9 9CDokumen60 halamanSec9 9CMarc MarcelleBelum ada peringkat

- LED Solar ProjectDokumen102 halamanLED Solar ProjectBrandy RomanBelum ada peringkat

- Multiquip SP2S20HDokumen40 halamanMultiquip SP2S20Heltomy1Belum ada peringkat

- Manual Turbo Chef Technologies C3 - CDokumen105 halamanManual Turbo Chef Technologies C3 - CVanguard HatBelum ada peringkat

- NTN Shaft & Housing DesignDokumen3 halamanNTN Shaft & Housing DesignArun KiranBelum ada peringkat

- GM 6T70-Ford 6F50 Parts CatalogueDokumen4 halamanGM 6T70-Ford 6F50 Parts CatalogueAndrés Caleb Blanco GuzmanBelum ada peringkat

- Industry Standard Sized Laser Sensors With Built-In AmplifiersDokumen8 halamanIndustry Standard Sized Laser Sensors With Built-In AmplifiersJunaidi ArigaBelum ada peringkat

- File 1579168020Dokumen40 halamanFile 1579168020Upik DwiganiBelum ada peringkat

- 350 Series Broce Broom PartsDokumen168 halaman350 Series Broce Broom Partsjuan apaza100% (1)

- UT ID 4 - 6 8 ADA PhoneDokumen20 halamanUT ID 4 - 6 8 ADA PhoneHumberto Andrade DominguezBelum ada peringkat

- Power Transistors 2SD1264 2SD1264A GuideDokumen2 halamanPower Transistors 2SD1264 2SD1264A GuideRoni SocompiBelum ada peringkat

- Tata Indigo DicorDokumen190 halamanTata Indigo DicorxtempBelum ada peringkat

- ELEC 344 - Module 2 Lecture NotesDokumen45 halamanELEC 344 - Module 2 Lecture NotesMax HornerBelum ada peringkat

- Valveking 212 DiagramDokumen12 halamanValveking 212 DiagramDan Radu TalpalariuBelum ada peringkat

- Spherical Roller Bearings ULTAGE Series: (Type EA, Type EM)Dokumen12 halamanSpherical Roller Bearings ULTAGE Series: (Type EA, Type EM)Varsha SinghBelum ada peringkat

- AUTOMATIC CHANGE OVER SWITCHDokumen11 halamanAUTOMATIC CHANGE OVER SWITCHwec11011Belum ada peringkat