The Original Attachment: Paper One

Diunggah oleh

Adil HasanovJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

The Original Attachment: Paper One

Diunggah oleh

Adil HasanovHak Cipta:

Format Tersedia

Download the original attachment

ANSWERS

PAPER ONE

1. d 2. d 3. b 4. c 5. c 6. b 7. c

8. a 9. c 10. a 11. d 12. a 13. b 14. b

15. c 16. a 17. a 18. b 19. a 20. d 21. c

22. a 23. d 24. c 25. d 26. d 27. c 28. b

29. b 30. b

PAPER TWO

1. b 2. a 3. b 4. d 5. c 6. c 7. d

8. d 9. d 10. d 11. b 12. b 13. c 14. b

15. c 16. b 17. b 18. c 19. b 20. c 21. b

22. d 23. c 24. b 25. c 26. c 27. b 28. b

29. d 30. b

PAPER THREE

1. d 2. a 3. d 4. d 5. d 6. c 7. b

8. d 9. d 10. d 11. d 12. d 13. b 14. d

15. d 16. d 17. b 18. d 19. a 20. d 21. d

22. d 23. d 24. c 25. d 26. d 27. d 28. b

29. c 30. b

PAPER FOUR

1. c 2. b 3. c 4. b 5. a 6. a 7. b

8. b 9. a 10. a 11. b 12. d 13. d 14. c

15. c 16. b 17. c 18. a 19. c 20. a 21. c

22. c 23. d 24. b 25. c 26. c 27. a 28. d

29. a 30. b

PAPER FIVE

1. a 2. b 3. c 4. d 5. b 6. d 7. b

8. c 9. d 10. d 11. d 12. d 13. d 14. d

15. a 16. a 17. d 18. d 19. d 20. c 21. b

22. a 23. b 24. b 25. a 26. b 27. b

28. a 29. b 30. b

PAPER SIX

1. b 2. c 3. b 4. d 5. c 6. b 7. d

8. c 9. b 10. d 11. d 12. c 13. c 14. c

15. a 16. b 17. d 18. a 19. c 20. c 21. c

22. a 23. b 24. c 25. b 26. a 27. a 28. b

29. d 30. a

PAPER SEVEN

1. c 2. d 3. a 4. c 5. c 6. d 7. b

8. b 9. b 10. a 11. d 12. d 13. b 14. a

15. b 16. a 17. c 18. a 19. c 20. c 21. d

22. a 23. a 24. a 25. d 26. c 27. c 28. a

29. a 30. b

PROPERTIES OF MATERIALS

1. Tensile Strengt. 2. !"ctilit#. 3. T$"gness. 4. %ardness.

5.&rittleness. 6. Elasticit#. 7. 'ncrease. 8. !"ctilit#.

9.0.2( 10. )rac*ing. 11. 'ncrease. 12. '+,"rities.

13. S+aller-Tinner. 14. )$rr$si$n. 15.'ncrease....!ecrease

16..artensite. 17./earlite. 18. )$$ling....)arb$n.

19.Te+,ering. 20. %ardness....T$"gness.

Download the original attachment

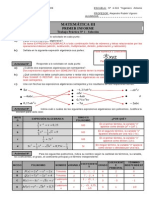

MULTICHOICE PAPER ONE

1. Wen 0#dr$gen c$ntr$l1 is s,eci2ied 2$r a +an"al +etal arc 3elding ,r$4ect te

electr$de 3$"ld n$r+all# be5

a. )ell"l$se b. 'r$n $6ide c. Acid d. &asic

2. 7$" 3$"ld certainl# rec$gnise a #dr$gen c$ntr$lled 2l"6 c$8ered electr$de 2r$+ its5

a. )$l$"r b. 9engt c. Trade na+e d. &S639-AWS c$de letter

3. Wen +an"al +etal arc 3elding is being carried $"t $n an $,en c$nstr"cti$n site:

3ic gr$", $2 3elders are +$st li*el# t$ re;"ire c$ntin"$"s +$nit$ring<

a. )$ncrete s"ttering 3elding tea+s

b. /i,e 3elding tea+s

c. /late 3elders

d. /lant +aintenance 3elders

4. 7$" n$tice +an"al +etal arc electr$des: stri,,ed $2 2l"6: are being "sed as 2iller 3ire

2$r T'= 3elding. 7$" 3$"ld $b4ect beca"se5

a. 't is t$$ e6,ensi8e b. Te 3ire 3$"ld be t$$ tic*

c. Te +etal c$+,$siti$n +a# be 3r$ng

d. Te 3ire is t$$ s$rt

5. Wen $,en site 3$r*ing: seri$"s ,$r$sit# in +etal arc 3elds is br$"gt t$ #$"r

attenti$n. Wat 3$"ld #$" in8estigate<

a. Electr$de t#,e b. /$3er ,lant t#,e

c. Electr$de st$rage

d. !a# te+,erat"re

6. Te steel c$+,$siti$n in a str"ct"ral c$ntract is canged 2r$+ 0.15( carb$n 0.6(

+anganese: t$ 0.2( carb$n 1.2( +anganese. Tis +igt in2l"ence te incidence $25

a. /$r$sit#

b. )rac*ing in te 3eld area

c. >nderc"t 2$r 2illet 3elds

d. 9ac* $2 2"si$n de2ects

7. ?ne $2 te 2$ll$3ing all$#s is n$n@+agnetic @ 3ic<

a. 4.0( cr$+i"+ +$l#bden"+

b. 12.0( cr$+i"+

c. A"stenitic stainless steel

d. 9.0( nic*el steel

8. Wen T'= 3elding a"stenitic stainless steel ,i,e: arg$n gas bac*ing is called 2$r. Tis

is t$5

a. /re8ent $6idati$n

b. /re8ent "nder bead crac*ing

c. /re8ent ,$r$sit# d. )$ntr$l te ,enetrati$n bead sa,e

9. /re@eating a carb$n steel +an"al +etal arc 3elding is carried $"t t$ +ini+iAe te ris*

$25

a. Scattered ,$r$sit# b. W$r+ $le ,$r$sit#

c. /arent +etal crac*ing d. 9ac* $2 ,enetrati$n

10. 'n >B ,ractice: &S499 s,eci2ies tat te dra3ing di+ensi$n ;"$ted 2$r a 2illet 3eld is

te5

a. 9eg lengt b. Tr$at tic*ness c. Weld 3idt

d. Act"al tr$at tic*ness

11. C$r $,en site +an"al +etal 3elding te 2$ll$3ing e;"i,+ent is a8ailable. Wic

3$"ld #$"< )$$se 2$r sa2e site 3$r*ing<

a. Single $,erat$r trans2$r+er

b. ."lti $,erat$r trans2$r+ers

c. A)-!) c$+,$site ,$3er "nit

d. !iesel engine dri8en +$t$r generat$r

12. '2 s"b+erged arc 3elding is "sed t$ +a*e b"tt 3elds: 3ic 3$"ld #$" be +$st

critical $2<

a. Te r$$t ga, t$lerance

b. Te angle $2 ,re,arati$n

c. Te r$$t 2aces 3idt

d. Te gas c"t 2inis

13. !"ring )?2 3elding: te arc lengt is +$st li*el# t$ be a22ected b#5

a. Te 3ire dia+eter

b. Te c"rrent ret"rn c$nnecti$ns

c. Te gas 2l$3 rate d. Te t$rc t$ 3$r* angle

14. /reeating 2$r arc 3elding a,,lies t$5

a. Asse+bl# 3elding $nl#

b. Asse+bl# and tac* 3elding

c. D$ints $8er 25 ++ tic* $nl# d. )r"ci2$r+ 3elds $nl#

15. Wic $ne $2 te 2$ll$3ing state+ents is c$rrect<

a. /reeating increases ardness

b. /reeating increases c$$ling

c. /reeating increases dil"ti$n

d. /reeating increases srin*age stress

16. 7$" see a 3elder "sing an $6#@acet#lene 2la+e 3it a l$ng 2eatered inner c$ne.

Wat 3$"ld be te e22ect $2 tis $n carb$n steel<

a. Te 3eld 3$"ld be ard and brittle

b. Te 3eld c$"ld be t$$ s$2t

c. Tere 3ill be n$ e22ect $n te 3eld

d. Te 3eld 3ill a8e "nderc"t

17. A 3elder ;"ali2icati$n test is t$ 8eri2#5

a. Te s*ill $2 te 3elder

b. Te ;"alit# $2 te +aterials

c. Te n$n@destr"cti8e test ,r$ced"res

d. Te +an"2act"ring +et$ds

18. A 2abricating ,r$ced"re calls 2$r 2illet 3elds t$ be Eblended inE b# grinding. Tis

in2l"ences5

a. %AF. )rac*ing

b. Catig"e li2e

c. Resid"al stress

d. 7ield strengt

19. &end test s,eci+ens a8e been ta*en 2r$+ a 25 ++ tic* carb$n steel b"tt 3eld.

Wic 3$"ld s$3 lac* $2 inter@r"n 2"si$n<

a. Side bend b. R$$t bend c. Cace bend d. ="ided bend

20. 9a+ellar tearing as $cc"rred in a steel 2abricati$n. &EC?RE 3elding c$"ld it a8e

been 2$"nd b#5

a. G@ra# e6a+inati$n b. !#e ,enetrant c. >ltras$nic e6a+inati$n

d. 't 3$"ld n$t a8e been 2$"nd b# an# ins,ecti$n +et$d

21. 7$" are t$ $8ersee te arc 3elding $2 s$+e +acine 2ittings and 2ind tat te# are

cad+i"+ ,lated. W$"ld #$"5

a. /er+it it t$ ,r$ceed

b. /er+it it t$ ,r$ceed 3it 2"+e e6tracti$n

c. St$, te $,erati$n at $nce

d. Ad8ise te 3elder t$ drin* +il* and ,r$ceed

22. ?ne $2 te reas$ns 2$r e6cl"ding #dr$gen 2r$+ te 3eld +etal is t$ ,re8ent te 3eld

2r$+5

a. )rac*ing b. )$$ling sl$3l# c. )$$ling ;"ic*l#

d. E6,anding

23. Wen a +etal regains its $riginal sa,e 3en a stress acting ",$n it is re+$8ed: te

+etal is said t$ a8e5

a. !"ctilit# b. /lasticit# c. .alleabilit# d. Elasticit#

24. /r$$2 stress is "sed 3en n$n@2err$"s +etals are "nderg$ing tensile tests t$ deter+ine

te e;"i8alent5

a. Tenacit# b. Elasticit# c. 7ield strengt d. Tensile strengt

25. T$ test a c$+,$nent 2$r 8ibrati$nal l$ading: a s"itable +ecanical test 3$"ld be5

a. '+,act b. Tensile c. )$+,ressi8e d. Catig"e

26. Te +ain reas$n 2$r ,re@eating +edi"+ and ig carb$n steels be2$re c"tting b#

$6#@2"el gas tecni;"e is t$5

a. '+,r$8e te ;"alit# $2 te c"t

b. 'ncrease te c"tting s,eed

c. Re2ine te grain str"ct"re

d. /re8ent ardening and crac*ing

27. ?ne ,"r,$se $2 a +icr$sc$,ic e6a+inati$n $2 a 3eld is t$ establis te5

a. Strengt $2 te 3eld b. N"+ber $2 all$#ing ele+ents

c. =rain siAe d. N"+ber $2 r"ns "sed

28. Te ,red$+inant str"ct"re $2 an #,er@e"tect$id steel tat as been ;"enced at

ab$8e its ",,er critical ,$int 3ill be5

a. A"stenite b. .artensite c. Tr$$stite d. S$rbite

29. Wen 3eld +etal re2ine+ent ta*es ,lace in a +"lti@r"n de,$sit: it is *n$3n b# te

ter+5

a. Weld annealing b. Weld re2ining c. Weld n$r+aliAing d. Weld recr#stallisati$n

30. ?ne ad8antage $2 +etal gas arc sielded 3elding is5

a. )an be "sed in dra"gt# l$cati$ns 3it$"t ,r$tecti$n

b. /r$d"ces a de,$sit l$3 in #dr$gen c$ntent

c. An# 3elding ,$siti$n can be 3elded 3it s,ra# trans2er

d. Cine s,atter at n$AAle restricting gas 2l$3

MULTICHOICE PAPER TWO

1. &S499 c$++"nicates b# te "se $2 s#+b$ls te t#,e $2 4$int ,re,arati$n t$ be "sed.

Wic $2 te 2$ll$3ing s#+b$ls indicates te de,t $2 3eld ,enetrati$n re;"ired $n te

4$int<

2. Wic $2 te 2$ll$3ing s#+b$ls 3$"ld indicate tat a 3eld as t$ be 2inised $n te

E$terE side $2 te 3eld<

3. Te "se $2 2l"6 3it gas sielded +etal arc 3elding all$3s5

a. Seet +etal t$ be 3elded

b. A stable arc 3en "sing ig c"rrent densities

c. Al"+ini"+ t$ be 3elded

d. 9ess dil"ti$n $2 te 3eld b# te ,arent +etal

4. 'n ..A 3elding 3at ,ara+eter is "sed 2$r c$ntr$l $2 ,enetrati$n int$ te base

+aterial<

a. H$ltage b. Welding s,eed c. 'r$n ,$3ders in te c$ating d. )"rrent

5. 'n te 3elding $2 a b"tt 4$int 2r$+ $ne side: te ,r$2ile $2 te r$$t bead is c$ntr$lled

b#5

a. R$$t 2ace b. &e8el angle c. R$$t ga, d. All $2 te ab$8e

6. Wat t#,e $2 ,$3er caracteristic is re;"ired 2$r +an"al 3elding<

a. )$nstant 8$ltage b. Clat caracteristic

c. !r$$,ing caracteristic d. !) generat$r

7. Wic $2 te 2$ll$3ing tests 3$"ld indicate te t$"gness $2 3eld +etal-,arent +etal @

%AF<

a. .acr$ b. Nic* brea* c. %ardness d. )ar,# 8ee n$tc

8. !egreasing c$+,$nents is essential 2$r ;"alit# 3elding b"t s$+e agents +a#5

a. )a"se c$rr$si$n ,r$ble+s b. =i8e $22 ,$sgene gas c. 9ea8e resid"es

d. All te ab$8e

9. Wic $2 te 2$ll$3ing ele+ents as te greater e22ect $n te ardenabilit# $2 a steel

,late<

a. .$l#bden"+ b. )r$+i"+ c. Titani"+ d. )arb$n

10. 'n .A=-)?2 3elding 3ic ,ara+eter gi8es te greatest c$ntr$l $2 3eld a,,earance

d"ring di, trans2er $r s$rt@circ"iting 3elding<

a. Wire stic*@$"t lengt b. A+,erage c. Wire 2eed s,eed d. 'nd"ctance

11. 'n ..A 3elding: te slags ,r$d"ced can be 8aried t$ s"it te 3elding ,$siti$n.

Wic t#,e $2 slag 3$"ld be re;"ired 2$r 3elding in te %H ,$siti$n<

a. Cl"id b. Hisc$"s c. Se+i 2l"id d. N$ne $2 te ab$8e

12. Te 3eld +etal de,$sit $2 ..A electr$des acie8es its +ecanical strengt tr$"g5

a. Te c$re 3ire b. Te 2l"6 c$ating c. 'r$n ,$3ders 3it te 2l"6 c$ating

d. N$ne $2 te ab$8e

13. Wat c$nstit"ent is needed in te c$ating $2 an electr$de t$ ,re8ent te 2$r+ati$n $2

,$r$sit# in te 3elding $2 a ri++ing steel<

a. 'r$n ,$3ders b. )alci"+ 2l"$ride c. Silic$n d. )alci"+ carb$nate

14. Welds +ade 3it ig eat in,"ts s$3 a red"cti$n in 3ic $2 te 2$ll$3ing

,r$,erties<

a. !"ctilit# b. T$"gness c. Catig"e strengt d. .ecanical strengt

15. 'n te 3elding $2 a"stenitic ,i,e3$r* te b$re is "s"all# ,"rged 3it arg$n t$5

a. /re8ent 2$r+ati$n $2 ,$r$sit# in te 3eld

b. /re8ent b"rn@tr$"g in te r$$t r"n

c. /re8ent $6idati$n $2 te r$$t bead

d. Eli+inate te 2$r+ati$n $2 #dr$gen

16. 'n G@ra# 3$r* te ;"alit# $2 te radi$gra,ic i+age is assessed b# te5

a. !ensit# $2 te 2il+ b. 'I' indicat$r

c. BHA a8ailable d. Stand@$22 distance

17. A steel described as IT 3ill a8e i+,r$8ed tensile ,r$,erties beca"se it as5

a. %ad c$ntr$l $2 ce+ical c$+,$siti$n

b. &een eat@treated

c. &een ;"alit# tested

d. &een 8ac""+ +elted

18. Wic $ne $2 te 2$ll$3ing t#,es $2 steel 3$"ld gi8e rise t$ te 2$r+ati$n $2 ,$r$sit#

3en a"t$gen$"sl# 3elded 3it an arc ,r$cess<

a. C"ll# *illed steel b. Se+i *illed steel

c. Ri++ing steel d. Cine grained steel

19. 'n s"b+erged arc 3elding te "se $2 e6cessi8el# ig 8$ltage 3$"ld res"lt in5

a. 'ns"22icient 2l"6 +elting b. E6cessi8e 2l"6 +elting

c. Slag re+$8al di22ic"lties d. S,atter

20. )ell"l$sic electr$des are $2ten "sed 3en 3elding te r$$t ,ass $2 ,i,es in te 2ield

beca"se5

a. %#dr$gen c$ntr$l is needed b. Tere are ir$n ,$3ders in te electr$de

c. %iger arc 8$ltage can be $btained d. S$rter arc lengt can be $btained

21. 'n te 3elding $2 a"stenitic stainless steels: te electr$de and ,late +aterial can be

,"rcased 3it l$3 carb$n c$ntents. Te reas$n 2$r tis is t$ ,re8ent5

a. )rac*ing in te eat a22ected A$ne

b. Te 2$r+ati$n $2 cr$+i"+ carbides

c. )rac*ing in te 3eld +etal

d. !ist$rti$n

22. S"b+erged arc 2l"6es can be s",,lied in t3$ 2$r+s. Tese are5

a. Sintered and agitated

b. Agitated and 2"sed

c. Sintered and aggl$+erated

d. C"sed and aggl$+erated

23. 'n a steel tat as i+,r$8ed cree, ,r$,erties at ele8ated te+,erat"res: 3ic $ne $2

te 2$ll$3ing ele+ents el,s in tis i+,r$8e+ent<

a. T"ngsten b. .anganese c. .$l#bden"+ d. )arb$n

24. Welding a steel ,late 3it a )E $2 0.45 3$"ld re;"ire ,reeating t$5

a. /re8ent te 2$r+ati$n $2 s"l,ides

b. /re8ent ardening in te %AF

c. /re8ent te 2$r+ati$n $2 carbides

d. T$ i+,r$8e +ecanical ,r$,erties in te 3eld

25. Wic $2 te 2$ll$3ing ,r$cesses "ses te E*e# $lingE s#ste+ $2 2"si$n<

a. Cricti$n 3elding b. !i22"si$n b$nding

c. Electr$n bea+ 3elding d. A"t$gen$"s T'= 3elding

26. 'n 2ricti$n 3elding te +etal at te inter2ace is in te5

a. 9i;"id state b. S$lid state c. /lastic state d. Elastic state

27. Welding ,r$ced"res +a# re;"ire 3elds t$ be de,$sited at a c$ntr$lled rate $2 eat

in,"t. %ig eat in,"ts 3$"ld5

a. %a8e ,$$r ,r$2ile

b. %a8e larger grain siAe

c. %a8e ig ardness in te %AF

d. %a8e l$3 el$ngati$n ,r$,erties

28. 'n a tensile test a brittle +aterial 3$"ld be indicated i2 te 2ract"re s"r2ace5

a. S$3s a red"cti$n in siAe

b. 's 2lat and 2eat"reless

c. &rea*s in te ,arent +aterial

d. &rea*s at 45J t$ te l$ad

29. Wat destr"cti8e test 3$"ld be re;"ired t$ ascertain te li*eli$$d $2 crac*ing in te

eat a22ected A$ne $2 a 3eld<

a. Nic* brea* b. Side bend test

c. )ar,# i+,act test d. .acr$ test

30. 'n s"b+erged arc 3elding e6cessi8e arc 8$ltage +a# ca"se5

a. E6cessi8e ,enetrati$n b. )ange in 3eld +etal c$+,$siti$n

c. Narr$3 3eld 3idt d. E6cessi8e bead ,r$2ile

.>9T')%?')E /A/ER T%REE

1. Te &ritis c$de 2$r 8is"al ins,ecti$n re;"ire+ents is5

a. &S 4872 b. &S 499 c. &S 4870 d. N$ne $2 te ab$8e

2. A c$de $2 ,ractice 2$r 8is"al ins,ecti$n s$"ld incl"de te 2$ll$3ing5

a. &e2$re: d"ring and a2ter 3elding acti8ities

b. &e2$re 3elding acti8ities $nl#

c. A2ter 3elding acti8ities $nl#

d. N$ne $2 te ab$8e

3. 'nc$+,lete r$$t ,enetrati$n in a b"tt 4$int c$"ld be ca"sed b#5

a. E6cessi8e r$$t 2ace 3idt b. E6cessi8e r$$t ga, siAe

c. 9$3 c"rrent setting

d. &$t A and )

4. 'nc$+,lete r$$t 2"si$n 3$"ld certainl# be ca"sed b#5

a. 9inear +isalign+ent b. 'nc$rrect tilt angle

c. !i22ering r$$t 2ace 3idts

d. All $2 te ab$8e

5. Wen 8is"all# ins,ecting a c$+,leted single 8ee b"tt 3eld ca,: #$" 3$"ld certainl#

assess5

a. )a, eigt b. T$e blend c. Weld 3idt d. All te ab$8e

6. 7$" n$tice a 8er# E8eedE ri,,le sa,e. Tis is +$st li*el# ca"sed b#5

a. /$$r c$ns"+able c$ice

b. Welding ,$siti$n

c. E6cessi8e tra8el s,eed

d. All te ab$8e

7. T$e blending is i+,$rtant as it +a# a22ect5

a. )$rr$si$n b. Catig"e li2e c. ?8erla, t#,e de2ects d. All te ab$8e

8. Slag incl"si$ns 3$"ld $cc"r 3it5

a. .an"al +etal arc b. .etal inert gas

c. S"b+erged arc 3elding d. &$t A and )

9. >nderc"t is ,rinci,all# ca"sed b#5

a. E6cessi8e a+,s b. E6cessi8e 8$lts c. E6cessi8e tra8el s,eed

d. All te ab$8e

10. >nderc"t is n$r+all# assessed b#5

a. 'ts de,t b. 'ts lengt c. 'tEs blending d. All te ab$8e

11. A 3elding ,r$ced"re is "se2"l t$5

a. =i8e in2$r+ati$n t$ te 3elder

b. =i8e in2$r+ati$n t$ te ins,ect$r

c. =i8e c$n2idence t$ a ,r$d"ct

d. All te ab$8e

12. An essential 8ariable +a#5

a. )ange te ,r$,erties $2 a 3eld b. 'n2l"ence te 8is"al acce,tabilit#

c. Re;"ire re@a,,r$8al $2 a 3eld ,r$ced"re d. All te ab$8e

13. A +agni2#ing glass +a# be "sed d"ring 8is"al ins,ecti$n: b"t &S 5289 states tat its

+agni2icati$n s$"ld be5

a. >, t$ 5

b. 2 t$ 2.5

c. 5 t$ 10

d. N$ne $2 te ab$8e

14. Wen 8is"all# ins,ecting a 2illet 3eld it 3$"ld n$r+all# be siAed b#5

a. Te leg lengts b. Te act"al tr$at tic*ness

c. Te design tr$at tic*ness

d. &$t A and )

15. A ,lanar de2ect is5

a. 'nc$+,lete 2"si$n de2ects b. Slag incl"si$n

c. 'nc$+,lete ,enetrati$n

d. &$t A and )

16. /enetrant ins,ecti$n and +agnetic ,article ins,ecti$n are +ainl# "sed5

a. T$ aid 8is"al ins,ecti$n

b. &eca"se te a,,licati$n sa#s s$

c. T$ c$n2ir+ 8is"al "ncertainties

d. All te ab$8e

17. !e2ects $"tside te li+its s,eci2ied in a standard s$"ld al3a#s be5

a. Re,aired b. Re,$rted t$ Ea seni$r ,ers$nE

c. Assessed al$ng 3it $ter de2ects

d. All te ab$8e

18. .'= 3elding tends t$ be s"sce,tible t$ lac* $2 2"si$n ,r$ble+s. Tis is beca"se $25

a. /$$r +aintenance $2 e;"i,+ent

b. 'nc$rrect settings

c. /$$r inter@r"n cleaning

d. All te ab$8e

19. ..A electr$des can be gr$",ed int$ tree +ain t#,es. Tese are5

a. &asic: cell"l$sic and r"tile b. Ne"tral: cell"l$sic and r"tile

c. &asic: cell"l$sic and ne"tral d. N$ne $2 te ab$8e

20. Te +ain ca"se $2 ,$r$sit# in 3elded 4$ints is5

a. /$$r access b. 9$ss $2 gas sield c. E!irt#E +aterials d. All te ab$8e

21. )rac*s in 3elds +a# be d"e t$5

a. S$lidi2icati$n ,r$ble+s b. %#dr$gen ,r$ble+s c. E6cessi8e stresses

d. All te ab$8e

22. A 3ea8e tecni;"e +a# gi8e rise t$5

a. &etter ,r$2iles b. '+,r$8ed t$e blending c. '+,r$8ed ri,,le sa,e

d. All te ab$8e

23. Wit re2erence t$ a r$$t ,enetrati$n bead #$" 3$"ld certainl# assess5

a. R$$t 2"si$n and ,enetrati$n b. R$$t c$nca8it#

c. &"rntr$"g d. All te ab$8e

24. 'n a 2atig"e 2ail"re te a,,earance $2 te 2ract"re s"r2ace is caracteristic. 't 3$"ld

be5

a. R$"g and t$rn b. E)e8r$nE@li*e c. S+$$t d. N$ne $2 te ab$8e

25. Stra# arcing +a# be regarded as a seri$"s de2ect beca"se5

a. 't +a# red"ce te tic*ness di+ensi$n $2 a c$+,$nent

b. 't +a# ca"se l$;"ati$n crac*s

c. 't +a# ca"se ard A$nes

d. All te ab$8e

26. ?8erla, in 3elds c$"ld be in2l"enced b#5

a. /$$r 3elding tecni;"e

b. Welding ,r$cess

c. Welding ,$siti$n

d. All te ab$8e

27. Cla+e c"t ,re,arati$ns +a#: d"ring 3elding: increase te li*eli$$d $25

a. )rac*ing b. .isalign+ent ,r$ble+s c. 'ncl"si$ns d. All te ab$8e

28. .acr$sc$,ic e6a+inati$n re;"ires an# s,eci+en t$ be ins,ected5

a. ?nce: a2ter etcing

b. T3ice: be2$re and a2ter etcing

c. >sing a +icr$sc$,e

d. N$ne $2 te ab$8e

29. Wic $2 te 2$ll$3ing +a# be classed as a +$re seri$"s de2ect5

a. Slag incl"si$ns

b. C"si$n de2ects Kinter@r"nL

c. C"si$n de2ects Ks"r2aceL

d. /$r$sit#

30. A c$de $2 ,ractice is5

a. A standard 2$r 3$r*+ansi, $nl#

b. A set $2 r"les 2$r +an"2act"ring a s,eci2ic ,r$d"ct

c. 9e8els $2 acce,tabilit# $2 a 3eld+ent

d. N$ne $2 te ab$8e

MULTICHOICE PAPER FOUR

1. .$8e+ent $2 te arc in ..A 3elding b# +agnetic 2$rces is called5

a. Arc de8iati$n

b. Arc +isalign+ent

c. Arc bl$3

d. Arc e#e

2. A +etall"rgical ,r$ble+ +$st ass$ciated 3it s"b+erged arc 3elding is5

a. %#dr$gen crac*ing in te %AF

b. S$lidi2icati$n crac*ing in te 3eld +etal

c. %#dr$gen crac*ing in te 3eld +etal

d. 9a+ellar tearing in te 3eld +etal

3. ?6# ,ress"re and n$AAle siAe in 2la+e c"tting 3$"ld in2l"ence5

a. Te te+,erat"re re;"ired 2$r c"t initiati$n

b. Te abilit# t$ c"t stainless steels

c. Te de,t $2 te c"t $btainable

d. N$ne $2 te ab$8e

4. Te +ain "sage $2 arc c"tting-g$"ging ,r$cesses is5

a. Te c"tting $2 single be8el ,re,arati$ns

b. Te re+$8al $2 de,$sited 3elds

c. Te c"tting $2 single > t#,e ,re,arati$ns

d. Te c"tting-g$"ging $2 n$n@2err$"s +aterials $nl#

5. Wic $2 te 2$ll$3ing ,r$cesses 4$ins +etals ,lasticall#<

a. Cricti$n 3elding b. Resistance 3elding

c. /las+a 3elding d. All te ab$8e

6. Wic electr$de classi2icati$n 3$"ld be rele8ant t$ AWS A5.1@81<

a. E 6013 b. E 5133 c. E 7018 M = d. Cleet3eld 5

7. Wic $2 te 2$ll$3ing c$atings is ass$ciated 3it st$8e 3elding<

a. R"tile b. )ell"l$sic c. &asic d. ?6idising

8. A c$++$n gas +i6t"re "sed in .'= 3elding nic*el all$#s: t$ c$+bine g$$d le8els $2

,enetrati$n 3it g$$d arc stabilit# 3$"ld be5

a. 100( )?2 b. 100( arg$n

c. 80( arg$n and 20( )?2

d. 98( arg$n and 2( $6#gen

9. Wic t#,e $2 SAW 2l"6 is +$re resistant t$ +$ist"re abs$r,ti$n<

a. C"sed b. Aggl$+erated c. &asic

d. All te ab$8e a8e te sa+e resistance

10. Te 2la+e te+,erat"re $2 $6#-acet#lene +i6t"re gas is gi8en as5

a. 3200J) b. 2300J) c. 5000J) d. N$ne $2 te ab$8e

11. A large grain str"ct"re in steels is said t$ ,r$d"ce5

a. 9$3 d"ctilit# 8al"es b. 9$3 2ract"re t$"gness 8al"es

c. %ig 2ract"re 8al"e 8al"es d. %ig tensile strengt

12. Te li*eli$$d $2 brittle 2ract"re in steels 3ill increase 3it5

a. A large grain 2$r+ati$n

b. A red"cti$n $2 in@ser8ice te+,erat"re t$ s"b Aer$ te+,erat"res

c. Cerritic rater tan a"stenitic steels

d. All te ab$8e

13. Re,air 3elding is $2ten +$re di22ic"lt tan ,r$d"cti$n 3elding d"e t$5

a. Te +aterial being ingrained 3it in@ser8ice c$nta+inants

b. Restricted access 3itin te re,air area

c. Te ,$ssible ,$siti$n $2 te 3eld re,air

d. All te ab$8e

14. %#dr$gen crac*ing in te 3eld +etal is li*el# 3en 3elding5

a. )arb$n +anganese steels

b. Stainless steels

c. .icr$ all$#ed steels K%S9AL

d. 9$3 carb$n steels

15. EN 288 standard 3$"ld re2er t$ 3ic $2 te 2$ll$3ing5

a. Welder a,,r$8al testing

b. Welding e;"i,+ent

c. Welding ,r$ced"re a,,r$8al

d. )$ns"+ables 2$r 3elding

16. /$r$sit# is ca"sed b#5

a. Entra,,ed slag in te s$lidi2#ing 3eld

b. Entra,,ed gas in te s$lidi2#ing 3eld

c. Entra,,ed +etallic incl"si$ns in te s$lidi2#ing 3eld

d. N$ne $2 te ab$8e

17. 'n a bend test te 2ace $2 te s,eci+en is in tensi$n and te r$$t is in c$+,ressi$n.

Wat t#,e $2 test is being carried $"t<

a. A r$$t bend test b. A side bend test c. A 2ace bend test

d. N$ne $2 te ab$8e

18. >ltras$nic testing is +$re ad8antage$"s in detecting 3ic $2 te 2$ll$3ing 3eld

i+,er2ecti$ns: $8er $ter N!T +et$ds<

a. 9ac* $2 side3all 2"si$n b. S"r2ace "nderc"t

c. 'nc$+,letel# 2illed gr$$8e

d. ?8erla,

19. Te+,ering is $2ten carried $"t t$ regain t$"gness a2ter 3ic $2 te 2$ll$3ing

,r$cesses<

a. Annealing b. N$r+aliAing c. %ardening d. Stress relie8ing

20. Te ,resence $2 ir$n s"l,ide in te 3eld +etal is +$st li*el# t$ ,r$d"ce 3ic $2 te

2$ll$3ing ",$n c$ntracti$n $2 te 3eld<

a. S$lidi2icati$n crac*ing b. %#dr$gen crac*ing c. 'ntergran"lar c$rr$si$n

d. Stress c$rr$si$n crac*ing

21. A"stenitic stainless steel electr$des are generall# s+aller in lengt tan +ild steel

electr$des beca"se5

a. %ig a+,erage is "sed b. Sel2 li2e 3ill be decreased

c. Teir electrical c$nd"cti8it# is less tan tat $2 steel

d. Te# are +$re e6,ensi8e

22. Te 8$ltage necessar# t$ +aintain an arc d"ring +etal arc 3elding is ter+ed5

a. .ains s",,l# 8$ltage b. Arc c"rrent c. Arc 8$ltage

d. ?,en circ"it 8$ltage

23. Wen ..A 3elding l$3 carb$n steel 3ic electr$de 3ill gi8e te greatest

de,$siti$n rate<

a. %#dr$gen c$ntr$lled b. )ell"l$sic c. R"tile d. 'r$n ,$3der

24. 'nerent recti2icati$n $2 te electrical $"t,"t is ,r$d"ced in te arc 3en T'= 3elding

"sing5

a. A) 3it a s",,ress$r

b. A) 3it$"t a s",,ress$r

c. !) 3it re8erse ,$larit#

d. !) 3it straigt ,$larit#

25. =a++a ra#s and G@ra#s are ,art $2 a 2a+il# $2 3a8es called5

a. Ac$"stic 3a8es b. 9igt 3a8es

c. Electr$+agnetic 3a8es d. Trans8erse 3a8es

26. A +eas"re $2 te acc"rac# $2 a radi$gra, as an N!T t$$l is gi8en b# its5

a. 'ntensit# b. !ensit# c. Sensiti8it# d. E6,$s"re

27. A s"r2ace brea*ing crac* 3ill be detected d"ring a +agnetic ,article ins,ecti$n i2 it

is5

a. At rigt angles t$ te lines $2 2l"6

b. /arallel t$ te lines $2 2l"6

c. At 25J t$ te lines $2 2l"6

d. All te ab$8e

28. Te ad8antage $2 "ltras$nic n$n@destr"cti8e testing 2$r te e6a+inati$n $2 3eld+ents

is5

a. 't can be "sed t$ l$cate 2la3s

b. 't can be "sed t$ siAe 2la3s

c. 't as a ig sensiti8it# t$ ,lanar 2la3s

d. All te ab$8e

29. >nder n$r+al c$ntract c$nditi$ns 3eld ,r$ced"re a,,r$8al tests 2$r ,i,e3$r* are5

a. .andat$r# b. !e,endant $n site and 3eater c$nditi$ns

c. !e,endant ",$n te c$ntract$rEs c$n2idence in is ,r$ced"res

d. ?nl# re;"ired 3en ..A 3elding is "sed

30. %#dr$gen c$ntr$lled electr$des 3ere de8el$,ed ,rinci,all# 2$r5

a. Te ,re8enti$n $2 ,$r$sit# b. Te ,re8enti$n $2 crac*ing

c. Te enance+ent $2 arc 8$ltage d. Teir ease $2 arc starting

MULTICHOICE PAPER FIVE

1. =enerall# te +$st s"itable +et$d $2 detecting lac* $2 side3all 2"si$n 3$"ld be5

a. >ltras$nic b. ./'. c. Radi$gra,#. d. /enetrant ins,ecti$n.

2. %$t s$rtness is a ter+ "sed t$ indicate5

a. 9a+ellar tearing. b. S$lidi2icati$n crac*ing. c. %#dr$gen crac*ing.

d. N$ne $2 te ab$8e.

3. )$balt as an is$t$,e 3$"ld generall# be "sed $n5

a. Tin +aterial. b. Tee 4$ints. c. /late tic*nesses greater tan 25 ++.

d. All te ab$8e.

4. 'n 3elding ,r$ced"re ter+s: a cange in essential 8ariable +eans5

a. Re@;"ali2icati$n $2 te 3eld ,r$ced"re.

b. /$ssible canges in te 3eldEs +icr$str"ct"re.

c. /$ssible canges in te +ecanical ,r$,erties.

d. All te ab$8e.

5. Weld s#+b$ls ,laced $n a d$tted line in acc$rdance 3it 'S? re;"ire+ents +eans5

a. Weld $n Earr$3E side. b. Weld $n E$terE side. c. Weld $n site. d. C"ll ,enetrati$n

re;"ired.

6. A 3elding ins,ect$rEs +ain attrib"tes incl"de5

a. Bn$3ledge and e6,erience. b. 9iterac#. c. %$nest# and integrit#.

d. All te ab$8e.

7. Tecnicall#: a c$de $2 ,ractice is5

a. A standard. b. A Eset $2 r"lesE 2$r te +an"2act"re $2 a ,r$d"ct.

c. Related t$ 3elder and 3eld ,r$ced"re a,,r$8al. d. All te ab$8e.

8. Te c$rrect ter+ 2$r Eca, eigtE is5

a. Rein2$rce+ent. b. )a, ,r$2ile eigt. c. E6cess 3eld +etal. d. All te ab$8e.

9. A tensile test 3ill assess5

a. '+,act 8al"es. b. Stress. c. Strain. d. &$t b and c.

10. Te i+,$rtant ,$int $2 ig te+,erat"re steels is tat5

a. Te# can 3itstand cree, 2ail"re.

b. Te# +a# s"22er re@eat crac*ing ,r$ble+s.

c. Te# +a# s"22er l$ss $2 t$"gness.

d. All te ab$8e.

11. An a"stenitic stainless steel +a# s"22er5

a. Weld deca#. b. Sensitisati$n. c. S$lidi2icati$n crac*ing. d. All te ab$8e.

12. )arb$n e;"i8alent 8al"es are "se2"l t$ deter+ine5

a. Weldabilit# as,ects. b. )rac* sensiti8it# as,ects. c. T#,ical +ecanical

,r$,erties.

d. All te ab$8e.

13. A basic electr$de 3$"ld n$r+all#5

a. %a8e s",eri$r +ecanical ,r$,erties. b. Re;"ire ba*ing be2$re "se.

c. N$t be "sed $n l$3 carb$n steels. d. &$t a and b.

14. Wen re2erring t$ T'= 3elding: te sielding gas c$"ld be5

a. Arg$n and #dr$gen. b. Arg$n and eli"+. c. Arg$n and nitr$gen.

d. All te ab$8e.

15. Wen re2erring t$ .'= 3elding: te sielding gas 3$"ld be5

a. Arg$n. b. Arg$n N 1( $6#gen. c. Arg$n N 20( carb$n di$6ide.

d. N$ne $2 te ab$8e.

16. S"b+erged arc "tilises5

a. !ee, ,enetrati$n caracteristic. b. %ig de,$siti$n rates $n !)N.

c. Clat K/AL 3elding $nl#. d. N$ne $2 te ab$8e.

17. >ltras$nics 3$"ld be ,re2erred $8er radi$gra,# d"e t$5

a. Abilit# t$ 2ind +$st de2ects. b. 9$3er s*ill re;"ire+ent. c. Abilit# t$ detect

la+inati$ns. d. &$t a and c.

18. Te +$st seri$"s de2ect t#,es are5

a. /lanar. b. )rac*s. c. 9ac* $2 2"si$n. d. All te ab$8e.

19. ..A 3elding $2 l$3 all$# steels is +$re li*el# t$ be ,er2$r+ed 3it5

a. R"tile electr$des. b. )ell"l$sic electr$des.

c. 'r$n ,$3der electr$des.

d. &asic #dr$gen c$ntr$lled electr$des.

20. Wic $2 te 2$ll$3ing de2ects is +$re c$++$n t$ 3elds de,$sited b# )?2 3elding

tan

3elds de,$sited b# ..A<

a. Slag incl"si$ns. b. E6cess ,enetrati$n. c. 9ac* $2 side3all 2"si$n.

d. T"ngsten incl"si$ns.

21. Wic de2ect 3$"ld #$" e6,ect t$ get in T'= 3elds in n$n@de$6idised steel<

a. >nderc"t. b. /$r$sit#. c. T"ngsten incl"si$ns. d. 9inear +isalign+ent.

22. Wic $2 te 2$ll$3ing can arise 2r$+ c$,,er incl"si$ns in a 2erritic steel 3eld<

a. Weld +etal crac*s. b. %AF crac*s. c. 9a+ellar tearing. d. /$r$sit#.

23. Wic $2 te 2$ll$3ing is li*el# t$ gi8e te igest i+,act strengt in 2erritic 3eld

+etal<

a. )ell"l$sic electr$des. b. S"b+erged arc 3it acid 2l"6. c. S,ra# trans2er )?2

3elding. d. &asic c$ated ..A electr$des.

24. 7$" s"s,ect tat 2erritic steel ,lates c$ntain crac*s in te ,re,ared edges. Wat N!T

+et$d 3$"ld #$" "se t$ cec* tis<

a. Radi$gra,#.

b. .agnetic ,article ins,ecti$n.

c. /enetrant ins,ecti$n.

d. >ltras$nic 2la3 detecti$n.

25. Wic $2 te 2$ll$3ing de2ects 3$"ld #$" n$t e6,ect t$ 2ind b# 8is"al ins,ecti$n $2

3elds<

a. 9inear slag incl"si$ns. b. >nderc"t. c. ?8erla,. d. 9inear +isalign+ent.

26. Stress relie8ing is n$t el,2"l in 3ic $2 te 2$ll$3ing cases<

a. '+,r$8ing resistance t$ stress c$rr$si$n crac*ing.

b. '+,r$8ing di+ensi$nal stabilit# a2ter +acining.

c. 9$3ering te ,ea* resid"al stress.

d. S$2tening te steel.

27. Wat is te +a6i+"+ ardness "s"all# rec$++ended 2$r te eat@a22ected A$ne $2 a

+edi"+ strengt 2erritic steel 3eld<

a. 100 !/ %8. b. 350 !/ %8. c. 500 !/ %8. d. 750 !/ %8.

28. Wat e22ect d$es +id tic*ness la+inati$ns in steel ,late n$r+all# a8e 3en te#

are

l$cated 3itin a 3eld eat a22ected A$ne<

a. )a"se la+ellar tearing. b. C"se t$geter t$ 2$r+ a b$nd. c. A22ect te 3eld

+etal c$+,$siti$n. d. )a"se internal tearing $n a +icr$ scale.

29. Te ,er+anent bac*ing +aterial 2$r ..A 3elding $2 l$3 carb$n steel s$"ld be

+ade

2r$+5

a. )$,,er. b. 9$3 carb$n steel. c. IT steel. d. )ast ir$n.

30. Te $8erall lengt $2 a ,i,eline can be a22ected b#5

a. Trans8erse srin*age. b. 9$ngit"dinal srin*age. c. Ang"lar srin*age.

d. )irc"+2erential srin*age.

MULTICHOICE PAPER SIX

1. Te 3eld di+ensi$n "sed t$ indicate te +ini+"+ strengt $2 a 2illet 3eld is5

a. 9eg lengt. b. Tr$at tic*ness. c. Widt $2 bead. d. 9engt $2 3eld ele+ent.

2. An electr$slag 3eld re;"ires 3at eat treat+ent t$ i+,r$8e te grain str"ct"re<

a. Annealing.b. Stress relie8ing. c. N$r+aliAing. d. I"enc and te+,ering.

3. Te +$st c$++$n t#,e $2 2ail"re ass$ciated 3it sar, 2illets: n$tces and "nderc"t is5

a. )r#stallisati$n. b. Catig"e. c. )$rr$si$n. d. &rittle 2ract"re.

4. Weld deca# in stainless steels can be a8$ided b#5

a. Stress relie8ing. b. Sl$3 c$$ling a2ter 3elding.

c. Additi$n $2 +$re +anganese t$ te steel.

d. Additi$n $2 titani"+ t$ te steel.

5. An e"tect$id +i6t"re in steel is5

a. A +i6t"re $2 2errite and a"stenite. b. A +i6t"re c$+,rising a s"bstit"tinal s$lid

s$l"ti$n. c. )alled ,earlite. d. )alled ledeb"rite.

6. 9$3 all$# steels a8ing a ig carb$n e;"i8alent be2$re 3elding 3ill re;"ire5

a. A red"cti$n in carb$n c$ntent. b. %ig ,re@eat te+,erat"res.

c. 9$3 ,re@eat te+,erat"res. d. N$ ,re@eating.

7. Te electr$des 2$r 3elding l$3 all$# steels s$"ld be5

a. >sed 3it a l$3 c"rrent 8al"e. b. ?ne siAe larger tan 2$r general ,"r,$se

electr$des.

c. >sed 2$r 3elding in te 2lat ,$siti$n $nl#.

d. %eated in a dr#ing $8en be2$re "se.

8. Te ,"r,$se $2 ,re@eating l$3 all$# steel ,i,es be2$re electric arc 3elding is t$5

a. Re2ine grain str"ct"re. b. Relie8e internal stress.

c. Retard ra,id c$$ling.

d. Reg"late e6cessi8e e6,ansi$n.

9. Welder ;"ali2icati$n tests are designed t$5

a. Test te c$rrectness $2 te 3elding ,r$ced"re.

b. Test te 3elderEs s*ill.

c. /r$8e te 3eldabilit# $2 te ,arent +aterial.

d. All te ab$8e.

10. 'n ,$siti$nal ..A 3elding $n ,i,e 3$r*: 3elders are a8ing di22ic"lt# in $btaining

g$$d

ca,,ing ,r$2iles 3en 3elding in te $8eread ,$siti$n. W$"ld #$"5

a. Ad8ise te+ t$ increase te c"rrent.

b. Ad8ise te+ t$ increase te 8$ltage.

c. As* 2$r a ne3 3elding tea+.

d. S"ggest te "se $2 a s+aller dia+eter electr$de.

11. 7$" a8e a +acr$ secti$n $2 a ETE b"tt 4$int tat s$3s a ste,@li*e de2ect l#ing $"tside

te

8isible %AF. Wat 3$"ld tis de2ect ,$ssibl# signi2#<

a. %AF crac*ing. b. T$e crac*ing. c. 9a+inati$n. d. 9a+ellar tearing.

12. Wic electr$de de,$sits 3eld +etal 3it te greatest d"ctilit# and resistance t$

crac*ing<

a. R"tile. b. )ell"l$sic. c. &asic. d. ?6idising.

13. Wic $ne $2 te 2$ll$3ing is n$t el,2"l in +ini+ising ang"lar dist$rti$n d"ring

3elding<

a. >se $2 d$"ble EHE 3eld ,re, "sing balanced 3elding tecni;"e.

b. /re@setting $2 3$r* ,iece. c. A,,l#ing ,$st 3eld eat s$a*.

d. )anging 2r$+ a single EHE ,re, 2$r tic* +aterial.

14. Arg$n ,"rging $n te r$$t side is necessar# in te T'= 3elding $2 stainless steel t$5

a. ?btain 2"ll ,enetrati$n. b. ?btain 2"ll 2"si$n.

c. A8$id ,$r$sit# in te r$$t. d. ?btain a satis2act$r# 3eld s"r2ace 2inis.

15. Wic $2 te 2$ll$3ing can arise 2r$+ c$,,er incl"si$ns in a +ild steel 3eld<

a. Weld +etal crac*s. b. %AF crac*s. c. 9ac* $2 2"si$n. d. /$r$sit#.

16. Stress relie2 is n$t el,2"l in 3ic $2 te 2$ll$3ing cases<

a. 'n i+,r$8ing resistance t$ stress c$rr$si$n.

b. 'n i+,r$8ing di+ensi$nal stabilit# a2ter +acining.

c. 'n l$3ering te ,ea* resid"al stresses.

d. 'n s$2tening te +etal.

17. Stra# arc stri*es are "ndesirable since te#5

a. 9ea8e a ,$$r s"r2ace 2inis. b. )a"se 3eld +etal crac*ing.

c. Red"ce c$rr$si$n resistance.

d. )a"se l$cal ardening and crac*ing in te ,arent +aterial.

18. )$ld crac*ing is +$st li*el# t$ $cc"r in a 3eld+ent i25

a. Te rate $2 c$$ling is t$$ 2ast. b. Te rate $2 c$$ling is t$$ sl$3.

c. 't lac*s d"ctilit# at ig te+,erat"res.

d. '+,"rities are ,resent at its grain b$"ndaries.

19. )r$+i"+: 3en added t$ steel as an all$#ing ele+ent: as te e22ect $2 +a*ing te

all$#

+$re5

a. !"ctile. b. /lastic. c. %ardenable. d. .alleable.

20. Wen de,$siting 3eld +etal: 2"si$n 3ill ta*e ,lace at te sides $2 te 4$int res"lting

in an

ad+i6t"re bet3een 3eld +etal and ,arent +etal. Tis all$#ing e22ect is *n$3n as5

a. !i22"si$n. b. Abs$r,ti$n. c. !il"ti$n. d. .igrati$n.

21. /ercentage el$ngati$n $2 a +etal "nderg$ing a tensile test is a +eas"re $25

a. Elasticit#. b. /lasticit#. c. !"ctilit#. d. .alleabilit#.

22. Wen a l$ngit"dinal l$ad is ,"t $n a la, 4$int: te stress set ", is n$r+all#5

a. Sear stress. b. Tensile stress. c. )$+,ressi8e stress. d. Resid"al stress.

23. Wen a +etal is s"b4ected t$ a 2l"ct"ating l$ad: a c$nditi$n $2 c#clic stressing can be

set ",:

3ic e8ent"all# can res"lt in str"ct"ral brea*d$3n *n$3n as5

a. Tensile 2ail"re. b. Catig"e 2ail"re. c. 7ield 2ail"re. d. Sear 2ail"re.

24. Wat a,,ens t$ te +ecanical ,r$,erties $2 steel i2 te carb$n c$ntent is increased

t$

0.5(<

a. Te +aterial bec$+es s$2ter. b. .alleabilit# is increased.

c. Te tensile strengt is increased. d. !"ctilit# is increased.

25. )$l"+nar gr$3t ta*es ,lace 3en a +etal is5

a. )$ld. b. 9$sing eat. c. &eing eated. d. &eing r$lled.

26. '2 a l$3 carb$n steel ,i,e as t$ carr# a li;"id: care +"st be ta*en 3en +a*ing te

b"tt

3elds t$ ens"re ,enetrati$n is n$t e6cessi8e beca"se it5

a. Red"ces te 2l$3 rate $2 te li;"id. b. .a# increase te rate $2 c$rr$si$n.

c. )an c$nta+inate te li;"id. d. .a# ca"se e6cessi8e ,i,e 3ear.

27. Wen a steel s"22ers $t s$rtness: it is +$stl# d"e t$ te ,resence $25

a. S"l,"r. b. /$s,$r$"s. c. Silic$n. d. .anganese.

28. Wen a steel is eated t$ ab$8e its ",,er critical te+,erat"re: te str"ct"re ,r$d"ced

is5

a. .artensite. b. A"stenite. c. /earlite. d. S$rbite.

29. Te t#,e $2 cr#stal n$r+all# 2$"nd in a single r"n arc 3eld in te as 3elded c$nditi$n

is5

a. E;"i@a6ed. b. /$l#cr#stalline. c. !endritic. d. )$l"+nar.

30. Te 2irst s"b@A$ne in te eat a22ected A$ne $2 te ,arent +etal nearest te 3eld

de,$sit 3ill

c$nsist $25

a. 9arge cr#stal grains. b. S+all cr#stal grains. c. El$ngated cr#stal grains.

d. !ist$rted cr#stal grains.

MULTICHOICE PAPER SEVEN

1. /i,e 3elding c$des are set ", b#5

a. Welding $,erat$rs. b. State g$8ern+ents.

c. Ass$ciati$ns: s$cieties: ins"rance c$+,anies: +an"2act"rers and te +ilitar#.

d. )$nstr"cti$n "ni$ns.

2. Te di22erent grain str"ct"re bet3een te 3eld de,$sit and te base +etal can be

deter+ined

b#5

a. A 2ace bend test. b. A r$$t bend test. c. A ardness test.

d. An etcing test.

3. A r$$t bend test is "sed t$ test te a+$"nt $2 3eld5

a. !"ctilit#. b. El$ngati$n. c. %ardness. d. /enetrati$n.

4. Wat 3$"ld be $bser8ed i2 a 2illet 3eld 3ere secti$ned and +acr$@etced<

a. Te grain $2 te $ter beads is c$arser tan te 2inal bead.

b. Te ,enetrati$n and 2"si$n int$ te r$$t is 8er# dee,.

c. Eac bead a,,ears t$ be distinctl# se,arated 2r$+ te ad4$ining beads.

d. Te grain str"ct"re re+ains te sa+e in all ,asses.

5. Wat is te +$st c$++$n ca"se $2 2ail"re in r$$t bend tests<

a. T$$ ig a c"rrent setting.

b. T$$ l$ng a ,a"se in te d$3n c#cle $2 te 3ea8e.

c. 9ac* $2 2"si$n and ,enetrati$n.

d. T$$ ig a tra8el s,eed.

6. Te ,"r,$se $2 a nic* brea* s,eci+en is t$ ,r$8ide a test 2$r5

a. Tensile strengt and 2ract"re a,,earance.

b. !"ctilit# and 2ract"re a,,earance.

c. El$ngati$n and 2ract"re a,,earance.

d. S$"ndness and 2ract"re a,,earance.

7. Wic $rganiAati$n ,"blises te +$st c$++$nl# "sed c$de 2$r b$iler and ,ress"re

8essel

3elding<

a. A+erican Welding S$ciet#.

b. A+erican S$ciet# $2 .ecanical Engineers.

c. A+erican /etr$le"+ 'nstit"te.

d. A+erican Nati$nal Standards 'nstit"te.

8. A l$3 #dr$gen electr$de: acc$rding t$ &S 639: 3$"ld c$ntain5

a. N$ #dr$gen.

b. 9ess tan 15 +l $2 #dr$gen ,er 100 gra+s $2 de,$sited 3eld +etal.

c. &et3een 15 +l and 25 +l $2 #dr$gen ,er 100 gra+s $2 de,$sited 3eld +etal.

d. 9ess tan 25 +l $2 #dr$gen ,er 100 gra+s $2 de,$sited 3eld +etal.

9. Te sec$nd r"n in a tree r"n b"tt 3eld "sing te st$8e,i,e tecni;"e is *n$3n as te5

a. Cilling r"n. b. %$t ,ass. c. 'nter+ediate r"n. d. Sealing r"n.

10. 7$" c$"ld deter+ine tat an electr$de is cell"l$sic b# its5

a. &S 639 c$ding. b. )$l$"r. c. Trade na+e. d. &S 499 c$ding.

11. Wic t#,e $2 electr$de c$ating gi8es te +$st 8$l"+in$"s gas sield<

a. R"tile. b. &asic. c. ?6idising. d. )ell"l$sic.

12. Wic $2 te 2$ll$3ing steels is li*el# t$ be +$re s"sce,tible t$ #dr$gen crac*ing<

a. )arb$n e;"i8alent $2 less tan 0.25 (. b. )arb$n e;"i8alent $2 0.35(.

c. )arb$n e;"i8alent $2 0.38(. d. )arb$n e;"i8alent $2 0.43(.

13. /reeating and inter,ass eating are "sed ,ri+aril# 2$r5

a. Aiding 2"si$n. b. Red"cing #dr$gen c$ntent $2 3eld ,re,arati$n ,ri$r t$

3elding.

c. Ens"re a 2ine grain siAe. d. Sl$3 d$3n te c$$ling rate a2ter 3elding.

14. S"b+erged arc 3elds +ade 3it re@c#cled 2l"6 are liable t$5

a. /$r$sit#. b. )$"rse grain siAe. c. >nderc"t. d. 'nc$+,lete ,enetrati$n.

15. 'nc$+,lete ,enetrati$n in a single EHE b"tt 4$int c$"ld be ca"sed b#5

a. T$$ large a r$$t ga,. b. T$$ s+all a r$$t ga,. c. T$$ ig a eat in,"t.

d. T$$ s+all a r$$t 2ace.

16. 'n s"b+erged arc 3elding: 3ic $2 te 2$ll$3ing 3idt t$ de,t rati$s 3$"ld be

li*el# t$

res"lt in s$lidi2icati$n crac*ing<

a. 1 5 3. b. 3 5 1. c. 2 5 1. d. 1 5 1.

17. 7$" are res,$nsible 2$r c$ntr$lling 3elding $n site. A large incidence $2 ,$r$sit# as

been

re,$rted in recent 3elding. W$"ld #$" in8estigate<

a. Te electr$de t#,e. b. /$3er s$"rce. c. Electr$de st$rage. d. !a# te+,erat"re.

18. Te +ain reas$n 3# all adering scale s$"ld be re+$8ed 3en te ,i,e end

,re,arati$n is

+ade b# $6#@gas c"tting is<

a. ?6idiAati$n $2 te 3eld +etal is +ini+iAed.

b. Te s,eed $2 3elding is increased.

c. /i,e b$re align+ent is +ade easier.

d. Red"cti$n $2 te 3eld de,$sit is ,re8ented.

19. Wen +an"al +etal arc 3elding l$3 carb$n steel: 3ic electr$de c$8ering 3ill gi8e

te

greatest degree $2 ,enetrati$n<

a. 'r$n ,$3der. b. R"tile. c. )ell"l$sic. d. 9$3 #dr$gen.

20. Wen t"ngsten arc gas sielded 3elding stainless steel: 3ic $ne $2 te 2$ll$3ing

s$"ld

be "sed<

a. Alternat$r. b. A. ). trans2$r+er. c. !. ). generat$r. d. )$nstant ,$tential

recti2ier.

21. Wic gas sr$"d s$"ld be "sed 3en t"ngsten arc gas sielded 3elding al"+ini"+

all$#s<

a. Nitr$gen. b. )arb$n di$6ide. c. Arg$n-carb$n di$6ide +i6t"re. d. Arg$n.

22. Te +$st c$++$n t#,e $2 de2ect 2$"nd in a str"ct"re 3en it is "nderg$ing ser8ice

is5

a. Catig"e crac*ing. b. )r#stalliAati$n. c. Weld deca#. d. Stress 2ract"re.

23. 'n te e6a+inati$n $2 a 3elded al"+in"+ 4$int: +acr$ etcing +a# re8eal5

a. 9ac* $2 inter@r"n ,enetrati$n. b. )arb$n ,ic*@",. c. Weld deca#.

d. .icr$ crac*s.

24. ..A 3elds +ade 3it da+aged electr$de c$atings are s"b4ect t$5

a. /$r$sit#. b. >nderc"t. c. E6cessi8e ,enetrati$n. d. E6cessi8e bead eigt.

25. Wic ,#sical test is +$re li*el# t$ re8eal %AF e+brittle+ent<

a. Trans8erse tensile. b. All 3eld tensile. c. R$$t bend. d. )ar,# i+,act.

26. Wic $2 te 2$ll$3ing destr"cti8e tests is n$t n$r+all# re;"ired 2$r 3elder a,,r$8al<

a. &end tests. b. .acr$ e6a+inati$n. c. '+,act tests. d. Cract"re tests.

27. T$$ large a dia+eter $2 2iller r$d s$"ld n$t be "sed t$ +a*e a 3elded 4$int beca"se5

a. E6cess rein2$rce+ent ,r$2ile 3ill be di22ic"lt t$ $btain.

b. Te incl"ded be8el angle 3ill a8e t$ be red"ced.

c. R$$t 2"si$n +a# be di22ic"lt t$ $btain.

d. Te ga, setting 3ill a8e t$ be canged.

28. '2 ,i,e b$res are n$t +atced c$rrectl# it can res"lt in5

a. 9ac* $2 r$$t ,enetrati$n. b. 'nc$rrect ga, setting. c. E6cessi8e r$$t 2aces.

d. ?8ereating d"ring 3elding.

29. A c$rrectl# +ade tac* 3eld s$"ld sl$,e 2r$+ te +iddle t$ te ends in $rder t$5

a. Aid better ,enetrati$n at te 4$in@",. b. /re8ent ,$r$sit# at te 4$in@",.

c. Red"ce te electr$de siAe re;"ired.

d. Red"ce te $8erall c$ns"+able c$ns"+,ti$n.

30. T3$ l$3 carb$n steel ,i,es: 150++ dia+eter and 6++ 3all tic*ness: are t$ be b"tt

3elded "sing te T'= ,r$cess. T$ ens"re a 2"ll strengt 4$int: 3ic $2 te 2$ll$3ing

,re,s is +$st s"itable<

a. ?,en single be8el. b. ?,en single Hee.

c. ?,en s;"are ,re,arati$n.

d. )l$sed s;"are ,re,arati$n.

PROPERTIES OF MATERIALS

1. Te abilit# $2 a +aterial t$ 3itstand a l$ad ,"lling it a,art is called its Tensile

Strength.

2. Te abilit# $2 a +aterial t$ be stretced $"t 3it$"t brea*ing is called Ductility

3. An 'A$d i+,act +acine is "sed t$ gi8e indicati$n $2 te Toughness $2 a +aterial.

4. Te abilit# t$ 3itstand indentati$n is called Hardness.

5. 9ac* $2 d"ctilit# is called Brittleness.

6. Te ,r$,ert# $2 a +etal t$ ret"rn t$ its $riginal sa,e is called Elasticity.

7. 'ncrease in carb$n c$ntent ca"ses an Increase in strengt and ardness.

8. Wen carb$n ,ercentage increases: tere is a decrease in Ductility

9. 9$3 carb$n steel c$ntains less tan 02 % carb$n.

10. 9$3 d"ctilit# in a 3eld +etal c$"ld res"lt in Cracking.

11. All$#ing is "sed t$ Increase +ecanical and ,#sical ,r$,erties $2 a steel.

12. S"l,"r and ,$s,$r"s are n$t all$#ing ele+entsO te# are Impurities.

13. All$#ing all$3s designers t$ "se SmallarThinner secti$ns and still a8e te sa+e

strengt.

14. An all$# tat c$ntains a ig ,ercentage $2 cr$+i"+ and nic*el 3$"ld a8e

resistance

t$ Corrosion.

15. I"encing a carb$n $r l$3 all$# steel 3ill res"lt in an Increase in ardness and a

Decrease

in d"ctilit#.

16. Te ard c$nstit"ent tat res"lts 3en steel is ;"enced is called !artensite.

17. Te t$"g la+inated str"ct"re tat is 2$r+ed $n sl$3 c$$ling $2 2errite and ir$n

carbide

Kce+entiteL is called "earlite.

18. Te a+$"nt $2 +artensite 2$r+ed de,ends $n te s,eed $2 cooling and te ,ercentage

$2 Car#on.

19. A2ter ;"encing: te str"ct"re +a# be i+,r$8ed b# reeating t$ 200@300J). Tis is

called

Tempering.

20. S+all ,ercentages $2 cr$+i"+ 3ill increase te strengt and Hardness: 3ile a

s+all

,ercentage $2 nic*el 3ill increase Toughness.

Anda mungkin juga menyukai

- Cloud Paas and Iaas Playbook 2993836Dokumen35 halamanCloud Paas and Iaas Playbook 2993836Blizard80Belum ada peringkat

- Ihs Kingdom Hot Keys ReferenceDokumen1 halamanIhs Kingdom Hot Keys ReferenceMuhammad Jahangir100% (1)

- Topic 1 Planet Earth (Intensive Notes) by Ricky Tsui - IssuuDokumen1 halamanTopic 1 Planet Earth (Intensive Notes) by Ricky Tsui - IssuuTU YUZE TU BILLY (4L27)Belum ada peringkat

- Paper 2 - Set B Answer Key: General InstructionsDokumen13 halamanPaper 2 - Set B Answer Key: General Instructionsash_chhatbarBelum ada peringkat

- Paper 1 - Set A Answer Key: General InstructionsDokumen13 halamanPaper 1 - Set A Answer Key: General InstructionsKattukolu KishorereddyBelum ada peringkat

- S.3 Physics Exam End of First Term APRIL 2007 Time: 2 HoursDokumen10 halamanS.3 Physics Exam End of First Term APRIL 2007 Time: 2 HoursNdawula IsaacBelum ada peringkat

- PDF Building Technology DDDokumen81 halamanPDF Building Technology DDFrances Irish MarasiganBelum ada peringkat

- Ex Final Mat 2o12 9°Dokumen3 halamanEx Final Mat 2o12 9°Jonathan Luis Saavedra CubaBelum ada peringkat

- Related Texts: Suggested Books As Authorized by GuidesDokumen9 halamanRelated Texts: Suggested Books As Authorized by GuidesSama Sh Al-araj0% (1)

- Amc Clinical Material and TipsDokumen4 halamanAmc Clinical Material and TipsTrisBelum ada peringkat

- STD IX - 2013 DR Homi Bhabha BalVaidyanik Competition Test PaperDokumen8 halamanSTD IX - 2013 DR Homi Bhabha BalVaidyanik Competition Test PaperDr Mohan Savade0% (1)

- Ice 204 - chp3 - Non Catalytic Reaction KineticsDokumen22 halamanIce 204 - chp3 - Non Catalytic Reaction KineticsThomas SantosaBelum ada peringkat

- Superioridad Aérea en Aplicaciones Android: Saúl Díaz GonzálezDokumen28 halamanSuperioridad Aérea en Aplicaciones Android: Saúl Díaz GonzálezAlejandro Nortes GarcíaBelum ada peringkat

- Matemática Iii: Primer InformeDokumen3 halamanMatemática Iii: Primer Informerulo_charlyBelum ada peringkat

- ! A B DG BF: AC AbfeDokumen6 halaman! A B DG BF: AC Abfe張家樂Belum ada peringkat

- Paper - 1 - SetA - QADokumen16 halamanPaper - 1 - SetA - QARamesh AnanthanarayananBelum ada peringkat

- CalculusDokumen4 halamanCalculusCharles EsicoBelum ada peringkat

- Abc de FC BGHC I JHDKBLC MC Noe P o JQC IgrsktbDokumen5 halamanAbc de FC BGHC I JHDKBLC MC Noe P o JQC IgrsktbThirumalBelum ada peringkat

- Section - A: ChemistryDokumen4 halamanSection - A: ChemistryGadde Gopala KrishnaBelum ada peringkat

- Causes and PreventionDokumen38 halamanCauses and PreventionHamed RazaBelum ada peringkat

- Philippine Supreme Court Jurisprudence Year 1966 September 1966 DecisionsDokumen9 halamanPhilippine Supreme Court Jurisprudence Year 1966 September 1966 Decisionsanewor_ogaborratBelum ada peringkat

- Zadul Khateeb Jild 3Dokumen632 halamanZadul Khateeb Jild 3sindhislam fortBelum ada peringkat

- MT Exam Paper 1 Y5Dokumen8 halamanMT Exam Paper 1 Y5mariam7718Belum ada peringkat

- 01 PitraStava 0001Dokumen2 halaman01 PitraStava 0001Darshan KamatBelum ada peringkat

- Speckle The DragonDokumen6 halamanSpeckle The DragonbuffylovezBelum ada peringkat

- Area and Volume: General ObjectiveDokumen30 halamanArea and Volume: General ObjectiveAdron LimBelum ada peringkat

- Marking SBP Mid Year 08Dokumen21 halamanMarking SBP Mid Year 08SueBelum ada peringkat

- X 6 N 5 N 4 N 3 N 2 N 1 N 6 X 6 N 5 X 5 N 4 X 4 N 3 X 3 N 2 X 2 N 1 X 1 NDokumen5 halamanX 6 N 5 N 4 N 3 N 2 N 1 N 6 X 6 N 5 X 5 N 4 X 4 N 3 X 3 N 2 X 2 N 1 X 1 NEieiz DyBelum ada peringkat

- Mathematical Ability A. Numerical FacilityDokumen6 halamanMathematical Ability A. Numerical FacilityRyalyn_AnneBelum ada peringkat

- Credit Risk ManagementDokumen6 halamanCredit Risk ManagementAshadur Rahman JahedBelum ada peringkat

- 9th MathsDokumen4 halaman9th MathsYashoda Kumawatgģ वफपमठप हसहबूसयह तBelum ada peringkat

- List of FormulaeDokumen17 halamanList of FormulaemarlontaylorBelum ada peringkat

- 5th STD Languages Subjects Csas Exam Question Paper Series-4 Kan Version 2018-19Dokumen12 halaman5th STD Languages Subjects Csas Exam Question Paper Series-4 Kan Version 2018-19Sai SundeepBelum ada peringkat

- 1a Model SolutionDokumen15 halaman1a Model SolutionRamKannanBelum ada peringkat

- 5th STD Core Subjects Csas Exam Question Paper Series-2 Kan Version 2018-19Dokumen12 halaman5th STD Core Subjects Csas Exam Question Paper Series-2 Kan Version 2018-19Sai SundeepBelum ada peringkat

- Chemistry Form 4 NotesDokumen46 halamanChemistry Form 4 Notessegarthana1567% (3)

- C For C ProgrammersDokumen41 halamanC For C ProgrammersLeo ValentineBelum ada peringkat

- 002 Vaccum Testing ProcedureDokumen4 halaman002 Vaccum Testing Procedurehasan_676489616Belum ada peringkat

- Agenda 11-4-13Dokumen1 halamanAgenda 11-4-13api-202041946Belum ada peringkat

- Distillation Column Design MulticomponentDokumen23 halamanDistillation Column Design Multicomponentsuleman205100% (1)

- State Level Preparatory Mathsq3weDokumen24 halamanState Level Preparatory Mathsq3weultimatorZBelum ada peringkat

- Historic Preservation & RehabilitationDokumen2 halamanHistoric Preservation & RehabilitationJamie JensenBelum ada peringkat

- Energy Manager Certification ExamDokumen16 halamanEnergy Manager Certification Examasamad54100% (2)

- 1314lab - Reaction Prediction and ObservationsshortDokumen3 halaman1314lab - Reaction Prediction and Observationsshortapi-239325344Belum ada peringkat

- Variables TareaDokumen10 halamanVariables TareaLuisito MorlaBelum ada peringkat

- Backward Category (SL No 5)Dokumen1 halamanBackward Category (SL No 5)rsronalsBelum ada peringkat

- De Thi Thu DH A1D 2014Dokumen13 halamanDe Thi Thu DH A1D 2014Phạm Thi Như NguyệtBelum ada peringkat

- Chapter IDokumen7 halamanChapter IoctatheweelBelum ada peringkat

- 1.2 Exercise 3 - Ideal Gas EquationDokumen1 halaman1.2 Exercise 3 - Ideal Gas EquationAAEFDSAFDSAFBelum ada peringkat

- 21st Century Pedagogy - What Does It Mean For TeacDokumen1 halaman21st Century Pedagogy - What Does It Mean For TeacMarc LaurenceBelum ada peringkat

- Srinivasa Ramanujan Srīnivāsa Rāmānujan IyengarDokumen6 halamanSrinivasa Ramanujan Srīnivāsa Rāmānujan IyengarsarayooBelum ada peringkat

- Test Math For PracticeDokumen2 halamanTest Math For PracticeAjay_Midha_9769Belum ada peringkat

- Chemical Properties Reactivity of Alkenes: Double Covalent BondDokumen24 halamanChemical Properties Reactivity of Alkenes: Double Covalent BondJaybeeAngelBelum ada peringkat

- Myers Human Survival After DeathDokumen1.624 halamanMyers Human Survival After Deathdionysus999100% (1)

- เฉลยครึ่งหลัง เคมี by Hestia John - IssuuDokumen1 halamanเฉลยครึ่งหลัง เคมี by Hestia John - IssuuWedphisit TreephiphitBelum ada peringkat

- Album of Dated Latin Inscriptions, Part II, Plates: Rome and the Neighborhood, A.D. 100-199Dari EverandAlbum of Dated Latin Inscriptions, Part II, Plates: Rome and the Neighborhood, A.D. 100-199Belum ada peringkat

- Album of Dated Latin Inscriptions, Part III, Plates: Rome and the Neighborhood, A. D. 200-525Dari EverandAlbum of Dated Latin Inscriptions, Part III, Plates: Rome and the Neighborhood, A. D. 200-525Belum ada peringkat

- Answers to Selected Problems in Multivariable Calculus with Linear Algebra and SeriesDari EverandAnswers to Selected Problems in Multivariable Calculus with Linear Algebra and SeriesPenilaian: 1.5 dari 5 bintang1.5/5 (2)

- Divided States: Strategic Divisions in EU-Russia RelationsDari EverandDivided States: Strategic Divisions in EU-Russia RelationsBelum ada peringkat

- Creativity and Change in Nigerian ChristianityDari EverandCreativity and Change in Nigerian ChristianityBelum ada peringkat

- Final Exam (Closed) Answer SheetDokumen1 halamanFinal Exam (Closed) Answer SheetAdil HasanovBelum ada peringkat

- Project QAQC Inspector - Quality MSDokumen4 halamanProject QAQC Inspector - Quality MSAdil HasanovBelum ada peringkat

- Asme Sec 5Dokumen16 halamanAsme Sec 5Adil HasanovBelum ada peringkat

- Electrical HazardsDokumen37 halamanElectrical HazardsAdil HasanovBelum ada peringkat

- ASME B31.3 Daily Exam 2 SolutionDokumen3 halamanASME B31.3 Daily Exam 2 SolutionAdil HasanovBelum ada peringkat

- BGAS Experience FormDokumen2 halamanBGAS Experience FormAdil HasanovBelum ada peringkat

- BgasslideshowDokumen55 halamanBgasslideshowAdil Hasanov100% (1)

- BGAS Experience Form (May 16)Dokumen2 halamanBGAS Experience Form (May 16)Adil HasanovBelum ada peringkat

- New-NDT 15A - Experience Claim Form (Rev. 2)Dokumen2 halamanNew-NDT 15A - Experience Claim Form (Rev. 2)Adil HasanovBelum ada peringkat

- New-NDT 15A - Experience Claim Form (Rev. 2)Dokumen4 halamanNew-NDT 15A - Experience Claim Form (Rev. 2)Adil HasanovBelum ada peringkat

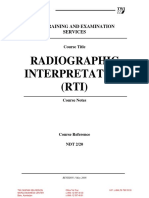

- RTI - Rev.2010 (NDT2A 2B Course Notes)Dokumen191 halamanRTI - Rev.2010 (NDT2A 2B Course Notes)Adil Hasanov100% (1)

- Ultrasonic Inspection Report Appendix 2aDokumen1 halamanUltrasonic Inspection Report Appendix 2aAdil HasanovBelum ada peringkat

- RTI - Rev.2010 (NDT2A 2B Course Notes)Dokumen191 halamanRTI - Rev.2010 (NDT2A 2B Course Notes)Adil Hasanov100% (1)

- Multiple Choice 60Dokumen8 halamanMultiple Choice 60Adil Hasanov100% (1)

- New-NDT 15A - Experience Claim Form (Rev. 2)Dokumen2 halamanNew-NDT 15A - Experience Claim Form (Rev. 2)Adil HasanovBelum ada peringkat

- TestDokumen6 halamanTestAdil Hasanov100% (2)

- Ttransition JointsDokumen15 halamanTtransition JointsAdil HasanovBelum ada peringkat

- NDT Report Check List Appendix 2Dokumen4 halamanNDT Report Check List Appendix 2Adil HasanovBelum ada peringkat

- RTI Course Notes 2008 PDFDokumen169 halamanRTI Course Notes 2008 PDFhailay83Belum ada peringkat

- Esc101: Fundamentals of Computing: 2011-12-Monsoon SemesterDokumen6 halamanEsc101: Fundamentals of Computing: 2011-12-Monsoon SemesterMukesh Kumar DewraBelum ada peringkat

- Delphi Client ServerDokumen9 halamanDelphi Client Serverlukgv,hBelum ada peringkat

- SWOT Analysis of Viyellatex Spinning LimitedDokumen81 halamanSWOT Analysis of Viyellatex Spinning LimitedHossain RanaBelum ada peringkat

- Ee BD ManualDokumen37 halamanEe BD Manualsergey62Belum ada peringkat

- 3 Carpentry Technology 1Dokumen7 halaman3 Carpentry Technology 1Czar InaBelum ada peringkat

- Excel To C I For Positive in PutDokumen23 halamanExcel To C I For Positive in PuthimanshuBelum ada peringkat

- Teodoriu 2010Dokumen13 halamanTeodoriu 2010JhormanBelum ada peringkat

- Power Quality Standards in ChinaDokumen21 halamanPower Quality Standards in ChinaCarlos Talavera VillamarínBelum ada peringkat

- Wolf Range TopDokumen2 halamanWolf Range TopArt BowlingBelum ada peringkat

- TK3302 - Service Manual PDFDokumen40 halamanTK3302 - Service Manual PDFsil182Belum ada peringkat

- Meritor Axle MT 40 143MA NDokumen55 halamanMeritor Axle MT 40 143MA Nford62bBelum ada peringkat

- Conformity Assessment For The Execution of Steel & Aluminium StructuresDokumen14 halamanConformity Assessment For The Execution of Steel & Aluminium StructuresJevgenijsKolupajevsBelum ada peringkat

- Earthquake in TaguigDokumen4 halamanEarthquake in TaguigDianca Zyra Rodil-CabanelaBelum ada peringkat

- Ms2N Synchronous Servomotors: Project Planning ManualDokumen408 halamanMs2N Synchronous Servomotors: Project Planning ManualGuido PerezBelum ada peringkat

- Assignment 1 Low Temperature and SuperconductivityDokumen3 halamanAssignment 1 Low Temperature and SuperconductivityNadhrah MuradBelum ada peringkat

- Manual Multisim 2001 (Ingles)Dokumen72 halamanManual Multisim 2001 (Ingles)Anonymous W1QQcbA4sWBelum ada peringkat

- DATA SHEET Industrial Enamel BlancoDokumen4 halamanDATA SHEET Industrial Enamel BlancoAlfredo OrellanaBelum ada peringkat

- CM P1CM EP1 Operation ManualDokumen24 halamanCM P1CM EP1 Operation Manualnguyen vuBelum ada peringkat

- Fortranv 7Dokumen173 halamanFortranv 7mu4viewBelum ada peringkat

- IC Course Guide BookDokumen5 halamanIC Course Guide BookAddisu AyeleBelum ada peringkat

- Gopakumar 2002Dokumen9 halamanGopakumar 2002mihaela_myky14Belum ada peringkat

- Fizik F4 P2 (2016)Dokumen19 halamanFizik F4 P2 (2016)AHMAD FAISALBelum ada peringkat

- Aqueous EquilibriumDokumen7 halamanAqueous EquilibriumWONG TSBelum ada peringkat

- Intelligent Control LED Integrated Light Source: Features and BenefitsDokumen6 halamanIntelligent Control LED Integrated Light Source: Features and BenefitsRazvy StoianBelum ada peringkat

- ReactionsDokumen30 halamanReactionskaloibestBelum ada peringkat

- Computation For Concrete Mix 120221Dokumen3 halamanComputation For Concrete Mix 120221MASGRO BUILDERSBelum ada peringkat

- Ntu IgpDokumen6 halamanNtu IgpRobertCallaghanBelum ada peringkat

- Valbart: API 6D & 6A Trunnion Mounted Ball ValvesDokumen36 halamanValbart: API 6D & 6A Trunnion Mounted Ball Valvesbabis1980Belum ada peringkat