1987 - Generalized Predictive Control - Part I - Clarke PDF

Diunggah oleh

ademargcjuniorDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1987 - Generalized Predictive Control - Part I - Clarke PDF

Diunggah oleh

ademargcjuniorHak Cipta:

Format Tersedia

Automatica, VoL 23, No. 2, pp. 137 148, 1987 0005 1098/87 $3.00+0.

0~

Printed in Great Britain. Pergamon Journals Ltd.

~ 1987 International Federation of Automatic Control

Generalized Predi cti ve Control

Al gori thm*

Part I. The Basic

D. W. CLARKEt , C. MOHTADI t and P. S. TUFFS~:

A new member of the family of long-range predictive controllers is shown to be suitable

f or the adaptive control of processes with varying parameters, dead-time and model-

order.

Key Words--Adapt i ve control; predictive control; LQ control; self-tuning control; nonminimum-phase

plant.

Akst raet --Current self-tuning algorithms lack robustness to

prior choices of either dead-time or model order. A novel

method--generalized predictive control or GPC- - i s developed

which is shown by simulation studies to be superior to accepted

techniques such as generalized minimum-variance and pole-

placement. This receding-horizon method depends on predicting

the plant' s output over several steps based on assumptions

about future control actions. One assumpt i on--t hat there is a

"control horizon" beyond which all control increments become

zer o- - i s shown to be beneficial both in terms of robustness and

for providing simplified calculations. Choosing particular values

of the output and control horizons produces as subsets of the

method various useful algorithms such as GMV, EPSAC,

Peterka' s predictive controller (1984, Automatica, 20, 39-50)

and Ydstie's extended-horizon design (1984, IFAC 9th World

Congress, Budapest, Hungary). Hence GPC can be used either

to control a "simple" plant (e.g. open-loop stable) with little

prior knowledge or a more complex plant such as nonminimum-

phase, open-loop unstable and having variable dead-time. In

particular GPC seems to be unaffected (unlike pole-placement

strategies) if the plant model is overparameterized. Furthermore,

as offsets are eliminated by the consequence of assuming a

CARIMA plant model, GPC is a contender for general self-

tuning applications. This is verified by a comparative simulation

study.

1. I NTRODUCTI ON

ALTHOUGH SELF-TUNING and adaptive control has

made much progress over the previous decade,

both in terms of theoretical understanding and

practical applications, no one method proposed so

far is suitable as a "general purpose" algorithm for

the stable control of the majority of real processes.

To be considered for this role a method must be

applicable to:

* Received 2 March 1985; revised 7 July 1985; revised 3 March

1986; revised 22 September 1986. The original version of this

paper was not presented at any IFAC meeting. This paper was

recommended for publication in revised form by Associate

Editor M. Gevers under the direction of Editor P. C. Parks.

t Department of Engineering Science, Parks Road, Oxford

OXI 3PJ, U.K.

Aluminum Company of America, Alcoa Technical Center,

Pittsburgh, PA 15069, U.S.A.

(1) a nonminimum-phase plant: most continuous-

time transfer functions tend to exhibit discrete-time

zeros outside the unit circle when sampled at a fast

enough rate (see Clarke, 1984);

(2) an open-loop unstable plant or plant with

badly-damped poles such as a flexible spacecraft or

robots;

(3) a plant with variable or unknown dead-time:

some methods (e.g. minimum-variance self-tuners,

/~str6m and Wittenmark, 1973) are highly sensitive

to the assumptions made about the dead-time and

approaches (e.g. Kurz and Goedecke, 1981) which

attempt to estimate the dead-time using operating

dat a tend to be complex and lack robustness;

(4) a plant with unknown order: pole-placement

and LQG self-tuners perform badly if the order of

the plant is overestimated because of pole/zero

cancellations in the identified model, unless special

precautions are taken.

The method described in this paper--General -

ized Predictive Control or GPC- - appear s to over-

come these problems in one algorithm. It is capable

of stable control of processes with variable parame-

ters, with variable dead-time, and with a model

order which changes instantaneously provided that

the input/output data are sufficiently rich to allow

reasonable plant identification. It is effective with

a plant which is simultaneously nonminimum-

phase and open-loop unstable and whose model

is overparameterized by the estimation scheme

without special precautions being taken. Hence it

is suited to high-performance applications such as

the control of flexible systems.

Hitherto the principal applied self-tuning

methods have been based on the "Generalized

Minimum-Variance" approach (Clarke and

Gawthrop, 1975, 1979) and the pole-placement

algorithm (Wellstead et al . , 1979; /~str6m and

137

A U T 2 3 / 2 - A

138 1). W. CLARKk et al.

Wi t t enmark, 1980). The implicit GMV self-tuner

(so-called because the controller parameters are

directly estimated wi t hout an intermediate calcul-

ation) is robust against model order assumptions

but can perform badly if the plant dead-time varies.

The explicit pole-placement method, in which a

Di ophant i ne equat i on is numerically solved as a

bridging step between plant identification and the

control calculation, can cope with variable dead-

time but not with a model with overspecified order.

Its good behavi our with variable dead-t i me is due

to overparamet eri zat i on of the numer at or dynami cs

B(q - 1); this means t hat the order of the denomi nat or

dynami cs has to be chosen with great care to avoid

singularities in the resolution of the Di ophant i ne

identity. The GPC approach being based on an

explicit plant formul at i on can deal with variable

dead-time, but as it is a predictive met hod it can

also cope with overparamet eri zat i on.

The type of plant t hat a self-tuner is expected to

cont rol varies widely. On the one hand, many

industrial processes have "simple" models: low

order with real poles and probabl y with dead-time.

For some critical loops, however, the model might

be more complex, such as open-loop unstable,

under damped poles, multiple integrators. It will be

shown t hat GPC has a readi l y-underst andabl e

def aul t operat i on which can be used for a simple

plant wi t hout needing the detailed prior design of

many adaptive methods. Moreover, at a slight

increase of comput at i onal time more complex pro-

cesses can be accommodat ed by GPC within the

basic framework.

All industrial plants are subjected to load-dis-

turbances which tend to be in the form of random-

steps at r andom times in the deterministic case or

of Browni an mot i on in stochastic systems. To

achieve offset-free closed-loop behaviour given

these disturbances the controller must possess

inherent integral action. It is seen t hat GPC adopt s

an i nt egrat or as a nat ural consequence of its

assumpt i on about the basic plant model, unlike the

maj ori t y of designs where integrators are added in

an ad hoc way.

2. THE CARIMA PLANT MODEL AND OUTPUT

PREDICTION

When considering regulation about a particular

operat i ng point, even a non-linear pl ant generally

admits a locally-linearized model:

If the plant has a non-zero dead-time the leading

elements of the pol ynomi al B( q - ~) are zero. In (1),

u(t) is the control input, .~t) is the measured variable

or out put , and x(t ) is a disturbance term.

In the literature x(t ) has been considered to be

of movi ng average form:

x ( t ) = C ( q - ~)~.(t) ( 2 )

where C( q - 1 ) = I + c l q ~ + ' + c,cq -"c.

In this equation, (t) is an uncorrel at ed r andom

sequence, and combi ni ng with (I) we obt ai n the

CARMA (Controlled Auto-Regressive and Mov-

ing-Average) model:

A ( q - l ) y ( t ) = B ( q ~ 1 ) u ( t - I )

+ C( q - l ) ~ ( t ) . (3)

Though much self-tuning t heory is based on this

model it seems to be i nappropri at e for many

industrial applications in which disturbances are

non-st at i onary. In practice, two principal disturb-

ances are encountered: r andom steps occuring at

r andom times (for example, changes in material

quality) and Browni an mot i on (found in plants

relying on energy balance). In bot h these cases an

appropri at e model is:

x(t ) = C( q - 1)~(t)/A (4)

where A is the differencing operat or I - q - 1 .

Coupl ed with (1) this gives the CARI MA model

(integrated moving-average):

A ( q - l )y(t ) = B( q l )u(t - 1)

+ C( q - l)~(t)/A.

This model has been used by Tufts and Clarke

(1985) to derive GMV and pole-placement self-

tuners with inherent integral action. For simplicity

in the development here C( q - 1 ) is chosen to be 1

(alternatively C-1 is t runcat ed and absorbed into

the A and B polynomials; see Part II for the case

of general C) t o give the model:

A( q - 1 ) y ( t ) = B( q 1)u(t - l) + ~(tffA. (5)

A( q l )y(t ) = B( q - 1 ) u ( t - 1) + x( t ) (1)

where A and B are pol ynomi al s in the backward

shift oper at or q-1:

A( q - 1) = 1 + a l q - 1 + . . , + a, ~q -"~

B(q - 1) = b o + b l q - ~ + . . . + bnbq -rib.

To derive a j-step ahead predictor of ~t +j )

based on (5) consider the identity:

1 = E ~ q - 1 ) A A + q - J Fj ~ q - l ) (6)

where Ej and Fj are pol ynomi al s uniquely defined

given A( q - 1 ) and the prediction interval j. If (5) is

Generalized predictive c ont r ol - - Pa r t I 139

multiplied by E j A q j we have:

Subt ract i ng (9) from (10) gives:

E j A A y ( t + j ) = E j B A u ( t + j - 1)

+ E j ( t + j )

and subst i t ut i ng for E j A A from (6) gives:

y ( t + j ) = E j B A u ( t + j - 1)

+ F j y ( t ) + E~(t + j ) . (7)

0 = .4(R - E) + q-J(q-1S - F).

The pol ynomi al R - E is of degree j and may be

split into two parts:

R - E = ~ + r j q - j

so that:

As E j ( q - 1 ) is of degree j - 1 the noise component s

are all in the future so t hat the opt i mal predictor,

given measured out put dat a up to time t and any

given u ( t + i) for i > l, is clearly:

9( t + j I t ) = G j A u ( t + j - 1) + F j y ( t ) (8)

where G j ( q - 1 ) = E j B .

Not e t hat G j ( q - 1) = B ( q - 1)[1 - q - ~ F j ( q - t)]/

A ( q - t)A so t hat one way of comput i ng G~ is simply

to consider the Z-t ransform of the plant' s step-

response and to t ake the first j terms (Clarke and

Zhang, 1985).

In the devel opment of the GMV self-tuning

cont rol l er onl y one prediction ~ ( t + k i t ) is used

where k is the assumed value of the plant' s dead-

time. Here we consider a whole set of predictions

for which j runs from a mi ni mum up to a large

value: these are termed the mi ni mum and maxi mum

"predi ct i on horizons". For j < k the prediction

process .P(t +J l t) depends entirely on available

dat a, but for j >/ k assumpt i ons need to be made

about future cont rol actions. These assumpt i ons

are the cornerst one of the GPC approach.

2. 1. R e c u r s i o n o f t h e D i o p h a n t i n e e q u a t i o n

One way to i mpl ement long-range prediction is

to have a bank of self-tuning predictors for each

hori zon j; this is the approach of De Keyser

and Van Cauwenberghe (1982, 1983) and of the

MUSMAR met hod (Mosca e t al . , 1984). Altern-

atively, (6) can be resolved numerically for E i and

F i for the whole range of j s being considered.

Bot h these met hods are comput at i onal l y expensive.

Inst ead a simpler and more effective scheme is to

use recursion of the Di ophant i ne equat i on so t hat

the pol ynomi al s E j + I and F j + I are obt ai ned given

the values of E j and Fj.

Suppose for clarity of not at i on E = E j , R = E j . 1,

F = F j , S = F j + ~ and consider the two Di ophant i ne

equat i ons with $ defined as AA:

1 = E A + q- i F ( 9 )

1 = R.4 + q- tJ + 1~S. ( 1 0 )

~I R + q - J ( q - t S - F + , 4 r j ) = O.

Clearly t hen /~ = 0 and also S is given

S q ( F - , ~r j).

As ,4 has a unit leading element we have:

by

r j -~ f o (1 la)

S i = f i + 1 - - ~l i + l r i (1 lb)

for i = 0 to the degree of S ( q - 1 ) ;

and: R ( q - i ) = E ( q - 1 ) + q - J r j (12)

G j + I = B ( q - 1 ) R ( q - 1). (13)

Hence given the plant pol ynomi al s A ( q - 1 ) and

B ( q - 1 ) and one sol ut i on E j ( q - a ) and F j ( q - 1 ) t hen

(11) can be used to obt ai n F j + ~ ( q - 1 ) and (12) to

give E j+ l(q- 1) and so on, with little comput at i onal

effort. To initialize the iterations not e t hat f or j = 1:

1 --- E 1 . 4 + q - 1 F t

and as the leading element of ,4 is 1 then:

E1 = 1, F1 = q(1 - ,']).

The calculations involved, therefore, are straightfor-

ward and simpler t han those required when using

a separate predictor for each out put horizon.

3. THE PREDICTIVE CONTROL LAW

Suppose a future set-point or reference sequence

[ w ( t + j); j = 1,2 . . . . ] is available. In most cases

w ( t + j ) will be a const ant w equal to the current set-

point w(t), t hough sometimes (as in batch process

cont rol or robotics) future variations in w ( t + j )

would be known. As in the I DCOM al gori t hm

(Richalet e t al . , 1978) it might be considered t hat a

smoot hed approach from the current out put Xt) to

w is required which is obt ai nabl e from the simple

140 D. W. CLARKE et al.

Y

t - 2 t

u [ - -

j J

/ / -

J

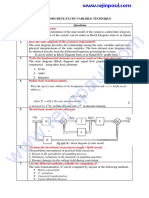

w s e t - p o i n t

P r e d i c t e d o u t p u t

I t + I N u I ! .

t ~ l t + N T i me t

P r o j e c t e d c o n t r o t s

FIG. 1. Set -poi nt , cont r ol and out put s in GPC.

fi rst -order lag model:

w( t ) = y ( t )

w( t + j ) = ~ w( t + j - 1)

+ ( 1 - a ) w j = l , 2 . . . .

where ~ ~ 1 for a slow t ransi t i on from the cur r ent

measured-vari abl e t o the real set -poi nt w. GPC is

capabl e of consi deri ng bot h const ant and varyi ng

fut ure set-points.

The objective t hen of the predictive cont r ol law

is t o drive fut ure pl ant out put s Xt +j ) "close" t o

w( t + j ) in some sense, as shown in Fig. 1, beari ng

in mi nd t he cont r ol activity requi red t o do so. Thi s

is done using a recedi ng-hori zon appr oach for

which at each sampl e-i nst ant t:

(1) the fut ure set -poi nt sequence w(t + j ) is calcu-

lated;

(2) the predi ct i on model of (8) is used to generat e

a set of predi ct ed out put s ~(t + j l t ) with corre-

spondi ng predi ct ed system errors e(t + j )

= w ( t + j ) - p ( t + j l t ) not i ng t hat p ( t + j [ t ) for

j > k depends in par t on fut ure cont r ol signals

u(t + i) which are to be det ermi ned;

(3) some appr opr i at e quadr at i c funct i on of the

fut ure er r or s and cont rol s is minimized, assumi ng

t hat after some "cont r ol hor i zon" furt her incre-

ment s in cont r ol are zero, to pr ovi de a suggested

sequence of fut ure cont rol s u(t + j);

(4) the first el ement u(t) of t he sequence is asserted

and t he appr opr i at e dat a vect ors shifted so t hat t he

cal cul at i ons can be repeat ed at the next sample

instant.

Not e t hat the effective cont r ol law is st at i onary,

unlike a fi xed-hori zon LQ policy. However, in the

self-tuned case new estimates of the pl ant model

par amet er s requires new values for t he par amet er

pol ynomi al s, which means t hat the fast Di ophant i ne

recursi on is useful for adapt i ve cont r ol appl i cat i ons

of the GPC met hod.

Consi der a cost funct i on of the form:

t~j=N 1

}

+ ~ i ( j ) [ A u ( t + j - It ] 2

j = l

(14)

where:

N 1 is the mi ni mum costing hori zon;

N 2 is t he maxi mum costing hori zon, and

).(j) is a cont rol -wei ght i ng sequence.

The expect at i on in (14) is condi t i oned on dat a up

to time t assuming no fut ure measurement s are

available (i.e. the set of cont r ol signals are appl i ed

in open- l oop in the sequel). As ment i oned earlier,

the first cont r ol is appl i ed and the mi ni mi zat i on is

repeat ed at the next sample. The resulting cont r ol

law bel ongs t o the class known as Open- Loop-

Feedback-Opt i mal cont rol (Bertsekas, 1976). Appen-

dix A examines t he rel at i on bet ween GPC and

Cl osed- Loop- Feedback- Opt i mal when the di st urb-

ance process is autoregressive. It is seen t hat costing

on t he cont r ol is over all fut ure inputs which affect

the out put s included in J. In general N2 is chosen

to encompass all the response which is significantly

affected by the cur r ent cont rol ; it is reasonabl e t hat

it shoul d at least be great er t han the degree of

B( q - 1) as t hen all states cont r i but e t o the cost

(Kailath, 1980), but mor e typically N2 is set to

appr oxi mat e t he rise-time of t he plant. N 1 can often

be t aken as 1; if it is known a pri ori t hat the dead-

time of the pl ant is at least k sample-intervals t hen

General i zed predictive c o n t r o l - - Pa r t I

N1 can be chosen as k or mor e t o minimize

comput at i ons. It is found, however, t hat a large

class of pl a nt model s can be stabilized by GP C

with default values of 1 and 10 for N1 and N2. Par t

II provi des a t heoret i cal j ust i fi cat i on for these

choices of hori zon. For simplicity in the deri vat i on,

bel ow 2(j) is set t o t he const ant 2, N1 to 1 and N 2

to N: the "out put hori zon".

Recall t hat (7i model s t he fut ure out put s:

y(t + 1) = GxAu( t ) + F l y ( t ) + E ~ ( t + 1)

y(t + 2) = G2Au( t + 1) + F2y(t) + E2~(t + 2)

y ( t + N) = GNAu( t + N - 1)

+ FNy(t ) + EN~(t + N) .

Consi der Xt +j ) , It consists of t hree terms: one

dependi ng on fut ure cont r ol actiol,s yet to be

det ermi ned, one dependi ng on past known cont rol s

t oget her with filtered measur ed variables and one

dependi ng on fut ure noise signals. The assumpt i on

t hat t he cont r ol s are t o be per f or med in open- l oop

is t ant amount t o i gnori ng t he fut ure noise sequence

{~(t + j)} in cal cul at i ng the predictions. Let f ( t + j )

be t hat component of Xt + j ) composed of signals

which are known at time t, so t hat for example:

f ( t + 1) =

f ( t + 2) =

[ GI ( q - 1) _ g l o ] Au ( t )

+ Fl y ( t ) , and

q [ G2 ( q - 1) _ q - tg21

- - g20] Au( t ) + F2y(t ),

etc.

where Gi( q - 1 ) = gio + g i l q - 1 + . . . .

141

go

g t

G=

0

go

g N- 1 g N- 2 go

Not e t hat if the pl ant dead-t i me is k > 1 the first

k - 1 rows of G will be null, but if instead N1 is

assumed t o be equal t o k the l eadi ng el ement is

non-zero. However, as k will not in general be

known in the self-tuning case one key feat ure of

t he GP C appr oach is t hat a stable sol ut i on is

possible even i f t he l eadi ng r ows o f G are zero.

Fr om the definitions of the vect ors above and

with:

w = [w(t + 1), w(t + 2 ) . . . . . w(t + N) ] T

the expect at i on of the cost -funct i on of (14) can be

written:

J1 ~-- E{J ( I , N)}

= E{(y - w)T(y -- W) + 2iiTii}

(16)

i.e.

Jl = {(Gii + f - w)T(Gii + f - w) + 2iiTii}.

The mi ni mi zat i on of J1 assumi ng no const rai nt s

on fut ure cont r ol s results in the proj ect ed cont r ol -

i ncrement vector:

fi = (GTG + 2I ) - 1Gr(w - f). (17)

Not e t hat the first el ement of fi is Au(t) so t hat

the cur r ent cont r ol u(t) is given by:

Then t he equat i ons above can be wri t t en in the key

vect or form:

9 = Ga + f (15)

where the vect ors are all N x 1:

= [j~(t + 1),j~(t + 2 ) , . . . , ~ t + N)] T

ii _ [Au(t), Au ( t + 1) . . . . . Au ( t + N - 1)] T

f = [ f ( t + 1 ) , f ( t + 2 ) , . . . , f ( t + N ) ] r .

As i ndi cat ed earlier, t he first j t erms in Gj ( q - 1) are

the par amet er s of the st ep-response and t herefore

g~j = g~ for j = 0, I, 2 . . . . < i i ndependent of t he

par t i cul ar G pol ynomi al .

The mat r i x G is t hen l ower - t r i angul ar of di men-

sion N x N:

u(t) = u(t - 1) + ~T(w - f) (I 8)

where ~r is t he first row of ( GTG + 2I ) - tGT. Hence

t he cont r ol includes integral act i on which provi des

zero offset pr ovi ded t hat for a const ant set -poi nt

w( t + i) = w, say, the vect or f i nvol ves a unit steady-

state gain in the feedback path.

Now the Di ophant i ne equat i on (6) for q = 1 gives

1 = Ej(1)A(1)A(I) + Fj(1)

and as A( 1 ) = 0 t hen F j ( 1 ) = I so t hat

f ( t + j ) = Fj)~t) is a signal whose mean value equals

t hat of y(t ). Fur t her mor e, defining F j ( q - i ) t o be

E j ( q - 1). ~(q- 1) gives:

F j ( q - 1)y(t) = (1 - F~( q- l)A)y(t)

= y( t ) - F j Ay ( t )

142 D. W. CLARKE et al.

which shows t hat if y(t) is the const ant y so t hat

A3~t) = 0 t hen the component Fj l q-1)~t } reduces

to f. This, t oget her with the cont rol given by (18),

ensures offset-free behavi our by integral action.

of di mensi on N U and the predi ct i on equat i ons

reduce to:

~ = G~ i i + f

3,1. The control horizon

The di mensi on of the mat ri x involved in (17) is

N x N. Al t hough in the non- adapt i ve case the

inversion need be performed once only, in a self-

t uni ng versi on t he comput at i onal l oad of inverting

at each sample woul d be excessive. Mor eover , if

the wr ong value for dead-t i me is assumed, GVG is

singular and hence a finite non- zer o value of

weighting 2 woul d be requi red for a realizable

cont r ol law, which is i nconveni ent because the

"cor r ect " value for 2 woul d not be known a priori.

The real power of the GPC appr oach lies in the

assumpt i ons made about future cont r ol actions.

Inst ead of allowing t hem to be "free" as for the

above devel opment , GPC bor r ows an idea from

the Dynami c Mat r i x Cont r ol met hod of Cut l er and

Ramaker (1980). Thi s is t hat after an interval

NU < N 2 projected control increments are assumed

to be zero,

i.e. Au(t +j - 1) = 0 j > NU. (19)

The value NU is called the "cont r ol hori zon". In

cost -funct i on t erms this is equi val ent to placing

effectively infinite weights on cont r ol changes after

some fut ure time. For example, i f NU = 1 onl y one

cont r ol change (i.e. Au(t)) is consi dered, after which

the cont rol s u(t + j) are all t aken to be equal t o

u(t). Suppose for this case t hat at time t t here is a

step change in w(t) and t hat N is large. The choice

of u(t) made by GPC is the opt i mal "mean-l evel "

cont rol l er which, if sustained, woul d place the

settled pl ant out put to w with the same dynami cs

as the open- l oop plant. Thi s cont r ol law (at least

for a simple stable plant) gives act uat i ons which

are generally smoot h and sluggish. Larger values

of N U, on the ot her hand, provi de mor e active

controls.

One useful intuitive i nt er pr et at i on of the use

of a cont r ol hor i zon is in the stabilization of

nonmi ni mum- phase plant. If the cont r ol weighting

2 is set to zero the opt i mal cont r ol which minimizes

J 1 is a cancel l at i on law which at t empt s t o remove

the process dynami cs using an inverse pl ant model

in the cont rol l er. As is well known, such (mi ni mum-

variance) laws are in practice unst abl e because

t hey involve growi ng modes in the cont r ol signal

cor r espondi ng to the pl ant ' s nonmi ni mum- phase

zeros. Const r ai ni ng these modes by placing infinite

cost i ng on fut ure cont r ol increments stabilizes the

resulting cl osed-l oop even if the weighting 2 is zero.

The use of NU < N mor eover significantly reduces

the comput at i onal burden, for the vect or fi is t hen

where:

GI =

-go

gl

gN- 1

0

go

gN- 2

0

0

i s N x NU.

go

g N - N u

The cor r espondi ng cont r ol law is given by:

f i = [ G ~ G I + ) . I ] - l G ~ ( w - f ) ( 2 0 )

and the mat ri x i nvol ved in the i nversi on is of the

much reduced di mensi on NU NU. In part i cul ar,

if NU = 1 (as is usefully chosen for a "simple"

plant), this reduces to a scalar comput at i on. An

exampl e of the comput at i ons i nvol ved is given in

Appendi x B.

3.2. Choice of the output and control horizons

Si mul at i on exercizes on a vari et y of pl ant models,

including stable, unst abl e and nonmi ni mum- phase

processes with variable dead-time, have shown how

N1 , N 2 and NU shoul d best be selected, These

studies also suggest t hat the met hod is robust

against these choices, giving the user a wide latitude

in his design.

3.2.1. NI: The minimum output horizon. If the

dead-t i me k is exactly known t here is no poi nt in

setting N1 t o be less t han k since t here would t hen be

superfl uous calculations in t hat the cor r espondi ng

out put s cannot be affected by the first act i on u(t).

If k is not known or is variable, t hen N1 can be set

to 1 with no loss of stability and the degree of

B(q-1) increased to encompass all possible values

of k.

3.2.2. N 2 : The maxi mum output horizon. If the

pl ant has an initially negat i ve-goi ng nonmi ni mum-

phase response, N 2 shoul d be chosen so t hat the

later positive-going out put samples are included in

the cost: in discrete-time this implies t hat N z exceeds

the degree of B( q- 1) as demonst r at ed in Appendi x

B. In practice, however, a r at her larger value of N2

is suggested, cor r espondi ng mor e closely to the rise-

time of the plant.

3.2.3. NU: The control horizon. Thi s is an i mport -

ant design paramet er. For a simple pl ant (e.g. open-

l oop stable t hough with possible dead-t i me and

Generalized predictive c ont r ol - - Pa r t I 143

nonmi ni mum-phasedness) a value of NU of 1 gives

generally acceptable control. Increasing NU makes

the cont rol and the correspondi ng out put response

more active until a stage is reached where any

furt her increase in NU makes little difference. An

increased value of NU is more appropri at e for

complex systems where it is found t hat good control

is achieved when NU is at least equal to the number

of unst abl e or badl y-damped poles.

One i nt erpret at i on of these rules for chosing NU

is as follows. Recall t hat GPC is a receding-

hori zon LQ cont rol law for which the future cont rol

sequence is recalculated at each sample. For a

simple, stable plant a cont rol sequence following a

step in the set-point is generally well-behaved (for

example, it would not change sign). Hence there

would not be significant corrections to the control

at the next sample even if NU = 1. However, it is

known from general state-space consi derat i ons t hat

a plant of order n needs n different control values

for, say, a dead-beat response. Wi t h a complex

system these values might well change sign frequ-

ently so t hat a short control hori zon would not

allow for enough degrees of freedom in the deriv-

at i on of the current action.

General l y it is found t hat a value of NU of 1 is

adequat e for typical industrial plant models,

whereas if, say, a modal model is to be stabilized

NU shoul d be set equal to the number of poles

near the stability boundary. If furt her dampi ng of

the cont rol act i on is then required 2 can be increased

from zero. Not e in part i cul ar that, unlike with

GMV, GPC can be used with a nonmi ni mum-

phase plant even if 2 is zero.

The above discussion implies t hat GPC can be

considered in two ways. For a process cont rol

default setting of N 1 = 1, N 2 equal to the plant rise-

time and NU = 1 can be used to give reasonable

performance. For hi gh-performance applications

such as the cont rol of coupled oscillators a larger

value of NU is desirable.

4. RELATI ONSHI P WI TH OTHER APPROACHES

GPC depends on the i nt egrat i on of five key

ideas: the assumpt i on of a CARI MA rat her t han

a CARMA plant model, the use of long-range

prediction over a finite hori zon greater t han the

dead-t i me of the plant and at least equal to the

model order, recursion of the Di ophant i ne equ-

ation, the consi derat i on of weighting of control

increments in the cost-function, and the choice of

a cont rol hori zon after which projected cont rol

increments are t aken to be zero. Many of these

ideas have arisen in the literature in one form or

anot her but not in the part i cul ar way described

here, and it is their j udi ci ous combi nat i on which

gives GPC its power. Nevertheless, it is useful

to see how previous successful met hods can be

considered as subsets of the GPC approach so t hat

accepted theoretical (e.g. convergence and stability)

and practical results can be extended to this new

met hod.

The concept of using long-range prediction as a

potentially robust control tool is due to Richalet

et al. (1978) in the I DCOM algorithm. This met hod,

t hough report edl y having some industrial success,

is restricted by its assumpt i on of a weighting-

sequence model (all-zeros), with an ad hoc way of

solving the offset probl em and with no weighting

on control action. Hence it is unsuitable for unstable

or nonmi ni mum- phase open-loop plants. The

DMC al gori t hm of Cut l er and Ramaker (1980) is

based on step-response models but does include

the key idea of a control horizon. Hence it is

effective for nonmi ni mum- phase plants but not

for open-l oop unstable processes. Again the offset

problem is dealt with heuristically and moreover

the use of a step-response model means t hat the

savings in paramet eri zat i on using a A( q- 1) poly-

nomi al are not available. Clarke and Zhang (1985)

compare the I DCOM and DMC designs.

The GMV approach of Clarke and Gawt hr op

(1975) for a plant with known dead-time k can be

seen to be a special case of GPC in which bot h the

mi ni mum and maxi mum horizons N1 and N2 are

set to k and onl y one cont rol signal (the current

cont rol u(t) or Au(t)) is weighted. This met hod is

known to be robust against overspecification of

model -order but it can onl y stabilize a certain class

of nonmi ni mum- phase plant for which the control

weighting 2 has to be chosen with reasonable care.

Moreover, GMV is sensitive to varying dead-t i me

unless 2 is large, with correspondi ngl y poor control.

GPC shares the robustness properties of GMV

wi t hout its drawbacks.

By choosing N1 = N2 --- d > k and NU -- 1 with

2 = 0, GPC becomes Ydstie' s (1984) extended-

hori zon approach. This has been shown theoret-

ically to be a stabilizing cont rol l er for a stable

nonmi ni mum- phase plant. Ydstie, however, uses a

CARMA model and the met hod has not been

shown to stabilize open-l oop unstable processes.

Indeed, for a plant with poorl y damped poles

si mul at i on experience shows t hat the extended-

hori zon met hod is unstable, unlike the GPC design.

This is because in this case more t han one future

out put needs to be account ed for in the cost-

function for stability (i.e. N 2 > N1).

Wi t h NI = 1, N z = d > k and NU= 1 with

2 = 0 and a CARI MA model, GPC reduces to

the independently-derived EPSAC al gori t hm (De

Keyser and Van Cauwenberghe, 1985). This was

shown by the aut hors to be a part i cul arl y useful

met hod with several practical applications; this is

verified by the simulations described below where

the "defaul t " settings of GPC t hat were adopt ed

144 I). W. C L AR KE et al.

with N 2 = 10 are similar to those of EPSAC Part

lI of this paper gives a stability result for these

settings of the GPC horizons.

Peterka' s elegant predictive cont rol l er (1984) is

nearest in phi l osophy to GPC: it uses a CARI MA-

like model and a similar cost-function, t hough

concent rat i ng on the case where N2--, ~ . The

algorithmic development is then rat her different

from GPC, relying on matrix factorization and

decomposi t i on for the finite-stage case, instead of

the rather more direct formul at i on described here.

Though Pet erka considers two values of control

weighting (2 x for the first set of controls and 22 for

the final 6B steps), he does not consider the useful

GPC case where 22 = ~,. GPC is essentially a

finite-stage approach with a restricted cont rol hor-

izon. This means (though not considered here) t hat

constraints on bot h future controls and control

rates can be t aken into account by suitable modi-

fications of tile GPC calculations - a generalization

which is impossible to achieve in infinite-stage

designs. Nevertheless, the Peterka procedure is an

i mport ant and applicable approach to adaptive

control.

5, A S I MUL AT I ON S T UDY

The objective of this st udy is to show how an

adaptive GPC i mpl ement at i on can cope with a

plant which changes in dead-time, in order and in

parameters compared with a fixed PID regulator,

with a GMV self-tuner and with a pole-placement

self-tuner. The PI D regulator was chosen to give

good cont rol of the initial plant model which for

this case was assumed to be known. For simplicity

all the adaptive met hods used a st andar d recursive-

least-squares paramet er est i mat or with a fixed for-

getting-factor of 0.9 and with no noise included in

the simulation.

The graphs display results over 400 samples of

si mul at i on for each met hod, showing the cont rol

signal in the range - 100 to 100, and the set-point

w(t) with the out put )~t) in the range - 1 0 to 80.

The control signal to the simulated process was

clipped to lie in [ - 100, 100], but no const rai nt was

placed on the plant out put so t hat the limitations

on ~(t) seen in Fig. 4 are graphical with the actual

out put exceeding the displayed values.

Each si mul at i on was organized as follows. Dur-

ing the first 10 samples the cont rol signal was fixed

at 10 and the est i mat or (initialized with parameters

[1, 0, 0 . . . . ]) was enabled for the adapt i ve control-

lers. A sequence of set-point changes between three

distinct levels was provided with switching every

20 samples. After every 80 samples the simulated

cont i nuous-t i me plant was changed, following the

models given in Table 1. It is seen t hat these changes

in dynami cs are large, and t hough it is difficult to

imagine a real plant varying in such a drastic way,

TABLE l , TRANSIER-FUNCTIONS Ot THE SIMlr

LATED MODELS

Nu mb e r S a mp l e s Mo d e l

1

I 1 79

I + 10s + 40s 2

2 8 0 - 1 5 9 e 2 ....

f + 10s + 40s 2

3 1 6 0 - 2 3 9 e .,7~

I + 10s

l

4 240 -319

1 + 10s

1

5 3 2 0 - 4 0 0

10s(l + 2. 5s)

the simulations were chosen to illustrate the relative

robustness and adapt i vi t y of the methods. The

models are given as Laplace transforms and the

sampling interval was chosen in all cases to be 1 s.

Figure 2 shows the behaviour of a fixed digital

PI D regulator which was chosen to give reasonable

if rat her sluggish cont rol of the initial plant. It

was i mpl ement ed in interacting PID form with

numer at or dynami cs of (I + 10s + 25s z) and with

a gain of 12. For models 1 and 5 this controller

gave acceptable results but its performance was

poor for the other models with evident excessive

gain. Despite integral action (with desaturation)

offset is seen with models 3 and 4 due to persistent

control sat urat i on.

The first adaptive controller to be considered

was the GMV approach of Clarke and Gawt hr op

(1975, 1979) using design transfer-functions:

p(q- 1 ) = ( 1 - 0 . 5 q - 1 ) / 0 . 5 and

Q(q- 1) = (1 - q- ~)/(1-0.5q- ~),

with the "det uned model-reference" interpretation.

This implicit self-tuner used a k-step-ahead predi-

ctor model with 2F(q-1) and 5 G(q-1) parameters

and with an adopt ed fixed value for k of 2. The

det uned version of GMV was chosen as the dead-

time was known to be varying and the use of Q(q- 1)

makes the design less sensitive to the value of k.

Not e in part i cul ar t hat for models 2 and 3 the

real dead-time is greater t han in the two samples

assumed.

The si mul at i on results using GMV are shown in

Fig. 3; reasonable if not particularly "t i ght " cont rol

was achieved for models 1, 3, 4 and 5. The weighting

of control increments (as found in other cases)

contributes to the overshoots in the step responses.

The behavi our with model 2 was, however, less

acceptable with poorl y damped transients. Never-

theless, the adapt at i on mechanism worked well and

the responses are certainly better t han with the

nonadapt i ve PI D controller.

An increasingly popul ar met hod in adaptive

General i zed predictive c o n t r o l - - Pa r t I 145

6 0 o/~

- l a */

Out put ( Y )

Systeml~ change

'~ 400

Syst em chonge

I OO */~

0",

-I00"/@

Cont r ot si gnal

400

FIG. 2. The fixed PID controller with the variable plant.

60 / -

- i o o / ~

Out put ( Y

S y s t e m ~ c h a n g e

, 1 I 1 1

' t ' ' t ' '

Syst em ~ change Syst em change Syst em change ~oo

Cont r o I . signaL

400

FIG. 3. The behaviour of the adaptive GMV controller.

cont r ol is pol e-pl acement (Wellstead et al . , 1979) as

vari at i ons in pl ant dead-t i me can be cat ered for

using an augment ed B( q- 1) pol ynomi al . To cover

the range of possibilities of dead-t i me here 2 A( q - ~)

and 6B(q -1) par amet er s were est i mat ed and the

desired pol e-posi t i on was specified by a pol ynomi al

p ( q - l ) = 1 - 0 . 5 q -1 (i.e. like the GMV case

wi t hout detuning). Fi gure 4 shows how an adapt i ve

pol e-pl acer which solves the cor r espondi ng

Di ophant i ne equat i on at each sampl e coped with

the set of si mul at ed models. For cases 1, 2 and 5

the out put response is good with less over shoot

t han t he GMV appr oach. For t he fi rst -order model s

3 and 4, however, the al gor i t hm is ent i rel y ineffective

due to singularities in t he Di ophant i ne solution.

This verifies the observat i ons t hat pol e-pl acement

is sensitive t o model - or der changes. In ot her cases,

even t hough the response is good, the cont r ol is

r at her "jittery".

The GPC cont r ol l er i nvol ved the same number s

of A and B (2 and 6) par amet er s as in t he pole-

pl acement simulation. Defaul t settings of t he out put

and cont r ol hor i zons were chosen with N 1 = I,

N 2 = 10 and N U = 1 t hr oughout , as it has been

f ound t hat this gives r obust performance. Fi gure 5

shows the excellent behavi our achi eved in all cases

6 0 ,~

-IOO/o

lOG / *

0 */ *

-IOO/o

Output ( Y ]

System change Systerr change

, I

i t ,

System change Syst em change 400

Cont r ol si gnal

146 D. W. CLARKE e t al .

0 400

FIG. 4. The behavi our of the adaptive pole-placer.

6O*/o Out put ( Y )

- i o /o

o

Cont rol signal

o o I I I . . . . .

o

i I

a o o

FIG. 5. The behavi our of the adaptive GPC algorithm.

by the GPC algorithm. For each new model only

at most two steps in the set-point were required for

full adaptation, but more importantly there is no

sign of instability, unlike all the other controllers.

6. CONCLUSI ONS

This paper has described a new robust algorithm

which is suitable for challenging adaptive control

applications. The method is simple to derive and

to implement in a computer; indeed for short

control horizons GPC can be mounted in a micro-

computer. A simulation study shows that GPC is

superior to currently accepted adaptive controllers

when used on a plant which has large dynamic

variations.

Montague and Morris (1985) report a compar-

ative study of GPC, LQG, GMV and pole-place-

ment algorithms for control of a heat-exchanger

with variable dead-time (12-85s, sampled at 6s

intervals) and for controlling the biomass of a

penicillin fermentation process. The controllers

were programmed on an IBM PC in pro-

Fortran/proPascal. Their paper concludes that the

GPC approach behaved consistently in practice

and that "the LQG and GPC algorithms gave the

best all-round performance", the GPC method

Generalized predictive cont r ol - - Par t I 147

being preferred for long time-delay processes, and

it confirms that GPC is simple to implement and

t o u s e .

The GPC method is a further generalization of

the well-known GMV approach, and so can be

equipped with design polynomials and transfer-

functions which have interpretations as in the GMV

case. The companion paper Part II, which follows,

explores these ideas and presents simulations which

show how GPC can be used for more demanding

control tasks.

e = [El ( t + 1),E2~(t + 2) . . . . . EN(t + N)] r.

Cl earl y as e is a st ochast i c pr ocess t he expect ed value of t he

cost subj ect t o appr opr i at e condi t i ons must be mi ni mi zed. The

cost t o be mi ni mi zed t herefore becomes

J l = E{(y - w)T(y - w) + )~firfi}.

Two different assumpt i ons will be made in t he next sect i on

about t he class of admi ssi bl e cont r ol l er s for t he mi ni mi zat i on

of t he cost above. Onl y model s of aut oregressi ve t ype are

consi dered:

A( q- l)y(t) = B( q- ~)u(t - 1) + (t)/A.

REFERENCES

As t r r m, K. J. and B. Wi t t enmar k (1973). On sel f-t uni ng regula-

tors. Aut omat i ca, 9, 185-199.

, ~st r r m, K. J. and B. Wi t t enmar k (1980). Sel f-t uni ng cont r ol l er s

based on pol e-zero pl acement . Proc. l EE, 127D, 120-130.

Bertsekas, D. P. (1976). Dynami c Programmi ng and St ochat i c

Control. Academi c Press, New York.

Cl arke, D. W. (1984). Sel f-t uni ng cont r ol of nonmi ni mum- phas e

syst ems. Aut omat i ca, 20, 501-517.

Cl arke, D. W. and P. J. Ga wt hr op (1975). Self-tuning cont rol l er.

Proc. I EE, 122, 929-934.

Clarke, D. W. and P. J. Ga wt hr op (1979). Sel f-t uni ng cont rol .

Proc. I EE, 126, 633-640.

Clarke, D. W. and L. Zhang (1985). Does l ong- r ange predi ct i ve

cont r ol work? l EE Conf er ence "Cont r ol 85", Cambr i dge.

Cut l er, C. R. and B. L. Ramaker (1980). Dynami c Mat r i x

Co n t r o l - - A Comput er Cont rol Algorithm. JACC, San Fr anci -

sco.

De Keyser, R. M. C. and A. R. Van Cauwenber ghe (1982).

Typical appl i cat i on possi bi l i t i es for sel f-t uni ng predi ct i ve

cont rol . I F A C Syrup. Ident. Syst . Param. Est., Washi ngt on.

De Keyser, R. M. C. and A. R. Van Cauwenber ghe (1983).

Mi cr ocomput er - cont r ol l ed servo syst em based on sel f-adap-

tive l ong- r ange predi ct i on. Advances in Meas ur ement and

Co n t r o l - - - MECO 1983.

De Keyser, R. M. C. and A. R. Van Cauwenber ghe (1985).

Ext ended pr edi ct i on sel f-adapt i ve cont rol . I F A C Syrup. l dent .

Syst . Param. Est., York.

Kai l at h, T. (1980). Li near Syst ems. Prent i ce-Hal l , Engl ewood

Cliffs, NJ.

Kurz, H. and W. Goedecke (1981). Digital par amet er - adapt i ve

cont r ol of processes wi t h unknown dead time. Aut omat i ca,

17, 245-252.

Mont ague, G. A. and A. J. Mor r i s (1985). Appl i cat i on of adapt i ve

cont rol : a heat exchanger syst em and a penicillin f er ment at i on

process. Thi r d wor ks hop on t he t heor y and appl i cat i on of

sel f-t uni ng and adapt i ve cont rol , Oxford, U. K.

Mosca, E., G. Zappa and C. Manf r edi (1984). Mul t i st ep hor i zon

sel f-t uni ng cont rol l ers: t he MUS MAR appr oach. I FAC 9th

Wor l d Congr ess, Budapest , Hungar y.

Pet erka, V. (1984). Pr edi ct or - based sel f-t uni ng cont rol . Aut oma-

tica, 20, 39-50.

Richalet, J., A. Rault, J. L. Test ud and J. Pa pon (1978).

Model predi ct i ve heuri st i c cont rol : appl i cat i ons t o i ndust ri al

processes. Aut omat i ca, 14, 413-428.

Schweppe, F. C. (1973). Uncert ai n Dynami c Syst ems. Pr ent i ce

Hall, Engl ewood Cliffs, NJ.

Tufts, P. S. and D. W. Cl ar ke (1985). Sel f-t uni ng cont r ol of

offset: a unified appr oach. Proc. I EE, 132D, 100-110.

Wellstead, P. E., D. Pr ager and P. Zanker (1979). Pol e assi gnment

sel f-t uni ng regul at or. Proc. l EE, 126, 781-787.

Ydstie, B. E. (1984). Ext ended hor i zon adapt i ve cont rol . I FAC

9th Wor l d Congr ess, Budapest , Hungary.

AP P ENDI X A. MI NI MI ZATI ON PROPERTI ES OF GP C

Cons i der t he per f or mance i ndex

J = (y - w)r(y - w) + 2iiTii wher e y = Gii + f + e

wher e y, w, fi are as defi ned in t he mai n t ext and

In t he general case of CARI MA model s wher e t he di st ur bances

are non- whi t e t he pr e di c t i ons f ( t + i) are onl y opt i mal as ympt ot -

ically as t hey have pol es at t he zeros of t he C( q- 1) and t he effect

of initial condi t i ons is onl y el i mi nat ed as t i me t ends t o infinity.

The cl osed- l oop pol i cy requi res an opt i mal Ka l ma n filter wi t h

t i me-varyi ng filter gains, see Schweppe (1973); t he par amet er s

of t he C- pol ynomi al are onl y t he gai ns of t he st eady- st at e

Kal man filter once conver gence is at t ai ned. Thus t he cl osed-

l oop and t he open- l oop- f eedback policies exami ned bel ow are

different in t he case of col our ed noise.

A.1. RELATI ON OF GP C AND OP E N- L OOP -

F EEDBACK- OP TI MAL CONTROL

In t hi s st rat egy it is assumed t hat t he fut ure cont r ol si gnal s

are i ndependent of fut ure measur ement s (i.e. all will be per f or med

in open- l oop) and we cal cul at e t he set fi such t hat it mi ni mi zes

t he cost J~. The first cont r ol in t he sequence is appl i ed and at

t he next sampl e t he cal cul at i ons are repeat ed. The cost becomes:

J l = E{iiT( Gr G + 2I)fi + 2/ i r ( GT( f - W) + Gre)

+ f r f + ere + WTW + 2fr(e _ w) -- 2eTw}.

Because of t he as s umpt i on above, E{/iTGTe} = 0; not e al so t hat

t he cost is onl y affected by t he first t wo t erms. By put t i ng t he

first deri vat i ve of t he cost equal t o zer o one obt ai ns:

fi = ( Gr G + 21)- IGT(w - t).

A.2. RELATI ON OF GP C AND CLOS ED- LOOP -

F EEDBACK- OP TI MAL CONTROL

Choos e t he set ii such t hat t he cost J l is mi ni mi zed subj ect

to t he condi t i on t hat Au(i) is onl y dependent on dat a up t o t i me

i. Thi s is t he st at ement of causality. In or der to find t he set ii

assume t hat by some means {Au(t), Au(t + 1) . . . . . Au(t + N - 2)}

is available.

Jl = E{(Au(t) . . . . .

Au(t + N - 1))(GrG + ~I)(Au(t) . . . . .

A u ( t + N - 1) "r

+ 2 i l r ( Gr ( f - w))

+ 2(Au(t) . . . . . Au(t + N - 1))Gre}

+ ext r a t er ms i ndependent of mi ni mi zat i on.

Not e t hat in eval uat i ng Au(t + N - 1) t he last row Gr e is

g o ~ e i ~ ( t + N - i ) and E { A u ( t + N - 1) ( t +N) } = 0 by t he

as s umpt i on of part i al i nf or mat i on. Ther ef or e Au(t + N - 1) can

be cal cul at ed assumi ng ~(t + N) = 0. Fr om general st at e- space

consi der at i ons it is evi dent t hat when mi ni mi zi ng a quadr at i c

cost, assumi ng a l i near pl ant model wi t h addi t i ve noise, t he

resul t i ng cont r ol l er is a l i near funct i on of t he avai l abl e measure-

ment s (i.e. u(t) = - k ( t ) wher e k is t he feedback gai n and ~(t)

is t he st at e est i mat e from t he appr opr i at e Ka l ma n filter).

Au(t + N - 1) = linear funct i on(Au(t + N - 2),

A u ( t + N - 3 ) . . . . . ~ ( t + N- 1 ) ,

~(t + N - 2) . . . . . y(t ), y(t - 1),...).

148 D. W. CLARKE et al .

In c a l c u l a t i n g A u ( t + N 2) t he f o l l o wi n g e x p e c t a t i o n s ar e zer o:

E I A u l t + N 2)~(t + N) ] - 0,

E f L A u ( t + N 2)~{t + N 1) ~, - 0.

I n o r d e r t o wo r k o u t E I A u { t + N - 1)Au(t + N - 2)I, t he pa r t

of t he e x p e c t a t i o n a s s o c i a t e d wi t h {(t + N - 1) i s set t o zer o as

t he c o n t r o l s i gna l A u ( t + N 2) c a n n o t be a f unc t i on of

5 , ( t + N - 1 ) . As A u ( t + N - 1 ) is a l i n e a r f unc t i on of

( t + N- I) t hi s i mpl i e s t h a t as f ar as c a l c u l a t i o n of

A u ( t + N - 2) i s c o n c e r n e d , A u ( t + N - 1) c o u l d be c a l c u l a t e d

by a s s u mi n g t h a t {(t + N - 1) a n d {(t + N) wer e zer o. Si mi l a r l y,

t he s a me a r g u me n t a p p l i e s f or t he r est of c o n t r o l s i gna l s a t e a c h

s t e p i a s s u mi n g E { A u ( t + i ) { ( t + j ) t _ 0 f o r ) > i. Th i s i mpl i e s

t h a t e a c h c o n t r o l s i gna l A u ( t + i ) i s t he i t h c o n t r o l i n t he

s e q u e n c e a s s u mi n g t h a t (t + j ) = 0 f or j > i. He n c e f or Au(t)

t he s o l u t i o n a mo u n t s t o c a l c u l a t i n g t he f i r st c o n t r o l s i g n a l

s e t t i n g {(t + j ) f or j > 0 t o zer o t he s a me as t h a t c o n s i d e r e d

i n pa r t I f or a n Op e n - L o o p - F e e d b a c k - Op t i ma l c ont r ol l e r . No t e

t h a t i n t he cas e of N U < N 2 t he mi n i mi z a t i o n i s p e r f o r me d

s ubj e c t t o t he c o n s t r a i n t t h a t t he l a s t N 2 - N U + 1 c o n t r o l

s i g n a l s a r e al l equal . Co n s i d e r a t i o n of c a u s a l i t y of t he c o n t r o l l e r

i mp l i e s t h a t A u ( t + N U - 1) i s t he fi rst free s i gna l t h a t c a n be

c a l c u l a t e d as a f unc t i on of d a t a a v a i l a b l e u p t o t i me t + N U - 1

i n t he s e que nc e a n d t he a r g u me n t a b o v e f ol l ows a c c or di ngl y.

The r e f or e , t he GP C mi n i mi z a t i o n ( OL F O) i s e q u i v a l e n t t o t he

c l o s e d - l o o p pol i c y f or mo d e l s of r e gr e s s i on t ype.

AP P E NDI X B. AN E XAMP L E F OR A F I RS T OR DE R

P R OC E S S

Th i s a p p e n d i x e x a mi n e s t he r e l a t i o n of N 2 a n d t he c l os e d-

l o o p pol e p o s i t i o n f or a s i mp l e e x a mp l e . Co n s i d e r a n o n mi n i m-

ur n- pha s e f i r s t - or de r pr oc e s s ( f i r s t - or de r + f r a c t i ona l de a d- t i me ) :

(1 + a l q - 1 ) y ( t } = ( b o + b l q - l l u ( t - I)

1 1 - - 0 . g q - l ) y { t ) = ( I + 2 q - l ) u l t - - I ) .

B. I. E AND F P AR AME T E R S

F r o m t he r e c ur r e nc e r e l a t i o n s h i p s i n t he ma i n t ext i t f ol l ows

t hat :

e i = 1 - - a l e i _ G.lio - 1 -- J l G . t i l = e i a a

eo = l : [ 1. O] ; f l o = (1 - aO: [ 1. 9] ; . l ; ~ = a , : [ - 0 . 9 ]

e 1 = 1 - a l : [ l . 9 ] ; J 2 o = 1 - al{1 - a 0 : [ 2 . 7 1 ] ;

J21 = a d l - a 0 : [ - 1.71]

e 2 = 1 - a d l - a l ) : [ 2. 71] ;

f3o = 1 a l ( l -- at ( 1 -- a 0 ) : [ 3 . 4 3 9 ]

.131 = a d 1 - al ( 1 - a 0 ) : [ - 2 . 4 3 9 ] -

B.2. C ONT R OL L E R P AR AME T E R S

go = bo: [ 1. 0] ; g t 1 = b~: [ 2. 0]

g l = bo{l - a l ) + b l : [ 3 . 9 ] ; g 2 2 = bt{1 - a 0 : [ 3 . 8 ]

g2 = b0( l - al ( 1 - a~)) + bl (1 - a t ) : [ 6. 51] ;

g33 = bl ( 1 - a d l - a 0 ) : [ 5 . 4 2 ] .

As s u mi n g N U = 1, t he effect of N 2 o n t he c o n t r o l c a l c u l a t i o n

a n d t he c l o s e d - l o o p pol e p o s i t i o n i s n o w e x a mi n e d :

A u { t ) = ( ~ , g d w , - J i o y ( t - 1 ) - l i l y ( t - 2 ) )

- g , A u t t - l)y~ (g~)2.

Fo r a c o n t r o l l e r of t he f or m R l q ~ l A u { t ) = w ( t ) - S ( q ~l,~,t~

'SO = 'ff'~ g i . iO, L,~gt

. ~ 1 = Y . ~ , J i , . . ' Z g ,

2 ,

ro = Z ( g a . ' ~ . ~ ,

r , = ~ , , g l g l i , " ~ g i

a n d t he c l o s e d - l o o p p o l e - p o s i t i o n s a r e at t he r o o t s of

R A A + q - t S B .

N2 = I

Au(t) = [ w - 1.9y(t) + 0. 9y(t - 1} - 2Au( t - 1)]

R A A + q - I S B : : : > ( I + 2q- 1) .

Th i s i s t he mi n i mu m- p r o t o t y p e c o n t r o l l e r whi c h, b e c a u s e of t he

c a n c e l l a t i o n of t he n o n mi n i mu m- p h a s e zer o, i s uns t a bl e .

N 2 = 2 ( i . e . g r e a t e r t h a n deg(B))

Au(t) = [ w - 1.9y(t) + 0. 9y(t - 1) - 2Au(t - 1)

+ 3.91w - 2.71y~t} + 1.71y(t - 1)

- 3. 8Au(t - 1))]/16.21

o r ~

and:

Au(t ) = [ 4. 9w - 12. 469y(t) + 7. 569y(t - 1)

- 16. 82Au(t - 1)]/16. 21

A R A + q - I S B ~ ( I - 0. 09q- 1).

Th e c l o s e d - l o o p pol e i s wi t h i n t he u n i t ci r cl e a n d t her ef or e t he

c l o s e d - l o o p i s s t abl e. I n f act i t c a n e a s i l y be d e mo n s t r a t e d t h a t

f or al l f i r st o r d e r pr oc e s s e s N2 > 6 B ( q - 1 ) + k - 1 s t a bi l i z e s a n

/ k

o p e n - l o o p s t a b l e pl a nt , f or s i g n ( Z g i ] = s i g n ( D. C. g a i n ).

\ /

N2 = 3

and:

Au(t ) = [ 11. 41w - 34. 857y{t) + 23. 447y( t - 1)

- 52. 104Au(t - 1)]/58. 591

A R A + q I S B = * . ( 1 - 0 . 4 1 6 q - 1 ) .

Th e pol e i s a g a i n wi t h i n t he uni t ci rcl e. No t e t h a t t he c l os e d-

l o o p pol e i s t e n d i n g t o wa r d s t he o p e n - l o o p pol e as N 2 i nc r e a s e s

(see Pa r t II).

Anda mungkin juga menyukai

- Generalized Predictive Control Part II. Extensions and InterpretationsDokumen12 halamanGeneralized Predictive Control Part II. Extensions and Interpretationsfiregold2100% (1)

- Induction Motor Control Through AC DC AC ConverterDokumen7 halamanInduction Motor Control Through AC DC AC ConverterJohn CollinsBelum ada peringkat

- Solution To The Positive Real Control Problem For Linear Time-Invariant SystemsDokumen13 halamanSolution To The Positive Real Control Problem For Linear Time-Invariant SystemsRohit GandhiBelum ada peringkat

- BOOK4 PsDokumen128 halamanBOOK4 Psgoyo2kBelum ada peringkat

- Dynamic Model of Induction Motors for Vector ControlDokumen10 halamanDynamic Model of Induction Motors for Vector ControlMarica RalucaBelum ada peringkat

- Complex Vector Model of The Squirrel Cage Induction Machine Including Instantaneous Rotor Bar CurrentsDokumen8 halamanComplex Vector Model of The Squirrel Cage Induction Machine Including Instantaneous Rotor Bar CurrentsJorge Luis SotoBelum ada peringkat

- bjorckLSbSolving Linear Least Squares Problems by Orthogonal Gramschmidt OrthogonalizationDokumen21 halamanbjorckLSbSolving Linear Least Squares Problems by Orthogonal Gramschmidt Orthogonalizationdgh3Belum ada peringkat

- Modelling and Control of A Gas Pressure Reduction SystemDokumen339 halamanModelling and Control of A Gas Pressure Reduction SystemErick Renzo Hidalgo OrtegaBelum ada peringkat

- Investigation On The Performance of Linear Antenna Array Synthesis Using Genetic AlgorithmDokumen7 halamanInvestigation On The Performance of Linear Antenna Array Synthesis Using Genetic AlgorithmCyberJournals MultidisciplinaryBelum ada peringkat

- Embedded Model Predictive Control For An ESP On A PLCDokumen7 halamanEmbedded Model Predictive Control For An ESP On A PLCRhaclley AraújoBelum ada peringkat

- Matrix ExponentialDokumen14 halamanMatrix Exponentialvignesh0617Belum ada peringkat

- Symmetrical ComponentsDokumen8 halamanSymmetrical Componentssrikanth velpulaBelum ada peringkat

- 1980 - Stable Adaptive Controller Design, Part II - Proof of Stability (Narendra)Dokumen9 halaman1980 - Stable Adaptive Controller Design, Part II - Proof of Stability (Narendra)ademargcjuniorBelum ada peringkat

- IC1252Dokumen0 halamanIC1252Eugin RajBelum ada peringkat

- Feedback Amplifiers Analysis PDFDokumen2 halamanFeedback Amplifiers Analysis PDFDanBelum ada peringkat

- Feedback Amplifiers PDFDokumen2 halamanFeedback Amplifiers PDFMariaBelum ada peringkat

- Electrical Drives Course CodeDokumen2 halamanElectrical Drives Course Coderamkashyap117Belum ada peringkat

- Athans, M. - The Matrix Mininum Principle (NASA)Dokumen23 halamanAthans, M. - The Matrix Mininum Principle (NASA)benito59olivaresBelum ada peringkat

- Lab 591 - B Analysis and Design of CSDokumen2 halamanLab 591 - B Analysis and Design of CSDevine WriterBelum ada peringkat

- Magnetic Equivalent Circuit ModelingDokumen12 halamanMagnetic Equivalent Circuit ModelingJavad Rahmany FardBelum ada peringkat

- Improved Active Power Filter Performance For Renewable Power Generation SystemsDokumen8 halamanImproved Active Power Filter Performance For Renewable Power Generation SystemsKuncham SateeshBelum ada peringkat

- (George C. Chryssis) High Frequency Switching Powe PDFDokumen151 halaman(George C. Chryssis) High Frequency Switching Powe PDFJesus BarraganBelum ada peringkat

- Determination of Instantaneous Currents and Voltages by Means of Alpha, Beta, and Zero ComponentsDokumen8 halamanDetermination of Instantaneous Currents and Voltages by Means of Alpha, Beta, and Zero ComponentsEmre Özer100% (1)

- Course Code Course Name Course Structure Ececc05 Signal and Systems 3-1-0 L-T-PDokumen2 halamanCourse Code Course Name Course Structure Ececc05 Signal and Systems 3-1-0 L-T-PSuvdeep NayakBelum ada peringkat

- Analysis of Class B Push-Pull Amplifier CircuitDokumen24 halamanAnalysis of Class B Push-Pull Amplifier CircuitMbugua DuncanBelum ada peringkat

- Convex Programming LecturesDokumen212 halamanConvex Programming LecturespdfeeBelum ada peringkat

- MatlabDokumen45 halamanMatlabHamid SiBelum ada peringkat

- Mehra - On The Identification of Variances and Adaptive Kalman FilteringDokumen10 halamanMehra - On The Identification of Variances and Adaptive Kalman FilteringSean ShugarBelum ada peringkat

- Emanuel Parzen Modern Probability Theory and Its ApplicationsDokumen480 halamanEmanuel Parzen Modern Probability Theory and Its ApplicationsAlfonzo Orozco100% (1)

- Cascode CS LNA Design ExampleDokumen8 halamanCascode CS LNA Design Examplesviji100% (1)

- Multisim Unsolved Questions BITS PilaniDokumen2 halamanMultisim Unsolved Questions BITS Pilanimanish_genus100% (1)

- Design DC-DC Converter Topology Full-Bridge 24/400 V 300 W 100Khz With Zero Voltage Switching Phase Shift PWM MethodDokumen6 halamanDesign DC-DC Converter Topology Full-Bridge 24/400 V 300 W 100Khz With Zero Voltage Switching Phase Shift PWM MethodtriwahonoBelum ada peringkat

- Enhanced Single-Loop Control StrategiesDokumen26 halamanEnhanced Single-Loop Control Strategiesmeseret sisay100% (1)

- Discriminating Large Inrush Currents Due To Fault CurrentsDokumen9 halamanDiscriminating Large Inrush Currents Due To Fault CurrentsgilbertomjcBelum ada peringkat

- Modeling and Simulation of Sensorless Control of PMSM With Luenberger Rotor Position Observer and Sui Pid ControllerDokumen8 halamanModeling and Simulation of Sensorless Control of PMSM With Luenberger Rotor Position Observer and Sui Pid ControllerYassine MbzBelum ada peringkat

- Mod12 - Lecture 1Dokumen31 halamanMod12 - Lecture 1VAISHAKA N RAJ100% (1)

- Kaddour Najim Control of Continuous Linear SystemsDokumen11 halamanKaddour Najim Control of Continuous Linear SystemsChrislei RizzattiBelum ada peringkat

- CorrectDokumen3 halamanCorrectapi-3779248Belum ada peringkat

- Extraction of The Internal Parameters of Solar Photovoltaic Module by Developing Matlab / Simulink Based ModelDokumen5 halamanExtraction of The Internal Parameters of Solar Photovoltaic Module by Developing Matlab / Simulink Based Modelzameer05090% (1)

- ZSimpWin EIS Software Technical Note on Kramers-Kronig ExtrapolationDokumen13 halamanZSimpWin EIS Software Technical Note on Kramers-Kronig ExtrapolationChaitanya RaiBelum ada peringkat

- Boukamp 2020 J. Phys. Energy 2 042001Dokumen25 halamanBoukamp 2020 J. Phys. Energy 2 042001Jayveer JoshiBelum ada peringkat

- Line Follower RobotDokumen16 halamanLine Follower RobotAmit KumarBelum ada peringkat

- Chapter 8Dokumen29 halamanChapter 8Deivasigamani SubramaniyanBelum ada peringkat

- Unit I - Discrete State-Variable Technique Q.No Questions: Scalar Adder IntegratorDokumen184 halamanUnit I - Discrete State-Variable Technique Q.No Questions: Scalar Adder IntegratorAgatha ChristieBelum ada peringkat

- Mandatory Assignment Robust and Fault Tolerant ControlDokumen8 halamanMandatory Assignment Robust and Fault Tolerant ControlMassimiliano CurziBelum ada peringkat

- HFSS Tutorial 1Dokumen7 halamanHFSS Tutorial 1Tushar DebnathBelum ada peringkat

- A 1.5-V, 1.5-GHz CMOS Low Noise Amplifier - Solid-State Circuits, IEEE Journal of PDFDokumen15 halamanA 1.5-V, 1.5-GHz CMOS Low Noise Amplifier - Solid-State Circuits, IEEE Journal of PDFAnirban HomroyBelum ada peringkat

- KLP 2780 PG1Dokumen1 halamanKLP 2780 PG1Batzorig RegzenBelum ada peringkat

- Mwoc Final Lab Manual 28-08-2010Dokumen77 halamanMwoc Final Lab Manual 28-08-2010downloadscribdpdfBelum ada peringkat

- Unified Theory of Machine Paper PDFDokumen1 halamanUnified Theory of Machine Paper PDFOladeji Ifedayo RBelum ada peringkat

- Novel Switching Sequences For A Space Vector Modulated Three Level Inverter-LibreDokumen11 halamanNovel Switching Sequences For A Space Vector Modulated Three Level Inverter-LibreHollie RosaBelum ada peringkat

- System Level Simulation of Acoustic DevicesDokumen8 halamanSystem Level Simulation of Acoustic DevicesErdet NasufiBelum ada peringkat

- Model Predictive Control of A DC-DC Buck ConverterDokumen7 halamanModel Predictive Control of A DC-DC Buck ConverterMeral MeralBelum ada peringkat

- Electrical Overstress (EOS): Devices, Circuits and SystemsDari EverandElectrical Overstress (EOS): Devices, Circuits and SystemsBelum ada peringkat

- Mathematical Aspects of Seismology: Developments in Solid Earth GeophysicsDari EverandMathematical Aspects of Seismology: Developments in Solid Earth GeophysicsBelum ada peringkat

- 2015 - Measurement-Based Analysis of The Dynamic Performance of Microgrids Using System Identification TechniquesDokumen14 halaman2015 - Measurement-Based Analysis of The Dynamic Performance of Microgrids Using System Identification TechniquesademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 97Dokumen5 halamanIeee Argencon 2016 Paper 97ademargcjuniorBelum ada peringkat

- 2015 - System Identification of An Interconnected Power System With An Energy Storage System For Robust Stability ImprovementDokumen5 halaman2015 - System Identification of An Interconnected Power System With An Energy Storage System For Robust Stability ImprovementademargcjuniorBelum ada peringkat

- 2015 - Data-Driven Predictive Direct Load Control of Refrigeration SystemsDokumen12 halaman2015 - Data-Driven Predictive Direct Load Control of Refrigeration SystemsademargcjuniorBelum ada peringkat

- 2014 - A System Identification Method For Smart Distribution GridDokumen6 halaman2014 - A System Identification Method For Smart Distribution GridademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 94Dokumen6 halamanIeee Argencon 2016 Paper 94ademargcjuniorBelum ada peringkat

- 2012 - Solar Generation Prediction Using The ARMA Model in A Laboratory-Level Micro-GridDokumen6 halaman2012 - Solar Generation Prediction Using The ARMA Model in A Laboratory-Level Micro-GridademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 89Dokumen5 halamanIeee Argencon 2016 Paper 89ademargcjuniorBelum ada peringkat

- 2012 - Noninvasive Monitoring of Residential LoadsDokumen5 halaman2012 - Noninvasive Monitoring of Residential LoadsademargcjuniorBelum ada peringkat

- Causal and Non-Causal Entropy Quantifiers Implemented in FPGADokumen5 halamanCausal and Non-Causal Entropy Quantifiers Implemented in FPGAademargcjuniorBelum ada peringkat

- 2015 - Building Energy Forecasting Using System Identification Based On System Characteristics TestDokumen6 halaman2015 - Building Energy Forecasting Using System Identification Based On System Characteristics TestademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 95Dokumen6 halamanIeee Argencon 2016 Paper 95ademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 28Dokumen6 halamanIeee Argencon 2016 Paper 28ademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 98Dokumen4 halamanIeee Argencon 2016 Paper 98ademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 33Dokumen6 halamanIeee Argencon 2016 Paper 33ademargcjuniorBelum ada peringkat

- Localizador de Fuente Sonora Basado en Red Inal Ambrica de SensoresDokumen6 halamanLocalizador de Fuente Sonora Basado en Red Inal Ambrica de SensoresademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 74Dokumen7 halamanIeee Argencon 2016 Paper 74ademargcjunior100% (1)

- An Analysis of Recurrent Neural Networks For Botnet Detection BehaviorDokumen6 halamanAn Analysis of Recurrent Neural Networks For Botnet Detection BehaviorademargcjuniorBelum ada peringkat

- Analysis and Emulation of A Photovoltaic Solar System Using A MATLAB/Simulink Model and The DS1104 UnitDokumen6 halamanAnalysis and Emulation of A Photovoltaic Solar System Using A MATLAB/Simulink Model and The DS1104 UnitademargcjuniorBelum ada peringkat

- Covert Channel Sobre SSL Heartbeat: Luis A. Catanzariti y Nestor MasnattaDokumen6 halamanCovert Channel Sobre SSL Heartbeat: Luis A. Catanzariti y Nestor MasnattaademargcjuniorBelum ada peringkat

- Numerical Study of The Unsteady Aerodynamics of Rotating SeedsDokumen6 halamanNumerical Study of The Unsteady Aerodynamics of Rotating SeedsademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 19Dokumen7 halamanIeee Argencon 2016 Paper 19ademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 12Dokumen4 halamanIeee Argencon 2016 Paper 12ademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 8Dokumen6 halamanIeee Argencon 2016 Paper 8ademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 30Dokumen6 halamanIeee Argencon 2016 Paper 30ademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 11Dokumen6 halamanIeee Argencon 2016 Paper 11ademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 5Dokumen6 halamanIeee Argencon 2016 Paper 5ademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 9Dokumen6 halamanIeee Argencon 2016 Paper 9ademargcjuniorBelum ada peringkat

- Ieee Argencon 2016 Paper 14Dokumen6 halamanIeee Argencon 2016 Paper 14ademargcjuniorBelum ada peringkat

- CC ST Overview BrochureDokumen8 halamanCC ST Overview BrochureademargcjuniorBelum ada peringkat

- Chapter 1Dokumen19 halamanChapter 1Shehzana MujawarBelum ada peringkat

- Mineline MSP Sell SheetDokumen2 halamanMineline MSP Sell SheetMary Huaylla ABelum ada peringkat

- Consultancy Project Assessment SheetDokumen1 halamanConsultancy Project Assessment SheetSadeeqBelum ada peringkat

- Dabhol Power Plant: Case Analysis Report OnDokumen11 halamanDabhol Power Plant: Case Analysis Report OnDhruv ThakkarBelum ada peringkat

- Debpriyo Roy Lab 1Dokumen7 halamanDebpriyo Roy Lab 1udaikiranBelum ada peringkat

- BRCC Selection Policy HP Sept 2014 by Vijay Kumar Heer PDFDokumen7 halamanBRCC Selection Policy HP Sept 2014 by Vijay Kumar Heer PDFVIJAY KUMAR HEERBelum ada peringkat

- Educ 210Dokumen2 halamanEduc 210Julie Ann CruzBelum ada peringkat

- A Sample Demonstration Lesson PlanDokumen9 halamanA Sample Demonstration Lesson PlanMarie Patrize Punzalan100% (1)

- Jamel P. Mateo, Mos, LPTDokumen7 halamanJamel P. Mateo, Mos, LPTmarieieiemBelum ada peringkat

- Total Chrom TutorialDokumen94 halamanTotal Chrom TutorialRachelHechanovaBelum ada peringkat

- CCE Student Wise SA1 Marks Report for Class 3 Section ADokumen1 halamanCCE Student Wise SA1 Marks Report for Class 3 Section AKalpana AttadaBelum ada peringkat

- IUSServer 8 5 SP3 Admin enDokumen118 halamanIUSServer 8 5 SP3 Admin enmahmoud rashedBelum ada peringkat

- TerraPower Case PDFDokumen7 halamanTerraPower Case PDFKaustav DeyBelum ada peringkat

- Asmo Kilo - PL Area BPP Juni 2023 v1.0 - OKDokumen52 halamanAsmo Kilo - PL Area BPP Juni 2023 v1.0 - OKasrulBelum ada peringkat

- Advance Accountancy Inter PaperDokumen14 halamanAdvance Accountancy Inter PaperAbhishek goyalBelum ada peringkat

- Fromm, Erich - Working Class in Weimar Germany (Berg, 1980)Dokumen302 halamanFromm, Erich - Working Class in Weimar Germany (Berg, 1980)RyadStarXWBelum ada peringkat

- Opa An AssDokumen8 halamanOpa An Assgvkreddyg100% (1)

- 12 TalensDokumen12 halaman12 TalensConsignmenttoduatBelum ada peringkat

- Mastering Physics CH 14 HW College Physics I LCCCDokumen24 halamanMastering Physics CH 14 HW College Physics I LCCCSamuel100% (5)

- HCL Sample PaperDokumen32 halamanHCL Sample PaperVaishu RajanBelum ada peringkat

- Reaction PaperDokumen3 halamanReaction PaperCamilla Reyes100% (1)

- Prime-Hrm Forum 2017 - PMDokumen34 halamanPrime-Hrm Forum 2017 - PMsuzette100% (3)

- DFA and DOLE Not Liable for Repatriation Costs of Undocumented OFWDokumen80 halamanDFA and DOLE Not Liable for Repatriation Costs of Undocumented OFWdhanty20Belum ada peringkat

- Academic Reference Form - RCSI PDFDokumen2 halamanAcademic Reference Form - RCSI PDFibexamsBelum ada peringkat

- Glenn GreenbergDokumen3 halamanGlenn Greenbergannsusan21Belum ada peringkat

- TDS - J TOWhead D60Dokumen1 halamanTDS - J TOWhead D60TahirBelum ada peringkat

- Optidrive P2 Elevator User Guide V1 03Dokumen60 halamanOptidrive P2 Elevator User Guide V1 03Mohd Abu AjajBelum ada peringkat

- Part 3Dokumen28 halamanPart 3michaelliu123456Belum ada peringkat

- Propoxur (WHO Pesticide Residues Series 3)Dokumen26 halamanPropoxur (WHO Pesticide Residues Series 3)Desye MeleseBelum ada peringkat

- Metrology Public PDFDokumen9 halamanMetrology Public PDFLeopoldo TescumBelum ada peringkat