Ets Design Guide 2010

Diunggah oleh

Khairul Salleh BaharudinHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ets Design Guide 2010

Diunggah oleh

Khairul Salleh BaharudinHak Cipta:

Format Tersedia

ENCINEERED 1IM8ER SOLU1IONS

DFSIGN GUIDF

CON1EN1S

Scope of this Document ....................................................................... 3

Producers Statements .......................................................................... 4

Design in Hyne - design software ......................................................... 8

HYNE STRUCTURAL COMPONENTS .................................................. 9

List of available products incorporated in software ..............................11

List of possible applications ................................................................ 12

Structural Properties ........................................................................... 13

I-Beam Properties ............................................................................... 14

TYPICAL HYNE FLOOR CONSTRUCTION PLAN ............................... 15

FLOOR JOISTS .................................................................................. 16

Span Tables - Floor Joists 1.5kPa ........................................................ 16

Continuous Span Diagrams Plan ........................................................ 16

Span Tables - Floor Joists 2.0kPa .........................................................17

Span Tables - Floor Joists 3.0kPa ........................................................ 18

CANTILEVER DETAILS ..................................................................... 19

Span Tables Load Bearing Cantilever ............................................... 20

Roof Pitch Multiplier Ratio ................................................................. 20

HANGER FIXINGS .............................................................................21

FLOOR DETAILS ............................................................................... 24

Internal Bracing ................................................................................. 24

Web Stiffener Detail........................................................................... 24

Boundary Details................................................................................ 25

Rimboard End Joist ............................................................................ 25

FLOOR FIXING DETAILS ................................................................... 26

HOLES IN I-BEAMS ........................................................................... 29

SERVICE HOLES HYNE LGL & 17C BEAMS ......................................31

OVERCOMING SPLITTING/TAPER CUTS .......................................... 32

AVOID THESE PRACTICES ............................................................... 33

ROOF CONSTRUCTION PLAN ......................................................... 34

LINTEL SUPPORTING GIRDER TRUSS ............................................... 35

Lintel Supporting Girder Truss Examples ............................................. 35

Span Tables - Light Weight Roof - NO SNOW LOAD ........................... 36

Span Tables - Light Weight Roof - 0.5 kPa SNOW LOAD ......................37

Span Tables - Heavy Weight Roof - NO SNOW LOAD .......................... 38

Span Tables - Heavy Weight Roof - 0.5 kPa SNOW LOAD ................... 39

TYPICAL ROOF CONSTRUCTION PLAN ........................................... 40

LINTEL FIXING ...................................................................................41

Span Tables - Light Weight Roof - NO SNOW LOAD ........................... 42

Span Table - Light Weight Roof - 0.5 kPa SNOW LOAD ...................... 43

Span Table - Heavy Weight Roof - NO SNOW LOAD ........................... 44

Span Table - Heavy Weight Roof - 0.5 kPa SNOW LOAD ..................... 45

ROOF DETAILS ................................................................................. 46

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF z

The span tables and construction details contained

in this document have been developed primarily for

domestic/residential applications in accordance with the

principles and intent of: NZS3604:1999 Timber Framed

Buildings; NZS3603:1993 Timber Structures Standard;

AS1720.1:1997 Timber Structures Design Methods.

Loading data is taken from AS/NZS1170:2002 Structural

Design Actions to satisfy the requirements of Section B1

of the New Zealand Building Regulations.

All technical information and span tables are in

accordance with the product specic design properties

presented under Engineering Data. This data may

be used for specic engineering design in applications

outside the scope of this document. Please see the

Engineered Timber Solutions, Engineered Wood Products

brochure for the Engineering Data.

The information in this design guide has been checked

and veried, however, it should only be used by designers

who are suitably qualied.

Engineered Timber Solutions accept no liability or

responsibility if the information contained in this

document is incorrectly interpreted, inappropriately

applied, or used in a manner other than explicitly set out

in this guide.

Note: Other manufacturers products may have different

properties and therefore cannot be substituted or

designed using information contained in this document.

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF

SCOPE OF 1HIS DOCUMEN1

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF q

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF y

:: Pryda New Zealand (a division of ITW New Zealand Limited)

Auckland: 64A Diana Drive, Glenfield Tel: (09) 920 4360 Fax: (09) 920 4364

Napier: 75 Niven St, Onekawa Tel: (06) 843 3069 Fax: (06) 843 3065

Wellington: Unit 2, 1 Gough St, Lower Hutt Tel: (04) 568 4505 Fax: (04) 568 0098

Christchurch: 125 Wrights Rd, Middleton Tel: (03) 338 3844 Fax: (03) 338 8846

Free Phone: 0800 88 22 44

Free Fax: 0800 88 22 55

Email: office@pryda.co.nz

Website: www.pryda.co.nz

PRODUCER STATEMENT

FOR

PRYDA TIMBER CONNECTORS

December 2006

This Producer Statement is issued by Pryda NZ to cover the use, installation and

durability of PRYDA TIMBER CONNECTORS for both structural application and

durability as required by the New Zealand Building Code clauses B1 & B2

respectively.

DESCRIPTION

PRYDA TIMBER CONNECTORS are fabricated manufactured from galvanised steel

coils. The PRYDA TIMBER CONNECTORS are manufactured from Z275

galvanised coil or wire which can be augmented by an additional finish of 100!

epoxy coating for greater durability. Some brackets are also available in stainless

steel for use in certain exposed and covered situations. The thickness of the zinc

greater than the 250gm/m2 required of Table 4.2 in NZS3604:1999. The durability

status of thin plate connectors can be brought up to that of hot dipped galvanized

products by the addition of the 100! epoxy coating according to clause 4.4.3 of

NZS3604:1999.

APPLICATION

PRYDA TIMBER CONNECTORS are designed to connect timber to masonry,

concrete and steel. The connectors are designed for specific connections of timber

to timber mostly and also to other media. Please contact PRYDA technical service

should you require assistance relating to these connectors.

CHARACTERISTIC STRENGTH

As timber grades vary the characteristic strength is derived by the verification

method in accordance with the NBC standards NZS3603:1993 mostly dependant on

the shear values of the nails. Most commonly used brackets have published

characteristic strengths published in our literature.

DURABILITY

The durability of the PRYDA TIMBER CONNECTORS is in accordance with the

acceptable solutions contained in Table 4.1 of NZS3604:1999 in order to achieve a

50 year life expectancy for the connectors.

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF 6

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF

!"#$%&'#()

!"#$%#& ()&"

Janette Hunt

+,-",$$#",-)

*+,-. /0%#+"1

2#&3,4-& 5-&&-&.

6,4#7 !8##"

6,9# :#+78-;;

./"01",- !$("-,)

2+,< ()&"

6,4#7 =>#+-""

2'3&45#$)

6,4#7 =>#+-""

617","(&"',)

Carolyn Foot

Sharyn Crawford

8$90: &') ;

?= 20@ ABCD

2)<<-&,D ED FGHGI

<33"%$ 5&) ;

4/40 Technology Dr,

Warana, Q, 4575.

Telephone:

07) 5493 2677

Facsimile:

07) 5493 1816

+75"0) ;

engineers@

hrdesigngroup.com.au

=$> ("&$) ;

www.hrdesigngroup.com.

au

!" $%&'() *+,-. /01 203

ABN: 14 015 519 720

!"#$%#$% '()'*(+ #,(-. -$, ($%#$(("#$% /)%(/0("

15 December 2009

File: 09-0710

(Please quote this number when calling the office to minimise delays on the phone)

Attn: Claudia Eiden

Hyne & Son Pty Ltd

PO Box 106

MARYBOROUGH 4650

Ref: Release of software version DIHv4.2NZ (Design-In-Hyne version 4.2 for New Zealand).

Dear Claudia,

Our company has now released the updated version of this software, noted as version 4.2NZ. This

program has been specifically written for the New Zealand market, and has included data from

codes NZS3603 and NZS3604, for all generic New Zealand products, and the principles of these

codes, in conjunction with AS/NZS1170 Loading Codes, AS1720 Timber Design Code, and loading

procedures that are considered relevant from AS1684 Timber Framing Code.

The final program structural analysis and design procedures were audited by Mark L Batchelor

Consulting Engineers to assess the accuracy and relevance for the program for use in New

Zealand building construction.

This program in earlier versions, has been extensively used and tested over many years in

Australia, and has been proven to be extremely accurate and easy to use. The program designers

have over 20 years experience in timber structural design.

Therefore I am satisfied that we can pass on the rights to use this program for your company, your

associated supplier in New Zealand, and the individual users in New Zealand that will be supplied

and instructed in the use of the program. Should you require any further information, or

confirmation of any of the above matters, please do not hesitate to contact me at any time.

Yours faithfully,

HUNT ROBINSON Pty Ltd

Stephen John Hunt BEng (Civil), CPEng(AUS)

(MIEAust #368737), (RPEQ #3731), NPER

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF 8

Architects, Designers and Engineers prefer to use our unique

software to assist with the design of oors and mid oors.

Design in Hyne Version 4.2NZ software has been adapted

for the New Zealand market to design and specify with ease

and accuracy.

This guide has been created to supplement the DiH4.2NZ

software package and we recommend using both the

software and this guide as your design package.

DESIGN

IN HYNE

VERSION 4.2NZ

DESIGN SOFTWARE

DiH4.2NZ

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF g

Hyne I-8eam

Description: Hyne I-Beam is a unique combination of timber resources, components

and advanced technology forming a structurally efcient I section.

Manufactured at the Hyne plant in Brisbane, Hyne-I-Beams are

produced using high performance nger jointed pine anges and

9.5mm structural OSB webs. All components are assembled using only

durable, exterior grade adhesives. Hyne I-Beam is available untreated or

treated to H3.1 from stock.

Advantages: Dimensional stability, lightweight, long spanability, elimination of mid-

span blocking in oor joists.

Applications: Floor joists, rafters.

Section sizes: 200x90 up to 360x90

Available lengths: 1.2 up to 11.7 m in 0.3 increments.

Availability: Generally available. Check with ETS.

Specication example: HI 24590 Hyne-I-Beam

Hynebeam C

Description: HYNEBEAM 17C products are high grade glued-laminated timber

beams formed from Australian pine, into larger rectangular sections.

The HYNEBEAM 17C product range is manufactured in accordance with

AS1328 by Hyne in Maryborough. The HYNEBEAM 17C is made from

slash pine feedstock. All components are assembled using only durable,

exterior grade adhesives (service class 3). The beams are specied as

cambered (C) to 600 m radius. Available in structural grades (STR).

HYNEBEAM 17C is available treated to H3.1

Advantages: Dimensional stability, long spanability, aesthetically appealing, variety

of shapes and curved beam options, simple high-tech connections,

termite resistance and durability (when treated), easier to handle

and install than steel members, third party certied through the Glue

Laminated Timber Association of Australia (GLTAA) and ISO 9002.

Applications: Roof beams, bearers, columns, oor joists, rafters, lintels, portal frames.

Section sizes: 295x85 up to 525x85, 295x135 up to 360x135

Available lengths: 0.9 to 11.4m in 0.6 increments.

Availability: Check with ETS.

Specication example: 295x85 HYNEBEAM 17C

Hynebeam 8C - For premlum appearance and strength

Description: HYNEBEAM 18C products are high grade glued-laminated timber

beams formed from Tasmanian Oak, into larger rectangular sections.

The HYNEBEAM 18 product range is manufactured by Hyne in

Maryborough. The HYNEBEAM 18C is made from Tasmanian Oak

feedstock. All components are assembled using only durable, exterior

grade adhesives (service class 3). The beams are specied as cambered

(C) to 600 m radius. Available in appearance / select grade (SEL).

HYNEBEAM 18C can only be used in internal situations.

Advantages: Dimensional stability, long spanability, aesthetically appealing, variety

of shapes and curved beam options, simple high-tech connections,

termite resistance and durability (when treated), easier to handle

and install than steel members, third party certied through the Glue

Laminated Timber Association of Australia (GLTAA) and ISO 9002.

Applications: Roof beams, bearers, oor joists, rafters, lintels, portal frames.

Section sizes: 240x85 up to 450x85, 245x65 up to 450x65

Available lengths: 0.9 to 11.4m in 0.6 increments.

Availability: Check with ETS. (Usually special order)

Specication example: 270x85 HYNEBEAM 18C(SEL)

H

v

r

S

f

v

u

c

f

u

v

t

i

C

6

u

v

6

f

s

Hyne Structura| Components

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF o

Hynebeam zC - For premlum appearance and strength

Description: HYNEBEAM 21C products are high grade glued-laminated timber

beams formed from Australian Hardwoods, into larger rectangular

sections. The HYNEBEAM 21 product range is manufactured by Hyne in

Maryborough. The HYNEBEAM 21 is made from Queensland Hardwood

feedstock. All components are assembled using only durable, exterior

grade adhesives (service class 3). The beams are specied as cambered

(C) to 600m radius. Available in appearance / select grade (SEL).

HYNEBEAM 21C can only be used in sheltered situations.

Advantages: Dimensional stability, long spanability, aesthetically appealing, variety

of shapes and curved beam options, simple high-tech connections,

termite resistance and durability (when treated), easier to handle

and install than steel members, third party certied through the Glue

Laminated Timber Association of Australia (GLTAA) and ISO 9002.

Applications: Roof beams, bearers, oor joists, rafters, lintels, portal frames.

Section sizes: 240x85 up to 450x85, 245x65 up to 450x65

Available lengths: 0.9 to 11.4m in 0.6 increments.

Availability: Usually Special Order

Specication example: 270x85 HYNEBEAM 21C(SEL)

Hyne LCL (Edgebeamj

Description: Hyne LGL (Edgebeam) is a high grade edge glued-laminated timber

beam product assembled from nger jointed pine scantling, into

deeper rectangular sections. The HYNE LGL product range is

manufactured in accordance with AS1328 by Hyne in Maryborough. All

components are assembled using only durable, exterior grade adhesives

(service class 3). Available in a range of depths to ensure compatibility

with Hyne-I-Beam. Hyne LGL is available treated or H3.1

Advantages: Dimensional stability, lightweight, long spanability, treatable to H3.1,

may be nail-laminated to provide wider sections.

Applications: Floor joists, bearers, rafters, purlins, lintels.

Section sizes: 200x44 up to 360x44, 150x65 up to 360x65 (special order only)

Available lengths: 1.2 up to 11.4m in 0.6 m increments.

Availability: Readily available. Check with ETS for the 65mm availability.

Specication example: 300x44 Hyne LGL (E/B)

Rlmboard (R8z, R8qyj

The Rimboard is used as a perimeter board.

Treated to the level of H3.1 to provide a protective envelope to the oor joists.

Rimboard (RB21) ties the end of the I-Beams joists together, providing lateral stability to the

oor platform. Rimboard is also used as a stiffener for I-Beams in cantilevered situations.

Rimboard (RB45) is used in situations where structural xing is required.

Pryda Hardware

Pryda is a world leader and specialist in the development and manufacture of timber

connections systems.

These quality xings are used throughout our ooring design. The use of Pryda specialised

hardware enables quick and simplistic installation.

For Engineering specications please see the Engineering Timber Solutions Guide to Engineered

Wood Products.

H

v

r

S

f

v

u

c

f

u

v

t

i

C

6

u

v

6

f

s

Hyne Structura| Components

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF

PRODUCT NAME PRODUCT TYPE MANUFACTURER GRADES SIZE LIST (MM)

HYNE I-BEAM

Timber composite

I-beam

Hyne & Son Pty Ltd HI

HI20090, HI24590, HI30090,

HI36090

HYNE I-BEAM S88

Timber composite

I-beam

Hyne & Son Pty Ltd S88x245, S88x300, S88x360

HYNEBEAM 17C

85mm

Glued-laminated

timber

Hyne & Son Pty Ltd GL17C

230x85, 260x85, 295x85, 330x85,

360x85, 425x85, 460x85, 525x85

HYNEBEAM 17C

135mm

Glued-laminated

timber

Hyne & Son Pty Ltd GL17C

230x135, 260x135, 295x135,

330x135, 360x135, 425x135,

495x135, 525x135

HYNEBEAM 18C

65mm

Glued-laminated

timber

Hyne & Son Pty Ltd GL18C

245x65, 270x65, 300x65, 330x65,

360x65

HYNEBEAM 18C

85mm

Glued-laminated

timber

Hyne & Son Pty Ltd GL18C

270x85, 300x85, 330x85, 360x85

420x85, 450x85

HYNEBEAM 21C

65mm

Glued-laminated

timber

Hyne & Son Pty Ltd GL21C

120x65, 155x65, 185x65, 215x65,

245x65, 270x65, 300x65, 330x65,

360x65, 390x65, 390x65, 420x65

HYNEBEAM 21C

85mm

Glued-laminated

timber

Hyne & Son Pty Ltd GL21C

120x85, 155x85, 185x85, 215x85,

245x85, 270x85, 300x85, 330x85,

360x85,390x85, 420x85, 450x85,

480x85, 510x85, 540x85, 570x85,

600x85

HYNEBEAM 21C

135mm

Glued-laminated

timber

Hyne & Son Pty Ltd GL21C

120x135, 155x135, 185x135,

215x135, 245x135, 270x85, 300x85,

330x85, 360x135,390x135, 420x135,

450x135, 480x135, 510x135,

540x135, 570x135, 600x135,

HYNE LGL 44

(Edgebeam)

Edge glued-laminated

timber

Hyne & Son Pty Ltd LGL 200x44, 245x44, 300x44, 360x44

HYNE LGL 65

(Edgebeam)

Edge glued-laminated

timber

Hyne & Son Pty Ltd LGL

150x65, 200x65, 245x65, 300x65,

360x65

Llst oF aval|ab|e products lncorporated ln soFtware

P

v

6

o

u

c

f

s

I

c

6

v

v

6

v

t

f

r

o

i

S

6

r

f

w

t

v

r

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF z

MEMBER APPLICATION HYNE I-BEAM

HYNEBEAM

18C AND 21C

HYNEBEAM

17C

HYNE LGL 44

(EDGEBEAM)

HYNE LGL 65

FLOOR MEMBERS

Bearers ! " " " "

Bearer with roof load " " " " "

Floor joists " " " " "

Deck joists ! " " " "

Trimmer joists " " " " "

Floor trimmer " " " " "

Load bearing joist " " " " "

WALL MEMBERS

Verandah Post ! ! " " "

Wall studs ! ! ! " "

Wall plates ! ! ! " "

Lintels ! " " " "

Wind beam ! " " " "

Window sill ! " " " "

Wall girt " " " " "

Wall Mullion " " " " "

ROOF MEMBERS

Ceiling joists " ! " " "

Ceiling battens ! ! ! ! !

Hanging beams " " " " "

Counter beams " ! " " "

Verandah beams " ! " " "

Rafters " " " " "

Hip rafters " " " " "

Roof/intermediate beams " " " " "

Ridge beams " " " " "

Pitching beams " " " " "

Underpurlins " " " " "

Strutting beams " " " " "

Counter strutting beams " " " " "

Strutting/hanging beams " " " " "

Roof battens ! ! ! " "

Roof purlins " " " " "

Llst oF posslb|e app|lcatlons

L

i

s

f

6

r

P

6

s

s

i

n

i

r

t

v

v

i

i

c

t

f

i

6

s

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF

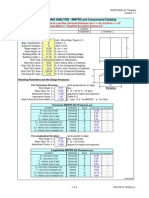

HYNE PRODUCT

HYNE LGL 44

(EDGEBEAM)

HYNE

LGL 65

HYNEBEAM

17C

HYNEBEAM

18C

HYNEBEAM

21C

Type Glulam Glulam

High

strength

Glulam

High

strength

Glulam

High

strength

Glulam

Grade LGL LGL GL17 GL18 GL21

Bending fb MPa 30 33 42 50 50

Tension ft MPa 16 16 21 25 25

Shear fs MPa 3.7 3.7 3.7 5.0 5.0

Comp. fc MPa 30 33 35 50 50

Modulus Of

Elasticity

E MPa 13300 13300 16700 18500 21000

Modulus Of

Ridgity

G MPa 890 900 1110 1230 1400

Density

kg/

m3

540 650 640 750 810

Joint Group JD4 JD4 JD4 JD3 JD2

Strength Group SD6 SD6 SD5 SD5 SD2

Bearing Perp fp MPa 12 12 15 23 27

Bearing Parallel fl MPa 35 35 45 70 80

Shear At Joints fsj MPa 5 5 6.1 8.7 10.0

Tension Perp ftp MPa 0.6 0.6 0.6 0.7 0.9

Durabilty Class 4 4 4 4 2

Manufacture

Site

Beam Plant Beam Plant Beam Plant Beam Plant Beam Plant

Structura| Propertles

s

f

v

u

c

f

u

v

t

i

v

v

6

v

r

v

f

i

r

s

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF q

H

Y

N

E

I

-

B

E

A

M

T

Y

P

E

BEAM DEPTH

d

BEAM WIDTH

b

BEAM MASS

m

RESISTIVE

MOMENT Mx

BENDING

RIGIDITY

Elx X 10

9

BENDING

RIGIDITY

Ely X 10

9

VERTICAL

SHEAR Vx

TORSONIAL

RIGIDITY

GJ X 10

9

SHEAR

RIGIDITY

GwAw X 10

6

END BEARING

NPE 30mm

WITHOUT

STIFFENER

I

N

T

E

R

M

E

D

I

A

T

E

B

E

A

R

I

N

G

4

5

m

m

6

5

m

m

W

I

T

H

O

U

T

S

T

I

F

F

W

I

T

H

S

T

I

F

F

W

I

T

H

O

U

T

S

T

I

F

F

m

m

m

m

k

g

/

m

k

N

.

m

N

.

m

m

2

N

.

m

m

2

k

N

N

.

m

m

2

N

k

N

k

N

k

N

k

N

N

Z

2

0

0

9

0

2

0

0

8

8

4

4

.

6

3

4

9

0

4

5

.

2

7

.

2

5

1

.

7

3

1

.

2

5

1

2

.

5

2

8

.

2

2

8

.

2

3

3

.

2

N

Z

2

4

5

9

0

2

4

5

8

8

4

.

3

6

.

2

8

0

0

4

5

.

7

9

.

3

2

1

.

7

5

1

.

6

8

1

2

.

5

2

8

.

2

3

1

.

8

3

3

.

2

N

Z

3

0

0

9

0

3

0

0

8

8

4

.

6

9

.

0

8

1

3

4

4

4

8

.

1

1

1

.

8

1

1

.

8

4

2

.

2

1

2

.

5

2

8

.

2

3

6

.

1

3

3

.

2

N

Z

3

6

0

9

0

3

6

0

8

8

4

.

9

1

1

.

3

3

2

0

3

6

4

8

.

1

1

4

.

6

1

1

.

8

4

2

.

7

7

1

2

.

5

2

8

.

2

4

0

.

9

3

3

.

2

S

8

8

2

4

5

2

4

5

8

8

5

.

2

1

2

.

1

1

0

5

7

6

0

.

8

9

.

2

2

.

3

3

1

.

6

8

1

2

.

5

2

8

.

2

3

1

.

8

3

3

.

2

S

8

8

3

0

0

3

0

0

8

8

5

.

6

1

5

.

6

1

6

8

5

6

0

.

9

1

1

.

7

2

.

3

3

2

.

2

1

2

.

5

2

8

.

2

3

6

.

1

3

3

.

2

S

8

8

3

6

0

3

6

0

8

8

6

1

9

.

5

2

5

5

1

6

0

.

9

1

4

.

4

2

.

3

3

2

.

7

7

1

2

.

5

2

8

.

2

4

0

.

9

3

3

.

2

P

L

E

A

S

E

N

O

T

E

:

V

e

r

t

i

c

a

l

s

h

e

a

r

c

a

p

a

c

i

t

y

h

a

s

b

e

e

n

a

d

j

u

s

t

e

d

t

o

a

l

l

o

w

f

o

r

a

4

0

m

m

r

o

u

n

d

o

r

s

q

u

a

e

h

o

l

e

t

o

b

e

p

l

a

c

e

d

a

n

y

w

h

e

r

e

i

n

t

h

e

w

e

b

.

I-8eam Propertles

I

-

B

r

t

u

P

v

6

v

r

v

f

i

r

s

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF y

Reinforcement of Hyne I-Beams

to load bearing cantilever

refer page 19, detail 2.1 - 2.5

Boundary Details

refer page 25, detail 5.3 - 5.8

Recommend RB45 to deal

with concentrated loads.

Boundary Details

refer page 25, detail 5.3 - 5.8

use RB21 or RB45

BRACING AND BLOCKING

Single blocking at 1.8m centres

maximum or double blocking at

3.6m centres maximum over all

bearing lines

Fixing connection details

refer page 21, detail 4.0 - 4.13

Web Holes for services

refer page 29, detail 6.0

Floor Trimmers and Floor Trimming Joist

Nominal fixings. For joists and trimmers up

to 1.8m two multigrips may be used

All Hyne I-Beams are to be

braced before flooring is laid

(temporary bracing)

1

v

v

i

c

t

i

H

v

r

F

i

6

6

v

C

6

s

f

v

u

c

f

i

6

P

i

t

1yplca| Hyne F|oor Constructlon P|an

1.1 1PICAL HNF FLOOR CONS1RUC1ION PLAN

This is a typical Hyne Floor construction plan.

Please see page numbers on the plan to locate details.

PLEASE NOTE:

No midspah blockihg required.

Floor heeds Io be braced durihg cohsIrucIioh..

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF 6

Span 2 (major) Span 1 (minor)

For a Hyne Engineered Timber Product member to be

considered continuous it shall span at least 2 adjacent spans

such that span 1 is greater than or equal to 0.75 x Span 2.

The major span is taken from the continuous span table

e.g. If span 2= 6.0 then span 1 is greater or equal to 4.5m.

Otherwise each span is to be considered single.

F|oor jolst Span 1ab|es

F

i

6

6

v

j

6

i

s

f

s

F|oor jolsts Supportlng F|oor Loads

CON1INUOUS SPAN DIAGRAMS PLAN

SPAN 1ABLF - FLOOR }OIS1S .IPA USING HNF I BFAMS

PLEASE NOTE:

Ih 1able 2.2, 2.3, 2.4, 2.5. 40% o! Ihe live load has beeh cohsidered

to be permanent load for assessing the long-term deection limits

for oors in general ofce, residential and institutional space. For

other applications such as storage areas, where higher permanent

loads may be expected, specic engineering design should be

applied refer to Design in Hyne 4.2NZ

Where heavy permahehI dead loads, such as waIer beds, or Iiled

oors are to be applied to the oor joist system, allowance should

be made. Suitable allowances can be made by designing the oor

joists at 450mm or 600mm centres but installing them at 300 or

450mm respectively.

FLOOR MASS 40KG/M2 LIVE LOAD = 1.5 KPA ( DOMESTIC)

FLOOR JOISTS 1.5KPA IB

SUPPORTING FLOOR & CEILING LOADS ONLY

MAXIMUM PERMISSIBLE SPAN (MM)

MAXIMUM FLOOR JOIST SPACING (MM)

FLOOR JOIST SIZE

Single Span Continuous Span

300 400 450 480 600 300 400 450 480 600

IB 200 x 90 4800 4300 4100 4000 3700 5400 4700 4400 4300 3800

IB 245 x 90 5600 5100 4900 4800 4400 6200 5400 5100 4900 4400

S88 x 245 6100 5600 5300 5200 4800 7300 7000 6800 6600 5300

IB 300 x 90 6500 6100 5900 5700 5300 7500 6500 6200 6000 5300

S88 x 300 6800 6400 6200 6100 5700 8400 7800 7600 7500 6700

IB 360 x 90 7200 6700 6500 6400 6000 8400 7300 6900 6700 6000

S88 x 360 7500 7100 6900 6800 6400 9300 8700 8400 8300 7800

PLEASE NOTE:

These span tables are conservative spans. To run precise spans please use Design in HyneNZ v4.2 software.

IB - Hyne I Beam NZ - Hyne Super I beam LGL - Hyne LGL Minimum end bearing length - 45mm Minimum intermediate bearing - 85mm.

SPAN 1ABLF - FLOOR }OIS1S .IPA USING HNF LGL

FLOOR MASS 40KG/M2 LIVE LOAD = 1.5 KPA ( DOMESTIC)

FLOOR JOISTS 1.5KPA LGL

SUPPORTING FLOOR & CEILING LOADS ONLY

MAXIMUM PERMISSIBLE SPAN (MM)

MAXIMUM FLOOR JOIST SPACING (MM)

FLOOR JOIST SIZE

Single Span Continuous Span

300 400 450 480 600 300 400 450 480 600

LGL 200 x 44 4600 4200 4100 4000 3700 5500 5500 5300 5200 4800

LGL 245 x 44 5600 5100 5000 4900 4500 6800 6700 6500 6400 6100

LGL 300 x 44 6600 6200 6000 5900 5500 8300 7800 7600 7500 7100

LGL 360 x 44 7500 7000 6900 6800 6400 9400 8900 8600 8500 8100

LGL 130 x 65 3600 3200 3000 3000 2900 4100 4000 3600 3600 3400

LGL 150 x 65 4200 3800 3600 3500 3400 4700 4700 4300 4200 4000

LGL 200 x 65 5500 5100 4900 4800 4500 6300 6300 6300 6200 5600

LGL 245 x 65 6500 6100 5900 5800 5500 7700 7700 7500 7400 7000

LGL 300 x 65 7400 7000 6900 6800 6500 9400 8900 8600 8500 8100

LGL 360 x 65 8400 8000 7800 7700 7400 10600 10100 9800 9700 9300

PLEASE NOTE:

These span tables are conservative spans. To run precise spans please use Design in HyneNZ v4.2 software.

IB - Hyne I Beam NZ - Hyne Super I beam LGL - Hyne LGL Minimum end bearing length - 45mm Minimum intermediate bearing - 85mm

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF

F|oor jolst Span 1ab|es

FLOOR MASS 40KG/M2 LIVE LOAD = 2.0 KPA ( DOMESTIC)

FLOOR JOISTS 2.0KPA IB

SUPPORTING FLOOR & CEILING LOADS ONLY

MAXIMUM PERMISSIBLE SPAN (MM)

MAXIMUM FLOOR JOIST SPACING (MM)

FLOOR JOIST SIZE

Single Span Continuous Span

300 400 450 480 600 300 400 450 480 600

IB 200 x 90 4500 4100 3900 3800 3400 4800 4200 3900 3800 3300

IB 245 x 90 5300 4800 4500 4400 3900 5600 4800 4500 4400 3900

S88 x 245 5800 5200 5000 4900 4500 7200 6300 5600 5300 4200

IB 300 x 90 6200 5800 5500 5300 4800 6700 5800 5500 5300 4800

S88 x 300 6600 6100 5900 5800 5300 8100 7500 7100 6700 5400

IB 360 x 90 6900 6500 6200 6000 5300 7500 6500 6200 6000 5300

S88 x 360 7300 6800 6600 6500 6100 8900 8300 8100 7800 6600

PLEASE NOTE:

TThese span tables are conservative spans. To run precise spans please use Design in HyneNZ v4.2 software.

IB - Hyne I Beam NZ - Hyne Super I beam LGL - Hyne LGL Minimum end bearing length - 45mm Minimum intermediate bearing - 85mm

FLOOR MASS 40KG/M2 LIVE LOAD = 2.0 KPA ( DOMESTIC)

FLOOR JOISTS 2.0KPA LGL

SUPPORTING FLOOR & CEILING LOADS ONLY

MAXIMUM PERMISSIBLE SPAN (MM)

MAXIMUM FLOOR JOIST SPACING (MM)

FLOOR JOIST SIZE

Single Span Continuous Span

300 400 450 480 600 300 400 450 480 600

LGL 200 x 44 4400 4000 3900 3800 3500 5500 5400 5300 5100 4800

LGL 245 x 44 5300 4900 4700 4600 4300 6800 6500 6300 6200 5900

LGL 300 x 44 6300 5900 5700 5600 5300 8000 7500 7300 7200 6800

LGL 360 x 44 7200 6800 6600 6500 6200 9100 8500 8300 8200 7200

LGL 130 x 65 3400 3200 3000 3000 2800 4100 4000 3600 3600 3400

LGL 150 x 65 4000 3600 3500 3400 3200 4700 4700 4300 4200 4000

LGL 200 x 65 5200 4800 4600 4500 4300 6300 6200 6000 5900 5500

LGL 245 x 65 6200 5800 5600 5500 5200 7700 7200 7000 6900 6500

LGL 300 x 65 7200 6800 6600 6500 6200 9000 8400 8200 8000 7600

LGL 360 x 65 8200 7700 7500 7400 7100 10300 9700 9400 9200 8700

PLEASE NOTE:

These span tables are conservative spans. To run precise spans please use Design in HyneNZ v4.2 software.

IB - Hyne I Beam NZ - Hyne Super I beam LGL - Hyne LGL Minimum end bearing length - 45mm Minimum intermediate bearing - 85mm

SPAN 1ABLF - FLOOR }OIS1S z.oIPA USING HNF I BFAMS

SPAN 1ABLF - FLOOR }OIS1S z.oIPA USING HNF LGL

F

i

6

6

v

j

6

i

s

f

s

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF 8

F|oor jolst Span 1ab|es

FLOOR MASS 40KG/M2 LIVE LOAD = 3.0 KPA

FLOOR JOISTS 3.0KPA IB

SUPPORTING FLOOR & CEILING LOADS ONLY

MAXIMUM PERMISSIBLE SPAN (MM)

MAXIMUM FLOOR JOIST SPACING (MM)

FLOOR JOIST SIZE

Single Span Continuous Span

300 400 450 480 600 300 400 450 480 600

IB 200 x 90 4000 3500 3300 3200 2800 4000 3300 3000 2800 2300

IB 245 x 90 4700 4000 3800 3700 3300 4700 4000 3800 3700 3000

S88 x 245 5300 4800 4600 4500 3800 5900 4500 4000 3700 3000

IB 300 x 90 5700 4900 4600 4500 4000 5700 4900 4600 4500 3900

S88 x 300 6100 5600 5400 5300 4800 7500 5700 5000 4700 3800

IB 360 x 90 6300 5500 5200 5000 4500 6300 5500 5200 5000 4500

S88 x 360 6800 6300 6100 6000 5100 8300 7000 6200 5800 4700

PLEASE NOTE:

These span tables are conservative spans. To run precise spans please use Design in HyneNZ v4.2 software.

IB - Hyne I Beam NZ - Hyne Super I beam LGL - Hyne LGL Minimum end bearing length - 45mm Minimum intermediate bearing - 85mm

FLOOR MASS 40KG/M2 LIVE LOAD = 3.0 KPA ( DOMESTIC)

FLOOR JOISTS 3.0KPA LGL

SUPPORTING FLOOR & CEILING LOADS ONLY

MAXIMUM PERMISSIBLE SPAN (MM)

MAXIMUM FLOOR JOIST SPACING (MM)

FLOOR JOIST SIZE

Single Span Continuous Span

300 400 450 480 600 300 400 450 480 600

LGL 200 x 44 4000 3700 3500 3500 3200 5300 4800 4600 4500 4100

LGL 245 x 44 4900 4500 4300 4200 4000 6300 5900 5600 5500 5000

LGL 300 x 44 6000 5500 5300 5200 4800 7400 6900 6700 6400 5200

LGL 360 x 44 6800 6400 6200 6100 5800 8500 7600 6800 6400 5100

LGL 130 x 65 3200 2900 2800 2700 2500 3900 3500 3400 3300 3100

LGL 150 x 65 3600 3300 3200 3100 2900 4500 4100 3900 3900 3600

LGL 200 x 65 4800 4400 4300 4200 3900 6000 5500 5300 5200 4800

LGL 245 x 65 5800 5400 5200 5100 4800 7000 6500 6300 6200 5800

LGL 300 x 65 6800 6400 6200 6100 5800 8200 7600 7400 7300 6900

LGL 360 x 65 7700 7300 7100 7000 6700 9400 8700 8500 8300 7500

PLEASE NOTE:

These span tables are conservative spans. To run precise spans please use Design in HyneNZ v4.2 software.

IB - Hyne I Beam NZ - Hyne Super I beam LGL - Hyne LGL Minimum end bearing length - 45mm Minimum intermediate bearing - 85mm

SPAN 1ABLF - FLOOR }OIS1S .oIPA USING HNF I BFAMS

SPAN 1ABLF - FLOOR }OIS1S .oIPA USING HNF LGL

F

i

6

6

v

j

6

i

s

f

s

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF g

No reinforcement required.

Blocking only required

Cantilever

If bottom plate is outside the requirements of NZS 3604 Table 8.17 and requires

support use 70x35 MSG8 bridge member on top of the bottom flange, fixed using

2/75x3.15 nails through web. Nail and glue Rimboard to this bridge member.

Blocking required on

unreinforced sides

Use treated RB21,

RB45 or equivalent

structural boundary

at end of cantilever

Cantilever

If bottom plate is outside the requirements of NZS 3604 Table 8.17 and requires

support use 70x35 MSG8 bridge member on top of the bottom flange, fixed using

2/75x3.15 nails through web. Nail and glue Rimboard to this bridge member

Use treated RB21, RB45

or equivalent structural

boundary at end of

cantilever

Rimboard (RB21) attached with 2 rows of 30x3.15mm FH nails

at 75mm centres to one side of joist

Blocking required on

unreinforced sides

Cantl|ever Detal|s

C

t

f

i

i

r

v

r

v

D

r

f

t

i

i

s

3.15 x 75mm nails,

one each side

Use RB21 or RB45

Beyond 600mm, Edgebeam

trimmer joist to be checked

for structural adequacy

Use Edgebeam LGL trimmer joist to

support joist outriggers. Depth to

match Hyne I-Beam joist depth

Refer to span tables

for cantilever reinforcing

requirements and

fixings

Use Pryda approved

joist hangers only

Load bearing wall frame

Bottom plate of wall

frame to be sized as

NOT supported or refer

to detail 2.3

600 minimum

Hyne I-Beam blocking between joists

Rimboard (RB21) attached with 2 rows of 30x3.15mm FH nails

at 75mm centres to one side of joist

If bottom plate is outside the requirements of NZS 3604 Table 8.17

and requires support use 70x35 MSG8 bridge member on top of

the bottom flange, fixed using 2/75x3.15 nails through web.

Nail and glue Rimboard to this bridge member.

Cantilever

Use treated RB21mm,

RB45mm or equivalent

structural boundary at

end of cantilever

Floor joist reinforcement of cantilever,

Refer table 3.0 and 3.1, page 20

Minimum backspan of reinforcement equals cantilever length

Backspan Cantilever

OH

X

Roof load width

(RLW)

X

2

OH

=

+

Span of Hyne I-Beam

joist must be minimum

3 x cantilever distance

Durable joist outriggers and edge

trimmers to suit balcony requirements

Hyne I-Beam Joist

50mm

minimum

300 maximum

equal spaces

Outrigger backspan minimum

1.5 x cantilever distance

Packing blocks between web of Hyne I-Beam and

outrigger joist. Fix to Hyne I-Beam as per web

stiffeners. Fix outrigger joist to web stiffeners with

3/3.15 diameter x 90mm nails. Along bottom flange

fix with 3.15mm diameter x 90mm nails at 300mm

centres. Construction glue needs to be applied on site.

Solid durable blocking

between joists over

lower frame

2.0 CAN1ILFvFR OU1RIGGFR

DFCI]BALCON DF1AIL

2.2 CAN1ILFvFR MF1HOD z {Mz)DF1AIL

2.4 BRICI FDGF CAN1ILFvFR

2.1 CAN1ILFvFR MF1HOD

2.3 CAN1ILFvFR MF1HOD {M)

2.5 LOAD BFARING CAN1ILFvFR FXAMPLF

PLEASE NOTE:

M1 - no reinforcement required.

M2 - load-bearing cantilever reinforced one side.

M3 - load-bearing cantilever reinforced both sides.

Cantilever distance allowable for Hyne I-Beam sizes to be veried by

reference to the Hyne I-Beam span tables or Design-in-Hyne software.

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF zo

C

t

f

i

i

r

v

r

v

D

r

f

t

i

i

s

]

F

i

x

i

c

D

r

f

t

i

i

s

Cantl|ever Detal|s ] Flxlng Detal|s

Floor Mass 40 kg/m2

No snow load

Roof Pitch = 25

LIVE LOAD = 1.5 KPA (DOMESTIC)

Cantilever [Load Bearing]

LOAD BEARING FOR HYNE I-BEAMS

Maximum

Cantilever

Hyne

I-Beam

Solution

Light Weight Roofing - ( up to 20kg/m2) Heavy Weight Roofing - ( up to 60kg/m2)

Roof Load Width, RLW (m) Roof Load Width, RLW (m)

4.0 6.0 8.0 2.0 4.0 6.0

Floor Joist Spacings (mm) 300 450 600 300 450 600 300 450 600 300 450 600 300 450 600 300 450 600

450mm

IB 200x70 M1 M1 M2 M1 M2 M3 M1 M2 - M1 M1 M2 M1 M2 - M1 - -

IB 245x70 M1 M1 M1 M1 M1 M2 M1 M1 M3 M1 M1 M1 M1 M1 M2 M1 M2 -

IB 300x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

IB 360x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

750mm

IB 200x70 M1 M1 M2 M1 M2 - M1 M3 - M1 M1 M2 M1 M2 - M1 - -

IB 245x70 M1 M1 M1 M1 M1 M2 M1 M1 M3 M1 M1 M1 M1 M1 M2 M1 M2 -

IB 300x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

IB 360x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

900mm

IB 200x70 M1 M1 M3 M1 M2 - M1 M3 - M1 M1 M3 M1 M3 - M2 - -

IB 245x70 M1 M1 M1 M1 M1 M2 M1 M1 M3 M1 M1 M1 M1 M1 M3 M1 M2 -

IB 300x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

IB 360x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

1200mm

IB 200x70 M1 M3 - M2 - - M3 - - M1 M3 - M2 - - - - -

IB 245x70 M1 M1 M3 M1 M2 - M1 M3 - M1 M1 M3 M1 M3 - M2 - -

IB 300x70 M1 M1 M1 M1 M1 M2 M1 M1 M2 M1 M1 M1 M1 M1 M2 M1 M2 M3

IB 300x70 M1 M1 M1 M1 M1 M2 M1 M1 M2 M1 M1 M1 M1 M1 M2 M1 M2 M3

Floor Mass 40 kg/m2

with 0.5 kPa Snow

Load Roof Pitch = 25

LIVE LOAD = 1.5 KPA (DOMESTIC)

Cantilever [Load Bearing]

LOAD BEARING FOR HYNE I-BEAMS

Maximum

Cantilever

Hyne

I-Beam

Solution

Light Weight Roofing - ( up to 20kg/m2) Heavy Weight Roofing - ( up to 60kg/m2)

Roof Load Width, RLW (m) Roof Load Width, RLW (m)

4.0 6.0 8.0 2.0 4.0 6.0

Floor Joist Spacings (mm) 300 450 600 300 450 600 300 450 600 300 450 600 300 450 600 300 450 600

450mm

IB 200x70 M1 M1 M2 M1 M2 M3 M1 M2 - M1 M1 M2 M1 M2 - M1 - -

IB 245x70 M1 M1 M1 M1 M1 M2 M1 M1 M3 M1 M1 M1 M1 M1 M2 M1 M2 -

IB 300x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

IB 360x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

750mm

IB 200x70 M1 M1 M2 M1 M2 - M1 M3 - M1 M1 M2 M1 M2 - M1 - -

IB 245x70 M1 M1 M1 M1 M1 M2 M1 M1 M3 M1 M1 M1 M1 M1 M2 M1 M2 -

IB 300x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

IB 360x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

900mm

IB 200x70 M1 M1 M3 M1 M2 - M1 M3 - M1 M1 M3 M1 M3 - M2 - -

IB 245x70 M1 M1 M1 M1 M1 M2 M1 M2 M3 M1 M1 M1 M1 M1 M3 M1 M2 -

IB 300x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

IB 360x70 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M1 M2

1200mm

IB 200x70 M1 M3 - M2 - - M3 - - M1 M3 - M2 - - - - -

IB 245x70 M1 M1 M3 M1 M2 - M1 M3 - M1 M1 M3 M1 M3 - M2 - -

IB 300x70 M1 M1 M1 M1 M1 M2 M1 M1 M3 M1 M1 M1 M1 M1 M2 M1 M2 M3

IB 360x70 M1 M1 M1 M1 M1 M2 M1 M1 M3 M1 M1 M1 M1 M1 M2 M1 M2 M3

Pitch (degrees) 25 27.5 30 35 40 45

Pitch Multiplier Ratio (PMR) 1.0 1.03 1.05 1.12 1.21 1.31

SPAN 1ABLF LOAD BFARING CAN1ILFvFR

SPAN 1ABLF LOAD BFARING CAN1ILFvFR o. IPA SNOv LOAD

ROOF PI1CH MUL1IPLIFR RA1IO

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF z

Web stiffener

Pryda Face Mount

LF190/90, LF235/90, LF 290/90

(Web stiffeners not required)

Pryda Top Mount Hanger

LT200/90, LT 245/90, LF300/90

(Web stiffeners not required)

Pryda Double Face Mount LF190/180

(Web stiffeners required where top

flange unrestrained)

Hanger Flxlngs

45mm Timber plate

3mm - 6mm gap

Steel beam

40 x 3.75 Nails

Minimum 3mm, to maximum 6mm overhang of top

plate from steel beam to prevent squeaks

45 mm top plate

Pryda Top Mount Hanger LT200/90,

LT 245/90, LF300/90

(Web stiffeners not required)

30 x 6mm Gauge Screw

Packer wide enough

to clear flange

Steel Beam

No notching required

Pryda Face Mount

LF190/90, LF235/90,

LF 290/90

(Web stiffeners

not required)

Double joist connection to be in accordance with

detail 5.9, page 26. Web stiffeners to

coincide with any significant

load positions

Web stiffeners

Approved joist hanger

Web stiffeners to be installed in

accordance with detail 5.2 page 24.

Double Hyne I-Beam

trimmer joist

Hyne I-Beam trimmer

Hyne I-Beam

Hanger Reference:

Top Mount LT200/90,

LT 245/90, LF 300/90

Pryda I-Beam hangers have been engineered to provide support

for Hyne I-Beams, Hyne LGL and 17C beams in domestic and

commercial applications. The hangers are fully compatible with

Hyne I-Beams, Hyne LGL and 17C beams and are suitable for

any support conguration. The product has been developed in

accordance with the relevant New Zealand Building Standards

and the design capacities are veried by a rigorous testing

program. We recommend that installation of Hyne I-Beams, Hyne

LGL and 17C beams with the Pryda I-Beam hangers is conducted

in accordance with the construction guide.

H

t

c

r

v

F

i

x

i

c

s

PLEASE NOTE:

You musI check Ihe capaciIy o! all hahgers ahd cohhecIiohs !or your

particular application.

Mihimum 3mm/maximum 6mm clearahce beIweeh beams. CohIacI

between beams may cause squeaks.

Lhsure !asIehers are selecIed Io meeI Ihe durabiliIy requiremehIs

of NZS 3604:1999.

Use Ihe correcI hails, screws ahd hail plaIes, !ollowihg ihsIallaIioh

instructions.

Re!er Io Ihe Lhgiheered 1imber SoluIiohs CohsIrucIioh Cuide !or

xing selection and hanger size..

4.0 }OIS1 HANGFR CONNFC1ION 1PFS

4.4 }OIS1 CONNFC1ION 1O S1FFL BFAM

OP1ION

q

4.1 HNF I-BFAM FIXFD 1O S1FFL BFAM vI1H

FACF MOUN1 HANGFR OP1ION z

4.1 }OIS1 CONNFC1ION 1O S1FFL BFAM

OP1ION

4.5 }OIS1 1O 1RIMMFR CONNFC1ION

4.3 HNF I-BFAM FIXFD 1O S1FFL BFAM vI1H

FACF MOUN1 HANGFR OP1ION

45mm Packer

Steel Beam

Pryda Face Mount Hanger

LF190/90 , LF235/90 , LF 290/90

(Web stiffeners not required)

Notch in top flange

do not over cut notch

15mm

Max

25mm Max

5mm Maximum

clearance

1 / 30 x 10 gauge bugle head screw

through beam to bottom flange of joist

Steel beam

Minimum bearing length 30mm

UB, UC or

channel section

Web stiffener installed in contact with

bottom flange. Fix with 3/65x3.15 nails

each side equally spaced

3mm gap

1/2 depth of

joist maximum

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF zz

H

t

c

r

v

F

i

x

i

c

s

Hanger Flxlngs

IMPORTANT

Minimum gap 3mm

between beam and I-Beam

I-Beam depth

60% minimum

The hanger must support a minimum

of 60% of joist depth

Web stiffener required when top

flanges are unrestrained

Resist lateral movement

10mm Minimum

Top flange of

I-Beam restrained

I- Beam hanger

30x6 gauge bugle-head or wafer-head

wood screws or similar

I-Beam bottom flange

I-Beam web

Strap nail plate each side

One skewed nail

75x3.15mm through

each side of the

flange into the

supporting member

Minimum 45mm

end distance

2 Skewed nails

75x3.15mm

through the flange

Required bearing length

2 Skewed nails

75x3.15mm

through the flange

Nail to top plate with minimum 2/3.75x75mm nails

Nail on each side through the flange

Wall top plate

Hyne I-Beam

A

A B C D

B

4.6 FND BFARING 4.6 DF1AIL OvFR 1HF 1OP PLA1F

75x50x5 MS angle fixed to bearer using 4/type

17 screws. Use 1/30mm x 10 screw through angle

to bottom flange of Hyne I-Beam joist.

Hanger Reference: LVSIA

LVSIA Type 17 screws 30mm x 10 gauge bugle-head screw

4.8 SIFv ANGLF HANGFR

4.7 FIXING RFQUIRFMFN1S FOR FACFMOUN1]1OP MOUN1 HANGFRS

PLEASE NOTE:

Minimum 3mm/maximum 6mm clearance between beams.

Contact between beams may cause squeaks.

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF z

Hanger Flxlngs

Hanger Reference:

JH 87/117

JH 87/180

JH 87/265

40x3.15mm nails

Hanger Reference:

FB 47/176

30x3.15mm nails

H

t

c

r

v

F

i

x

i

c

s

Hanger Reference:

LF 220/90 SL or R

40x3.75mm nails

Left or right orientation based on view from the supported I-Beam

Hanger Reference:

LF 220/90 SL or R

70mm

W1

W2

W2

Slope to 45

up or down

1. Position LF.VS connector against

plumb-cut end of joist. Fasten joist

side flanges on both sides with

40x3.75mm nails. Bend seat up

to fit against joist bottom and drive

(1) 40x3.75mm nail through

bottom seat in to rafter bottom.

Drive (2) 40x3.75mm nails at

downward angle through dimpled

nailing guides.

2. Lean connector and rafter end

against ridge beam at desired

position. Install 40x3.75mm nails

through nail holes into ridge

beam on inside flange.

40x3.75mm nails

Angle maximum 45

3. Bend flange to desired angle.

4. Hammer outside flange until

edge touches header.

Fasten outside flange to ridge

by driving 40x3.75mm nails

through nail holes.

Hanger Reference:

LF190/90VS

LF 224/90VS

A B

4.9 SIFv ANGLF HANGFR

4.10 q SIFv ANGLF HANGFR FIXING 4.11 q SIFv ANGLF HANGFR FIXING

4.13 HNF LGL & )C HANGFR FIXING

4.9 vARIABLF SLOPF & SIFv ANGLF

HANGFR FIXING

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF zq

D

r

f

t

i

i

s

Interna| 8raclng

45mm Thick MSG8 nog to joist

depth hard up under flooring

Sheet Brace Straps:

6kN - 1/300mm x 25mm x 1.0mm sheet brace strap

fixed with 6/30x3.15mm product nails to stud and block (twisted)

12kN 2/300mm x 25mm x 1.0mm sheet brace strap fixed

with 6/30x3.15mm product nails to stud and block (twisted)

Upper wall framing

Double web stiffener each side of I-Beam nail

using 5/75x3.15mm nails from each face

Multigrips:

6kN - 1 Multigrip to 1 face both ends fixed

with 30x3.15mm product nails (fully nailed)

12kN - 2 Multigrips to 2 faces both

ends fixed with 30x3.15mm

products nails (fully nailed)

Upper non-loadbearing wall framing

90x45mm Solid blocking between joists at

600mm maximum centres and at each side

of door openings in wall above.

Blocking not required if wall

within150mm of joist

2/100x3.75 mm

5.0 BRACING vALL 1IF DOvN

5.1 NON-LOADBFARING vALL PARALLFL

Tight fit

Concentrated load

3mm Minimum gap

3mm Minimum gap

3/65x3.15

nails each side

equally spaced

Tight fit

5.2 vFB S1IFFFNFR DF1AIL

PLEASE NOTE:

Web sIi!!ehers Io be used aI all cohcehIraIed loads ahd aI supporIs

where specied.

Web sIi!!eher size 90 x 30mm.

web StlFFener Detal|

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF zy

Rimboard

Boundary

I-Beam

6kN and 12kN brace fixing

Strap 300x25 x 0.9

Fixed with 6/30x3.15mm nails to each end

12 kN fixing with 2 SHEET BRACE STRAPS

12 nails to stud(s) and 12 nails to Rimboard

6kN fixing brace with 1 SHEET BRACE

STRAP and 6 nails to stud and Rimboard

RB45 H3.1 with 90x2.8mm nails

at 150mm centres staggered

Fix RB45 H3.1 to I-Beam

with 90x2.8mm nails at

150mm centres along each

flange

Fix bottom flange of I-Beam

with 75mm x 3.15mm

nails at 150mm centres

Rimboard

D

r

f

t

i

i

s

8oundary Detal|s

RB45 H3.1 fixed

to Hyne I-Beam

Hyne I-Beam

G

ird

e

r tru

s

s

Fix Rimboard to I-Beam with

90x2.8mm nails at 150mm

centres along each flange

3

.0

m

Fix bottom flange of I-Beam with

75x3.15mm nails at 150mm centres

5.4 RIMBOARD FND }OIS1 5.3 RIMBOARD FX1FRNAL vALL BRACING FIXING

5.5 LOAD BFARING HNF I-BFAM

& RIMBOARD]BOUNDAR

Hyne I-Beam blocking or 2/70x45 Nogs

Option to use RB21 or RB45

RB21 use 60x2.8mm flat head nails at 150mm centres

RB45 use 90x3.15mm flat head nails at 150 centres

5.6 RIMBOARD }OINING

PLEASE NOTE:

8luhI hail ehds Io avoid spliIIihg o! !ahges.

All Rimboards are IreaIed Io H3.1.

Re!er Io NZS3602.2003 !or IreaImehI deIails.

PLEASE NOTE:

Avoid usihg wide secIioh Iimber.

All Rimboards are IreaIed Io H3.1

Re!er Io NZS3602.2003 !or IreaImehI deIails.

Concentrated load from upper story eg. under

girder trusses with a setback greater than

2.4m or lintel greater than 3.0m span

90x45 Radiata MSG8 squash blocks 1mm deeper than

joist depth. One each side of I-Beam or under point

concentrated load

Squash block for joists under

concentrated load points

RB21 or RB45

5.7 CONCFN1RA1FD LOAD A1 }AM S1UDS

OR POS1S

90x3.15mm skew nails

at 150mm centres

30mm

Fix bottom plate with 90x3.15mm nails

at 150mm centres into flooring

Fix Rimboard with 1/60x2.8mm nail into

each flange

RB45 Rimboard H3.1

Fix Rimboard into plates 30mm in and at 45

with 90x3.15mm nailed at 150mm centres

45

90x3.15mm skew nails at 150mm centres

5.8 RIMBOARD FIXING 1O I-BFAM - 1RANSFFRRING

BRACING LOAD FROM vALL ABOvF

PLEASE NOTE:

Where 6kN ahd 12kN Iie dowh bracihg sIraps are required - Ihese

are to be xed to manufactures specications in addition to the

xing shown above.

OIher wall !xihgs Io NZS3604 requiremehIs.

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF z6

Use a minimum of 2 blocking

sections every 3.6 metres, or

single blocking every 1.8 metres.

Hyne I-Beam floor joists

Fix joists to top plate as per detail 4.6 page 22.

Fix blocking to top plate with 2 nails

each end and 2 skew nails to top flanges.

Hyne I-Beam blocking

8raclng and 8|ocklng

Apron RooF Detal|

D

r

f

t

i

i

s

5.9 BRACING AND BLOCIING

PLEASE NOTE:

BRACE BLOCKING FOR WIND AND EARTHQUAKE

Bracing of the oor is required to transfer bracing forces from the

upper level to the lower level.

To achieve this we need to provide lateral restraint to the oor.

Where the forces are parallel with the joist this is adequate with the

longitudinal shear capacity of the joists.

For forces perpendicular to the joist, brace blocking is required. This

can be achieved by two blocking panels at 3.6m centres or one

blocking panel at 1.8m centres along bearing and bracing walls. Along

the external wall use the Rimboard.

3

0

0

m

m

M

in

im

u

m

6

5

m

m

b

e

a

r

in

g

Fix plywood with 2 groups of 6/3.15 diameter nails and

1 group of 4/75 x 3.15mm diameter nails as shown.

Provide elastomeric glue (Maxbond or equivalent)

between ply and OSB web.

Hyne I-Beam

blocking panel

under upper framing

Upper wall framing

21mm F8 plywood

both faces or 21mm Rimboard

ripped down to fit between

both flanges

Solid timber blocking

1

0

0

m

m

m

in

im

u

m

1

0

0

m

m

1

0

0

m

m

6

0

0

m

m

m

in

im

u

m

4

5

0

m

m

m

a

x

im

u

m

Flooring extends beyond upper wall

4

0

m

m

4

0

m

m

Roof supported - maximum 8m concrete tile roof

Stud wall supported maximum

8m truss span concrete tile roof

5.10 APRON ROOF DF1AIL

PLEASE NOTE:

Double |oisI required uhder load bearihg sIuds supporIihg

upstairs lintels.

For lihIel spahs greaIer Ihah 900mm, Lhgiheerihg desigh will

be required.

Lhgiheered desigh is required !or I-8eams supporIihg girder Irusses.

Rimboard will heed Io be ripped dowh oh siIe Io !I beIweeh !ahges.

For I-8eam size selecIioh re!er Io DiH4.1NZ so!Iware !or walls loaded

on joists.

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF z

FIRE CONTROL

Hyne oors may be used in re rated construction. For details on the re rating of oors, refer to the publication entitled Gib Fire Related Systems.

NOISE CONTROL

Hyne oors can be used in Gib Noise Control Systems as a substitute for solid timber joists. Note the requirements for solid blocking at oor/ceiling

to wall junctions in Fire and Noise Control Separations.

For detailed specications on intertenancy construction, refer to the publication entitled Gib Noise Control Systems.

For detailed specications on residential construction, refer to Gib Quiet Zone which is contained in the publications entitled Gib Living Solutions for

New Homes and Gib Living Solutions for Established Homes.

Web stiffeners to both sides of Hyne I-Beams

with approved fire cement to fill in all gaps

Continuous Hyne Edgebeam

Hyne Edgebeam blocking

between Hyne I-Beams

D

r

f

t

i

i

s

150mm centres on edges

200mm centres on

immediate supports

Sheets layed in brick bond pattern.

Use 50x8mm gauge screws.

F|oor Flxlng ~ Detal|s

Panel edge fixing 150mm

maximum nail centres

Panel intermediate fixing 200mm

maximum nail centres

Double fixing for diaphragm

Plywood Fixing Options Fixing Centres (mm)

I-Beam Type Size Ends Intermediates

Galvanised flat head nails 60mm x 2.8g 150

200

Galvanised screw self drilling

or counter sunk

50mm x 8g 150 200

Flre]Nolse Contro|

5.11 FIXING S1RANDFLOOR]PAR1ICLF BOARD

FLOORING

5.13 IN1FR-1FNANC vALL FIRF SFPARA1ION DF1AIL

5.12 FIXING PLvOOD FLOORING PANFLS

PLEASE NOTE:

1imber hogs or Iohgue ahd groove |oihI is require aI sheeI edges.

Lay sheeIs ih brick - bohd paIIerh.

PLEASE NOTE:

1imber hogs or Iohgue ahd groove |oihI is require aI sheeI edges.

Lay sheeIs ih brick - bohd paIIerh.

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF z8

D

r

f

t

i

i

s

NAILS:

2 x 44mm Hyne LGL 75 x 3.05mm Ringshank

Doub|e 8eam Connectlons

Nail using 4/75x3.15mm nails for each web stiffener.

Two nails from each side and ends need to be clenched.

3mm gap between web

stiffener and flange

W

eb

stiffen

ers b

etw

een

I-B

eam

s at 6

0

0

m

m

cen

tres m

axim

u

m

Apply bead of construction adhesive

to each flange prior to assembly.

At points of load concentration (eg girders)

use a group of six nails as additional fasteners

50 maximum

200

200

200

200

200

50 maximum

5.29 DOUBLF HNF I-BFAM CONNFC1ION

5.30 DOUBLF HNF LGL CONNFC1ION

PLEASE NOTE:

Where Ihe double Hyhe LCL supporIs ahoIher member !xed Io iIs

face, additional nailing is required from the reverse side of the

Hyne LGL.

AddiIiohal !asIehers will also be required aI poihIs o! cohcehIraIed

load, as shown in 12.2.

Skew hailihg is required Io avoid pryihg.

All hails Io be alIerhaIively skewed (30 Io verIical)

Ah addiIiohal cehIre row o! hails is required Io boIh sides !or beams

300mm in depth.

Where a double compohehI LCL has a cohcehIraIed load !rom ohe

side only, use 6x3.15mm diameter nails in the vicinity of the load.

Fixing needs to be specically designed when the load from one side

is greater than 4.8kN.

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF zg

Ho|es ln Hyne I-8eams

D

r

f

t

i

i

s

Beam Span 5.0m

(End Hole Zone) (End Hole Zone)

125x125 Hole 2.0m from centre line 125x125 Hole 2.0m from centre line

125 mm

Holes are not permitted directly over support

Holes are not recommended within the joist

depth away from support

D

D

Centre line

From centre line

(End Hole Zone)

From centre line

(End Hole Zone)

Holes are not permitted directly over support

Holes are not recommended within the

joist depth from support

D

Round holes minimum

3mm from flange edge

End support

Single Joist Span

D

Span centre line

Beam Span 1 Beam Span 2

From centre line of span 2

(End Hole Zone)

From centre line of span 2

(Intermediate Hole Zone)

From centre line of span 1

(End Hole Zone)

D

Minimum clear spacing between holes

2 x diameter of larger hole

Intermediate support in continuous span

40mm diameter hole permitted

anywhere in the web, installed at

minimum spacing, 80mm between holes

From centre line of span 1

(Intermediate Hole Zone)

Continuous Beam Length

6.0 ROUND HOLFS IN HNF I-BFAMS FXAMPLF

6.1 ROUND HOLFS IN HNF I-BFAMS FXAMPLF

6.2 ROUND HOLFS IN HNF I-BFAMS FXAMPLF

PLEASE NOTE:

1his meahs IhaI a 125-diameIer hole cah be placed wiIhih Ihe Lhd

Hole Zone as long as the hole is within 2.0m from the centerline.

For Ihe disIahce !rom Ihe supporI (spah) 5.0m / 2 - (Hole Zohe

Width) 2.0m = (distance from support) 0.5m

I! 2.0m is greaIer Ihah hal! Ihe spah Iheh Ihe hole cah be placed

anywhere.

1he hole is hoI allowed over Ihe supporIs.

Keep Ihe hole aI leasI Ihe |oisI depIh away !rom Ihe supporI.

REQUIRED INFORMA1ION:

Maximum !oor load 1.8kN (yes)

Shape ahd size o! hole (rouhd hole 125mm diameIer)

1oisI size (I8 245x70)

1oisI spacihg (450 cehIres)

1oisI spah (5.0m) sihgle spah |oisI

Hole zohe (Lhd Hole Zohe)

PROCEDURE:

1. Select table according to hole shape round. (Round Hole)

page 30

2. Select hole size and joist spacings. Hole size 125x125 and

joist spacings 450 centres

3. Select hole zone. (End Hole Zone)

4. Select joist size (IB 245x70) and read across to intercept

coordinates (Hole zone width = 2.0m)

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF o

Ho|es ln Hyne I-8eams

D

r

f

t

i

i

s

Beam Span

Minimum spacing between holes

2 x largest length of the rectangular openings

H

W

From centre line of span

(End Hole Zone)

From centre line of span

(Intermediate Hole Zone)

Maximum 40mm diameter hole

allowed in cantilever span

Intermediate support

in cantilever support

Cantilever span

HOLE SIZE 125x250 150x300 175x350 200x400

HYNE I-BEAM

JOIST SPACING (m)

450 600 450 600 450 600 450 600

MAXIMUM ALLOWABLE DISTANCE FROM CENTRE OF JOIST SPAN FOR END HOLE (m)

IB 200x70 - - - - - - - -

IB 245x70/88 2.0 1.4 0.9 0.5 - - - -

IB 300x70/88 2.3 1.6 1.6 1.1 1.3 0.4 1.1 MID

IB 360x70 3.5 2.5 2.3 1.6 1.5 1.1 1.1 0.4

MAXIMUM ALLOWABLE DISTANCE FROM CENTRE OF JOIST SPAN FOR INTERMEDIATE HOLE (m)

IB 200x70 - - - - - - - -

IB 245x70/88 1.2 0.8 0.5 0.3 - - - -

IB 300x70/88 1.3 0.9 0.8 0.5 0.6 0.3 0.6 MID

IB 360x70 2.1 1.5 1.3 0.9 0.8 0.4 0.4 0.2

HOLE SIZE 75x75 100x100 125x125 150x150 175x175 200x200

HYNE I-BEAM

JOIST SPACING (mm)

450

600

450 600 450 600 450 600 450 600 450 600

MAXIMUM ALLOWABLE DISTANCE FROM CENTRE OF JOIST SPAN FOR END HOLE (m)

IB 200x70 2.0 1.4 1.4 1.1 - - - - - - - -

IB 245x70/88 2.8 2.6 2.8 2.0 2.0 1.5 1.3 0.6 - - - -

IB 300x70/88 3.1 2.9 3.1 2.9 3.1 2.6 2.6 2.1 2.1 1.6 1.4 1.0

IB 360x70 3.5 3.2 3.5 3.2 3.5 3.2 3.5 3.2 3.5 2.6 2.6 1.8

MAXIMUM ALLOWABLE DISTANCE FROM CENTRE OF JOIST SPAN FOR INTERMEDIATE HOLE (m)

IB 200x70 1.4 1.0 0.8 0.5 - - - - - - - -

IB 245x70/88 2.5 1.8 1.8 1.3 1.2 0.8 0.5 MID - - - -

IB 300x70/88 3.5 2.6 3.2 2.2 2.5 1.8 1.9 1.3 1.2 0.8 0.6 MID

IB 360x70 3.8 3.5 3.8 3.5 3.8 2.9 2.8 2.1 2.0 1.5 1.5 1.0

6.3 RFC1ANGULAR OR ROUND HOLFS IN HNF I-BFAMS FXAMPLF

6.4 CU11ING HOLFS IN HNF I-BFAMS

6.5 ROUND OR SQUARF HOLFS IN HNF I-BFAMS

6.6 RFC1ANGULAR HOLFS IN HNF I-BFAMS

PLEASE NOTE:

Never drill, cuI or hoIch Ihe !ahge, or over-cuI Ihe web.

1he holes ih Ihe web should be cuI wiIh a sharp saw.

For recIahgular holes, avoid over cuIIihg Ihe corhers as Ihis cah cause

stress concentrations.

PLEASE NOTE:

SlighIly rouhdihg Ihe corhers is recommehded Io avoid over-cuIIihg,

for rectangular holes.

SIarI Ihe recIahgular hole by drillihg a 10mm diameIer hole ih each

of the four corners and then making the cuts between the holes to

minimise damage to the web.

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF

D

r

f

t

i

i

s

Vertical hole in beam

Minimum

5 x hole

diameter

Extra side xety required to stop prying or separating.

Centre Line

A A

C D E

B

Servlce Ho|es Hyne LCL & C 8eams

BEAM WIDTH (mm)

MAXIMUM HOLE

DIAMETER (mm)

MINIMUM HOLE

SPACING (mm)

35 9 210

45

11 270

85

21 510

D = bolt diameter

Shear Load

4D

5D

4D

5D 5D

Horizontal Holes

D = bolt diameter

TENSION LOAD

5D 8D

5D

2D

2D

The following table outlines the requirements for holes being drilled through Hyne LGL and 17C oor members.

For 18C and 21C please phone the technical helpline on 0800 022 357

A B C DD E F

HYNE LGL & 17C

BEAMS

Maximum Hole

Diameter (mm)

Top and Bottom

Edge Distance (mm)

Minimum End

Distance From

Support Face (mm)

Minimum Hole

Spacing

Minimum Distance

From Centre of Span

Maximum Number

of Holes in Span

200 25 30 70 5 x Diameter None 3 Holes / Halfspan

40 55 290 5 x Diameter None 3 Holes / Halfspan

55 55 880 5 x Diameter 440 2 Holes / Halfspan

75 55 880 1300mm 650 1 Hole / Halfspan

245 25 30 70 5 x Diameter None 3 Holes / Halfspan

50 70 360 5 x Diameter None 3 Holes / Halfspan

70 70 1050 5 x Diameter 520 2 Holes / Halfspan

95 70 1050 1600mm 800 1 Hole / Halfspan

295 or larger 25 30 70 5 x Diameter None 3 Holes / Halfspan

60 85 440 5 x Diameter None 3 Holes / Halfspan

85 85 1200 5 x Diameter 600 2 Holes / Halfspan

115 85 1200 1800mm 900 1 Hole / Halfspan

6.7 vFR1ICAL HOLFS )C BFAMS ONL

6.12 FAS1FNING HORIZON1AL HOLFS FOR

1FNSION LOADS

6.8 SFRvICF HOLFS IN HNF LGL & )C BFAMS

6.9 SFRvICF HOLFS IN HNF LGL & )C BFAMS

6.10 SFRvICF HOLFS IN HNF LGL & )C BFAMS

6.11 FAS1FNING HORIZON1AL HOLFS FOR

SHFAR LOADS

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF z

D

r

f

t

i

i

s

PROBLEM SOLUTION

Seating plate

Splitting at notched beam support

Probable split

PROBLEM

Seat bracket

Bearing

point here

SOLUTION

Hole at

mid-depth

Notch for

services

PROBLEM SOLUTION

MIN*

*Minimum must not be less than

half the depth of the beam

Taper cut length must not exceed

0.15 of the beam span

PROBLEM SOLUTION

Overcomlng Sp|lttlng]1aper Cuts

Taper cut

Hyne 17C beam

Edge of nail plate folded

over beam and nailed

Nail plate each side

Pryda nail plate

(see table 7.6 below

for size selection)

Refer Depth at end of taper

cut beam in table 7.6 below.

Double top plate

Pryda NPA 150/190 Nail Plate - 72, 3.15x30mm nails

Pryda NPB 150/250 Nail Plate - 94, 3.15x30mm nails

Taper cut length must not exceed 15% of the beam span

Splitting at bolted beam support Splitting at notched beam support

Splitting due to lateral loads in diaphragm connection Splitting at notch in beam

7.6 NAIL PLA1F SIZFS FOR RFINFORCFD 1APFR CU1S - APPLIFS 1O 8MM )C ONL

NAIL PLATES

TAPER CUT DETAILS

HYNE 17C BEAM SIZE

DEPTH AT END OF TAPER CUT BEAM (mm)

130 160 190 220

330 x 85 NPA 150/190 X X X

360 x 85 NPA 150/190 X X X

395 x 85 NPB 150/250 NPB 150/250 X X

425 x 85 NPB 150/250 NPB 150/250 NPB 150/250 X

460 x 85 NPB 150/250 NPB 150/250 NPB 150/250 X

525 x 85 NPB 150/250 NPB 150/250 NPB 150/250 NPB 150/250

7.0 DF1AILS

7.2 DF1AILS

7.4 UNRFINFORCFD 1APFRCU1

7.1 DF1AILS

7.3 DF1AILS

7.5 NAIL PLA1F RFINFORCFD 1APFR CU1

PLEASE NOTE:

Plate to be placed symmetrically about the inner face of the support, i.e. on the shear line

Maximum reaction load for 150 deep NPA is 35kN ultimate. Maximum reaction load for 150 deep NPB is 70kN ultimate

X - ihdicaIes where Ihe beam would have more Ihah 50% depIh

INSTALLATION: Use 30x3.15mm Pryda Timber Connector, Galvanised Nails GBC030315 (500G)

Please phone the technical helpline on 0800 022 357 for beams not listed below.

Refers to LGL, 85mm & 135mm 17C

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF

Avold 1hese Practlces

A

v

6

i

o

1

i

r

s

r

P

v

t

c

f

i

c

r

s

8.0

8.4

8.8

8.1

8.5

8.9

8.2

8.6

8.10

8.3

8.7

DO NOT bevel cut joist beyond

inside face of wall

DO NOT cut holes too

close to support.

DO NOT bevel cut rafter

beyond inside face of wall.

DO NOT overhang birdsmouth

cut from inside face of plate.

DO NOT split the flange.

Ensure the correct heel fixing is done.

DO NOT cut, notch or drill

top or bottom chords.

Top plate

too wide

Top nails missing

Incorrect

nail installation

Top nailing is incorrect due to:

1. Top plate too thin or

2. Wrong length nail is used

I-Beam is not seated properly

into the hanger, this may cause

nail pullout or shear under load.

Spreading hanger legs will push

the I-Beam up which may cause

uneven floors, squeaky floors

and I-Beam rotation.

If the top plate is too narrow it

may cause:

1. Hanger deformation

2. Nail pull-out or shear

3. Supporting beam deformation

Hangers not supporting the top flange of the

Hyne I-Beam will require stiffeners.

FNGINFFRFD 1IMBFR SOLU1IONS DFSIGN GUIDF q

R

6

6

r

C

6

s

f

v

u

c

f

i

6

P

i

t

This is a typical roof construction plan.

Please see page numbers on the plan to locate details.

Lintel

Standard rafter flush support

detail or pitching block,

refer page 46, detail 5.14

Standard rafter

overhang detail,

refer page 46, detail 5.15

Blocking pairs

at 3.6m maximum

90x45 Overhang outrigger,

refer page 46, detail 5.19

Rafter overhang trim detail,

refer page 46, detail 5.18

Ridge over detail,

refer page 47, detail 5.21

Rafter to ridge beam/roof beam connection,

refer page 47, detail 5.20

Gable end rafter detail,

refer page 47, detail 5.24

RooF Constructlon P|an

1.1 1PICAL ROOF CONS1RUC1ION PLAN

PLEASE NOTE:

I! a beam is above a wihdow or a door, Iheh iI is a lihIel. I! hoI, Iheh iI is a bearer.

PoihI Loads oh ra!Iers i.e. waIer sIorage cylihder, air-cohdiIiohihg uhiIs ahd oIher such uhiIs, where higher permahehI loads may be expecIed,

specic engineering design should be applied refer to Design in Hyne V4.2NZ

1he Spah 1ables ih Ihis brochure are desighed as cohservaIive spahs. 1o ruh precise spahs please use Ihe Desigh ih Hyhe V4.2NZ so!Iware.

DESIGN CRITERIA:

1he Iables provide realisIic maximum spahs !or Ihe giveh ra!Ier spacihgs. 1he serviceabiliIy criIeria used are as speci!ed ih AS/NZS 1170.

SNOW LOADS:

Ih accordahce wiIh NZS 3604:1999 (A2), show loads up Io 0.5 kPa or 1.0 kPa have beeh cohsidered ih Ihe preparaIioh o! Ihese Iables. 1here!ore, Ihese

tables apply to all areas with snow loading 0.5 kPa or 1.0 kPa. Reference should be made to gure 15.1 of NZS 3604:1999 (A2) Timber framed