RTA 03.4 Fuel Injection Nozzles

Diunggah oleh

Alexis Barnabás CollinsDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

RTA 03.4 Fuel Injection Nozzles

Diunggah oleh

Alexis Barnabás CollinsHak Cipta:

Format Tersedia

Service Bulletin

RTA3.4

30.03.98

(supersedes Bulletin

RTA3.3 of 25.04.94)

1. Introduction 1

2. Design Features 1

3. Tightening Instruction for 2

2Piece Nozzles

4. Tightening Instruction 2

for Fuel Valve

5. Maintenance 2

6. Assessment Criteria 2

7. Improved Nozzle Tip with Sleeve 3

2

8

.

2

1

.

0

7

.

4

0

P

r

i

n

t

e

d

i

n

S

w

i

t

z

e

r

l

a

n

d

Technical Information to all Owners /

Operators of Sulzer RTA -8 Series

and RTA -2, -U and -C Series Engines

(except RTA 38 and RTA 48)

Contents: Page

Wrtsil NSD Switzerland Ltd PO Box 414 Tel. +41 52 262 49 22

Wrtsil NSD Schweiz AG CH-8401 Winterthur Fax +41 52 212 49 17

Wrtsil NSD Suisse SA Switzerland Tlx 896 659 NSDL CH

Fuel Injection Nozzles

1 / 3 Service Bulletin RTA-3.4

1. INTRODUCTION

The fuel nozzles are exposed to harsh working conditions and have to be regarded as consumable

parts.

Since the introduction of the 2P-nozzles (two piece), we have gained positive performance

results from vessels equipped with this nozzle design concept.

Based on this experience they were introduced as the new standard, which is fully interchangeable

with the previous shrink-fit nozzle.

The 2P-nozzle design naturally incorporates all advantages of the former design such as the very

important rounded-off inner spray hole edges, but enables a much cheaper exchange of worn

nozzle tips only, instead of complete nozzles.

The RTA "8 Series" comprises the following engine types in this Service Bulletin:

RTA 58, RTA 68, RTA 76 and RTA 84

The RTA "2 Series" comprises the following engine types in this Service Bulletin:

RTA 52, RTA 62, RTA 72 and RTA 84M

The RTA "U Series" comprises the following engine types in this Service Bulletin:

RTA 52U, RTA 62U and RTA 72U

The RTA "C Series" comprises the following engine types in this Service Bulletin:

RTA 84C and RTA 84CU

This Service Bulletin should be kept in a separate file in the control room. The respective pages or tables

of the Service Bulletin with modifications to the Operating Manual, Maintenance Manual or Code

Book should be copied and filed in the respective Manual or Book.

2. DESIGN FEATURES

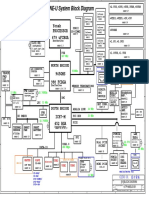

A comparison between the shrinkfit and the 2-piece design is shown on enclosure RTA-3.4/1.

Wrtsil NSD Switzerland Ltd is continuously searching for improvements in design and

materials in order to gain optimum injection conditions as well as increased lifetime for nozzle tip

and needle seat.

THEREFORE, IT IS OF UTMOST IMPORTANCE TO CONTACT WRTSIL NSD

SWITZERLAND LTD FIRST OR THE ENGINE BUILDER WHEN ORDERING NEW

FUEL NOZZLES, TO ENSURE THE DELIVERY OF THE ACTUAL DESIGN AND

SPECIFICATION FOR BEST ECONOMY AND ENGINE PERFORMANCE.

The initial purchase of the 2P-fuel injection nozzle will be slightly more expensive than the

shrink-fit type because of the different design.

But the later exchange of the 2P-nozzle tip, which is subject to wear and tear, will be much more

economical.

2 / 3 Service Bulletin RTA-3.4

3. TIGHTENING INSTRUCTION FOR 2-PIECE NOZZLES

Valid only for engines mentioned in paragraph 1

Experience has shown, that a tightening angle of 35_is on the lower side of the tightening range

necessary for the 2 piece nozzle!

The above mentioned limit on the angle originated from the previous atomizer material

TITANIUM which was deformed when it was tightened at higher angles than 35_.

For the 2P-fuel injection nozzle made of the Wrtsil NSD standard material which is used

today, it is practicable to increase the tightening angle back to 45_as instructed earlier without

having to fear that the atomizers will be deformed.

Therefore the new tightening instructions are as follows:

- First step: Hammer-blow or approx. 20 bar tightening pressure.

- Second step: 45_TIGHTENING ANGLE must be adhered to.

If new 2-piece nozzle parts have been fitted, loosen the cap nut again and repeat step 1 and step

2, in order to take up any initial surface roughness and to ensure the correct final tightening angle.

When fitting the nozzle holders to the cylinder cover, pay attention that the seating surface in the

cylinder cover is properly cleaned. The injection valve must be lowered carefully onto its seat, in

order not to damage the nozzle tip, and care should be taken to tighten the holders correctly.

4. TIGHTENING INSTRUCTION FOR FUEL VALVE

The instructions in the Maintenance Manual ask for a tightening of the Allen screws until their

heads are flush with the top face of the nozzle holders.

Experience has shown that for a number of reasons, e.g. setting of spring washers, different sizes

of bolt heads, change of dimensions of components due to overhauls etc., the tightening

procedure for the fuel valve has to be modified. Therefore the following new instruction has to be

applied.

Press down the fuel injector evenly onto its seat with the two Allen screws. The correct pretension

is reached, when the spring stacks are fully compressed by the two Allen screws, to their block

length, after which the Allen screws are again loosened by an angle of 90. The socalled Block

length is then reached, when a noticeable increase of the tightening torque is felt while tightening

the Allen screws.

Amend the respective section in the maintenance manual if required.

5. MAINTENANCE

For the 2-piece nozzles the same maintenance work is to be carried out as for the shrink-fit type.

The respective procedures to be applied can be found in the Maintenance Manual section

272/2or 2722/2.

6. ASSESSMENT CRITERIA

For the operative assessment of fuel nozzles please refer to the Maintenance Manual section

272or 2722.

Check and ensure that the nozzle body is manufactured with a shrunk-in hardened needle seat.

A characteristic of this nozzle body is a total length of the needle of 83 mm compared to 87 mm of

needles in earlier nozzles. Nozzle bodies without this feature should be scrapped.

3 / 3 Service Bulletin RTA-3.4

7. IMPROVED NOZZLE TIP (ATOMIZER) WITH SLEEVE as per Fig. 1

Standard on RTA U and C Series" Engines

To improve the atomizer of the 2-piece nozzle the radius R at the base of the nozzle tip has been

increased. Newly ordered atomizers will be of the improved execution with the enlarged radius.

On the previous sleeve, the chamfer on the landing surface for the atomizer of the 2-piece

nozzle was only 1 mm x 45.

On the newly designed sleeve the chamfer is now large enough (15.4 mm/ 45) to

accommodate the larger radius R of the new improved atomizer.

Note: This must be checked before a new atomizer is used. Old sleeves can be modified.

For more details please see insert-drawing in enclosure RTA-3.4/ 1

0

-0.2

Fig. 1 Sleeve with New Nozzle Tip

Previous Design New Design

Sleeve

Enlarged Chamfer

Contact on

the radius R

R

Wrtsil NSD Switzerland Ltd has issued this Service Bulletin with their best knowledge and ability.

However, Wrtsil NSD Switzerland Ltd can not take any liability for any or all information contained

in this or any other Service Bulletin.

Changes of any nature to the form and or to the content of this or any other Service Bulletin as published

by Wrtsil NSD Switzerland Ltd, are not permitted.

Service Bulletin Enclosure RTA-3.4/ 1

2P-Nozzle

1

2

3

4

Shrink-fit Nozzle

1 Tightening nut

2 Nozzle body with shrunk-in

needle seat and needle

3 Sleeve

4 Atomizer (nozzle tip)

Modification set from shrink-fit

consisting of: to 2P-nozzle type,

3

Anda mungkin juga menyukai

- FieldExperience MAN B&W L27-38 Diesel EngineDokumen16 halamanFieldExperience MAN B&W L27-38 Diesel EngineVito Digeo100% (1)

- Planning and Site Investigation in TunnellingDokumen6 halamanPlanning and Site Investigation in TunnellingJean DalyBelum ada peringkat

- Chap 08Dokumen63 halamanChap 08Sam KashBelum ada peringkat

- En 12604 (2000) (E)Dokumen7 halamanEn 12604 (2000) (E)Carlos LanzillottoBelum ada peringkat

- Deepwater Horizon Accident Investigation Report Appendices ABFGHDokumen37 halamanDeepwater Horizon Accident Investigation Report Appendices ABFGHBren-RBelum ada peringkat

- Electrical 02Dokumen10 halamanElectrical 02Hary Kriz33% (3)

- Rta 15Dokumen7 halamanRta 15George DomusciuBelum ada peringkat

- RT Flex 11 PDFDokumen4 halamanRT Flex 11 PDFMarijaŽaperBelum ada peringkat

- Rta 70Dokumen6 halamanRta 70George Domusciu100% (1)

- Service Bulletin RTA-43.3 RT-flex-05Dokumen12 halamanService Bulletin RTA-43.3 RT-flex-05Gaby CrisBelum ada peringkat

- Service Bulletin A - 2.2: Technical Information To All The Owners of Sulzer A - Type Diesel Engines 30.11.94Dokumen9 halamanService Bulletin A - 2.2: Technical Information To All The Owners of Sulzer A - Type Diesel Engines 30.11.94zbkt07Belum ada peringkat

- MAN Diesel and Turbo SL2014-571 PDFDokumen20 halamanMAN Diesel and Turbo SL2014-571 PDFparamjyot_sabharwal0% (1)

- W32 PinDokumen2 halamanW32 Pinzbkt07100% (1)

- UG-25 Plus FlyerDokumen4 halamanUG-25 Plus FlyerJoonki Yun100% (1)

- Honing Deglazing 4 Stroke Engines Dec 2018Dokumen5 halamanHoning Deglazing 4 Stroke Engines Dec 2018Sashka AleksandrBelum ada peringkat

- Gen No 8 Governor - Woodward UG-40 Product Spec 03030 - EDokumen4 halamanGen No 8 Governor - Woodward UG-40 Product Spec 03030 - EcrazycanuckBelum ada peringkat

- Maintenance Schedule For WARTSILA 20 B-C Engines Wfi 2004N007 02gbDokumen12 halamanMaintenance Schedule For WARTSILA 20 B-C Engines Wfi 2004N007 02gbDimitris Paliktoglou100% (4)

- 06 - Adjustments, Clearances and Wear Limits Updated 11302020Dokumen11 halaman06 - Adjustments, Clearances and Wear Limits Updated 11302020Sofwat SanjayaBelum ada peringkat

- General Information: Wärtsilä 2-Stroke RT-119Dokumen11 halamanGeneral Information: Wärtsilä 2-Stroke RT-119Raul DiazBelum ada peringkat

- Electronic Marine Engine VibrationDokumen1 halamanElectronic Marine Engine Vibrationvran77Belum ada peringkat

- Countermeasure For SurgingDokumen3 halamanCountermeasure For SurgingParthiban Nagarajan100% (1)

- Service Bulletin WCH Rt-82 Issue2Dokumen20 halamanService Bulletin WCH Rt-82 Issue2aleventBelum ada peringkat

- RT Flex 05Dokumen12 halamanRT Flex 05George Domusciu100% (1)

- ZXXCDokumen7 halamanZXXCarness22100% (1)

- RT 110 Issue2Dokumen30 halamanRT 110 Issue2papaki2100% (1)

- Connecting Rod: Ident No.: 0741673-1Dokumen15 halamanConnecting Rod: Ident No.: 0741673-1Şansal DikmenerBelum ada peringkat

- Wartsila O E W 38 TRDokumen12 halamanWartsila O E W 38 TRbunguiaoBelum ada peringkat

- RT-161 A1 PDFDokumen8 halamanRT-161 A1 PDFRaul Diaz100% (1)

- BulletinD17E DaihatsuDokumen5 halamanBulletinD17E DaihatsuMunawar Sher MuhammadBelum ada peringkat

- MAN SL2018-659 - JAP (2018.03) - Cerment-Coated Piston Rings For Low-Sulphur Fuels (0.5% or Lower)Dokumen9 halamanMAN SL2018-659 - JAP (2018.03) - Cerment-Coated Piston Rings For Low-Sulphur Fuels (0.5% or Lower)GrandpaBelum ada peringkat

- 4 21 31 Crankshaft PDFDokumen31 halaman4 21 31 Crankshaft PDFTansu Mavunacı100% (1)

- SW280 SW28 Cylinder Head OverviewDokumen2 halamanSW280 SW28 Cylinder Head OverviewD.Poljachihin100% (1)

- B33 - 102 - dd2015 - 07 - 15 - Ed006 - EN - Start - Up - of - Engine - OKDokumen21 halamanB33 - 102 - dd2015 - 07 - 15 - Ed006 - EN - Start - Up - of - Engine - OKCristian Ferchiu100% (1)

- Woodward GovernerDokumen4 halamanWoodward GovernerAbhilash100% (2)

- Inspection and Requalification of Flywheels Before Remounting - 09197Dokumen5 halamanInspection and Requalification of Flywheels Before Remounting - 09197Mark ChapmanBelum ada peringkat

- Crankshaft Damage and Overheating Leads To Replacing A Crankshaft On A Wartsila 32 PDFDokumen4 halamanCrankshaft Damage and Overheating Leads To Replacing A Crankshaft On A Wartsila 32 PDFKurupath SidharthanBelum ada peringkat

- Diesel Engine ConstructionDokumen53 halamanDiesel Engine ConstructionLasse HansenBelum ada peringkat

- Service Bulletin RTA-46Dokumen12 halamanService Bulletin RTA-46Christopher Garcia100% (1)

- Service Information M20Dokumen72 halamanService Information M20Alexander100% (1)

- 08 Exhaust ValveDokumen66 halaman08 Exhaust ValveSky RBelum ada peringkat

- K90MC-C MK 6 Project Guide Two-Stroke Engines: 4th Edition December 2000Dokumen279 halamanK90MC-C MK 6 Project Guide Two-Stroke Engines: 4th Edition December 2000faintaresBelum ada peringkat

- 2011 ABB Tips For TC Operators PDFDokumen40 halaman2011 ABB Tips For TC Operators PDFaresobscureBelum ada peringkat

- Man B&W k90mcc6Dokumen375 halamanMan B&W k90mcc6avm4343100% (2)

- RT 133 PDFDokumen6 halamanRT 133 PDFRaul DiazBelum ada peringkat

- 6L23 30H - Manual SHINA-UNICORN SAS-434Dokumen468 halaman6L23 30H - Manual SHINA-UNICORN SAS-434RK PanchalBelum ada peringkat

- Project Guide M20C Genset - 08.2012Dokumen102 halamanProject Guide M20C Genset - 08.2012jorgearoncancio100% (1)

- Man Diesel - Sl2013-571Dokumen17 halamanMan Diesel - Sl2013-571stopless_dalian685Belum ada peringkat

- k90mc CDokumen279 halamank90mc CfaintaresBelum ada peringkat

- Man 48 60cr Imo Tier II MarineDokumen438 halamanMan 48 60cr Imo Tier II Marinelaur100% (1)

- M001 eDokumen12 halamanM001 eAdolfo BurgosBelum ada peringkat

- WärtsiläDokumen28 halamanWärtsiläUsama Mughal100% (1)

- Cyl Liner Upper O-Ring PDFDokumen2 halamanCyl Liner Upper O-Ring PDFDimitrijs SilinsBelum ada peringkat

- Man B&W Serv LTR Sl09-511-MtsDokumen7 halamanMan B&W Serv LTR Sl09-511-Mtsafsal999Belum ada peringkat

- Table of Contents For Maintenance Manual: SulzlrDokumen40 halamanTable of Contents For Maintenance Manual: Sulzlrpendik kuswoyoBelum ada peringkat

- Project Guide C25 33 Propulsion EnginesDokumen138 halamanProject Guide C25 33 Propulsion EnginesJose RamonBelum ada peringkat

- WS A25 Connecting Rod Types Guidelines For Assessment at Bottom End TB00-3301-16Dokumen4 halamanWS A25 Connecting Rod Types Guidelines For Assessment at Bottom End TB00-3301-16DPBelum ada peringkat

- Typical Wear Mechanism 2 Stroke Exhaust ValvesDokumen5 halamanTypical Wear Mechanism 2 Stroke Exhaust ValvesdragoscodBelum ada peringkat

- MAN Diesel and Turbo SL2014-571 PDFDokumen20 halamanMAN Diesel and Turbo SL2014-571 PDFhiiiBelum ada peringkat

- B1 OperatingInstructionsDokumen294 halamanB1 OperatingInstructionscengiz kutukcu100% (4)

- Piston Ring PDFDokumen3 halamanPiston Ring PDFArun SBelum ada peringkat

- Pci 344Dokumen2 halamanPci 344Андрей АндреевBelum ada peringkat

- 4-Stroke Table of Content Temp PDFDokumen11 halaman4-Stroke Table of Content Temp PDFlavkeshBelum ada peringkat

- Common Rail Fuel Injection Technology in Diesel EnginesDari EverandCommon Rail Fuel Injection Technology in Diesel EnginesBelum ada peringkat

- Marine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionDari EverandMarine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionPenilaian: 5 dari 5 bintang5/5 (1)

- RTA-10 Piston Skirt in Two PartsDokumen6 halamanRTA-10 Piston Skirt in Two PartsCatalin CataBelum ada peringkat

- Undine & Cymbeline Wartsila Tech BulletinDokumen3 halamanUndine & Cymbeline Wartsila Tech BulletinAlexis Barnabás CollinsBelum ada peringkat

- Manual PS-100 Limpiador UltrasonicoDokumen6 halamanManual PS-100 Limpiador UltrasonicoAlexis Barnabás CollinsBelum ada peringkat

- Damcos Danfoss HP DHP 14 3 MS RS Parts List DrawingDokumen4 halamanDamcos Danfoss HP DHP 14 3 MS RS Parts List DrawingAlexis Barnabás CollinsBelum ada peringkat

- Garioni Naval Newsletter 32Dokumen5 halamanGarioni Naval Newsletter 32Alexis Barnabás CollinsBelum ada peringkat

- Rocking Test For Deck Crane MN RaulíDokumen1 halamanRocking Test For Deck Crane MN RaulíAlexis Barnabás CollinsBelum ada peringkat

- 15105Dokumen116 halaman15105Alexis Barnabás CollinsBelum ada peringkat

- 15201Dokumen16 halaman15201Alexis Barnabás CollinsBelum ada peringkat

- Purchasing ConditionsDokumen3 halamanPurchasing ConditionsAlexis Barnabás CollinsBelum ada peringkat

- Design Procedures For Dynamically Loaded Foundations Choice of Parameters For Equivalent Lumped SystemsDokumen11 halamanDesign Procedures For Dynamically Loaded Foundations Choice of Parameters For Equivalent Lumped SystemsAnonymous osfiXqUkBelum ada peringkat

- Fasteners Lecture 11-20-03Dokumen67 halamanFasteners Lecture 11-20-03laponggaBelum ada peringkat

- M.3 Pressure Switches Hex 24: Rohs IiDokumen18 halamanM.3 Pressure Switches Hex 24: Rohs IiSeyedAli TabatabaeeBelum ada peringkat

- BEC198 (Finals)Dokumen180 halamanBEC198 (Finals)Lorenz BerroyaBelum ada peringkat

- Practice Exam 1Dokumen7 halamanPractice Exam 1425Belum ada peringkat

- Adequate Bearing Material and Heat TreatmentDokumen20 halamanAdequate Bearing Material and Heat TreatmentdavideBelum ada peringkat

- Brochure FDP - EG 16.08.2021-1-2-2Dokumen3 halamanBrochure FDP - EG 16.08.2021-1-2-2sri sivaBelum ada peringkat

- Clevo M620ne-UDokumen34 halamanClevo M620ne-UHh woo't hoofBelum ada peringkat

- Jrules Installation onWEBSPHEREDokumen196 halamanJrules Installation onWEBSPHEREjagr123Belum ada peringkat

- Bomba FlightDokumen2 halamanBomba FlightGustavo HRBelum ada peringkat

- Chip DielDokumen45 halamanChip DielJUANCANEXTBelum ada peringkat

- Electrical Panel Data MSC PG: NO Panel Desc Panel CodeDokumen6 halamanElectrical Panel Data MSC PG: NO Panel Desc Panel CodeAjeng AyuBelum ada peringkat

- Strength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeDokumen6 halamanStrength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeansarBelum ada peringkat

- Data Flow Diagrams PDFDokumen9 halamanData Flow Diagrams PDFYasmine2410Belum ada peringkat

- Construction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDokumen23 halamanConstruction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDevendra SharmaBelum ada peringkat

- 2g SSV Drive Test Report 154128 - Yos - SudrsoDokumen8 halaman2g SSV Drive Test Report 154128 - Yos - SudrsohimmuraaBelum ada peringkat

- 4 MPM Scope - OutputDokumen45 halaman4 MPM Scope - OutputSajid Ali MaariBelum ada peringkat

- Software TestingDokumen4 halamanSoftware TestingX DevilXBelum ada peringkat

- Crisfield - Vol1 - NonLinear Finite Element Analysis of Solids and Structures EssentialsDokumen360 halamanCrisfield - Vol1 - NonLinear Finite Element Analysis of Solids and Structures EssentialsAnonymous eCD5ZRBelum ada peringkat

- NanoDokumen10 halamanNanoRavi TejaBelum ada peringkat

- Paper AeroplaneDokumen19 halamanPaper Aeroplanejkb SudhakarBelum ada peringkat

- RDBMS and HTML Mock Test 1548845682056Dokumen18 halamanRDBMS and HTML Mock Test 1548845682056sanjay bhattBelum ada peringkat

- Project Presentation SurveyingDokumen14 halamanProject Presentation SurveyingSACHIN MEENABelum ada peringkat

- SAP IdMDokumen34 halamanSAP IdMshabab_14Belum ada peringkat

- 2nd Term Physics ReviewerDokumen5 halaman2nd Term Physics ReviewerAlfredo L. CariasoBelum ada peringkat