Initial Pressures

Diunggah oleh

ClaudionorGomesFilhoDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Initial Pressures

Diunggah oleh

ClaudionorGomesFilhoHak Cipta:

Format Tersedia

Initial Pressures - Test and Adjust - Machine Preparation

1. Stop the machine. Engage the parking brake. Stop the engine.

2. Put blocks in front of the wheels and behind the wheels of the machine. Remove

the differential drive shaft.

(1) ransmission control valve (2) !uard

". Remove guard (2) from transmission control valve (1) in order to provide access

to the control.

ransmission control valve

(") #olts ($) %over (&) #olt (') %aps

$. Remove 1$ mounting bolts (") that are used to retain cover ($) . he top three

bolts cannot be removed without removing the entire valve. hese bolts should

be loosened. Remove bolt (&) from the transmission control valve.

&. Slide tooling (() under cover ($) . he )*shaped slots should be facing upward

so that the bolt holes line up with the holes in the plate.

'. ighten bolts (") and bolt (&) . Refer to Specifications+ ,ransmission %ontrol

-alve, for the correct tor.ue.

/. Remove caps (') . 0nstall tooling (1) or (#) on taps (2) and (3) .

Test Procedure

able 2

Initial Pressures

Callout Pressure

(1)

E 451

6

$1& 7 1& kPa ('8 7 2 psi)

! 451

9

$1& 7 1& kPa ('8 7 2 psi)

: 451

3

$;& 7 1& kPa (/8 7 2 psi)

2

"<& 7 1& kPa (&; 7 2 psi)

=

"$8 7 1& kPa ($< 7 2 psi)

( 1 )

1ll pressures are taken at 2888 rpm and &1> % (12"> 6).

able "

Test Port

Change in pressure for one 5J-

10! "hi#

Change in pressure for one $M-

1%51 "pacer

E

;; kPa (12.; psi) $$ kPa ('.$ psi)

6

// kPa (11.2 psi) "< kPa (&.' psi)

!

;; kPa (12.; psi) $$ kPa ('.$ psi)

9

111 kPa (1' psi) && kPa (;.8 psi)

:

<$ kPa (1".' psi) $/ kPa ('.; psi)

3

11' kPa (1'.< psi) &; kPa (;.$ psi)

2

111 kPa (1' psi) && kPa (;.8 psi)

=

'1 kPa (;.; psi) "8 kPa ($.$ psi)

1. ?perate the engine at high idle in P1R3 or 4E)R12. Record the pressures.

Pressure tap (2) is for clutch ; and pressure tap (3) is for clutch &. Remove the

pressure gauges and replace the caps (') .

2. Remove caps (') and install tooling (1) or (#) on pressure tap (!) + pressure tap

(9) + and pressure tap (=) .

". ?perate the engine at high idle in the 60RS SPEE( 6?R@1R( position.

Record the gauge pressures. Pressure tap (!) is for clutch 1. Pressure tap (9) is

clutch ' and pressure tap (=) is clutch /. Remove the pressure gauges and

replace caps (') .

$. Remove caps (') and install tooling (1) or (#) on pressure tap (:) and pressure

tap (6) .

&. ?perate the engine at high idle in the SE%?4( SPEE( 6?R@1R( position.

Record the gauge pressures. Pressure tap (:) is for clutch 2 and pressure tap (6)

is clutch $. Remove the pressure gauges and replace caps (') .

'. Remove caps (') and install tooling (1) or (#) on pressure tap (E) .

/. ?perate the engine at high idle in the 60RS SPEE( RE-ERSE position.

Record the gauge pressures. Pressure tap (E) is clutch ". Remove the pressure

gauges and replace caps (') .

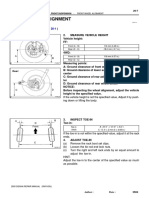

Adjust#ent Procedure

1. Refer to able 2 for the correct pressures. 0f an adAustment is needed+ follow

Step 2 and Step ".

(/) Shims and Spacers

(;) 1dAuster assemblB

(<) 1dAustment screw

(18) 2ocknut

(11)=anifold

2. 0f the pressures do not agree with the pressures that are listed in able 2+ use the

following procedure to adAust the pressures.

a. 2oosen locknut (18) on adAuster assemblB (;) .

b. @hile Bou monitor the pressure+ adAust the pressure bB turning

adAustment screw (<) . o lower the pressure+ turn the adAustment screw

clockwise. ?ne turn of the adAustment screw will change the pressure

approCimatelB 1"2 kPa (1< psi).

c. ighten locknut (18) . Refer to Specifications+ ,Selector and Pressure

%ontrol -alve, for the correct tor.ue. 6or all clutches eCcept clutch (2)

and clutch (3) + shift the transmission to the P1R3 or 4E)R12

position for a minimum of 1& seconds. hen+ shift the transmission back

to the gear that is specified in Step / through Step 1. 6or clutch (2) and

clutch (3) + shift the transmission to the 60RS SPEE( 6?R@1R( for

a minimum of 1& seconds. hen+ shift the transmission back to P1R3 or

4E)R12. =ake sure that the pressures agree with the pressures that

are listed in able 2.

d. 0f the pressure cannot be adAusted to the acceptable limits with

adAustment screw (<) + stop the engine and remove manifold (11) . his

action will allow Bou to access the selector spool. Remove the selector

spool. 1dd shims and spacers or remove shims and spacers+ as re.uired.

e. 0nstall the manifold (11) . 1dAust the initial pressure according to the

procedure that is listed in Steps 2.a through 2.c.

". %ontinue the procedure until all the pressure taps are checked and adAusted.

$. Stop the engine. Remove tooling (() .

&. )se new washers and install the transmission control valve on the transmission.

ighten bolts (") . Refer to Specifications+ ,ransmission %ontrol -alve, for the

correct tor.ue.

'. o verifB the clutch pressures+ refer to esting and 1dAusting+ ,ransmission

Pressures * est and 1dAust,.

/. 0nstall the guards and the differential drive shaft.

&ote' his procedure should be followed whenever a transmission control valve

is repaired. Replace anB of the springs or anB of the spools that are contained

within the individual clutch stations.

&ote' 0f the transmission clutch pressure is out of the tolerance range+ the most

likelB cause of the failure will be a failed modulation spring+ debris in the

control valve+ or a seal failure within the transmission.

(or)sheet

able $

(or)sheet

Callout Pressure

(1)

E

6

!

9

:

3

2

=

( 1 )

1ll pressures are taken at 2888 rpm and &1> % (12"> 6).

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Pokemon HeartGold & SoulSilver Johto Prima Official GuideDokumen355 halamanPokemon HeartGold & SoulSilver Johto Prima Official GuideAnonymous oEcQYMPA7Belum ada peringkat

- Testing and Adjusting d6NDokumen7 halamanTesting and Adjusting d6NClaudionorGomesFilho100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Amigurumi Demonstrative Bear Free PatternDokumen4 halamanAmigurumi Demonstrative Bear Free PatternMartin del BarrioBelum ada peringkat

- Fantasytowns 50townsandcitiesforfantasytabletoprole PlayinggamesDokumen107 halamanFantasytowns 50townsandcitiesforfantasytabletoprole PlayinggamesSirBelum ada peringkat

- 2023 PSC Terminal ReportDokumen3 halaman2023 PSC Terminal ReportBobby LopezBelum ada peringkat

- 2018 Palarong Pambansa Billiards Guidelines and Ground RulesDokumen4 halaman2018 Palarong Pambansa Billiards Guidelines and Ground RulesGagä VeralloBelum ada peringkat

- Compressor SectionDokumen79 halamanCompressor SectionMustakim shahrinBelum ada peringkat

- Skoda Felicia ManualDokumen2 halamanSkoda Felicia ManualSusana Corvillo Arroyo25% (4)

- Using Caterpillar Monitoring SystemDokumen6 halamanUsing Caterpillar Monitoring SystemClaudionorGomesFilhoBelum ada peringkat

- Transmission PressuresDokumen3 halamanTransmission PressuresClaudionorGomesFilhoBelum ada peringkat

- Fill d6tDokumen8 halamanFill d6tClaudionorGomesFilhoBelum ada peringkat

- P'COLOGYDokumen18 halamanP'COLOGYHeena BhojwaniBelum ada peringkat

- Bernat KW429 KN Pullover - en USDokumen1 halamanBernat KW429 KN Pullover - en USAnca Elena DulcinatuBelum ada peringkat

- Memories Aboard A Paper Plane: Ninja World Tournament - Ally EventsDokumen3 halamanMemories Aboard A Paper Plane: Ninja World Tournament - Ally EventsninosaurusBelum ada peringkat

- Mesterolone:: 83% Unique ContentDokumen2 halamanMesterolone:: 83% Unique ContentovizdikBelum ada peringkat

- READMEDokumen4 halamanREADMEElias DelgadoBelum ada peringkat

- Unit 2 - Fashion CategoriesDokumen6 halamanUnit 2 - Fashion CategoriesDeepali B MudalgiBelum ada peringkat

- Intoeing Gait: Association of Paediatric Chartered PhysiotherapistsDokumen2 halamanIntoeing Gait: Association of Paediatric Chartered PhysiotherapistsM. Eka PutraBelum ada peringkat

- Conceptest Clicker Questions: Physics, 4 EditionDokumen47 halamanConceptest Clicker Questions: Physics, 4 EditionstephensreenivasulutBelum ada peringkat

- King's GambitDokumen3 halamanKing's GambitAnonymous OCDJg17ZBelum ada peringkat

- Wheel AlignmentDokumen4 halamanWheel AlignmentdonlynBelum ada peringkat

- Mangaldan National High School: Long TestDokumen3 halamanMangaldan National High School: Long Testalipin ni shin ryujinBelum ada peringkat

- Injury Prevention Training in Football: Time To Consider Training Under Fatigue?Dokumen4 halamanInjury Prevention Training in Football: Time To Consider Training Under Fatigue?aminBelum ada peringkat

- Management Lessons From DhoniDokumen3 halamanManagement Lessons From DhonirockydondaBelum ada peringkat

- Orange Pi Zero v1 11Dokumen12 halamanOrange Pi Zero v1 11JederVieiraBelum ada peringkat

- Rigging and Its AffectsDokumen4 halamanRigging and Its AffectsIgnacio Benítez CortésBelum ada peringkat

- KMC2018 Result 7.0 PDFDokumen2.056 halamanKMC2018 Result 7.0 PDFSelene Chin0% (1)

- Doug PolkDokumen2 halamanDoug Polkshiva balram0% (1)

- General AwarenessDokumen137 halamanGeneral AwarenessswamyBelum ada peringkat

- Fly For Fun Knights Complete Guide Part 2 by RegaxionDokumen63 halamanFly For Fun Knights Complete Guide Part 2 by RegaxionEduardo SalvadorBelum ada peringkat

- PT SlabireDokumen2 halamanPT SlabireBogdanSpătaruBelum ada peringkat

- Cinderella: A) True or False? Answer The Questions. 1) 2)Dokumen1 halamanCinderella: A) True or False? Answer The Questions. 1) 2)JosesBelum ada peringkat

- Water AbsorptionDokumen6 halamanWater AbsorptionAbhijeethBelum ada peringkat

- Splicing of Wire Rope 2Dokumen27 halamanSplicing of Wire Rope 2Денис ХортюкBelum ada peringkat