ELECTRIC GENERATOR SYSTEM

Diunggah oleh

Mladen MuskinjaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ELECTRIC GENERATOR SYSTEM

Diunggah oleh

Mladen MuskinjaHak Cipta:

Format Tersedia

Electric energy generation system

WO 2013104040 A1

Abstract

The present invention relates to an electric energy generation system comprising

a frequency inverter (1) connected to an electric motor (2) in order to control

the rotation of the motor; and an alternator (8) connected to the electric moto

r (2) by a metal shaft (4.1) that includes or forms at least one solid concentri

c structure (7) arranged between the electric motor (2) and the alternator (8),

the mass of the shaft (4.1) and of the solid concentric structure (7) being prop

ortional to the power of the motor (2).

Description translated from Portuguese (Portugal)

Descriptive Report of Patent for "SYSTEM OF GENERATING ELECTRICITY".

Technical Field

The present invention relates to a system for generating electrical energy compr

ising an electrical generator coupled to an electric motor, controlled by a freq

uency converter-means comprising a shaft conforms or at least a solid concentric

.

Description of the Related Art

The conventional generators and alternators need at least a combustion engine co

upled to its operation in rotation and torque to generate electricity. In order

exemplary document PI9102642-3 autoexcitado describes a synchronous generator mo

tor injected copper or aluminum. Such generators are used coupled to an internal

combustion engine having means which allow the generator to operate at the most

appropriate speed range of the engine.

Currently, the known generators to generate electricity at a desired frequency g

enerally behave the rotation set, ie 1800 rpm 60 Hz, 1500 rpm 50 Hz These conven

tional generators and alternators have a high energy consumption at the time of

starting and consumption energy elava considerably.

The generators are devices for the production of electricity, alternative source

s of energy, and exist in various forms and types. The different types of genera

tors include, for example, electric generators, portable wind generators, emerge

ncy generators and RV generators. Each type has a specific function and can be f

ed, for example, propane gas, gasoline, natural gas and diesel. All these forms

of energy are used as initial force to fuel generators, contributing to global w

arming and harm the environment.

A fully electric generator does not pollute. However, when using an electric mot

or, engine power is greater than the power of the generator. Thus, the energy ge

nerator to generate power through electrical alternator electric motor is greate

r than the power to be generated, to produce because the pulling force would req

uire the motor to consume more power that the generator generates.

Summary of the Invention

The present invention relates to a system for generating electricity comprising

a frequency inverter three phase, three-phase electric motor, alternator and a g

enerator includes a shaft that conforms or at least a solid concentrically dispo

sed between the electric motor and generator. Such elements, properly arranged,

allow the set to operate in rotation and traction force appropriate to the opera

tion of the electric motor, which drives the generator to saving energy consumpt

ion for generation without considerable loss of power output and current output.

Obietivos the Invention

In view of the problems described, and in order to overcome them, we propose a s

ystem to generate electricity that is powered by electricity.

The cost of power generation is less than the cost of generating combustion, can

generate benefits for medium and large consumers, reducing operating cost throu

gh energy savings.

Moreover, when it generates a large amount of electricity from low electricity c

onsumption, contributes to the environment and reduces the cost of generation.

The cost of generation is reduced due to the replacement of the combustion engin

e by an electric motor. Thus, the energy consumption to be provided by the initi

al source that feeds the engine is electricity.

The objectives of the present invention are achieved by a system for generating

electricity using an axle or conforms includes at least a solid mass concentric

with appropriate that, in turn, due to the transfer of inertia of its mass in di

splacement rotation kinetic energy generated by a centrifugal force, increasing

the engine speed. Thus, the motor is replaced by the pull force required to move

the generator shaft connected to a load.

The system of generating electrical energy comprises a frequency converter conne

cted to an electric motor for controlling rotation of the motor, alternator and

generator connected to the electric motor via a shaft which includes at least on

e or conforms solid structure concentrically disposed between the altemador elec

tric motor and generator, the mass of the shaft that includes or conforms at lea

st a solid concentric proportional to power the electric motor.

The proper rotation is defined as a generator voltage and frequency. To obtain t

he proper rotation is required inverter frequency as the engine speed low or hig

h speed for the proper rotation of the generator.

Thus, the engine power can be up to four times smaller than the electric power g

enerator. Thus, although the engine being inferior to the generator, the consump

tion of electricity consumed by the engine to generate drops considerably, ie, i

s consumed little power and generates a lot of electricity.

Furthermore, the voltage and number of phases of the motor and generator may be

identical or different.

The power generation system of the present invention allows the use of an electr

ic motor coupled by a shaft conforms or that includes at least one solid structu

re concentric to an electric generator alternator. The electrical generator star

ts to generate electricity with low power consumption, since consumption of the

motor becomes smaller, consuming a smaller amount of initial energy source to ro

tate the generator shaft.

The advantage of the electric motor generator alternator of the present inventio

n in relation to other existing generators alternators is the generation of elec

tricity with low power consumption to perform work rotation of three-phase gener

ator.

The system of power generation is easy to use, as it features a compact structur

e. The mounting base is light, since the motor is lightweight and does not use a

ny type of tank liquid or gaseous fuel.

The system for generation of electricity is silent because the engine and genera

tor are electric, and also because the axis that includes conforms or at least a

solid concentric produces no noise, since it does not suffer intense friction.

The present invention will be described below with the aid of drawings, but whic

h are not absolutely limiting where it can be observed other details and advanta

ges of the present invention.

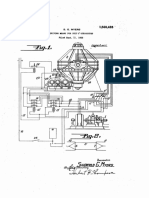

Brief Description of the Drawings

Figure 1 - A schematic representation of the system of power generation of the p

resent invention.

Detailed Description of the Drawings

Figure 1 shows a system for generating electricity comprising a three-phase inve

rter frequency 1 connected to a three phase electric motor high speed (2) and a

three-phase alternator generator 8.

The system further comprises a shaft conforms or 4.1 that includes at least a so

lid frame 7 concentrically disposed between the motor 2 and the generator 8 to g

enerate a tensile force required to decrease energy consumption while maintainin

g, in whole or in part, the tensile strength of the electrical alternators gener

ators provided by the electric motor.

The solid structure concentric 7 may have a variety of shapes, such as square, r

ectangular, hexagonal, round, spherical, oval, and star and others.

In a preferred embodiment, the shaft conforms or comprising at least a solid con

centric 7 as well as the very solid structure concentric 7 are constructed of re

silient metal, the latter of which has a rounded shape of a wheel.

As can be seen in Figure 1, the system further comprises a metal shaft connectin

g the motor 2 4.1 generator 8 couplings 3.1 and 3.2 which are used to secure the

second motor shaft 7 to the wheel axis and the wheel axis 7 generator shaft 8:0

1 support base and fastening the equipment (9).

The masses 4.1 shaft and concentric solid structure 7 are proportional to the po

wer of the engine 2, and the mass of the solid structure concentric 7 must be se

ven to nine times the mass of the shaft 4.1, more preferably eight times, most p

referably nine times. Thus, each horsepower - CV of the electric motor 2, the su

m of the masses of 4.1 shaft and concentric solid structure 7 must be between 5

Kg and 15 Kg per unit of horsepower electric motor (2) more preferably between 8

kg to 12 kg, even more preferably 10 kg

Thus for a 5 HP motor 2, the sum of the masses of solid structure concentric sha

ft 7 and the metal should be 4.1 to about 50 pounds. Whereas the mass of the met

al shaft 4.1 is about 1 kg per VC, the mass of the solid structure 7 is concentr

ic about 9 kg per CV.

The generator phase altemador 8 provides energy savings to be consumed in work f

or the generation of electricity, and can be configured with the power of 10 KVA

to 300 KVA in single phase, two phase or three phase, and may be above or below

these powers.

In a preferred embodiment, the system uses an electric motor 2 high-spin to work

in low speed. The inverter controls the rotation of the motor 2 rotation and to

achieve the ideal frequency of the system which are determined by obeying the s

peed and frequency of the generator 8, which can be 50 Hz or 60 Hz, depending on

the desired tension. Only when the system reaches the optimum tension is that e

nergy is released for consumption by an electrical control connected to the outp

ut of the generator 8, or the control only releases energy when the generator 8

reach the rotation, frequency and voltage suitable for power loads, avoiding und

er-and overvoltage.

In fixing the axle bearing is used 4.1 6.1 and 6.2 5.1 and bearing 5.2. The shaf

t weighs about 4.1 kg per 1 HP / HP in relation to the engine power, so there is

a transfer of adequate inertia.

In a preferred embodiment, the metal wheel 7 weighs about 9 kg per hp / HP in re

lation to power the electric motor so that there is adequate transfer of inertia

.

In the preferred embodiment, the electric motor can be of direct current or alte

rnating current and is controlled by a frequency inverter 1, which reduces power

consumption when starting the engine and controls the rotation of generation (w

hich may be substituted by any other similar equipment with the power of 10 KVA

to 300 KVA, single phase, two phase or three phase).

In a second preferred embodiment, the generator (8) has a power of 10 KVA to 300

KVA.

Having described examples of preferred embodiments, it should be understood that

the scope of the present invention encompasses other possible variations, being

limited solely by the terms of the appended claims, including therein the possi

ble equivalents.

Claims translated from Portuguese (Portugal)

CLAIMS

1. "System power generation" comprising: a frequency inverter (1) connected

to an electric motor (2) to control its rotation, and a generator alternator (8)

connected to the electric motor (2) through a shaft (4.1), characterized by the

fact that the shaft (4.1) or conforms includes at least one concentric solid st

ructure (7) disposed between the electric motor (2) and the generator alternator

(8) to power the rotation of the motor (2 .)

2. The system according to claim 1, characterized by the fact that the sum o

f the masses of the shaft (4.1) and concentric solid structure (7) is proportion

al to power the electric motor (2).

3. The system according to claim 1, characterized by the fact that the mass

of the solid structure concentric (7) is seven to nine times the mass of the sha

ft (4.1).

4. The system according to claim 3, characterized by the fact that the mass

of the solid structure concentric (7) and preferably eight times the mass of the

shaft (4.1).

5. The system according to claim 3, characterized by the fact that the mass

of the solid structure concentric (7) is most preferably nine times the mass of

the shaft (4.1).

6. System according to any one of claims 1 to 5, characterized by the fact t

hat the sum of the masses of solid structure concentric (7) and shaft (4.1) is i

n the range of 5 Kg and 15 Kg per unit horse Steam - hp electric motor (2).

7. The system according to claim 6, characterized by the fact that the sum o

f the masses of solid structure concentric (7) and shaft (4.1) is located, prefe

rably, in the range of 8 kg to 12 kg per unit of horsepower - CV of the electric

motor (2).

8. The system according to claim 6, characterized Peto fact that the sum of

the masses of solid structure concentric (7) and shaft (4.1) is more preferably

10 kg per unit of horsepower - CV of the electric motor ( 2).

9. System according to any one of claims 1 to 8, characterized by the fact t

hat the solid structure of concentric (7) has a diversity of formats.

10. The system according to claim 9, characterized by the fact that the soli

d structure of concentric (7) has preferably the shape of a wheel.

11. The system according to claim 1, characterized in that the motor (2) is

selected from the group consisting phase motor, three-phase two-phase motor and

motor.

12. The system according to claim 1, characterized by the fact that the gene

rator alternator (8) is selected from the group consisting generator single phas

e, two phase and three-phase generator generator

13. System according to claims 1 and 11, characterized in that the electric

motor (2) is selected from the group comprising high rotation motor and the low

rotation motor.

14. The system according to claims 1, 11 and 12 characterized by the fact th

at the tension and number of phases of the motor (2) and generator (8) are equal

.

15. The system according to claims 1, 11 and 12 characterized by the fact th

at the tension and number of phases of the motor (2) and generator (8) are diffe

rent.

Anda mungkin juga menyukai

- Study of a reluctance magnetic gearbox for energy storage system applicationDari EverandStudy of a reluctance magnetic gearbox for energy storage system applicationPenilaian: 1 dari 5 bintang1/5 (1)

- Integration of Large Scale Wind Energy with Electrical Power Systems in ChinaDari EverandIntegration of Large Scale Wind Energy with Electrical Power Systems in ChinaBelum ada peringkat

- EEPT - Kunjimon - High Efficiency IMDokumen30 halamanEEPT - Kunjimon - High Efficiency IMBuzurjmeherBelum ada peringkat

- Doubly Fed Electric MachineDokumen19 halamanDoubly Fed Electric MachineChristopher PerkinsBelum ada peringkat

- Content Beyond The Syllabus Unit 1Dokumen5 halamanContent Beyond The Syllabus Unit 1ANBARASU LBelum ada peringkat

- Wind Turbine Generator - SynchronousDokumen21 halamanWind Turbine Generator - SynchronousTahsin IbtidaBelum ada peringkat

- Small Wind Turbine ControllersDokumen25 halamanSmall Wind Turbine Controllersgabrielitos7891Belum ada peringkat

- Peres 10PPS103 2 Electrical Machines PDFDokumen71 halamanPeres 10PPS103 2 Electrical Machines PDFThanigaivel RajaBelum ada peringkat

- Patent Application - High Efficiency IM - Kunjimon - Provisional SpecDokumen10 halamanPatent Application - High Efficiency IM - Kunjimon - Provisional SpecBuzurjmeherBelum ada peringkat

- 2 Comparing Electric Machine Sys-TemsDokumen6 halaman2 Comparing Electric Machine Sys-TemsAnonymous E4Rbo2sBelum ada peringkat

- Flywheel Electric GeneratorDokumen16 halamanFlywheel Electric GeneratoravalosheBelum ada peringkat

- Microcontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiDokumen4 halamanMicrocontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiTarun SinghBelum ada peringkat

- Electrical Machines FundamentalsDokumen11 halamanElectrical Machines FundamentalsRochelle De LeonBelum ada peringkat

- Variable-Speed Wind Power Generation UsingDokumen8 halamanVariable-Speed Wind Power Generation Usingsrinu240000100% (1)

- Unit2 MachinesDokumen35 halamanUnit2 MachinesdineshkumarBelum ada peringkat

- A Novel Power Splitting Drive Train For Variable Speed Wind Power GeneratorsDokumen11 halamanA Novel Power Splitting Drive Train For Variable Speed Wind Power GeneratorsDork654651Belum ada peringkat

- Alternator Basics: How it Works to Charge a Car BatteryDokumen8 halamanAlternator Basics: How it Works to Charge a Car BatteryAsif Al FaisalBelum ada peringkat

- 129 - Ent 204Dokumen12 halaman129 - Ent 204Polutan ElvinBelum ada peringkat

- SChapter 34Dokumen9 halamanSChapter 34stban murilloBelum ada peringkat

- AlternatorDokumen8 halamanAlternatorBoreda RahulBelum ada peringkat

- Plant Efficiencies Benefit by Selection of Synchronous MotorDokumen9 halamanPlant Efficiencies Benefit by Selection of Synchronous Motorpichet_krongyart2859Belum ada peringkat

- Wind Generation SystemDokumen9 halamanWind Generation SystemShreya BagariaBelum ada peringkat

- Motor-Generator - WikipediaDokumen7 halamanMotor-Generator - Wikipediahema FawzyBelum ada peringkat

- Single Phase Induction MotorsDokumen19 halamanSingle Phase Induction MotorsRahulGundeBelum ada peringkat

- Tesla Patent,,,,Rotating Magnetic Field Using... Und A Ferrite Toroid1Dokumen5 halamanTesla Patent,,,,Rotating Magnetic Field Using... Und A Ferrite Toroid1anakedya13Belum ada peringkat

- Generators PDFDokumen16 halamanGenerators PDFKVVBelum ada peringkat

- A Simple Flywheel Induction Motor For Large Power Short Time Compensation in Inverter-Driven Stand-Alone Power SystemsDokumen7 halamanA Simple Flywheel Induction Motor For Large Power Short Time Compensation in Inverter-Driven Stand-Alone Power SystemstalatsonBelum ada peringkat

- Dynamic Modeling, Design of A Wind/fuel Cell/ultra-Capacitor-Based Hybrid Power Generation SystemDokumen16 halamanDynamic Modeling, Design of A Wind/fuel Cell/ultra-Capacitor-Based Hybrid Power Generation SystemYellaturi Siva Kishore ReddyBelum ada peringkat

- Reluctance MotorDokumen14 halamanReluctance Motortheodorakis017781Belum ada peringkat

- Electrical Machines: Low Power ApplicationsDokumen4 halamanElectrical Machines: Low Power ApplicationsOana PBelum ada peringkat

- Reaction PaperDokumen6 halamanReaction PaperAngelo Escoro Dante100% (1)

- A Single Phase Self-Excited Induction Generator WithDokumen6 halamanA Single Phase Self-Excited Induction Generator WithbourasnikBelum ada peringkat

- AC Motor Operating Principles & HistoryDokumen10 halamanAC Motor Operating Principles & HistoryArzuman HəsənovBelum ada peringkat

- Principles of Operation: A Three-Phase Power Supply Provides A Rotating Magnetic Field in An Induction MotorDokumen5 halamanPrinciples of Operation: A Three-Phase Power Supply Provides A Rotating Magnetic Field in An Induction MotorMohd akifBelum ada peringkat

- Study of Electricity Generated by Ceiling Fan & Car WheelDokumen6 halamanStudy of Electricity Generated by Ceiling Fan & Car WheelSaru TVBelum ada peringkat

- Induction Motor: AC Motor Electromagnetic Induction Commutator Slip Rings Polyphase Brushes FrequencyDokumen6 halamanInduction Motor: AC Motor Electromagnetic Induction Commutator Slip Rings Polyphase Brushes FrequencyShahidKhanBelum ada peringkat

- Electrical Braking of Large Wind TurbinesDokumen11 halamanElectrical Braking of Large Wind Turbineslaaloo41Belum ada peringkat

- SeminarDokumen15 halamanSeminarAkhil GuliaBelum ada peringkat

- Doubly-Fed Induction Machine Models For Stability Assessment of Wind FarmsDokumen6 halamanDoubly-Fed Induction Machine Models For Stability Assessment of Wind FarmsArun RajendranBelum ada peringkat

- 2011 Design and Construction of Axial Flux Permanent Magnet Generator For Wind Turbine Generated DC Voltage at Rated Power 1500 W (Office)Dokumen4 halaman2011 Design and Construction of Axial Flux Permanent Magnet Generator For Wind Turbine Generated DC Voltage at Rated Power 1500 W (Office)Fazal Karim Mahsud100% (1)

- Active and Reactive Power Control of Wound Rotor Induction GeneratorsDokumen34 halamanActive and Reactive Power Control of Wound Rotor Induction GeneratorsSherif M. DabourBelum ada peringkat

- AlternatorDokumen50 halamanAlternatorKR571Belum ada peringkat

- Induction Synchronous MotorsDokumen35 halamanInduction Synchronous MotorsDeandre LaingBelum ada peringkat

- Project Documentation For Multilevel InvertersDokumen89 halamanProject Documentation For Multilevel InvertersAnonymous hm7nSy1ebBelum ada peringkat

- Altena TorDokumen8 halamanAltena TorJb EnarioBelum ada peringkat

- Generators and Motors, Inductance Week 11Dokumen15 halamanGenerators and Motors, Inductance Week 11zaini.iqbal761Belum ada peringkat

- Bog HoseDokumen29 halamanBog HoseNadia BnBelum ada peringkat

- Why Use Very High Voltages in Power TransmissionDokumen42 halamanWhy Use Very High Voltages in Power TransmissionKhan YousafzaiBelum ada peringkat

- Sam Williamson Modelling and Simulation of A Pico Hydropower Off Grid Network PDFDokumen28 halamanSam Williamson Modelling and Simulation of A Pico Hydropower Off Grid Network PDFGabriel SimmerBelum ada peringkat

- Chapter 6 - Induction Motors (Part1)Dokumen18 halamanChapter 6 - Induction Motors (Part1)SanjanaLakshmiBelum ada peringkat

- Electrical Generators PDFDokumen71 halamanElectrical Generators PDFchaithra hsBelum ada peringkat

- Battery Energy Storage and Power Electronics Based Voltage and Frequency Controller ForDokumen10 halamanBattery Energy Storage and Power Electronics Based Voltage and Frequency Controller ForIAEME PublicationBelum ada peringkat

- Universal Moto1Dokumen12 halamanUniversal Moto1Saim MollahBelum ada peringkat

- Project Cell 1Dokumen12 halamanProject Cell 1muzzershawBelum ada peringkat

- Power-Generating Shock Absorber Converts Vehicle Vibration to ElectricityDokumen29 halamanPower-Generating Shock Absorber Converts Vehicle Vibration to ElectricitylucasBelum ada peringkat

- Mechanical Systems and Signal Processing: Marcus Vinícius Vitoratti de Araujo, Rodrigo NicolettiDokumen15 halamanMechanical Systems and Signal Processing: Marcus Vinícius Vitoratti de Araujo, Rodrigo NicolettiSagar MohanBelum ada peringkat

- Induction Generators With Squirrel-Cage Rotors Used in Wind TurbinesDokumen11 halamanInduction Generators With Squirrel-Cage Rotors Used in Wind TurbinesFitiu IoanBelum ada peringkat

- Hev MatlabDokumen5 halamanHev Matlabmihai_1957Belum ada peringkat

- A New System of Alternating Current Motors and Transformers and Other EssaysDari EverandA New System of Alternating Current Motors and Transformers and Other EssaysPenilaian: 5 dari 5 bintang5/5 (1)

- Espacenet DocumentDokumen1 halamanEspacenet DocumentMladen MuskinjaBelum ada peringkat

- Drawing Pages of JP2016174482 A PatentDokumen1 halamanDrawing Pages of JP2016174482 A PatentMladen MuskinjaBelum ada peringkat

- Us7224077 PDFDokumen6 halamanUs7224077 PDFMladen MuskinjaBelum ada peringkat

- 1974008662Dokumen4 halaman1974008662Mladen MuskinjaBelum ada peringkat

- Wind Energy Systems (Johnson)Dokumen449 halamanWind Energy Systems (Johnson)Mario Shawn Hayden Jr100% (1)

- Advanced Course Button Mushrooms (Agaricus Bisporus) : Daily Program On Delphy Mushroom FarmDokumen2 halamanAdvanced Course Button Mushrooms (Agaricus Bisporus) : Daily Program On Delphy Mushroom FarmMladen MuskinjaBelum ada peringkat

- Sand2012 0304Dokumen64 halamanSand2012 0304Emma GonzalezBelum ada peringkat

- More Thoughts On The Uwe Jarck DeviceDokumen5 halamanMore Thoughts On The Uwe Jarck DeviceMladen MuskinjaBelum ada peringkat

- Mushroom Production GuideDokumen123 halamanMushroom Production GuideMladen MuskinjaBelum ada peringkat

- Us7224077 PDFDokumen6 halamanUs7224077 PDFMladen MuskinjaBelum ada peringkat

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0148513 A1Dokumen18 halamanUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0148513 A1Mladen MuskinjaBelum ada peringkat

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0119826 A1Dokumen7 halamanUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0119826 A1Mladen MuskinjaBelum ada peringkat

- Book Cultivation Merged MushroomDokumen278 halamanBook Cultivation Merged MushroomHussain1006100% (2)

- JPS54159538A Original Document 20200712174721Dokumen4 halamanJPS54159538A Original Document 20200712174721Mladen MuskinjaBelum ada peringkat

- Application PDFDokumen6 halamanApplication PDFMladen MuskinjaBelum ada peringkat

- PR-14D Operating Instructions: 144 X 144 X 50 MMDokumen2 halamanPR-14D Operating Instructions: 144 X 144 X 50 MMMladen MuskinjaBelum ada peringkat

- PatentsDokumen7 halamanPatentsMladen MuskinjaBelum ada peringkat

- Online Course Mushrooms: HAS Training and ConsultancyDokumen2 halamanOnline Course Mushrooms: HAS Training and ConsultancyMladen MuskinjaBelum ada peringkat

- Wo2012140458a3 PDFDokumen3 halamanWo2012140458a3 PDFMladen MuskinjaBelum ada peringkat

- Wo2012140458a3 PDFDokumen3 halamanWo2012140458a3 PDFMladen MuskinjaBelum ada peringkat

- Application PDFDokumen2 halamanApplication PDFMladen MuskinjaBelum ada peringkat

- Wo2012140458a3 PDFDokumen3 halamanWo2012140458a3 PDFMladen MuskinjaBelum ada peringkat

- FR2876163A1Dokumen8 halamanFR2876163A1Mladen MuskinjaBelum ada peringkat

- Application PDFDokumen3 halamanApplication PDFMladen MuskinjaBelum ada peringkat

- US8047090B2 Original Document 20200618185937Dokumen9 halamanUS8047090B2 Original Document 20200618185937Mladen MuskinjaBelum ada peringkat

- Magnetic Electricity Generator DesignDokumen14 halamanMagnetic Electricity Generator DesignMladen MuskinjaBelum ada peringkat

- Application PDFDokumen2 halamanApplication PDFMladen MuskinjaBelum ada peringkat

- US9140341B2 Original Document 20200618185302Dokumen32 halamanUS9140341B2 Original Document 20200618185302Mladen MuskinjaBelum ada peringkat

- Double-Channel: Submersible PumpsDokumen4 halamanDouble-Channel: Submersible PumpsMladen Muskinja0% (1)

- Us 1560428Dokumen5 halamanUs 1560428Mladen MuskinjaBelum ada peringkat

- Humidity and terminal connection specifications for PIC101A process indicatorDokumen2 halamanHumidity and terminal connection specifications for PIC101A process indicatorசசி குமார்Belum ada peringkat

- DECS 250 DatasheetDokumen4 halamanDECS 250 DatasheetEda AryaniBelum ada peringkat

- Experiment No: 4 Characteristics of Welding TransformerDokumen5 halamanExperiment No: 4 Characteristics of Welding TransformerKunal TanwarBelum ada peringkat

- Käyttöohje Generaattori Esab LHN 250 EngDokumen34 halamanKäyttöohje Generaattori Esab LHN 250 EngmaciucapompaBelum ada peringkat

- 63040-010060-020 Fsp065-Rebn2: CB CBDokumen2 halaman63040-010060-020 Fsp065-Rebn2: CB CBaayush715Belum ada peringkat

- Electrical Converter: User GuideDokumen73 halamanElectrical Converter: User GuideLionildo LucyBelum ada peringkat

- Transform Ad orDokumen4 halamanTransform Ad orDaniel PradoBelum ada peringkat

- Repair Autocom CDP VCIDokumen5 halamanRepair Autocom CDP VCIAdi Catanescu100% (2)

- Datasheet PDFDokumen10 halamanDatasheet PDFShikamaru MendozaBelum ada peringkat

- Acs - June - 2015 - Webinar - Final Covered Conductors PDFDokumen30 halamanAcs - June - 2015 - Webinar - Final Covered Conductors PDFDaniel Marginean100% (1)

- bp37 50 Projects Using Relays Scrs TriacsDokumen106 halamanbp37 50 Projects Using Relays Scrs TriacsSegfred NavarroBelum ada peringkat

- Transformers 1Dokumen5 halamanTransformers 1Shubhangi SinghBelum ada peringkat

- 7805T Ecg-960Dokumen2 halaman7805T Ecg-960bellscbBelum ada peringkat

- Wiring Diagram Dse 7320 Amf PDF FreeDokumen1 halamanWiring Diagram Dse 7320 Amf PDF FreeSemih GençBelum ada peringkat

- Definitions For Distributed Generation A RevisionDokumen4 halamanDefinitions For Distributed Generation A RevisionFarouk KeniouBelum ada peringkat

- Eletronics Lab Report - Zener DiodesDokumen3 halamanEletronics Lab Report - Zener DiodesThan Lwin Aung71% (7)

- C Audio SR707 SchematicsDokumen4 halamanC Audio SR707 SchematicsBBelum ada peringkat

- LS - Catalogue - Fire Alarm Cable - FinalDokumen18 halamanLS - Catalogue - Fire Alarm Cable - FinalLe NghiBelum ada peringkat

- ECEN 5737 Optional HWDokumen2 halamanECEN 5737 Optional HWVIJAYPUTRABelum ada peringkat

- Intelligent Battery Charging: An Alternate Solution To Your Battery WoesDokumen10 halamanIntelligent Battery Charging: An Alternate Solution To Your Battery WoesArul N S100% (1)

- Apc Back Ups Bx1100ciDokumen1 halamanApc Back Ups Bx1100ciHuzairi SulaimanBelum ada peringkat

- HIP For AramcoDokumen6 halamanHIP For Aramcoahsanhasan84Belum ada peringkat

- ModotewuwunapibixifigiDokumen3 halamanModotewuwunapibixifigiHLULANI MAIMELABelum ada peringkat

- M 5625 SP PDFDokumen18 halamanM 5625 SP PDFLaudito HidayatullahBelum ada peringkat

- Generator Tests PDFDokumen3 halamanGenerator Tests PDFAnonymous bDco7fDMyBelum ada peringkat

- Gs1m Diode SMDDokumen2 halamanGs1m Diode SMDandrimanadBelum ada peringkat

- Off Grid Solar PV Design GuidelinesDokumen20 halamanOff Grid Solar PV Design GuidelinesAntónio BarrosBelum ada peringkat

- SPD Selection GuideDokumen8 halamanSPD Selection GuideLorenzo GuidaBelum ada peringkat

- Generation Scheduling in Power Systems OptimizationDokumen29 halamanGeneration Scheduling in Power Systems OptimizationImma TzBelum ada peringkat

- DSC 1280Dokumen11 halamanDSC 1280nhiahm nhiahmBelum ada peringkat