2006 IBC Guide To SCS - Dr. Klote and Doug Evans

Diunggah oleh

Walker DonujiJudul Asli

Hak Cipta

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

2006 IBC Guide To SCS - Dr. Klote and Doug Evans

Diunggah oleh

Walker DonujiHak Cipta:

A Guide to Smoke Control in the 2006 IBC

ISBN: 978-1-58001-659-9

Cover Design: Duane Acoba

Cover Art Director: Dianna Hallmark

Publications Manager: Mary Lou Luif

Illustrator/Interior Design: Dr. Klote

Manager of Development: Beth Tubbs

COPYRIGHT 2007

INTERNATIONAL

CODE COUNCir'

"Cover photo courtesy of The Forum Shops at Caesars Palace, Las Vegas"

ALL RIGHTS RESERVED. This publication is a copyrighted work owned by the International Code Council. Without advance

written permission from the copyright owner, no part of this book may be reproduced, distributed or transmitted in any form or by

any means, including, without limitation, electronic, optical or mechanical means (by way of example and not limitation, photo-

copying, or recording by or in an information storage and retrieval system). For information on permission to copy material exceed-

ing fair use, please contact: ICC Publications, 4051 W. Flossmoor Rd, Country Club Hills, IL 60478, Phone 888-ICC-SAFE

(422-7233).

The information contained in this document is believed to be accurate; however, it is being provided for informational purposes only

and is intended for use only as a guide. Publication of this document by the ICC should not be construed as the ICC engaging in or

rendering engineering, legal or other professional services. Use of the information contained in this workbook should not be consid-

ered by the user as a substitute for the advice of a registered professional engineer, attorney or other professional. If such advice is

required, it should be sought through the services of a registered professional engineer, licensed attorney or other professional.

Trademarks: "International Code Council" and the "ICC" logo are trademarks of International Code Council, Inc.

First Printing: December 2007

Printed in the United States of America

'

31

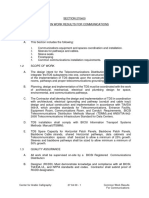

Chapter 3

CODE-MANDATED SMOKE BARRIERS

This chapter provides guidance regarding code-required separations that are

expected to serve as passive smoke barriers. The way to think about required smoke

barriers is whether the code intends to prevent smoke o ~ g i n t i n g in one

area/space from migrating across a specific building element: There are many

passive barriers that may be used to delineate smoke zones. Keep in mind that a

fire-rated assembly does not assure the assembly is constructed to restrict smoke

migration. SeveraliBC sections address fire-resistance-rated separations that are also

intended to act as smoke barriers (see Figure 3. 1 ).

Designating smoke zones/smoke barriers is a coordinated effort between the

appropriate design team members. This may include the architect, mechanical

engineer and fire protection engi neer. Smoke zones must also be coordinated with fire

alarm initi ating devices that activate mechanical smoke control systems. This can

include not only smoke detectors, but also water flow indicators for automatic

sprinkler systems. Smoke zones should be shown on the architectural, mechanical,

fire alarm and automatic sprinkler drawings, as well as control diagrams where

applicable.

Smoke barrier construction is required to meet the provisions outlined in Section

709 and associated referenced sections:

SECTION 709 SMOKE BARRIERS

709.1 General Smoke barriers shall comply with this section.

709.2 Materials. Smoke barriers shall be of materials permitted by the

building type of construction.

709.3 Fire-resistance rating. A ! -hour fire-resistance rating is required

fur smoke barriers.

Exception: Smoke barriers constructed of minimum 0. 10-inch-thick (2.5 rom)

steel in Group 1-3 buildings.

One-hour fire-resistance ratings are one of the least fire-resistive wall and

floor/roof-ceiling assemblies available (opening protectives are available that have

lower fire-protection ratings).

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

'

3-2 CODE-MANDATED SMOKE BARRIERS

~ ~ ~ ~ ~ ~

Figure 3.1

Code-mandated

smoke barriers

Grade

Level

\

R-1 floor with pass

doors

/

(f)'

/

"'-

/

'

/

......

@

/I

<V A

'J

Office floor

r-- s bl ym os:

<D Fire Walls

<6) Corridors in R-1

Occupancies

@ Elevator lobbies open in

onto corridors

@ Exit passageways

Floors

@ Horizontal exits

(f) Stairs with or without

vestibules

<D

I

Section A-A of high-rise tower with low-rise expansion

Not Shown: Subject to interpretation:

Areas of refuge Atria walls

1-1 and 1-2 occupancies Mall/tenant interface

Occupancy separati ons Resi dential rooms/suites

Proscenium walls/openings

Shafts

Smoke barriers (designated)

A

M

M

<D

and/or

B @

Ground floor plan view

ZK071

g

A GUI DE TO SMOKE CONTROL IN THE 2006 IBC

CODE-MANDATED SMOKE BARRIERS 3-3

The effect of automatic spri nklers can also be considered to determine if a I -hour

rating is really necessary. Section 909.9.4 all ows the fire to be considered steady state

when automatic sprinklers have activated. It may also be that the fire is fuel-limited.

Section 909 is not intended to be used when uncontrolled fires can be expected. In any

case, it is the design team's responsibility to determine if automatic sprinklers have

activated and performed their expected function or if the fire is fuel -limited. This

analysis can demonstrate how big the fire is. where it is and how much heat is being

generated. The point here is that a 1-hour rating may not be necessary to fulfill

proper functioning of the smoke control system. Even a glass wall will restri ct

smoke migration and may be a reasonable smoke barrier if it can be expected to remain

in place for a sufficient duration (20 minutes per Section 909.4.6). Section 709.3

specificall y mandates !-hour smoke barriers, but the code also grants the designers

and AHJ the option of consideri ng alternate methods and materials on a case-by-case

basis. If the designers wi sh to propose an equivalency for the fire-resistance rating of a

smoke barrier, it is recommended that they conduct preliminary discussions with the

AHJ as early as possible.

709.4 Continuity. Smoke barriers shall form an effective membrane

continuous from outside wall to outside wall and from the top of the

foundation or floor/ceiling assembly below to the underside of the floor or

roof sheeting, deck or slab above, including continuity through concealed

spaces, such as those found above suspended ceilings, and including

interstitial structural and mechanical spaces. The supporting

construction shall be protected TO afford the required .fire-resistance

rating of the wall or floor supported in buildings of other than Type liB,

/JIB or VB construction.

Exception: Smoke barrier walls are not required in inTerstitial spaces where

such spaces are designed and consTructed with ceilings that provide resis-

tance to the passage of fire and smoke equivalent to that provided by the

smoke barrier walls.

Whether specified or not, most of these requirements are obvious necessities for

proper performance of any method for reducing smoke migration. One significant

impact is that smoke barriers are required to be continuous from exterior wall to

exterior wall. Although required for specific occupancy classifications and horizontal

exits, this constraint was not specifically mandated by either the 1994 or the 1997

editi ons of the UBC for smoke barriers. There may be times that smoke zones are

established havi ng no exterior walls. Provided the smoke control system functions

within the intent of Section 909, an alternate method may be proposed by the designers

for consideration by the AHJ. Since the requirement for smoke barriers being

continuous from exterior wall to exterior wall seems more applicable to passive smoke

control, this alternate methods option may be more applicable when mechanical

systems are used.

One example of thi s is a minimum !-hour wall installed horizontally. Although it

mu t be reali zed that this is no longer really a !-hour rated assembly, ratetl walls

installed horizontally are frequently accepted as compliant. One must be careful with

the structural support of these assemblies. To provide protection to the structural

supports, the studs should be within the assembly. The supporting mechanism should

not be wires attached to the deck above, since there would be minimal, if any,

protection from fire. This type of ceiling should not have any openings int o the void

above, or appropriate opening protecti ves must be used. Jt is unlikely any lay-in tile

ceilings will meet the intent of this exception. If the ceiling portion of a

floor/roof-ceiling assembly is proposed to meet this exception, substantiation of

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

3-4

SMOKE AND FIRE

DAMPERS

CODE-MANDATED SMOKE BARRIERS

minimal leakage and ftre resistance to adjacent spaces must be included in the

analysis.

709.5 Openings. Openings in a smoke barrier shall be protected in

accordance with Section 715.

Exception: In Group l -2. where doors are installed arross corridors. a pair

ofopposite-swinging doors without a center mullion shall be installed having

Fisiun panels with fire-protertion-rated glazing materials in fire-protec-

tion-rated frames. the area of which shall not exceed that tested. The doors

shall be close fitting within operational tolerances, anti shall not have under-

cuts, louvPrs or grilles. The doors shall have head and jamb stops, astragals

or rabbets at meeting edges and shall be automatic closing by smoke detec-

tion in accordance with Section 715.4. 7.3. Positive-latching devices are not

required.

Table 7 I 5.4 requires opening protectives in smoke baniers to have a minimum

fire-protection rating of 20 minutes.

709.6 Penetrations. Penetrations of smoke barriers shall comply with

Section 712.

709.7 Joints. Joints made in or between smoke barriers shall comply with

Section 713.

709.8 Duct and air transfer openings. Penetrations in a smoke barrier by

ducts and air transfer openings shall comply with Section 716.

For smoke barriers to perform as intended, openings must be properly sealed to

limit leakage. Joints between smoke baniers can include the head-of-wall protection

and even edge-of-slab protection between floors. Even minor inadequacies in these

situations can compound and adversely affect the integrity of the smoke banier. For

penetrations, joints and ducUair transfer openings. compl iance with Sections 7 I 2, 713

and 7 I 6 helps ensure that smoke baniers will be constructed within the leakage

limitations of Section 909.

Section 716 specifies where fire and smoke dampers are required. Smoke

dampers are an indication of code-intended smoke barriers.

SECTION716

DUCTS AND AIR TRANSFER OPENINGS

716.1 General. The provisions of this section shall govern the protection

of duct penetrations and air transfer openings in assemblies required to

be protected.

716.l.I Ducts without dampers. Ducts that penetrate

fire-resistance-rated assemblies and are not required by this section to

have dampers shall comply with the requirements of Section 712.

716.2 Installation. Fire dampers, smoke dampers, combination

fire/smoke dampers and ceiling radiation dampers located within air

distribution and smoke control systems shall be installed in accordance

with the requirements of this section, the manufacturer's installation

instructions and the damper's listing.

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

____________________________________________________ 3-5

.,..._ ., --

I 't-....

....... _ )

. \

I

"

'

)

716.2.1 Smoke control system. Where the installation of a fire damper

will interfere with the operation of a required smoke control system in

accordance with Section 909, approved alternati ve protection shall be

utilized.

[t may be argued that fire dampers can invari ably interfere with proper operation of

a smoke control system. Does this mean that all fi re dampers in smoke control systems

should be deleted? Section 716.3.1.1 explicitly allows increased activation

temperatures for fire dampers installed within smoke control systems. If there is

sufficient heat at a fire damper to actuate the fusible link, there may be the possibility

of spreading fire ftom one side of the barrier to the ln most cases. it may be

preferable to allow the fire damper to dose and maintain the fire resistance ofthe

passive barrier, knowing that the mechanical smoke control system may no longer be

able to perform its intended function. The impact of this subject can be minimized by

careful layout of the smoke control system to reduce the number of fire dampers

required. As specified in Section 716.2.1 above, an approved alternative shall he used.

This may be interpreted to require consideration under Section I 04.11 of the fBC.

716.3 Damper testing and ratings. Dampers shall be listed and bear the

label of an approved tnting agency indicating compliance with the

standards in this section. Fire dampers shall comply with the

requirements of VL 555. Only fire dampers labeled for use in dynamic

systems shall be installed in heating, ventilation and air-conditioning

systems designed to operate with fans on during a fire. Smoke dampNs

shall comply with the requirements of UL 555S. Combination fire/smoke

dampers shall comply with the requirements of both UL 555 and UL 555S.

Ceiling radiation dampers shall comply with the requirements of UL

555C.

716.3. 1. 1 Fire damper actuation device. The fire damper actuating

device shall meet one of the following requirements:

litem I not reprinted here. I

2. The operating temperature shall be not more than 286 OF (141 C) where

located in a smoke control system complying with Section 909.

3. Where a combination fire/smoke damper is located in a smoke control system

complying with Section 909, the operating temperature rating shall be

approximately 50 F ( 10 C) above the maximum smoke control system

designed operating temperature, or a maximum temperature of 350 F ( 177

C). The temperature shall not e:J.ceed the UL 555S degradation test tempera-

ture rating for a combination fire/smoke damper.

716.3.2 Smoke damper ratings. Smoke damper leakage ratings shall not

be less than Class ll. Elevated temperature ratings shalL not be less than

250F(nrq

716.3.2.1 Smoke damper actuation methods. The smoke damper shall

close upon actuation of a listed smoke det ector or detectors installed in

accordance with Section 907.10 and one of the following methods, as

applicable:

!Items I through 5 have not been reiterated herein.l

Smoke dampers addressed in this sect ion are intended to restrict the transfer of

smoke through rated assemblies. As specified by Section 716.3.2.1, these dampers

must be actuated by smoke detector(s) at or near the respective damper. Since Section

7 16 only applies to dampers that protect openings through rated assemblies, smoke

A GUIDE TO SMOKE CONTROL IN THE 2006 1BC

I

' ' I

!

I

I

!

I

l'

I

II

' I

I'

:I

3-6

CODE-MANDATED SMOKE BARRIERS

detector activated closure does not apply to dampers that do not penetrate rated

assemblies and are only needed for proper configuration of HVAC, or smoke control

systems.

When smoke control systems are installed in the building, the specific fire alarm

initiating devices that cause those smoke dampers to properly configure must be

documented in the control diagrams. Positive indication of open/closed status is

required by Section 909. 16 for smoke/combination dampers that are part of a smoke

control system and/or that are installed within smoke barri ers separating smoke zones

where either zone is served by the mechanical smoke control equipment.

Although it may be appropriate (and required) to install smoke detectors in the

supply side of a smoke control system, one must be careful when installing smoke

detectors in ducts that are part of the exhaust side of a smoke control system.

When all aspects of the smoke control system are functioning properly, these smoke

detectors can be programmed 10 initiate smoke exhaust. [fa strategic portion of the

smoke control system indicates improper functioning (such as fan fai lure or a damper

incorrectly positioned, which could allow smoke to migrate across smoke barriers),

the same smoke detector can be programmed to initiate damper closure. Since damper

closure will typically be programmed as the fai lure mode of smoke control systems,

smoke detectors will frequently not be necessary at dampers in nondedicated

smoke control systems. Smoke detectors will rarely be needed at smoke dampers in

dedicated smoke control systems. Therefore, install ing smoke detectors to close

smoke dampers appli es primarily to air-handling systems that are not used for meeting

the provisions of Section 909.

716.5 Where required. Fire dampers. smoke dampers, combination

fire/smoke dampers and ceiling radiation dampers shall bf' provided at

the locations prescribed in Sections 716.5. 1 through 716.5.5. Where an

assembly is required to have both fire dampers and smoke dampers,

combination fire/smoke dampers or a fire damper and a smoke damper

shall be required.

Fire dampers (not smoke dampers) are required by Sections 716.5. 1 and 71 6.5.2 in

firewalls and fire barriers, respecti vely. ftem 2 of the exception to Section 716.5.2

allows fire dampers to be deleted when they are part of a ducted system used for

meeting the provisions of Section 909. See the discussion above for Section 716.2. I.

716.5.2 Fire barriers. Ducts and air transfer openings of fire barriers

shall be protected with approved fire dampers installed in accordance

with their listing. Durts and air transfer openings shall not penetrate exit

enclosures and exit passageways except as permitted by Sections

1020.1.2 and 1021.5, respectively.

Exception: Fire dampers are not required at penetrations of fire barriers

where any of the following apply:

[Item I of the exception is not reprinted here.]

2. Ducts are used as part of an approved smoke control system in accordance

with Section 909 and where the use of a fire damper would intetfere with the

operation of a smoke control system.

[Item 3 of the exception is not reprinted here.]

See the discussion for Section 716.2. 1

The second sentence of this requirement is consistent with, and necessary to meet,

the intent of Sections 1020.1.2 and I 021.5. Dampers cannot even be used to mitigate

ducts and air transfer openings into exit enclosures, or exit passageways. These types

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

CODE-MANDATED SMOKE BARRIERS 3-7

of openings and all other penetrations are restricted to only those necessary to serve

the enclosure. Provided any shaft enclosures containing ducts and other air

transfer grills that open into exit enclosures a r e protected equivalently to the exit

enc losure throughout their enti re length. they can be considered an extension of the

exit enclosure and meet the intent of this section. As extensions of the exit enclosure,

these enclosures (shafts) are not allowed to contain any conduit, plumbing, ducts or

anything else that is not needed to serve the exi t enclosure.

716.5.3 Shaft enclosures. Shaft enclosures that are permittPd to be

penetrated by ducts and air transfer openin!(s shall be protected with

approved fire and smoke dampers installed in accordance with their

Exceptions:

1. Fire dampers are not required at penetrations of shafts where:

1.1 Steel exhaust subducts Pxtend at least 22 inches ( 559 mm) vertirally in

exhaust shafts provided there is a continuous airflow upward to the out-

side, or ...

I Exception 1.2 is not reprinted here. I

1.3 Ducts are used as part of an approved smoke control system designed

and installed in uccordance with Section 909 and where the fire damper

will interfere with the operation of the smoke control system; or ...

I Exception 1.4 is not reprinted here.!

2. In Group B and R occupancies, equipped throughout with an automatic

sprinkler system in accordance with Section 903.3.1.1, smoke dampers are

not required at penetrations of shafts where:

2.1 Kitchen. clothes dryer, bathroam and toilet room exhaust openings are

installed with steel exhaust subducts, having a wall thickness of at least

0.019 inch (0.48 mm); and

2.2 That extend at least 22 inches (559 mm) vertically; and

2.3 An exhaust fan is installed at the upper terminus of the shaft that is,

powered continuously in accordance with the provisions of Section

909.11, so as to maintain a continuous upward airflow to the outside.

[Exception 3 is not reprinted here.!

4. Smoke dampers are not required at penetrations of shafts where ducts are

used as part of an approved mechanical smoke control system designed in

accordance with Section 909 and where the smoke damper will interfere with

the operation of the smoke control system.

See the discussion for Section 716.2. 1.

This exception allows omission of the fire dampers only. Toilet exhaust shafts are

frequently designed and constructed to take advantage of this exception. This

exception in conjunction with Exception 2 of this section can be used to allow

omission of the smoke damper in B and R occupancies (see below for clarification).

The conti nuous airflow upward to the exterior in conj unction with the 22-inch (559

mm) subduct allows both the smoke and fire dampers. respectively, to be omitted.

These fans are required to be powered continuously in accordance with Section

909. 11 , which requires both primary and secondary sources.

See the discussion for Section 716.3.2.1.

A GUI DE TO SMOKE CONTROL IN THE 2006 IBC

3-8

COMBINED ZONING

CODE-MANDATED SMOKE BARRIERS

716.5.4.1 Corridors. A listed smoke damper designed to resist the passage

of smoke shall be provided at each point a duct or air transfer opening

penetrates a corridor enclosure required to have smoke and draft control

doors in accordance with Section 715.4.3.

Exceptions:

1. Smoke dampers are not required where the building is equipped throughout

with an approved smoke control system in accordance with Section 909, and

smoke dampers are not necessary for the operation and control of the system.

2. Smoke dampers are not required in corridor penetrations where the duct is

constructed of steel not less than 0.019-inch (0.48 mm) in thickness and there

are no openings serving the corridor.

Exception l allows smoke dampers to be omitted in buildings fully protected by

an approved smoke control system, when they "are not necessary for the operation

and control of the system." This allowance should only be considered on a

case-by-case basis. When the smoke control system is operating properly, smoke

dampers can be programmed to remain in the open position and still allow the smoke

control system to function within the intent of its design. When airflow sensors do not

indicate adequate air movement, these dampers can be programmed to close and

maintain the passive smoke barrier. If smoke can migrate from one smoke zone to

another through a ducted or nonducted damper when fans are off, recognition of

this allowance is not appropriate. A fire damper must still be installed when

required elsewhere.

716.5.5 Smoke barrier.v. A listed smoke damper designed to resist the .

passage of smoke shall be provided at each point a duct or air transfer

opening penetrates a smoke barrier. Smoke dampers and smoke damper

ac:tuation methods shall comply with Section 716.3.2. 1.

Exception: Smoke dampers are not required where the openings in ducts are

limited to a single smoke compartment and the ducts are constructed of steel.

The exception recognizes that the smoke compartment may be considered

to include enclosed tubes (ducts) extending from the zone.

Passive smoke control systems utilize smoke barriers to limit smoke migration.

These passive barriers define passive smoke zones. Mechanical smoke control

systems utilize fans to produce pressure differences across smoke barriers or

establish airflow to limit and direct smoke movement. These mechanical systems

define active smoke zones.

A smoke control mode is defined as "an operational configuration of a system or

device for the purpose of smoke control." Smoke control zones can be defined by

their mode of operation (passive/active) and, in some instances, may change their

designation based on the mode of operation.

It is certainly within the intent of code to allow multiple passive smoke zones to be

exhausted simultaneously, provided smoke is not transferred across code-intended

smoke barri ers (including enclosed floors). Some passive smoke zones may constitute

a portion of a larger active smoke zone. When fans are operating properly and

dampers/doors are properly posi tioned, multiple passive zones may be served

simultaneously, provided that when fans fail to operate properly or dampers/doors

are not properly positioned, the system is designed to fail such that the passive barriers

can maintain the integrity of the passive smoke zone(s).

A GUIDE TO SMOKE CONTROL IN THE 2006 tBC

CODE-MANDATED

SMOKE ZONES

Conversely, it is reasonable to mechanically exhaust a portion of a large passive

zone, provided smoke is maintained in the general area of origin. In these si tuations,

one large passive smoke zone may be made up of several active smoke control

systems that activate independent! y.

Now let's take a look at specific code-mandated smoke zones and when it may be

reasonable to serve multiple passive smoke zones simultaneously.

Section I 002 defines a horizontal exit and clarifies that it is intended to establish an

area that is safe from fire and smoke originating in the area from which escape is made.

Therefore. under both passive and active conditions, horizontal exits always

constitute smoke barriers.

One contiguous facility may be viewed as multiple buildings when fire walls are

constructed in accordance with Section 705. Under both active and passive

conditions, fire walls are intended to act as smoke barriers. This is especially true

when fire walls are used to eliminate smoke control requirements from different

portions of a contiguous facility.

Sections I 020. 1.2 and I 021 .5 do not allow openings other than exit doors into stair

enclosures or exi t passageways. Mechanical smoke control is, therefore, not allowed

to simultaneously serve these rated exit enclosures and adjacent spaces. Based on this

requirement, stair enclosures and exit passageways must always be designed as

completely independent smoke zones from the remainder of the builuing.

Stair entrance vestibules. described in Section 909.20.2, are required to be

separated from the building and from the stair enclosure by a 2-hour fire barrier. As

specifietl in Sections 909.20.3.2 and 909.20.4.1, doors into the vestibule from the

building and from the vestibule into the stair enclosure are required to be smoke- and

draft-control assemblies in accordance with Section 715.4.3. Therefore, stair

entrance vestibules and all other portions of the building constitute separate

smoke zones.

Ducts serving exit passageways, stair enclosures and stair entrance vestibules

are also considered an extension of the respective exit component and are,

therefore, requiretl to be separated from all other portions of the building. To meet this

compartmentation requirement, shafts (whether ducted or not) providing smoke

control for these protected exit paths are not allowed to contain ducts, conduit or

piping serving any other portion of the building throughout the entire length of the

shaft.

Section 716.5.3 requires smoke dampers at openings into shafts. As such, shafts

constitute vertical smoke zones.

Floors define passive smoke zones. When two floors are open to each other as

allowed by Exception 7 of Section 707 .2, the interconnected levels may be viewed as a

single passive smoke zone.

Section 410.3.4 requires stages to be separated from the seating area with a wall

having not less than a 2-hour fire-resistance rating. Section 410.3.5 requires the

proscenium opening protection to intercept hot gases, flames anti smoke for 20

minutes. These requirements indicate that stages are considered separate smoke

zones from the adjacent public seating area.

Table I OJ 7.1 specifies the fire-resistance rating of corridors. Except for residential

occupancies, most buildings required to comply with Section 909 will not require

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

3-10 _________________________

fire-resistance-rated corridors. As in Table 715.4, all openings into

fire-resistance rated corridors are required to be protected. Section 715.4.3. 1 requires

doors in smoke barriers and rated corridors to be smoke- and draft-control assembl ies.

Class I I. 250F ( 12 I

0

C) smoke dampers are also required. The code: has always

intended that rated corridors constitute passive smoke zones. When corridors are

designed to be exhausted simultaneously with adjacent portions of the building, the

system should be designed such that the corridor is positive relative to the portion of

the building being exhausted.

Section 404.5 requires atria to be separated from nonatrium spaces by a 1-hour fire

barrier. Table 715.4 requires a minimum

3

/

4

-hour opening protection, but does not

specifically require smoke- and draft-control doors. There does not appear to be a

requirement for smoke dampers either. Taking these constraints into account, one may

conclude that atrium enclosures are not required to function as smoke barriers. This

conclusion contradicts the original intent of the atrium provisions, which expected

walls separating atria from nonatrium spaces to function more as smoke barriers than

fire barriers. Determination of the intended separation requirements between atria and

nonatrium spaces must be coordinated between the design team/owner and the AHJ

prior to design.

Similar to the preceding di scussion on atria, the original level of protection

intended for covered mall buildings has not been reiterated in the IBC. There is no

longer any requirement for smoke control systems serving tenant spaces to be separate

from those serving the mall. Although the original mall provisions intended that the

mall/tenant interface within covered mall buildings be considered a smoke barrier, this

level of protection is not specifically required by the IBC. When all ex it paths through

a high-bay mall are at the lowest level, it may be reasonable to exhaust all smoke from

the mall, whether it originates in the mall or an adjacent tenant area. When exi t paths

are through upper levels of multiple-level malls, an engineered analysis must be

performed to confirm that exit paths will not be adversely impacted by smoke

originating on a lower level being drawn across exit paths on upper levels. The design

team/owner and AHJ must be in concurrence with the goals for the smoke control

approach for covered mall buildings prior to design.

Office spaces are not required to be separated from adjacent office tenants. Walls

are not required to extend full height, nor are fire/smoke dampers required. Similar

allowances exist for adjacent retail tenants. Although smoke originating in one

such tenant space is not mandated by code to be contained within the space of

ori gin, it seems unlikely that you would appreciate your office or retail store being

considered part of your neighbors' smoke zone. This subject should be discussed

between the building owner and the design team. If each such tenant is to be a separate

smoke zone, the AHJ need only be made aware of this arrangement.

Sections 708 and 711 require R-1 guestrooms to be separated from adjacent units

by not less than !-hour fire-resistance-rated construction. Por other than corridor

walls, Table 715.4 requires openings in fire partitions (Section 708) to be 3/

4

-hour

rated, but does not require smoke- and draft-control assemblies. Cn addition. Section

716.5.4 only requires fire dampers and not smoke dampers in fire partitions that do not

create corridor . Based on these requirements, one may conclude that the code does

not intend guestroom separations tO function as smoke barriers. Ct may be concl uded

that the additional level of protection provided for R- 1 guestrooms, such as automatic

sprinklers throughout and smoke detection. is sufficient to warrant a fire-resistive

separation only. If the designers, owners and AIJJ are uncomfortable with this level of

protection, additional protection is always acceptable.

Rather than evacuate occupants, hospitals and correction facili ties use a defend-in-

place strategy. As such, Sections 407.4 and 408.6 require smoke barriers for l-2 and

------------------------------------- --- - --

A GUI DE TO SMOKE CONTROL IN THE 2006 IBC

4-1

Chapter 4

PRESSURIZATION SYSTEMS

PRESSURIZATION CONCEPT The pressurization method of smoke control uses pressure differences produced by

fans across barriers to control smoke movement. Figure 4.1 shows a pressure

difference being used to control smoke movement across a barrier. Within the barrier

is a door. The hi gh pressure side of the barrier is a space to be protected such as a

refuge area, egress route or other part of the building. The low pressure side of the

barrier is exposed to smoke from a fire. Airflow through the gaps around the door and

through construction cracks prevents smoke infiltration to the high pressure side. This

airflow through such small openings should not be confused with the airflow design

method (TBC 909.7) which is appropriate for large openings such as open doorways as

discussed in Chapter 5.

Figure 4.1

Pressure

difference across a

barrier controlling

smoke flow

909.6 PRESSURIZATION

METHOD

/I

Smoke /

High Pressure Side

Low Pressure Side

The commonly used pressurization systems are zoned smoke control , pressurized

stairs and pressurized elevators. The basic concepts of pressurization are discussed

below, and pressurized stairs and pressurized elevators are discussed in Chapters II

and 12.

909.6 Pressurization method. The primary mechanical means of

controlling smoke shall be by pressure differences across smoke barriers.

Maintenance of a tenable environment is not required in the smoke

control zone ofj!re origin.

This section, in conjunction with Section 909.4.6, clearly specifies that the

pressurization method is only intended tO contain smoke within the zone of origin for

at least 20 minutes. This design approach is not a ''purge" system, nor is it intended to

provide a tenable environment in the zone of origin. Smaller enclosed spaces with low

to moderate ceiling heights will typically use either a mechanical/active pressurization

approach or a nonmechanicallpassive approach. Mechanical systems will normally

use exhaust air to help reduce pressure in the area of fire origin. The proposed smoke

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

' I

..

. i

''

''

4-2

DESIGN PRESSURE

DIFFERENCE

Minimum Pressure

Difference

PRESSURIZATION SYSTEMS

control approach along with its design intent should be discussed with the AHJ prior to

design and submitted for review and approval.

[F) 909.6.1 Minimum pressure difference. The mzmmum pressure

difference across a smoke barrier shall be 0.05-inch water gage (0.0124

kPa) in fully sprinklered buildings.

In buildings permitted to be other than fully sprinklered, the smoke

control system shall be designed to achieve pressure differences at least

two times the maximum calculated pressure difference produced by the

design fire .

The minimum pressure difference of 0.05 inches of water ( 12.4 Pa) will be verifi ed

by testing in accordance with Section 909.5. 1. When the pressurization method is

used, 0.05 inches of water ( 12.4 Pa) across smoke barri ers separating adjacent smoke

zones constitutes code compliance. The fan's capacity (cfm or Llmin) is not relevant

to this design method and need not be tested or confirmed. [tis the responsibility of the

design professionals and contractors to achieve the required 0.05 inches of water (I 2.4

Pa) pressure difference.

The rational analysis of the smoke control system needs to show that the system

maintains at least the minimum pressure difference of 0.05 inches of water ( I 2.4 Pa)

under conditions of stack effect and wind effect.

Smoke control systems are designed to operate within a pressure difference range .

This range is between the minimum design pressure difference and the maximum

pressure difference.

The minimum design pressure difference is generally stipulated by the code. For

the pressurization method, Section 909.6. 1 states that the mi ni mum design pressure

difference is 0.05 inches of water ( 12.4 Pa). For stair pressuri zation systems. Section

909.20.5 states that the minimum design pressure difference is 0.15 inches of water

(37.3 Pa). For elevator hoistway pressurization, Sect ion 707. 14.2. 1 states that the

minimum design pressure difference is 0.04 inches of water (I 0.0 Pa). This section

discusses minimum design pressure differences, and what kind of performance can be

expected from various values of minimum pressure difference.

The minimum design pressure difference is a value of pressure difference that the

smoke control system needs to maintain under design conditi ons of stack effect and

wind effect. The analysis presented here is intended to provide insight into the level of

smoke protection that can be anticipated by the val ues of minimum pressure

difference in the code. The minimum design pressure difference can be calculated as a

safety factor plus the buoyancy pressure difference of the fire:

!1P. = !1P

5

F+ 7.64h[ I - I J

nun T

0

+ 460 T

0

-!- 460

For SJ: !1P . = !1PsF + 3460h [

1

-

1

]

mon T

0

+ 273 T F + 273

where:

!1P,.

1

= Minimum design pressure difference, inches of water (Pa).

!1P

5

F =Pressure difference safety factor, inches of water (Pa).

(4. 1)

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

=Distance above neutral plane, ft (m).

= Temperature of surroundings. "F (C).

T, = Temperature of hot gases, oF (C).

for purposes of Equation (4. 1 ). the neutral plane is a horizontal plane between the

fire space and surrounding space at whi ch the pressure difference between the fire

space and the surrounding space is zero. The 2006 edition ofNFPA 92A

1

recommends

conservati ve values: (I ) has two-thirds the floor to ceiling height, (2) = 0.03 inches of

water (7.5 Pa), and (3) TF = 1700 F (927 C) for fully developed fires. The safety

factor is chosen to account for the normal fluctuations in pressure due to changes in

wind and barometric pressure. for a sprinklered fire, temperature of hot gases, T,.-, is a

weighted average value of the smoke layer temperature and the lower layer

temperature.

Example 4. J. Part I. shows that the minimum pressure difference needed to control

smoke from a fully developed fire in space with a 9-foot (2. 74 m) ceil ing height is 0.10

inches of water (24.9 Pa). Pan 2 of this example shows that the minimum pressure

difference needed to control smoke from a successfully sprinklered fire in space with a

9-foot (2.74 m) cei ling hei ght is 0.05 inches of water ( 12.4 Pa). These values agree

with those presented in NFPA 92A.

___ ... _________ _

Example 4. 1 Minimum Design Pressure Difference

Part 1: For a cei ling height of 9 feet , what is the minimum design pressure difference with a fully

developed fire?

tlP

5

, = 0.03 in I 1!0

T

0

= 70 or

TF = 1700 "f

2

h =- (9) = 6ft

3

!lP . = !lP,r + 7.64h[--

1

- - _ _ I - - ] = 0.03 + 7.64(6)[ I - I ] = 0.10 in. Hp

""" T

0

+ 460 T F + 460 70 + -+60 1700 + 460

Part 2: For a ceiling height of 9 feet , what is the minimum design pressure difference with a

sprinklered fire?

!lP,F = 0.03 in HP

T

0

= 70F

2

h = - ( 9) = 6ft

3

The ceiling height is H = 9 ft.

The depth of the smoke layer is d = 0.9 ft.

The smoke layer temperature is 7 ~ = 1700 F

T F = ! .. d + ~ ( = ~ ~ = 1700(0.9) + 70(9 - 0.9) = 2330F

li 9

[

l I ] [ I I ] .

!lPmin = !lP SF+ 7.64h - = O.QJ + 7.64(6) - = 0.05 m. Hp

T 0 + 460 T F + 460 70 + 460 233 + 460

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

:;. ::

i '

' '

., '

' , .

:!'

1.;:

II' :

' .I

I

1 ,

1

I

I '

I I

I,

I

'I I;

'

,'

' I

I,

: ,; .

'

' "

'I '

' I

r

It I

,I

II 'i'' .,

I'

I

; ' !

i'j

f :::

' I

I :

I '

, I

.

'

:I 1

I' I

I ,

'I i

, I

1, I' I

. I

4-4

Maximum Pressure

Difference

Figure 4.2

Door opening force

for side-hinged

swinging door

Figure 4.3

Scale for

measuring door

opening force

PRESSURIZATION SYSTEMS

Section 909.6.2 of the IBC states that the maximum air pressure difference across a

smoke barrier shall be determined by required door-opening or closing forces. The

actual force required to open exit doors when the system is in the smoke control mode

shall be in accordance with Section 1 008.1 .2. Section 909.6 of the TBC states that the

door force to set a side-hinged, swinging door in motion is calculated by:

F = F +

de 2(W-d)

(4.2)

where:

=Door area, square feet (m'). A

d

F

= Distance from door handle to latch edge of door, feet (m).

= Total door opening force, pounds (N).

Fd, = Force required to overcome closing device, pounds (N).

K =Coefficient 5.2 (1.0).

W =Door width, feet (m).

M = Design pressure difference, inches of water (Pa).

Equation (4.2) is applicable for doors that do not stick to the frame and have

properly lubricated hinges (i.e., limited ftictional forces). The total door opening

force, F, and the door are shown in Figure 4.2.

HIGH PRESSURE SIDE

w

d!+-/Knob

Figure 4.3 is a scale that can be used for measuring the total door opening force, F.

One end of the scale is attached to the door, and the other end is pulled until the door

starts to move. When doing this, the knob needs to be turned so that the door latch is

disengaged. From Equation (4.2) it can be seen that when the pressure difference

across the door is zero, the total door opening force, F, is the same as the force required

to overcome the closing device, FJc An easy way to determine the force required to

overcome the closing device is to measure the total door opening force when there is

no pressure difference across the door.

Pull Here Until

Attached to Door Opens

I I I II I \Ill I \Ill\ I\\ I\\\\ I\ Ill I I I

z ... ,.

Section 1008.1 .2 limits the maximum force to set a door in motion to 30 pounds

( 133 N). The appropriate comractors, AHJ and/or the Special Inspection Agency, are

expected to verify that opening force limitations are in compliance. The rational

analysis of the smoke control system needs to show that the force to set a door in

motion does not exceed 30 pounds ( J 33 N) under conditions of stack effect and wind

effect.

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

PRESSURIZATION SYSTEMS 4-5

Example 4.2 shows that a door 3 feet wide by 7 feet high (0.914 m wide by 2.13 m

high) with a door closer that requires 9 pounds of force and a pressure difference

across it of 0.35 inches of water has a door opening force of 30 pounds ( 1 33 N). This

means that a pressure difference of0.35 inches of water (87 Pa) is about the maximum

that can be used for a 3-foot by 7-foot door (0.914 m by 2. 13 m) without exceeding the

aJlowable door-opening force. When pressures greater than this are expected,

power-assisted doors may be needed.

Example 4.2 Door Opening Force

What is the door opening force for a door 3 feet wide by 7 feet high with a door closer that requires 9

pounds of force and a pressure difference across it of 0.35 inches water gage? The knob is 3 inches

from the edge of the door.

W=3ft

FJc = 91b

d = 0.25 ft

A=3 X 7=21 ft

2

K= 5.2

11P=0.35 in Hp

From Equation (4.2):

I

F = F + W A ~ P ) =

9

+ 5.2(3)(21)(035) =

30

lb

de 2(W - d) 2(3 - 0.25)

PRESSURIZATION

SYSTEMS

Pressurized stairs and pressurized elevator hoi stways are forms of pressuri zation

systems, but they are not discussed here. Pressurized stai rs are treated in Chapter II

and Appendix E, and pressurized elevators are discussed in Chapter l 2.

The systems discussed here are what NFPA 92A refers to as zoned smoke control.

Zoned smoke control systems are sometimes called ''pressure sandwich" systems. fn a

zoned smoke control system, a building is divided into a number of smoke zones, each

separated from the others by smoke barriers. In the event of a fire, pressure differences

produced by mechanicaJ fans are used to limit the smoke spread to the zone in which

the fire initiated. The concentration of smoke in thi s zone goes unchecked.

Accordingly, in zoned smoke control systems, it is intended that occupants evacuate

the zone where the fire is as soon as possible.

Frequently, each floor of a building is designed as a separate smoke control zone, but

a smoke zone can be part of a floor or even more than one floor. Figure 4.4 (a) shows a

tall building where each floor is a smoke control zone. This figure shows the classical

smoke control concept of exhausting the fire floor and pressurizing the floor above and

below the fire floor. Figure 4.4 (b) shows a sprawling building where each floor is

divided into a number of smoke control zones. ln this figure the smoke zone is exhausted

and the surrounding zones are pressurized.

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

! I

Figure 4.4

Arrangements of

zones for zoned

smoke control

systems

Activation

v

I + /

-

II

+

/r/ /'//

(a) Relatively Short Building

Symbols:

- Smoke Zone

+ Pressurized Spaces

Smoke Zone

+

Notes:

1. Misidentification of the fire location can

result in incorrectly pressurizmg the zone

with the fire and forcing smoke into other

zones and into stairs. Classical zoned

smoke control should only be used with

extreme caution.

2. Because of concern about forcing smoke

into stairs as described above, classical

zoned smoke control is only recommended

for relatively short buildings.

3. Zoned smoke control works best for

buildings with open floor plans or corridors

with normally open doors.

4. Zoned smoke control does not work well

with buildings where the floors are divided

into many rooms such as hotels and

apartment buildings.

+

- ..--

Smoke Zone

+

-'/

//'/' // //'/'/'/'/' u /'/////////, // // //////..0

(b) Sprawling Building ZKMol

Jn addition to the classical zone smoke control approach of exhaust.ing the zone with

the fire and pressurizing adjacent zones, there are a number of other options. Two

options for zoned smoke control are (I) exhausting the fire zone and no treatment of

adjacent zones, and (2) venting the fire zone to the outside and pressurizing adjacent

zones. A passive approach to zoned smoke control can also be used that has ftre zone

venting and no treatment of adjacent zones.

Unless otherwise stated, the discussions that follow apply to the classical zone

smoke control approach.

It is common to activate zoned smoke control systems based on signals from smoke

detectors, sprinkler water flow or heat detectors. For proper operation of zoned smoke

control systems, it is important that the fire location be correctly identified. Smoke

detectors with the exception of those located in HV AC ducts have the advantage that

they respond very quickly to fire. Sprinkler water flow and heat detectors have a low

incidence of fal se alarms. Advances in smoke detector technology have significantly

reduced concerns about false alarm . A signal from at least two sources ( moke

detectors, sprinkler water flow or heat detectors) is recommended to assure activation

in the event of a component failure.

Smoke detectors located in HV AC ducts can be a secondary means of activating

zoned smoke control systems . Such duct smoke detectors must not be the primary

means of activation for two reasons: (I) duct smoke detectors are slow to respond to

smoke from outside the HVAC system, (2) clogging with dust and other particulates

can prevent duct smoke detectors from operating.

Zoned smoke control must not be activated by signals from manual pull stations,

because pull stations do not identify the location of the fire. A person seeing a fire may

start to exit the building only to activate the pull station a number of floors away from

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

PRESSURIZATION SYSTEMS

Interaction with

Pressurized Stairs

Open Floor Plans

Figure 4.5

A floor of an

idealized open plan

office

4-7

the fire. Because a signal from a pull station does not identify the fire location, manual

pull stations must not be used to activate zoned smoke control systems.

As stated above, the classical smoke control approach consists of exhausting the

smoke zone and pressurizing the surrounding zones. Zoned smoke control is often in

buildings with pressurized stairs. The exhaust on the fire floor increases the pressure

difference from the stairs to the smoke zones. and the pressurization of the

surrounding zones decreases the pressure difference from the stairs to the surrounding

zones. Sometimes the pressure difference of the stairs in the surrounding zones

becomes negative, and there is flow from the surrounding zones into the stairs. This

Joss of t a i r pressurization in the surrounding zones can be a concern as discussed

below.

As already stated, zoned smoke control needs to have the fire location properly

identified. On rare occasions the first detector acti vated was away from the fire floor

due to unusual smoke migration. Sometimes the wrong fire location is identified due

to an installation error. While such misidentification of the fire location is unusual, the

consequences need to be taken into account during system design. Such

misidentification of the fire location could result in pressurizing the fire floor and

forcing smoke into other floors and into stairs.

Because misidentification of the fire location can result in incorrectly pressurizing

the zone with the fire and forcing smoke into other zones and into stairs, zoned smoke

control should only be used with extreme caution. This misidentification of the fire

location can happen (I) when a detector away from the fire is the first one activated or

(2) when the detectors were installed with incorrect location identification. Tn unusual

situations smoke has migrated to tloors away from the fire fl oor and activated

detectors there before any detectors on the fire floor were activated.

For smoke control systems properly commi ssioned in accordance with Section

909.18 and tested weekly in accordance with Section 909.12, the potential for

detectors installed with incorrect location identification is minimized. Because of

concern about forcing smoke into stai rs as described above. classical zoned smoke

control is only recommended for relatively short buildings (6 or 8 stories).

Zoned smoke control works best for buildings with open floor plans. Figure 4.5

shows an idealized plan of a floor with an open office plan. Because the floor plan is

open, pressurizing and exhausting floors is easy to accomplish. The floor is expected

Symbols:

SW Stairs

WT Women's Toilet

MT Men's Toilet

181 Elevator

-++ Door

~ ~ ~ ~ ~

sw

Open Office Space

Open Office Space

~ ~ ~ ~ I

sw

Note: Zoned smoke control works

best for buildings with open floor

plans.

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

r

,I

,,

'!

I

4-8

Good for Sprawling

Buildings

Caution

PRESSURIZATION SYSTEMS

to have office furniture and office dividers, but otherwise the space is open. When

there is a fire on one floor, that tloor is exhausted and rhe floors above and below are

pressurized. This reduces the potential for smoke to go to the floors above and below

the fire floor. This provides protection from floor-to-floor smoke spread for fires that

can happen anywhere in an office space. Often open plan offices have a number of

small offices by the windows or in the interior, and such small offices do not generally

interfere with the performance of the zoned smoke control system.

Smoke control zones are typically large spaces, so that the smoke exhaust consists

of exhausting a large amount of air that dilutes the smoke from the fire so that the

temperature of the gases in the exhaust fan is relatively low. It was not mentioned

above, but the smoke control zone can consi t of a number of floors which also works

to keep the temperature of the gases in the exhaust relatively tow. rt is not appropriate

to rely on sprinklers to cool smoke down, because the smoke temperature from

successfully sprinklered fires that are shielded from sprinkler spray can be relatively

high [as high as 233 F (ll2C)].

Zoned smoke control can also work well for buildings that have corridors with

normally open doors. Examples of this are ( I ) a nursing wing of a hospital and (2) an

office where the corridor doors are normally open during working hours. As stated

above, classical zoned smoke control is only recommended for relati vely short

buildings.

Zoned smoke control can also work well with sprawling buildings that have a

number of wings. The smoke control zones can be each tl oor of each wing as shown in

Figure 4.4 (b). This approach works well with a horizontal evacuation of the zone of

the fire to other zones on the same floor.

Zoned smoke control does not work well with buildings where the floors are

divided into many rooms such as hotels and apartment buildings. This section does not

apply to passive smoke control which is addressed in Chapter 3. The discussion that

follows focuses on apartment buildings, but it is also completely appl icable to hotels,

condominiums and offices with normally closed corridor doors.

A particularly poor system approach for apartment buildings is to make each

apartment and the corridors separate smoke control zones. Such a large number of

small zones results in an overly complex system. With such small smoke control

zones, the smoke exhaust consists of exhausting only a little air to dilute the smoke

from the fire so that the temperature of the gases in the exhaust fan is relatively high.

The advantages of large smoke control L.ones have already been discussed.

While limiting zoned smoke control to the corridors may seem a good approach for

an apartment building, these corridor-only zoned smoke control systems provide little

smoke protection. The most common fire scenarios for these buildings consist of fi res

in the apartments. The corridor-only systems do not provide floor-to-floor pressure

differences for fires in the apartments, so smoke can flow vertically to apartments

above and below the apartment with the fire. Therefore, corridor-only zoned smoke

control systems do not provide any smoke protection for the major fire scenarios in

apartment buildings. However, the corridor-only zoned smoke control systems have

all of the concerns about interaction with pressurized stairs discussed above.

For the reasons discussed above, classical zoned smoke control is not

recommended for buildings where the floors are divided into many rooms such as

hotels and apartment buildings.

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

PRESSURIZATIOf'J

SYSTEM ANALYSIS

REFERENCE

A rational analysis of the smoke control system is required in accordance with

Seclion 909.4 of the IBC. Buildings with zoned smoke control may also have other

smoke control systems such as pressurized stairs and pressurized elevators. When

these systems are activated, they interact with each other, and the rational analysis of

smoke control sy terns need to be done with all the systems operating together as they

would during a fire. A network computer program su(;h as CONT AM should be used

for the rational analysis.

1

NFPA 92A. Standard for Smoke-Control Systems Utilizing Barriers and Pressure

Differences. Quincy, MA: National Pire Protection Association, 2006.

A GUIDE TO SMOKE CONTROL IN THE 2006 IBC

Anda mungkin juga menyukai

- Fire Fighting Single StoreyDokumen24 halamanFire Fighting Single Storeyluca0013Belum ada peringkat

- Vertical Openings Prevention: Means of EgressDokumen23 halamanVertical Openings Prevention: Means of EgressAhmed SowilemBelum ada peringkat

- Unit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Dokumen21 halamanUnit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Navya chowdaryBelum ada peringkat

- Electric Pump Acceptence ReportDokumen4 halamanElectric Pump Acceptence ReportNOMANBelum ada peringkat

- 04b FSI Design GuidesDokumen23 halaman04b FSI Design GuidesLai Kwok Kwan100% (1)

- Sikacrete Fire Protection Mortar 201102Dokumen12 halamanSikacrete Fire Protection Mortar 201102maximgh100% (1)

- English Book A4 Final UpdateDokumen221 halamanEnglish Book A4 Final UpdateVinay PallivalppilBelum ada peringkat

- Pressure Independent Control ValveDokumen12 halamanPressure Independent Control Valvekya_leyBelum ada peringkat

- For Construction: E W K C O N A L L DDokumen1 halamanFor Construction: E W K C O N A L L DJovenal Tuplano Jr.Belum ada peringkat

- FM 4922 Fume Exhaust Ducts or Fume and Smoke Exhaust Ducts 2016Dokumen24 halamanFM 4922 Fume Exhaust Ducts or Fume and Smoke Exhaust Ducts 2016andyBelum ada peringkat

- One Outlet at A Maximum of Every 3 Storeys: Reduction in The Floor Space Required. Under Design ConditionsDokumen1 halamanOne Outlet at A Maximum of Every 3 Storeys: Reduction in The Floor Space Required. Under Design ConditionsArul SankaranBelum ada peringkat

- 2019 ASHRAE Handbook HVAC Applications SI-Chapter 6-Ahu PDFDokumen15 halaman2019 ASHRAE Handbook HVAC Applications SI-Chapter 6-Ahu PDFLệ HoaBelum ada peringkat

- 1-0 Safeguard During Construction, Alteration and DemolitionDokumen16 halaman1-0 Safeguard During Construction, Alteration and DemolitionDaterBelum ada peringkat

- Fire Pumps in HighDokumen8 halamanFire Pumps in HighRaj KamalBelum ada peringkat

- I 769n Preaction Dpa PSTDokumen1 halamanI 769n Preaction Dpa PSTdemdiinBelum ada peringkat

- Isolation RoomDokumen19 halamanIsolation Roomamirin_kingBelum ada peringkat

- Regulationen 5.0 Water EnvironmentDokumen18 halamanRegulationen 5.0 Water Environmentmuthuswamy770% (1)

- NMMC DCR SummaryDokumen33 halamanNMMC DCR SummaryRoyal JadhavBelum ada peringkat

- MIFAB Control Flo Roof DrainsDokumen5 halamanMIFAB Control Flo Roof DrainsjavedwestBelum ada peringkat

- Ariston Electric Water HeatersDokumen2 halamanAriston Electric Water HeatersSuresh SubbarayanBelum ada peringkat

- 39HQ - AhuDokumen96 halaman39HQ - AhuperezismaelBelum ada peringkat

- Storm Drainage Systems & Facilities: Section 5600Dokumen112 halamanStorm Drainage Systems & Facilities: Section 5600Trav BlackBelum ada peringkat

- Duct SweatingDokumen6 halamanDuct SweatingNeal JohnsonBelum ada peringkat

- Distance From Sprinkler To HangerDokumen1 halamanDistance From Sprinkler To Hangerahmaborashed100% (1)

- Hord Hospital Operating Room Air Curtain CatalogDokumen7 halamanHord Hospital Operating Room Air Curtain CatalogZain ShariffBelum ada peringkat

- CRAC UnitDokumen76 halamanCRAC Unittjaycruz2Belum ada peringkat

- BAFSA Technical Guidance No 1, November 2012Dokumen30 halamanBAFSA Technical Guidance No 1, November 2012flegheton100% (1)

- On Elevator Shaft Pressurization System Standards and Codes For Smoke Control in Tall Buildings - SFPE PDFDokumen9 halamanOn Elevator Shaft Pressurization System Standards and Codes For Smoke Control in Tall Buildings - SFPE PDFDesigner ForeverBelum ada peringkat

- Air To Air Heat Exchangers For AirDokumen8 halamanAir To Air Heat Exchangers For AirOmair FarooqBelum ada peringkat

- 2014july 042-045 EngineersNotebook DudaDokumen3 halaman2014july 042-045 EngineersNotebook DudajacksonliBelum ada peringkat

- Fire and Smoke CurtainsDokumen21 halamanFire and Smoke CurtainsNghia Huynh NgocBelum ada peringkat

- Priest & Associates Consulting, LLC: Industry Alerts!Dokumen7 halamanPriest & Associates Consulting, LLC: Industry Alerts!PACFIREBelum ada peringkat

- TransportationDokumen12 halamanTransportationHabeebMohammedFarooqBelum ada peringkat

- Atria in BuildingsDokumen4 halamanAtria in Buildingssaifuddin722Belum ada peringkat

- Smoke Control System DesignDokumen4 halamanSmoke Control System DesignHermi DavidBelum ada peringkat

- Smoke Control in Very Tall Buildings - PastDokumen4 halamanSmoke Control in Very Tall Buildings - PastNestor S. ReEyesBelum ada peringkat

- Smoke Control Practice in MalaysiaDokumen5 halamanSmoke Control Practice in MalaysiaZacharul Shah100% (1)

- Smoke Control in Single Storey Buildings and Warehouses: Ci/Sfb Classification 284 (K5)Dokumen24 halamanSmoke Control in Single Storey Buildings and Warehouses: Ci/Sfb Classification 284 (K5)Dota NgBelum ada peringkat

- Fire Protection CDPDokumen29 halamanFire Protection CDPPopa IulianBelum ada peringkat

- FIRE PROTECTION IN BUILDINGS 20nov2015Dokumen9 halamanFIRE PROTECTION IN BUILDINGS 20nov2015nada_raadBelum ada peringkat

- Basement Smoke VentilationDokumen5 halamanBasement Smoke VentilationVarun MattooBelum ada peringkat

- Guide To Smoke Extraction in BuildingsDokumen76 halamanGuide To Smoke Extraction in BuildingsKc Hon100% (2)

- 27 05 00 Common Work Results For CommunicationsDokumen16 halaman27 05 00 Common Work Results For CommunicationsMohamed Abou El hassanBelum ada peringkat

- Civil Engineering in Installation of Substation Buildings and Switchboard RoomsDokumen11 halamanCivil Engineering in Installation of Substation Buildings and Switchboard RoomsJulioBelum ada peringkat

- Practical Applications of Smoke-Control SystemsDokumen7 halamanPractical Applications of Smoke-Control SystemsminiongskyBelum ada peringkat

- Roles and Applications of Mechanical Services in Defining The Massing and Form of The BuildingDokumen21 halamanRoles and Applications of Mechanical Services in Defining The Massing and Form of The BuildingRITAMBRA SINGHBelum ada peringkat

- Airport Noise Design StandardDokumen10 halamanAirport Noise Design StandardLakshmiWijayasiriBelum ada peringkat

- A Basic Introduction To Smoke ControlDokumen2 halamanA Basic Introduction To Smoke ControlNiong David100% (1)

- Guide To Smoke Extraction in Buildings PDFDokumen76 halamanGuide To Smoke Extraction in Buildings PDFMiroslav Luladžić100% (2)

- Technical Manual Fire Resistant DuctworkDokumen24 halamanTechnical Manual Fire Resistant DuctworkHakan GölcüoğluBelum ada peringkat

- Overview of Changes To The 2021 International Codes and 2020 National Electrical CodeDokumen9 halamanOverview of Changes To The 2021 International Codes and 2020 National Electrical Codeeng.muhanned1stBelum ada peringkat

- Civil Engineering in Installation of Substation Buildings and Switchboard RoomsDokumen12 halamanCivil Engineering in Installation of Substation Buildings and Switchboard RoomsMohammadImranRaza100% (1)

- Smoke Control Plan Review Checklist 11-05Dokumen7 halamanSmoke Control Plan Review Checklist 11-05Anonymous ixIhrPM2Belum ada peringkat

- ETFE and Smoke Control WhitepaperDokumen3 halamanETFE and Smoke Control Whitepapernawin10Belum ada peringkat

- Asdma Bulletin BS8214Dokumen2 halamanAsdma Bulletin BS8214Raju KCBelum ada peringkat

- DH18 Issue 1 Lean BuildDokumen28 halamanDH18 Issue 1 Lean Buildwinc9303Belum ada peringkat

- A1 Inta212 w6 A1 Reed LDokumen55 halamanA1 Inta212 w6 A1 Reed LLaShara ReedBelum ada peringkat

- Passive Fire Protection PDFDokumen7 halamanPassive Fire Protection PDFVictor SampaBelum ada peringkat

- FRM PG Article June 2010 Smoke ExtractDokumen4 halamanFRM PG Article June 2010 Smoke ExtractnhishamBelum ada peringkat

- What Is Fire StoppingDokumen19 halamanWhat Is Fire StoppingJemond PagunsanBelum ada peringkat

- Contoh MOTIVATION LETTERDokumen19 halamanContoh MOTIVATION LETTERDavin Tiska AbrianiBelum ada peringkat

- FijiTimes - June 7 2013Dokumen48 halamanFijiTimes - June 7 2013fijitimescanadaBelum ada peringkat

- Early Treatment of A Class III Malocclusion With The Myobrace SystemDokumen1 halamanEarly Treatment of A Class III Malocclusion With The Myobrace SystemThu Trang PhamBelum ada peringkat

- Trading With The Heikin Ashi Candlestick OscillatorDokumen7 halamanTrading With The Heikin Ashi Candlestick OscillatorDarren TanBelum ada peringkat

- 750-366 Hawk 1000 07 13 PDFDokumen82 halaman750-366 Hawk 1000 07 13 PDFAlexis CruzBelum ada peringkat

- Global Value Chain: Shikha GuptaDokumen19 halamanGlobal Value Chain: Shikha GuptaRushilBelum ada peringkat

- Trinity The Father, The Son and The Holy SpiritDokumen3 halamanTrinity The Father, The Son and The Holy SpiritThomas Lorenz (Fit For Faith Ministries)100% (1)

- Legal AgreementDokumen2 halamanLegal AgreementMohd NadeemBelum ada peringkat

- Travel To Egypt: Conversation Cheat SheetDokumen2 halamanTravel To Egypt: Conversation Cheat SheetNasima BegumBelum ada peringkat

- Kapil Choudhary: Personal ProfileDokumen2 halamanKapil Choudhary: Personal ProfileAishwarya GoelBelum ada peringkat

- My Slow Carb Diet Experience, Hacking With Four Hour BodyDokumen37 halamanMy Slow Carb Diet Experience, Hacking With Four Hour BodyJason A. Nunnelley100% (2)

- Cee 213 - Transport Principles in Environmental and Water Resources EngineeringDokumen3 halamanCee 213 - Transport Principles in Environmental and Water Resources EngineeringenjpetBelum ada peringkat

- XXXXXDokumen38 halamanXXXXXGarrett HughesBelum ada peringkat

- Excuse Letter For MerchandiserDokumen7 halamanExcuse Letter For MerchandiserJolly PostadanBelum ada peringkat

- Wavelets and Signal ProcessingDokumen193 halamanWavelets and Signal ProcessingAlbeno Saleh AhmadBelum ada peringkat

- Block RosaryDokumen9 halamanBlock RosaryRendine Rex Vizcayno100% (1)

- Teaching The GospelDokumen50 halamanTeaching The GospelgabrielpoulsonBelum ada peringkat

- Very Important General Knowledge MCQs With DetailsDokumen13 halamanVery Important General Knowledge MCQs With DetailsNiaz AsgharBelum ada peringkat

- Engineering Economics & Financial Accounting Two Mark Questions and AnswersDokumen15 halamanEngineering Economics & Financial Accounting Two Mark Questions and AnswerspothigaiselvansBelum ada peringkat

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Dokumen4 halamanAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Kris Wuthrich BatarioBelum ada peringkat

- Environmental Education Strategy (2010-2014) : United Republic of TanzaniaDokumen63 halamanEnvironmental Education Strategy (2010-2014) : United Republic of Tanzaniaalli sheeranBelum ada peringkat

- Sri Nikunja-Keli-VirudavaliDokumen12 halamanSri Nikunja-Keli-VirudavaliIronChavesBelum ada peringkat

- 1927 To 1939 New PDFDokumen8 halaman1927 To 1939 New PDFahmed razaBelum ada peringkat

- Education PhilosophyDokumen8 halamanEducation PhilosophyJustine Jerk BadanaBelum ada peringkat

- Lesson Plan 9th Grade ScienceDokumen2 halamanLesson Plan 9th Grade Scienceapi-316973807Belum ada peringkat

- Presented by Ms. Pallavi CharadeDokumen10 halamanPresented by Ms. Pallavi CharadePallavi KharadeBelum ada peringkat

- Soal Latihan Bahasa Inggris Asking and Giving OpinionDokumen2 halamanSoal Latihan Bahasa Inggris Asking and Giving OpinionAndy Luth100% (3)

- C5 Schematy 1 PDFDokumen294 halamanC5 Schematy 1 PDFArtur Arturowski100% (4)

- The Philippine Diary ProjectDokumen37 halamanThe Philippine Diary ProjectLilibeth OchiaBelum ada peringkat

- Cost Study On SHEET-FED PRESS OPERATIONSDokumen525 halamanCost Study On SHEET-FED PRESS OPERATIONSalexbilchuk100% (1)