Bartec Hazardous Class Poster

Diunggah oleh

Den Andri NchuHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bartec Hazardous Class Poster

Diunggah oleh

Den Andri NchuHak Cipta:

Format Tersedia

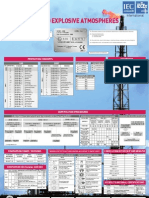

Conditions and subdivisions

methane

carbon dust

dusts

gases

vapours

Conditions and subdivisions

is present continuously or

for long periods or frequently

arises in normal

operation occasionally

is not likely toarise in normal

operation, or if it does, will

persist for a short time only

is present in the form of a

cloud continuously, or for

long periods or frequently

occasionally develops

into a cloud during

normal operation

is not likely to develop into

a cloud during normal

operation, or if it does,

for a short time only

operation where there is

a risk of explosion

disconnection where there

is a risk of explosion

zone 0

zone 1

zone 2

zone 20

zone 21

zone 22

-

-

II

II

II

II

II

II

I

I

1G

2G or 1G

3G or

2G or 1G

1D

2D or 1D

3D or

2D or 1D

M1

M2 or M1

II

II

II

III

III

III

I

I

Ga

Gb or Ga

Gc or

Gb or Ga

Da

Db or Da

Dc or

Db or Da

Ma

Mb or Ma

Required marking on the usable operating equipment

Equipment

category

as defined in

directive 94/9/EC

Equipment

protection level

(EPL) as defined in

EN 60079-O

Groups of dust

Marking Permissible

equipment group

IIIA

IIIB

IIIC

IIIA, IIIB, IIIC

IIIB, IIIC

IIIC

Dusts

combustible flyings

non-conductive dust

conductive dust

Ignition temperature of dust

T

perm. layer

= T

5 mm layer

- 75 K

T

perm. cloud

= 2/3 T

cloud

T

perm. layer

> T

perm.

< T

perm. cloud

permissible temperature

of the layer

permissible temperature

of the cloud

max. permissible

surface temperature

of the equipment

Marking according directive 94/9/EC

according norm EN 60079-0 ff

* Alternative Ex protection type

** Intrinsically safe systems

*** FISCO intrinsically safe field bus systems

Assignment

of gases and vapours

accordance to the

ignition temperature

Subdivisions of gases and vapours

Maximum

surface

temperature

of equipment

Permissible

temperature

classes

of equipment

Temperature

class

> 450 C

> 300 C... < 450 C

> 200 C... < 300 C

> 135 C... < 200 C

> 100 C... < 135 C

> 85 C ... < 100 C

T1

T2

T3

T4

T5

T6

450 C

300 C

200 C

135 C

100 C

85 C

T1 to T6

T2 to T6

T3 to T6

T4 to T6

T5 to T6

T6

Gases and vapours

town gas,

acrylnitril

ethylene,

ethylene oxide

ethylene glycol

hydrogen

sulphide

ethyl-ether

ammonia,

methane,

ethane, propane

ethyl alcohol,

cyclohexane,

n-butane

gasoline,

n-hexane

acetaldehyde

hydrogen

ethine

(acetylene)

sulphide of carbon

IIA IIB IIC

Explosion groups

Permissible equipment groups

IIA, IIB, IIC IIB, IIC IIC

Marking

without

X

U

Conditions

operating equipment can be used

without restriction

special conditions of use

operating equipment with partial certificate,

CE-conformity is certified when it is installed

into a complete item of operating apparatus

Use of the operating equipment

Marking of electrical equipment for use in potentially explosive atmospheres

Classification

of hazardous

areas

Temporary behaviour

of explosive atmosphere

Flammable

materials

Equipment

group

as defined in

EN 60079-O

Symbol Flammable materials Marking in accordance with the equipment protection level Type of protection Protection principle Applications

all applications

control stations, motors,

fuses, switchgear,

power electronics

junction and

connection boxes,

enclosures, motors,

lights, terminals

junction and connection

boxes, enclosures, motors,

lights, switch and control

cabinets, plugs

measurement and

control technology,

automation technology,

sensors, actuators

switch and control

stations,

motors, analyzers,

computers

coils of motors or

relays,

solenoid valves,

connection systems

transformers, relays,

control stations,

magnetic contactors

capacitors, transformers,

relays

all applications

for zone 2

gases, vapours and dusts

gases and vapours (G)

gases and vapours (G)

dusts (D)

gases and vapours (G)

dusts (D)

gases and vapours (G)

dusts (D)

gases and vapours (G)

dusts (D)

gases and vapours (G)

gases and vapours (G)

gases and vapours (G)

-

propagation of an explosion

inside to the outside is

excluded

avoidance of arcs, sparks and

excessive temperature

explosive dust atmosphere

keep at a distance from the

ignition source

limitation of energy as well

as arcs and temperature

explosive atmosphere

keep at a distance

from the ignition source

explosive atmosphere

keep at a distance

from the ignition source

explosive atmosphere

keep at a distance

from the ignition source

an propagation

of an explosion

inside to the outside

is excluded

all protection principles

for zone 2

general requirements

flameproof enclosure

increased safety

protection by enclosure

intrinsic safety

pressurization

encapsulation

oil immersion

powder filling

n type of protection

-

-

Ex ta

Ex ia

Ex ia

Ex ma

Ex ma

-

-

-

IEC EN 60079-1

IEC EN 60079-7

IEC EN 61241-1

IEC EN 60079-31

IEC EN 60079-11

IEC EN 60079-25**

IEC EN 60079-27***

IEC EN 61241-11

IEC EN 60079-2

IEC EN 61241-4

IEC EN 60079-18

IEC EN 61241-18

IEC EN 60079-6

IEC EN 60079-5

IEC EN 60079-15

-

a = very high level of protection

IEC EN 60079-0

Norm

-

-

-

-

Ex tc

Ex ic

Ex ic

-

-

Ex nA Ex nAc*

Ex nC Ex nCc*

Ex nR Ex nRc*

Ex nL Ex nLc*

-

-

Ex pz Ex pzc*

Ex pc

c = enhanced level of protection

-

Ex d

Ex db*

Ex e

Ex eb*

Ex tb

Ex ib

Ex ib

Ex mb

Ex mb

Ex o

Ex ob*

Ex q

Ex qb*

-

Ex px Ex pxb*

Ex py Ex pyb*

Ex pb

b = high level of protection

Official notified bodies

Code

number

Notified

Bodies

Country

0589

0158

0600

0637

0344

0081

0102

0518

0044

BAM

DEKRA

EXAM

EECS

(BASEEFA)

IBExU

KEMA

LCIE

PTB

SIRA

TV

(NORD CERT)

Germany

Germany

UK

Germany

Netherlands

France

Germany

UK

Germany

Group

as defined in

directive 94/9/EC

Zone 0, zone 20 Zone 1, zone 21 Zone 2, zone 22

Application in hazardous area

Protection principle/types of protection

11 ATEX 1234 Ex tb IIIB T120 C Db X NB 0044 II 2D

11 ATEX 1234 Ex de T4 Gb X NB 0044 II 2G IIB

Dust

Gas

BARTEC GmbH Max-Eyth-Strae 16 97980 Bad Mergentheim Phone: +49 7931 597-0 info@bartec.de www.bartec-group.com

B

A

R

T

E

C

W

e

r

b

e

A

g

e

n

t

u

r

-

0

6

/

1

1

Anda mungkin juga menyukai

- Intertek Poster A1 (HazLoc - Guide) - 0Dokumen1 halamanIntertek Poster A1 (HazLoc - Guide) - 0Antonio FilipeBelum ada peringkat

- Ex Poster SVDokumen1 halamanEx Poster SVsaiyedasadBelum ada peringkat

- Explosion Protection Wall Chart BASEEFADokumen1 halamanExplosion Protection Wall Chart BASEEFAweby98Belum ada peringkat

- Haz Area ChatDokumen1 halamanHaz Area Chatmaniking1Belum ada peringkat

- Zone Classification ChartDokumen1 halamanZone Classification ChartMaahiBelum ada peringkat

- Hazardous Area ClassificationsDokumen1 halamanHazardous Area ClassificationsAndrew Bull100% (2)

- Hazardous PosterDokumen1 halamanHazardous PosterMrudang MehtaBelum ada peringkat

- Atex Marking and Meaning For HazardousDokumen1 halamanAtex Marking and Meaning For Hazardousact_rahul53Belum ada peringkat

- ExtronicsWallchart 160708Dokumen1 halamanExtronicsWallchart 160708Shyam VarunBelum ada peringkat

- Lcie Bureau Veritas Atex Poster PDFDokumen1 halamanLcie Bureau Veritas Atex Poster PDFAncaOniscuBelum ada peringkat

- Poster Explosive CEDokumen1 halamanPoster Explosive CENico ArdeleanBelum ada peringkat

- Nfpa PurgeDokumen2 halamanNfpa PurgeZeeshan Anwar0% (1)

- UK ATEX IECEx Sensor CatalogueDokumen26 halamanUK ATEX IECEx Sensor Cataloguedj22500Belum ada peringkat

- CMP IECEx ATEX 01Dokumen10 halamanCMP IECEx ATEX 01rocket-vtBelum ada peringkat

- New Atex Directive: Lars EkströmDokumen23 halamanNew Atex Directive: Lars EkströmvalimironescuBelum ada peringkat

- 02 - BMS DEMO Help File Siemens PDFDokumen11 halaman02 - BMS DEMO Help File Siemens PDFSTABBelum ada peringkat

- Introduction To HacDokumen51 halamanIntroduction To HacYuliyaBelum ada peringkat

- Hazardous Area Classification & Intrinsic SafetyDokumen35 halamanHazardous Area Classification & Intrinsic SafetyMukesh C ChavanBelum ada peringkat

- DCS Grounding - LinkedInDokumen8 halamanDCS Grounding - LinkedInmaryamBelum ada peringkat

- What Is ATEXDokumen21 halamanWhat Is ATEXBymohamedfb DrillerBelum ada peringkat

- ATEX Advisory - Simple ApparatusDokumen2 halamanATEX Advisory - Simple ApparatusPeter AllisonBelum ada peringkat

- Condensate Pot Dimensions - Saton InstrumentsDokumen1 halamanCondensate Pot Dimensions - Saton InstrumentsnasirmuzaffarBelum ada peringkat

- ARC130 170 ManualDokumen28 halamanARC130 170 ManualPhilip Rosser100% (2)

- Engineering Standard: IPS-E-EL-110Dokumen105 halamanEngineering Standard: IPS-E-EL-110Kumar sssssBelum ada peringkat

- JTL Assessment Practice PaperDokumen20 halamanJTL Assessment Practice PaperKeystoneworks4me100% (1)

- Zincanode 620 Voc v1 Jan 2018Dokumen2 halamanZincanode 620 Voc v1 Jan 2018Moin AltafBelum ada peringkat

- Intertek Explosionproof Vs Flameproof IEC 60079 1 and UL 1203 PDFDokumen10 halamanIntertek Explosionproof Vs Flameproof IEC 60079 1 and UL 1203 PDFchertanBelum ada peringkat

- Loop Testing - MCCDokumen1 halamanLoop Testing - MCCMiko QuijanoBelum ada peringkat

- Epa 40 CFR 112Dokumen32 halamanEpa 40 CFR 112Vlad420Belum ada peringkat

- Scba & FMS PDFDokumen74 halamanScba & FMS PDFHamid MasoodBelum ada peringkat

- Grundlagen Explosionsschutz Eng WebDokumen48 halamanGrundlagen Explosionsschutz Eng WebsllazicBelum ada peringkat

- Po Ex en 170413 WebDokumen1 halamanPo Ex en 170413 Webswordleee swordBelum ada peringkat

- Pressure Gauge: Max Norm Min UnitsDokumen1 halamanPressure Gauge: Max Norm Min Unitssairam2234Belum ada peringkat

- Tamil Nadu Factories Rules 1950Dokumen18 halamanTamil Nadu Factories Rules 1950Sindarth RaveendrakrishnanBelum ada peringkat

- Sop GSSDokumen3 halamanSop GSSArun MurugaiyanBelum ada peringkat

- Pocket ManualDokumen21 halamanPocket Manualakhilesh_kabra17100% (1)

- H-S81-HS EN54 Manual June 2014 LS10114Dokumen190 halamanH-S81-HS EN54 Manual June 2014 LS10114Tanesan WyotBelum ada peringkat

- Hazardous Area Classification PDFDokumen23 halamanHazardous Area Classification PDFlagm54100% (1)

- Iec Hazardous Locations Certification DocumentsDokumen2 halamanIec Hazardous Locations Certification DocumentsbubuluqBelum ada peringkat

- Hazardous Areas Tech GuideDokumen70 halamanHazardous Areas Tech GuideMadhan Kumar100% (1)

- Safety StudiesDokumen37 halamanSafety StudiesJagan Bose100% (1)

- N176 Iso CD 5149 4 2006 PDFDokumen25 halamanN176 Iso CD 5149 4 2006 PDFniceday9_4100% (1)

- ATEX-affisch MaluxDokumen1 halamanATEX-affisch MaluxHomer SilvaBelum ada peringkat

- ISO Index Welding Standards - 1Dokumen1 halamanISO Index Welding Standards - 1Waqas WaqasBelum ada peringkat

- Seminar (PLC)Dokumen29 halamanSeminar (PLC)upendra35Belum ada peringkat

- Atex eDokumen1 halamanAtex egtomyBelum ada peringkat

- Hazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFDokumen1 halamanHazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFAgustinus Made Theo Dwijaya100% (4)

- Hazardous AREA ClassificationDokumen10 halamanHazardous AREA Classificationfarzam100% (1)

- Normes-Ex Poster EngDokumen1 halamanNormes-Ex Poster Engbuco2312Belum ada peringkat

- Hazardous Area Chart - BartecDokumen1 halamanHazardous Area Chart - BartecPutraSumatera100% (1)

- Ingress SafetyDokumen1 halamanIngress Safetyjohn_tigerBelum ada peringkat

- Your Safety - Our Reality: Electrical EquipmentDokumen1 halamanYour Safety - Our Reality: Electrical EquipmentHimanshu ChichraBelum ada peringkat

- At ExDokumen2 halamanAt ExMoustafa Ibrahim YehyaBelum ada peringkat

- Basics of Explosion Protection - IecDokumen4 halamanBasics of Explosion Protection - IecbenounaomarBelum ada peringkat

- IECDokumen1 halamanIECJay Jay100% (1)

- Equipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonDokumen1 halamanEquipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonBalan PalaniappanBelum ada peringkat

- Hazardous Area SH CourseDokumen22 halamanHazardous Area SH CourseafnakshBelum ada peringkat

- 986 07 1006 031 - ManDokumen8 halaman986 07 1006 031 - ManFernando Ledesma RamirezBelum ada peringkat

- Instruction Manual (Atex) : Bexbgl1D Flameproof Led Beacon For Use in Flammable Gas and Dust AtmospheresDokumen4 halamanInstruction Manual (Atex) : Bexbgl1D Flameproof Led Beacon For Use in Flammable Gas and Dust Atmospheresgelustan2006Belum ada peringkat

- ATEX Poster ENG PDFDokumen1 halamanATEX Poster ENG PDFCvitaCvitićBelum ada peringkat

- Advanced Engineered Systems - Fall ProtectionDokumen17 halamanAdvanced Engineered Systems - Fall ProtectionDen Andri NchuBelum ada peringkat

- Scaffolding WorkDokumen62 halamanScaffolding WorkDen Andri NchuBelum ada peringkat

- CoP For Metal Scaffolding SafetyDokumen85 halamanCoP For Metal Scaffolding SafetyChenthuran VilvarajahBelum ada peringkat

- Fall Protection For ToolsDokumen35 halamanFall Protection For ToolsDen Andri NchuBelum ada peringkat

- TomokoFuse HomeDecoratingOrigami PDFDokumen129 halamanTomokoFuse HomeDecoratingOrigami PDFDen Andri NchuBelum ada peringkat

- Book - Tomoko Fuse Kusudama PDFDokumen54 halamanBook - Tomoko Fuse Kusudama PDFMario YepesBelum ada peringkat

- Grounding and BondingDokumen47 halamanGrounding and BondingCharles BenwariBelum ada peringkat

- Origami Boxes by Tomoko Fuse PDFDokumen71 halamanOrigami Boxes by Tomoko Fuse PDFDen Andri NchuBelum ada peringkat

- The Mask Origami by Tomoko Fuse PDFDokumen172 halamanThe Mask Origami by Tomoko Fuse PDFDen Andri NchuBelum ada peringkat

- Process Plant Construction by Patrick J. NobleDokumen228 halamanProcess Plant Construction by Patrick J. NobleDen Andri NchuBelum ada peringkat

- IEC NEC ComparationDokumen18 halamanIEC NEC ComparationDen Andri NchuBelum ada peringkat

- IEEE STD 1050-1996 Guide For Instrumentation Control Equipment Grounding in Generating Stations PDFDokumen81 halamanIEEE STD 1050-1996 Guide For Instrumentation Control Equipment Grounding in Generating Stations PDFRandall Rodas R0% (1)

- Dimension Ing of CablesDokumen241 halamanDimension Ing of CablesAlberto VillegasBelum ada peringkat

- MTL Fieldbus DemystifiedDokumen18 halamanMTL Fieldbus DemystifiedDen Andri NchuBelum ada peringkat

- AV 2155 2185 SCHDokumen12 halamanAV 2155 2185 SCHlondon335Belum ada peringkat

- Panasonic Th-42pd50u Chassis Gp8duDokumen147 halamanPanasonic Th-42pd50u Chassis Gp8du02ury05Belum ada peringkat

- Metal-Air and Metal-Sulfur Batteries Fundamentals and Applications by Neburchilov, Vladimir Zhang, JiujunDokumen210 halamanMetal-Air and Metal-Sulfur Batteries Fundamentals and Applications by Neburchilov, Vladimir Zhang, JiujunjosephyfuBelum ada peringkat

- PomonatestcatalogDokumen100 halamanPomonatestcatalogvemuri_sriBelum ada peringkat

- v90 Operating InstructionsDokumen349 halamanv90 Operating InstructionsTodor NakovBelum ada peringkat

- CW-712 Smart Li-Ion Battery PackDokumen8 halamanCW-712 Smart Li-Ion Battery PackBradBelum ada peringkat

- Powerflex 750-Series Ac Drives: Programming ManualDokumen548 halamanPowerflex 750-Series Ac Drives: Programming ManualJose GimenezBelum ada peringkat

- WPS-Nozzle With Reinforcement Pad (CS-CS) .Dokumen1 halamanWPS-Nozzle With Reinforcement Pad (CS-CS) .suria qaqcBelum ada peringkat

- Projects Type FormatDokumen10 halamanProjects Type FormatBryan AvilaBelum ada peringkat

- 3d TSV Inductor - Mems RFDokumen4 halaman3d TSV Inductor - Mems RFSaikat MondalBelum ada peringkat

- 2021 - Power System Stability Issues & Classifications and Research Prospects in The Context of High-Penetration of Renewables and Power ElectronicsDokumen16 halaman2021 - Power System Stability Issues & Classifications and Research Prospects in The Context of High-Penetration of Renewables and Power ElectronicsJULIÁN ESTIBEN MESA CALLEBelum ada peringkat

- Arduino Based Third Eye For Blind PeopleDokumen7 halamanArduino Based Third Eye For Blind PeopleIJRASETPublicationsBelum ada peringkat

- Electrical DataDokumen43 halamanElectrical DataSidra QasimBelum ada peringkat

- 400 Volt ModelDokumen40 halaman400 Volt ModelTran Anh LeBelum ada peringkat

- Alternating Current - Definition, Working Principle, AC GeneratorDokumen22 halamanAlternating Current - Definition, Working Principle, AC GeneratorJatin VermaBelum ada peringkat

- Description Features: Ltc4100 Smart Battery Charger ControllerDokumen30 halamanDescription Features: Ltc4100 Smart Battery Charger ControllerAlexander VargasBelum ada peringkat

- Operation: Operation P846/En Op/A11 Micom P846Dokumen28 halamanOperation: Operation P846/En Op/A11 Micom P846kessir taouilBelum ada peringkat

- V3000Dokumen8 halamanV3000ranaway1Belum ada peringkat

- 2A Transformer Technical SpecificationDokumen9 halaman2A Transformer Technical SpecificationPraveen KumarBelum ada peringkat

- Morley Fire Panels Installation ManualDokumen55 halamanMorley Fire Panels Installation Manualtpqnhat100% (1)

- 08121-2901-01-Final-Report-Phase2 VFD CABLEDokumen353 halaman08121-2901-01-Final-Report-Phase2 VFD CABLEIsmael Ochoa JimenezBelum ada peringkat

- York VRF Odu - Jvor (080-540) - Service Manual - 1778 201604Dokumen231 halamanYork VRF Odu - Jvor (080-540) - Service Manual - 1778 201604SIDNEY DA CUNHA NEVES88% (8)

- BTB08 400CDokumen10 halamanBTB08 400CAlan AldereteBelum ada peringkat

- 12 Medical and Non MedicalDokumen21 halaman12 Medical and Non MedicalDevice LocatorBelum ada peringkat

- Remote and Automatic ControlDokumen11 halamanRemote and Automatic ControldenramrBelum ada peringkat

- Engineering Chemistry (BCHY101L) : Energy DevicesDokumen84 halamanEngineering Chemistry (BCHY101L) : Energy DevicesDeepali Mishra 21BCE3440Belum ada peringkat

- Product Data Sheet: Circuit Breaker Compact Ns800H, 70 Ka at 415 Vac, Micrologic 2.0 Trip Unit, 800 A, Fixed, 4 Poles 4DDokumen3 halamanProduct Data Sheet: Circuit Breaker Compact Ns800H, 70 Ka at 415 Vac, Micrologic 2.0 Trip Unit, 800 A, Fixed, 4 Poles 4DsoyalBelum ada peringkat

- Narayana: Common Practice Test-7Dokumen13 halamanNarayana: Common Practice Test-7AshutoshBelum ada peringkat

- Unit 3 Z BusDokumen5 halamanUnit 3 Z BusJJ KBelum ada peringkat