My Book

Diunggah oleh

SriArthi0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

14 tayangan3 halamangood prieview

Judul Asli

my book

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inigood prieview

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

14 tayangan3 halamanMy Book

Diunggah oleh

SriArthigood prieview

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

Research Article

PRODUCTION OF BIO-DIESEL USED IN DIESEL ENGINES

K. VinuKumar

Assistant Professor, Department of Mechanical Engineering, Dr.Sivanthi Aditanar College of Engineering, Tiruchendur, Thoothukudi

District; Tamil Nadu; India. E-mail: er.vinukumar@gmail.com

Received:3 June 2013, Revised and Accepted:5 June 2013

ABSTRACT

To obtain biodiesel, the vegetable oil is subjected to a chemical reaction termed transesterification. Cottonseed oil (CSO) was selected for biodiesel

production. In that reaction, the Cottonseed oil is reacted in the presence of a catalyst (sodium hydroxide) with an alcohol (methanol) to give the

corresponding methyl esters. Cottonseed is non-edible oil, thus food against fuel conflict will not arise if this is used for biodiesel production. The

experiments were conducted in order to evaluate the effects of reaction variable such as methanol/oil molar ratio (1:3.3), catalyst concentration

(0.25%), temperature (65

0

C), reaction time 3.0 hours and stirring intensity (300rpm). The methyl ester yield is (84.3%). The methyl esters of cotton

seed oil can be used in existing diesel engines without any modifications.

Keywords: Cottonseed oil, Transesterification, Cottonseed oil methyl esters (COME), Fuel properties

INTRODUCTION

The cottonseed which remains after the cotton is ginned will be used

to produce cottonseed oil. Cotton seed oil is a waste product of the

cotton industry, so it costs the food manufacturers next to nothing to

procure a plentiful supply [1]. The only problem with this is that

cotton is not a food crop, therefore is not subject to the same

restrictions as to pesticide and fungicide levels. In fact, cotton is one

of the most heavily sprayed crops in the world, due to its

susceptibility to the threats of insect predators, such as the boll

weevil.

It is important to explore the feasibility of substitution of diesel with

an alternative fuel, which can be produced with in the country on a

massive scale for commercial utilization. At present the potential

alternative fuels are Alcohols (Methanol and Ethanol), Liquefied

Petroleum Gas (LPG), Compressed Natural Gas (CNG), Hydrogen and

Vegetable oils [2, 3]. The cotton seed oil, a non-edible type vegetable

oil is chosen as a potential alternative for producing biodiesel and

used as fuel in compression ignition engines [5, 6]. Almost all

vegetable oils can be directly mixed with diesel oil. Micro-

emulsification, pyrolysis and transesterification are the remedies

used to solve the problems encountered due to high fuel viscosity.

The use of vegetable oils as I.C. engine fuels can play a vital role in

helping the developed world to reduce the environmental impact of

fossil fuels [7, 8].

EXPERIMENTAL

Materials

A raw cottonseed oil from a local firm (Thiagarajan Oil Mill, Madurai,

Tamil Nadu.) was used. Chemicals such as Methanol, sodium

hydroxide were purchased from known chemical companies.

Filtering

The cottonseed oil was extracted from the seeds by the mechanized

expeller. The extracted oil was very much translucent .Even though

the oil was translucent there were some residues of oil cake. These

residues were separated out by filtering it. The filtration was done

by the Bag filters made from the Canvas cloth. The oil was slightly

heated before pouring into the bag. In around 24 hrs .all the residues

settle down at the bottom of the filter.

Degumming

In this process the hydratable and non- hydratable phosphatides

along with various resinous and mucilaginous materials were

separated from the neat oil. The oil was treated with 12-13% volume

of NaOH at 80 to 90 deg C. The hydra table portions absorbed and

became heavy and the heat helps to coagulate these smaller

portions. The soap formation created and separation was achieved

through difference in specific gravity, oil being lighter floated on top

and soap, gums being heavier settled down. After and before added

the NaOH, the oil was washed three times using water at 80- 90 deg

C. The non- hydratable portion was separated by increasing the

phosphorous concentration by way of mixing with .01% to .02% of

phosphoric acid.

Choosing the Catalyst for the Transesterification Process

The transesterification process has to be carried out in the presence

of a catalyst. The selection of catalyst is based on pH value of neat

vegetable oil. If it is lesser than 7, acid catalyst should be selected

and if it is greater than 7, base catalyst should be selected. The

wrong selection of the catalyst leads to soap formation. Since the PH

value of cotton seed oil is greater than 7, so we had used NaOH (base

catalyst) as catalyst for the transesterification process.

Titration To Determine the Amount of Catalyst

It is necessary to determine the exact amount of catalyst

(NaOH) needed for the transesterification process. Since adding too

much or too little catalyst will just result in excessive amounts of bi-

product (soap).

The following steps were followed for the titration process:

Sodium Hydroxide solution was prepared by dissolving 1gm of

NaOH in 1000 ml of water.

Cotton seed oil solution was prepared by dissolving 1 ml. of oil in

10ml. of Isopropyl alcohol.

NaOH solution was added to the cotton seed oil, one drop at a time.

The PH level of the oil solution was checked, after adding each drop.

An eventual rise in PH level was noticed. This process was

continued till the oil solution attained a pH level of 8 to 9.

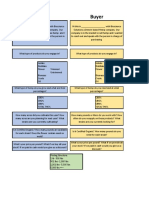

Fig. 1: Experimental Setup for Producing Biodiesel

Vol 1, Issue 1 , 2013

Vinukumar et al.

Innovare Journal of Eng.& Tech., Vol 1, Issue 1, 2013, 5-7

6

Fig. 2: Refrigeration unit for Producing Biodiesel

Transesterification of cotton seed oil

A round bottom flask of 500 ml is used for the present analysis. The

cotton seed oil in the flask was heated on a hot plate having

magnetic stirrer arrangement is shown in fig.1. The mixture was

stirred at the same speed for all test runs. Initially 100ml cotton seed

oil is heated to 50

0

C. Then the methanol 30ml and the catalyst

0.5gms (sodium hydroxide) are mixed. After the methanol and

catalyst are mixed, they are poured into a reactor. The temperature

maintained for the whole transesterification process is about

65

0

C.The refrigeration unit (fig.2) is provided to condense the

methanol and to get complete reaction. And heat up to three hours

and switch off the system until cooled. After the cooling is over, the

Glycerin that is present in the vegetable oil is settled down at the

bottom of the flask and the fatty acid esters are separated from the

Glycerin by using the separating funnel.

Separation

After the reaction is completed, the products are allowed to separate

into two layers by using the separating funnel. Gravity is used to

separate the two products, since they have different densities.

Glycerin is the denser of the two products. We can separate the

biodiesel (product) and glycerol. The lower layer contains impurities

and glycerol. This top layer (ester) is separated.

Washing

The purpose of a water wash is to remove un-reacted alcohol,

catalyst, or glycerin in the biodiesel. Two step wash is carried out

using hot water washing and another one is salt water washing. This

top layer (ester) is separated and purified using distilled water. Hot

distilled water is sprayed over the ester and stirred gently and

allowed to settle in the separating funnel. The lower layer is

discarded and upper layer (purified biodiesel) is separated. And

washed top layer of ester is rewashed with sodium chloride (Nacl).

Un-reacted alcohol decreases the flashpoint of biodiesel. Biodiesel

with 0.2% alcohol does not meet ASTM fuel Standards [4].Water

wash will also remove any soap in the biodiesel.

Drying

The final product of purified ester was heated to 106

0

C under

vacuum to remove residual moisture. Around three hours to heat by

using oven. Then the final biodiesel is got. Many of the parts in the

diesel fuel injection system are made of high carbon steels; thus,

they are prone to corrosion when in contact with water. Many diesel

engines are equipped with water separators that cause small water

droplets to coalesce until they are large enough to drop out of the

fuel flow where they can be removed. There are some reports that

these water separators are not effective when used with biodiesel.

RESULTS AND DISCUSSION

Calculation of Percentage Yield (% yield)

Percentage yield was calculated using the following formula: 548

Milliliters of methyl esters produced by 650Milliliter of oil taken for

reaction. The yield Percentage of methyl esters was 84.3% Yield of

methyl ester = (Milliliters of methyl esters produced/Milliliter of oil

taken for reaction) 100

Fuel properties of cottonseed oil methyl esters

The properties of COME are summarized in Table1 and compared

with raw cotton seed oil and diesel.

Cetane number

The cetane number, which is a dimensionless descriptor of the

tendency of the fuel to self ignite when the fuel is injected into the

combustion chamber, was determined using an Ignition Quality

Tester (IQT). The cetane number of cottonseed oil methyl esters was

determined as 51.

Kinematic viscosity

Viscosity is a key fuel property because it influences the atomization

of a fuel upon injection into the combustion chamber and eventually

the formation of soot and engine deposits. The viscosity of the

cottonseed oil methyl esters and diesel was measured by redwood

viscometer. The raw cottonseed oil Kinematic viscosity was 50.7 is

reduced to 5.20 at 40

0

C. The Kinematic viscosity of cottonseed oil

methyl esters is nearer to that of diesel.

Density and Heating value

The density of cottonseed oil methyl esters (COME) was 0.8752 g/cc

at 15

0

C.It is obvious that the density measurement of COME is quite

lower than that pure cottonseed oil. Higher heating value is a

measure of the energy produced when the fuel is burnt completely,

which also determines the suitability of biodiesel as an alternative to

diesel fuels. Table 1 shows that the gross calorific value of COME

produced were 10142 Kcal/Kg. It is always desirable for the

cottonseed oil methyl esters to have a calorific value nearer to that

of diesel.

Table 1: Typical Property of Diesel, Cotton Seed Oil Methyl Ester

and Cotton Seed Oil

Property Diesel

Cotton seed

oil

methyl ester

Raw cotton

seed oil

Density @15 C

g/cc 0.8218 0.8752

0.9169

Kinematic

viscosity@40C 3.01 5.2

50.7

Flash point (C) 53 171

316

Fire point (C) 61 182

322

Cloud point (C) 8 14

l3

Pour point (C)

Below

-13 8

2

Specific gravity

@15/15C 0.8225 0.8745

0.9176

Water content nil nil

nil

Gross caloric

value kcal/kg 10,713 10,142

9981

Sediments % nil nil

0.001

CetaneNumer 52 51 49

Important temperatures

Pour point and cloud point are important for cold weather

operations of the I.C. engine. For satisfactory working, the values of

both should be well below the freezing point of the oil used. The

cloud point (CP) and pour point (PP) observed for COME were 14 C

and 8 C, respectively (Table 1). The Flash point and fire point

observed for cottonseed oil methyl esters were 171 C and 182C,

respectively (Table 1). Flash point is an important temperature from

a safety point of view.

Vinukumar et al.

Innovare Journal of Eng.& Tech., Vol 1, Issue 1, 2013, 5-7

7

CONCLUSION

Cotton seed oil is chosen as a potential non-edible vegetable oil for

the production of biodiesel. Here the biodiesel was prepared from

cotton seed oil by transesterification process. Viscosity and density

of methyl esters of cotton seed oil are 5.20 mm2/s and 0.8752 g/cc,

which are very close to that of diesel. The calorific value of biodiesel

is found to be slightly lower than that of diesel. The flash point of

biodiesel is 1180C higher than that of diesel. The important

properties of biodiesel produced from cotton seed oil are quite close

to that of diesel. The methyl esters of cotton seed oil can be used in

existing diesel engines without any modifications.

ACKNOWLEDGEMENTS

The authors wish to express their thanks to Mr. K.Karuppasamy,

Assistant Professor, Department of Mechanical Engineering, Anna

University of Technology Tirunelveli and Dr. N.Vedaraman, Senior

Technical Officer, Chemical Engineering Department, Central

Leather Research Institute, Chennai, Tamil Nadu, India, for their

support in this investigation. Thanks are due to the Central Leather

Research Institute (Council of Scientific & Industrial Research)

Adyar, Chennai-600 020. India. for biodiesel production.

REFERENCES

1. FangruiMaa, Milford A. Hannab, Bioresource. Biodiesel

production: a review, Technology 70 (1999).

2. AS Ramadhas, S Jayaraj, C Muraleedharan. Use of vegetable

oils as

3. I.C. engine fuelsa review. Renewable Energy 2004; 29.

Syed Ameer Basha , K. Raja Gopal, S. Jebaraj A review on

biodiesel production, combustion, emissions and

performance, Renewable and Sustainable Energy Reviews

13(2009) 16281634

4. A.S. Ramadhas, S. Jayaraj, C. Muraleedharan Biodiesel

production from high FFA rubber seed oil, Fuel 84 (2005)

335-340

5. K. Karuppasamy, K. VinuKumar, M. Jegesh David and N.

Vedaraman, Design of Combustor Fueled with Methyl Esters

of Cottonseed Oil, CiiT International Journal of

Programmable Device Circuits and Systems, print: ISSN

0974 -973X & online: ISSN 0974-9624, Vol 3,No 10,pp.602-

607,August 2011

6. K. VinuKumar, Experimental Evaluation on Different Viscous

Fluids Spray Characteristics in Injector Using Constant

Volume Chamber, International Organization of Scientific

Research (IOSR) Journals of Civil and Mechanical Journals.

7. Syed Ameer Basha , K. Raja Gopal, S. Jebaraj A review on

biodiesel production, combustion, emissions and

performance, Renewable and Sustainable Energy Reviews

13(2009) 16281634

8. Qing Shu, Qiang Zhang, Guanghui Xu, Zeeshan Nawaz,

Dezheng Wang, Jinfu Wang, Synthesis of biodiesel from

cottonseed oil and methanol using a carbon-based solid acid

catalyst, Fuel Processing Technology 90 (2009) 10021008

Anda mungkin juga menyukai

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Screenshot 2023-03-27 at 12.28.40 PMDokumen1 halamanScreenshot 2023-03-27 at 12.28.40 PMSriArthiBelum ada peringkat

- Is Coconut Good For Diabetics Beat My SugarDokumen1 halamanIs Coconut Good For Diabetics Beat My SugarSriArthiBelum ada peringkat

- Searchq Omr+sheet&rlz 1C9BKJA enIN905IN906&oq Omr+shee&aqs Chrome.0.0i131i433i512j69i57j0i67i131i433j0i1Dokumen1 halamanSearchq Omr+sheet&rlz 1C9BKJA enIN905IN906&oq Omr+shee&aqs Chrome.0.0i131i433i512j69i57j0i67i131i433j0i1SriArthiBelum ada peringkat

- Screenshot 2023-03-27 at 12.34.42 PMDokumen1 halamanScreenshot 2023-03-27 at 12.34.42 PMSriArthiBelum ada peringkat

- Screenshot 2023-03-27 at 12.26.47 PMDokumen1 halamanScreenshot 2023-03-27 at 12.26.47 PMSriArthiBelum ada peringkat

- NEW OMR Sheet For NEET 2022 PDF - OfficiDokumen1 halamanNEW OMR Sheet For NEET 2022 PDF - OfficiSriArthiBelum ada peringkat

- Published Journal WordDokumen20 halamanPublished Journal WordSriArthiBelum ada peringkat

- Thermal Decomposition of Calcium Carbonate PDFDokumen3 halamanThermal Decomposition of Calcium Carbonate PDFSriArthiBelum ada peringkat

- How To Write The Best SOP Step by Step?Dokumen20 halamanHow To Write The Best SOP Step by Step?SriArthiBelum ada peringkat

- Natália A. Portela, Emanuele C.S. Oliveira, Alvaro C. Neto, Rayza R.T. Rodrigues, Samanta R.C. Silva, Eustáquio V.R. Castro, Paulo R. FilgueirasDokumen7 halamanNatália A. Portela, Emanuele C.S. Oliveira, Alvaro C. Neto, Rayza R.T. Rodrigues, Samanta R.C. Silva, Eustáquio V.R. Castro, Paulo R. FilgueirasSriArthiBelum ada peringkat

- Bioresource Technology: Soham Chattopadhyay, Ramkrishna SenDokumen6 halamanBioresource Technology: Soham Chattopadhyay, Ramkrishna SenSriArthiBelum ada peringkat

- Centre For Research: Dr. R.JayavelDokumen2 halamanCentre For Research: Dr. R.JayavelSriArthiBelum ada peringkat

- Renewable and Sustainable Energy Reviews: Alok Patel, Neha Arora, KM Sartaj, Vikas Pruthi, Parul A. PruthiDokumen20 halamanRenewable and Sustainable Energy Reviews: Alok Patel, Neha Arora, KM Sartaj, Vikas Pruthi, Parul A. PruthiSriArthiBelum ada peringkat

- Conversion of De-Oiled Castor Seed Cake Into Bio-Oil and Carbon AdsorbentsDokumen9 halamanConversion of De-Oiled Castor Seed Cake Into Bio-Oil and Carbon AdsorbentsSriArthiBelum ada peringkat

- Fly Ash Supported Ni Fe Solid Acid Catalyst For Efficient Production of Diesel Additive: Intensi Fication Through Far-Infrared RadiationDokumen10 halamanFly Ash Supported Ni Fe Solid Acid Catalyst For Efficient Production of Diesel Additive: Intensi Fication Through Far-Infrared RadiationSriArthiBelum ada peringkat

- Apj1909 PDFDokumen9 halamanApj1909 PDFSriArthiBelum ada peringkat

- Production of Biodiesel Using Homogeneous Alkali Catalyst and Its Effect On Vehicular EmissionDokumen7 halamanProduction of Biodiesel Using Homogeneous Alkali Catalyst and Its Effect On Vehicular EmissionSriArthiBelum ada peringkat

- Jojoba OilDokumen8 halamanJojoba OilSriArthiBelum ada peringkat

- Physico-Chemical Characterization of Caesalpinia Sappan Seed and Its OilDokumen4 halamanPhysico-Chemical Characterization of Caesalpinia Sappan Seed and Its OilSriArthiBelum ada peringkat

- Chemical EngineeringDokumen6 halamanChemical EngineeringSriArthiBelum ada peringkat

- Energy Conversion and ManagementDokumen9 halamanEnergy Conversion and ManagementSriArthiBelum ada peringkat

- Bioresource Technology: Wuttichai Roschat, Theeranun Siritanon, Teadkait Kaewpuang, Boonyawan Yoosuk, Vinich PromarakDokumen8 halamanBioresource Technology: Wuttichai Roschat, Theeranun Siritanon, Teadkait Kaewpuang, Boonyawan Yoosuk, Vinich PromarakSriArthiBelum ada peringkat

- Ijct Inst AuthDokumen2 halamanIjct Inst AuthSriArthiBelum ada peringkat

- Bioresource TechnologyDokumen10 halamanBioresource TechnologySriArthiBelum ada peringkat

- Industrial Crops and Products: Siqi Fan, Tianyu Liang, Haiyan Yu, Quanxin Bi, Gangtie Li, Libing WangDokumen5 halamanIndustrial Crops and Products: Siqi Fan, Tianyu Liang, Haiyan Yu, Quanxin Bi, Gangtie Li, Libing WangSriArthiBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- RV3 PDFDokumen1 halamanRV3 PDFTam SimeonBelum ada peringkat

- Review: Winery Wastewater Quality and Treatment Options in AustraliaDokumen13 halamanReview: Winery Wastewater Quality and Treatment Options in AustraliaMomirBelum ada peringkat

- The Problem and Its Setting Background of The StudyDokumen14 halamanThe Problem and Its Setting Background of The StudyMitzifaye TaotaoBelum ada peringkat

- 1.8 3 PVDF Hmwpe CableDokumen1 halaman1.8 3 PVDF Hmwpe CableRobert LiraBelum ada peringkat

- Lab 3Dokumen6 halamanLab 3Anonymous eGc6IFJc8GBelum ada peringkat

- Kendriya Vidyalaya Gachibowli, Gpra Campus, Hyd-32: Sample Paper Test 05 For Term-2 Exam (2021-22)Dokumen12 halamanKendriya Vidyalaya Gachibowli, Gpra Campus, Hyd-32: Sample Paper Test 05 For Term-2 Exam (2021-22)Ranjeet kumar PanditBelum ada peringkat

- As SNAB Revision NotesDokumen49 halamanAs SNAB Revision NotesXneo KMeng 茗茗 ~Belum ada peringkat

- Durability of Radiation-Sterilized Polyolefins: Stabilization of Ethylene-Polypropylene Copolymer To Gamma Initiated OxidationDokumen286 halamanDurability of Radiation-Sterilized Polyolefins: Stabilization of Ethylene-Polypropylene Copolymer To Gamma Initiated OxidationSameh AlariqiBelum ada peringkat

- Stanier Ingraham 5th EditionDokumen704 halamanStanier Ingraham 5th EditionChristopher Antony Kannamthara100% (1)

- 8 2 Introduction To Biodiesel ProductionDokumen7 halaman8 2 Introduction To Biodiesel ProductionshawonscribdBelum ada peringkat

- Microbiological Analysis of WaterDokumen7 halamanMicrobiological Analysis of WaterHemy MichaelBelum ada peringkat

- Activity 6 Laboratory ProcedureDokumen7 halamanActivity 6 Laboratory ProcedureAinie JuripaeBelum ada peringkat

- Polymax Broucher 4042023Dokumen12 halamanPolymax Broucher 4042023polymaxtradingllcBelum ada peringkat

- Extrusion ValidationDokumen5 halamanExtrusion ValidationIlayaraja BoopathyBelum ada peringkat

- Surface Tension of Various Liquids PDFDokumen43 halamanSurface Tension of Various Liquids PDFneha sahuBelum ada peringkat

- Tableau Commande 2023Dokumen72 halamanTableau Commande 2023ckouadio.cdmdciBelum ada peringkat

- Hepatoprotective Effects of Artichoke (Cynara Scolymus) : January 2013Dokumen7 halamanHepatoprotective Effects of Artichoke (Cynara Scolymus) : January 2013Chatjutha TangkomsaengtongBelum ada peringkat

- BIOENERGY PPT Final YearDokumen20 halamanBIOENERGY PPT Final YearAshith Ajith100% (1)

- Energetics Question DatabaseDokumen23 halamanEnergetics Question DatabaseKamrul Alam MasumBelum ada peringkat

- The United States Pharmacopeial (USP 37) Monographs, Vitamina D PDFDokumen2 halamanThe United States Pharmacopeial (USP 37) Monographs, Vitamina D PDFMeli AppelhansBelum ada peringkat

- Consumer Chemistry: 5 Quarter 2: Module 3Dokumen13 halamanConsumer Chemistry: 5 Quarter 2: Module 3Ces Michaela CadividaBelum ada peringkat

- Journal of Molecular Liquids: Chandrabhan Verma, Eno E. Ebenso, Indra Bahadur, M.A. QuraishiDokumen14 halamanJournal of Molecular Liquids: Chandrabhan Verma, Eno E. Ebenso, Indra Bahadur, M.A. QuraishiterBelum ada peringkat

- Stereochemistry Sem 1 2013Dokumen82 halamanStereochemistry Sem 1 2013Vaibhav RanaBelum ada peringkat

- Imagine A Healthy, Beautiful Smile: Oral Care Product GuideDokumen16 halamanImagine A Healthy, Beautiful Smile: Oral Care Product Guidecontentdrive4 drive4Belum ada peringkat

- Steps of DNA Replication: Download PDF - (Free)Dokumen3 halamanSteps of DNA Replication: Download PDF - (Free)Andrew HunterBelum ada peringkat

- 2021-Recent Advances in Polysaccharide-Based Adsorbents For Wastewater TreatmentDokumen27 halaman2021-Recent Advances in Polysaccharide-Based Adsorbents For Wastewater TreatmentCARLOS ALBERTO RAMIREZ BARRAGANBelum ada peringkat

- Brief History Cytology Hierarchy of Structural Organization - Cell Structure - MitosisDokumen52 halamanBrief History Cytology Hierarchy of Structural Organization - Cell Structure - MitosisPJ PomarBelum ada peringkat

- Chem Academy: Daily Assignment Iit-Jam Home Work DPPDokumen4 halamanChem Academy: Daily Assignment Iit-Jam Home Work DPPVkumar100% (1)

- MTT - Sigma AldrichDokumen2 halamanMTT - Sigma AldrichFellicia RachmadianaBelum ada peringkat

- Carbonato de Glicerina PDFDokumen29 halamanCarbonato de Glicerina PDFbexigaobrotherBelum ada peringkat