Plaxis-Triaxial Test With Hardening Soil Model

Diunggah oleh

limara65Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Plaxis-Triaxial Test With Hardening Soil Model

Diunggah oleh

limara65Hak Cipta:

Format Tersedia

TRIAXIAL TEST WITH HARDENING SOIL MODEL

TRIAXIAL TEST WITH HARDENING SOIL MODEL

This document describes an example that has been used to verify the elasto-plastic

deformation capabilities according to the Hardening Soil model of PLAXIS. The problem

involves axial loading under triaxial test conditions.

Used version:

PLAXIS 2D - Version 2011

PLAXIS 3D - Version 2012

Input: A triaxial test is conducted on a geometry displayed in Figure 1 for PLAXIS 2D

and PLAXIS 3D respectively. In PLAXIS 2D an Axisymmetric model is used. The

boundary conditions of the geometry are dened as prescribed displacements assigned

to the sides of the volume. In PLAXIS 2D the left and the bottom boundaries are xed in

the horizontal and vertical directions respectively.

The axial load

1

is represented by a distributed load on the top and bottom planes. The

pressure

2

is represented by a distributed load on the right plane and

3

is represented

by a distributed load on the front plane.

1

1

3

x

x

y

y

z

PLAXIS 2D PLAXIS 3D

Figure 1 Triaxial test - loading conditions

Material: The soil behaviour is modelled by means of the Hardening Soil model. The

density and are set to zero, the remaining model parameters are:

E

ref

50

= 2.0 10

4

kN/m

2

E

oed

= 2.0 10

4

kN/m

2

E

ref

ur

= 6.0 10

4

kN/m

2

power = 0.5 c'

ref

= 1kN/m

2

' = 35

' = 5

p

ref

= 100kN/m

2

Meshing: In order to create an extremely coarse mesh, the Very coarse option is used

for the Global coarseness in PLAXIS 2D. The Expert mesh settings used for the model in

PLAXIS 3D are:

PLAXIS 2012 | Validation & Verication 1

VALIDATION & VERIFICATION

Relative element size: 20.00

Polyline angle tolerance: 30.00

Surface angle tolerance: 15.00

Snapping tolerance: 1.0010

-3

Calculations: In the Initial phase zero initial stresses are generated by using the K0

procedure ( = 0). Three loading tests are performed. The sample is subjected to the

following loading tests:

Isotropic loading to -100 kN/m

2

In PLAXIS 2D the left and the bottom boundaries are xed in the horizontal and vertical

directions respectively. The loads applied to the top and the right boundary are activated.

The boundary and loading conditions for PLAXIS 3D are shown in Table 1.

Table 1 Boundary and loading conditions (Phase 1)

Location Points Disp

x

Disp

y

Disp

z

Load

x

Load

y

Load

z

Front (0; 0; 0) (1; 0; 0)

(1; 0; 1) (0; 0; 1)

- - - - 100.0 -

Rear (0; 1; 0) (1; 1; 0)

(1; 1; 1) (0; 1; 1)

Free Fixed Free - - -

Left (0; 0; 0) (0; 1; 0)

(0; 1; 1) (0; 0; 1)

Fixed Free Free - - -

Right (1; 0; 0) (1; 1; 0)

(1; 1; 1) (1; 0; 1)

- - - -100.0 - -

Bottom (0; 0; 0) (1; 0; 0)

(1; 1; 0) (0; 1; 0)

Free Free Fixed - - -

Top (0; 0; 1) (1; 0; 1)

(1; 1; 1) (0; 1; 1)

- - - - - -100.0

After the isotropic loading, the prescribed displacement are set to zero for the following

phases. Both axial loading phases start from the isotropic loading phase.

Axial compression until failure

In PLAXIS 2D the value of the vertical load applied to the top of the geometry is changed

to -450 kN/m

2

. The boundary and loading conditions for PLAXIS 3D are shown in Table 2.

Table 2 Boundary and loading conditions (Phase 2)

Location Points Disp

x

Disp

y

Disp

z

Load

x

Load

y

Load

z

Front (0; 0; 0) (1; 0; 0)

(1; 0; 1) (0; 0; 1)

- - - - 100.0 -

Rear (0; 1; 0) (1; 1; 0)

(1; 1; 1) (0; 1; 1)

Free Fixed Free - - -

Left (0; 0; 0) (0; 1; 0)

(0; 1; 1) (0; 0; 1)

Fixed Free Free - - -

Right (1; 0; 0) (1; 1; 0)

(1; 1; 1) (1; 0; 1)

- - - -100.0 - -

Bottom (0; 0; 0) (1; 0; 0)

(1; 1; 0) (0; 1; 0)

Free Free Fixed - - -

Top (0; 0; 1) (1; 0; 1)

(1; 1; 1) (0; 1; 1)

- - - - - -450.0

Axial extension until failure

In PLAXIS 2D the value of the vertical load applied to the top of the geometry is changed

to 100 kN/m

2

. The boundary and loading conditions for PLAXIS 3D are shown in Table 3.

Output: The failure stress values of the triaxial sample are given in Table 4. The

2 Validation & Verication | PLAXIS 2012

TRIAXIAL TEST WITH HARDENING SOIL MODEL

Table 3 Boundary and loading conditions (Phase 3)

Location Points Disp

x

Disp

y

Disp

z

Load

x

Load

y

Load

z

Front (0; 0; 0) (1; 0; 0)

(1; 0; 1) (0; 0; 1)

- - - - 100.0 -

Rear (0; 1; 0) (1; 1; 0)

(1; 1; 1) (0; 1; 1)

Free Fixed Free - - -

Left (0; 0; 0) (0; 1; 0)

(0; 1; 1) (0; 0; 1)

Fixed Free Free - - -

Right (1; 0; 0) (1; 1; 0)

(1; 1; 1) (1; 0; 1)

- - - -100.0 - -

Bottom (0; 0; 0) (1; 0; 0)

(1; 1; 0) (0; 1; 0)

Free Free Fixed - - -

Top (0; 0; 1) (1; 0; 1)

(1; 1; 1) (0; 1; 1)

- - - - - -

compression and extension results of triaxial test with the can be seen in Figure 2.

Table 4 Failure stress values

Model Compression Extension

PLAXIS 2D 372.85 26.07

PLAXIS 3D 372.57 24.72

-0.03 -0.02 -0.01 0.00 0.01 0.02 0.03 0.04 0.05 0.06 0.07

Extension Compression

0

-100

-200

-300

-400

V

e

r

t

i

c

a

l

s

t

r

e

s

s

[

k

N

/

m

2

]

Vertical strain []

PLAXIS 2D solution

PLAXIS 3D solution

Figure 2 Compression and extension results of triaxial test with the Hardening Soil model

Verication: The theoretical solution to the failure of the sample is given by the

Mohr-Coulomb criterion:

f =

|

1

3

|

2

+

1

+

3

2

sin c cos = 0

so that failure occurs in compression at:

1

=

3

1 + sin

1 sin

2c

cos

1 sin

= 372.86kN/m

2

and failure occurs in extension at:

PLAXIS 2012 | Validation & Verication 3

VALIDATION & VERIFICATION

1

=

3

1 sin

1 + sin

+ 2c

cos

1 + sin

= 26.08kN/m

2

The calculated and theoretical values are in good agreement with each other.

4 Validation & Verication | PLAXIS 2012

Anda mungkin juga menyukai

- Advanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniDokumen94 halamanAdvanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniSze Mian KuehBelum ada peringkat

- Plaxis TunnelDokumen0 halamanPlaxis TunnelSyazwan AbhBelum ada peringkat

- Slope Stability Analysis Grand Hyatt Hotel, Bahria Town Islamabad.Dokumen77 halamanSlope Stability Analysis Grand Hyatt Hotel, Bahria Town Islamabad.asif razaBelum ada peringkat

- Chapter 11 of Rock Mass PropertiesDokumen43 halamanChapter 11 of Rock Mass PropertiesJosé Luis Illanes100% (1)

- Hardening SoilDokumen24 halamanHardening SoildiegofernandodiazsepBelum ada peringkat

- Slope Stability 03092022Dokumen3 halamanSlope Stability 03092022Tanmay KalolaBelum ada peringkat

- ZSoilDay2011 HSmodels-Course v3.1Dokumen104 halamanZSoilDay2011 HSmodels-Course v3.1Mohamed A. El-BadawiBelum ada peringkat

- HS Model PresentationDokumen58 halamanHS Model Presentationgeologist84100% (2)

- Plaxis ValidationDokumen5 halamanPlaxis Validationعصام السامرائيBelum ada peringkat

- Estimating In-Situ Soil Permeability From CPT & CPTuDokumen8 halamanEstimating In-Situ Soil Permeability From CPT & CPTuJose Leo MissionBelum ada peringkat

- Trench Stability in Cohesive SoilDokumen6 halamanTrench Stability in Cohesive SoilShahab KhaledBelum ada peringkat

- Eygec 2014Dokumen214 halamanEygec 2014Ancuta CealaltaBelum ada peringkat

- Galavi Groundwater Flow and Coupled AnalysisDokumen290 halamanGalavi Groundwater Flow and Coupled AnalysisAnonymous D5s00DdUBelum ada peringkat

- Computers and Geotechnics: Sari W. Abusharar, Jun-Jie Zheng, Bao-Guo ChenDokumen10 halamanComputers and Geotechnics: Sari W. Abusharar, Jun-Jie Zheng, Bao-Guo ChenIrvin AlbertoBelum ada peringkat

- Bearing Capacity Calculation of Rock Foundation Based On Nonlinear Failure CriterionDokumen7 halamanBearing Capacity Calculation of Rock Foundation Based On Nonlinear Failure CriterionSpasenBelum ada peringkat

- Slope Stability Manual 8Dokumen12 halamanSlope Stability Manual 8YawgmothBelum ada peringkat

- Lecture 3 Constative Models (Plaxis) PDFDokumen119 halamanLecture 3 Constative Models (Plaxis) PDFMohamed OudaBelum ada peringkat

- Shaft 2012 ManualDokumen236 halamanShaft 2012 ManualRaynaldo JodistiroBelum ada peringkat

- Factor of Safety of A Consolidated SlopeDokumen33 halamanFactor of Safety of A Consolidated SlopeMadan RamuBelum ada peringkat

- GD Pile 2013Dokumen161 halamanGD Pile 2013Ericwww100% (2)

- Material Models in PlaxisDokumen136 halamanMaterial Models in PlaxismpvfolloscoBelum ada peringkat

- Soil Nail - GNP - GoodDokumen19 halamanSoil Nail - GNP - GoodgahsoonBelum ada peringkat

- Constitutive ModelsDokumen8 halamanConstitutive ModelsAnonymous D5s00DdUBelum ada peringkat

- Retaining StructuresDokumen15 halamanRetaining StructuresHarold TaylorBelum ada peringkat

- PLAXIS Site Response Analysis Liquefaction EvaluationDokumen42 halamanPLAXIS Site Response Analysis Liquefaction EvaluationHOMOUNIVERSALBelum ada peringkat

- Prof. B V S Viswanadham, Department of Civil Engineering, IIT BombayDokumen26 halamanProf. B V S Viswanadham, Department of Civil Engineering, IIT BombayBolton Alonso Yanqui SotoBelum ada peringkat

- Innovative Solutions For Slope Stability Reinforcement and CharacDokumen245 halamanInnovative Solutions For Slope Stability Reinforcement and CharacghkotxcgjfjerrBelum ada peringkat

- 2D Numerical Simulations of Soil Nail WallsDokumen12 halaman2D Numerical Simulations of Soil Nail WallsShahab KhaledBelum ada peringkat

- Stone Column 123Dokumen34 halamanStone Column 123Nilesh0% (1)

- Field Tests and Numerical Simulations: Research Scholar, IiscDokumen30 halamanField Tests and Numerical Simulations: Research Scholar, Iiscjs kalyana rama75% (4)

- Maccaferri Flexible Pavement Design SpreadsheetDokumen10 halamanMaccaferri Flexible Pavement Design SpreadsheetAlbaro Andres TorricoBelum ada peringkat

- Triaxial TestDokumen21 halamanTriaxial TestTshepiso NthiteBelum ada peringkat

- Stability Analysis Procedures - Theory and LimitationsDokumen41 halamanStability Analysis Procedures - Theory and LimitationsAndyra Jaiz BadduBelum ada peringkat

- Lecture 1Dokumen37 halamanLecture 1alfredomotaBelum ada peringkat

- PLAXIS Ground Response AnalysisDokumen46 halamanPLAXIS Ground Response AnalysisAnonymous D5s00DdUBelum ada peringkat

- For Finite Element AnalysisDokumen32 halamanFor Finite Element AnalysisZhenhe SongBelum ada peringkat

- Soil Mechanics - Consolidation - Solved ProblemsDokumen30 halamanSoil Mechanics - Consolidation - Solved Problemsselda durmazBelum ada peringkat

- Plaxis Common MistakeDokumen22 halamanPlaxis Common MistakeBenjamin HasecicBelum ada peringkat

- Soil Damping Formulation in Nonlinear Time Domain Site Response AnalysisDokumen27 halamanSoil Damping Formulation in Nonlinear Time Domain Site Response AnalysischaexBelum ada peringkat

- Iss34 Art2 - Validation of The Embeded Pile Row in PLAXIS 2DDokumen4 halamanIss34 Art2 - Validation of The Embeded Pile Row in PLAXIS 2DhapsinteBelum ada peringkat

- Quakecore Opensees Training Workshop 2017: Geotechnical Analysis in OpenseesDokumen70 halamanQuakecore Opensees Training Workshop 2017: Geotechnical Analysis in OpenseesTariq MahmoodBelum ada peringkat

- Chapter 12. Analysis of Consolidation Under EmbankmentDokumen9 halamanChapter 12. Analysis of Consolidation Under EmbankmentDEBASISBelum ada peringkat

- Soil MixingDokumen7 halamanSoil MixingLuchiian CezarBelum ada peringkat

- Pile Testing & Settlement Prediction-Poulos-2013Dokumen20 halamanPile Testing & Settlement Prediction-Poulos-2013Sorabh GuptaBelum ada peringkat

- The Use of Field Geophysical Techniques To Determine Geotechnical Stiffness ParametersDokumen12 halamanThe Use of Field Geophysical Techniques To Determine Geotechnical Stiffness ParametersoldinaBelum ada peringkat

- Liquefaction Analysis Using PLAXISDokumen19 halamanLiquefaction Analysis Using PLAXISdehevy50% (2)

- Soil Constitutive ModelDokumen36 halamanSoil Constitutive ModelMohamed YousufBelum ada peringkat

- Benz Small Strain Stifness in Geotechnical AnalysesDokumen12 halamanBenz Small Strain Stifness in Geotechnical AnalysesKurt CargoBelum ada peringkat

- Analysis of Basal Heave Stability For Excavations in Soft Clay Using The Finite PDFDokumen8 halamanAnalysis of Basal Heave Stability For Excavations in Soft Clay Using The Finite PDFJuan Carlos Patiño BautistaBelum ada peringkat

- Moment Load in WallapDokumen3 halamanMoment Load in WallapSajjad AnwarBelum ada peringkat

- Subgrade Reaction Modulus (KS) of Clayey SoilsDokumen26 halamanSubgrade Reaction Modulus (KS) of Clayey Soilssofronije2005100% (1)

- A Comprehensive Database of Tests on Axially Loaded Piles Driven in SandDari EverandA Comprehensive Database of Tests on Axially Loaded Piles Driven in SandBelum ada peringkat

- Ground Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsDari EverandGround Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsBelum ada peringkat

- International Society for Rock Mechanics: List of Members 1980Dari EverandInternational Society for Rock Mechanics: List of Members 1980Penilaian: 3.5 dari 5 bintang3.5/5 (2)

- Bi-Axial Test With Mohr-Coulomb ModelDokumen0 halamanBi-Axial Test With Mohr-Coulomb ModelMOSHITOMOSHITABelum ada peringkat

- Triaxial Test With Hardening Soil Model PDFDokumen4 halamanTriaxial Test With Hardening Soil Model PDFOmar BarrosBelum ada peringkat

- Figure 1 Triaxial Test: Model Geometries and Loading ConditionsDokumen3 halamanFigure 1 Triaxial Test: Model Geometries and Loading ConditionsGuillermo MondeBelum ada peringkat

- 10 3208jgssp SEA-13-15ARCDokumen7 halaman10 3208jgssp SEA-13-15ARClimara65Belum ada peringkat

- GTL SoftSoils Bandung FindingSuitableModelDokumen7 halamanGTL SoftSoils Bandung FindingSuitableModellimara65Belum ada peringkat

- Seed Synthetic and Artificial MotionDokumen56 halamanSeed Synthetic and Artificial Motionlimara65Belum ada peringkat

- ASCE7 16ground motionScalingProcedureForNonlinearAnalysisOfBuildingsInComparisonWithASCE7 10AndASCE7 0Dokumen34 halamanASCE7 16ground motionScalingProcedureForNonlinearAnalysisOfBuildingsInComparisonWithASCE7 10AndASCE7 0limara65Belum ada peringkat

- 20ICSMGE Vol 1 KeynotesDokumen643 halaman20ICSMGE Vol 1 Keynoteslimara65Belum ada peringkat

- Pile Load Test Frequently Asked QuestionsDokumen15 halamanPile Load Test Frequently Asked Questionslimara65Belum ada peringkat

- Gouw FindingSutableModelDokumen15 halamanGouw FindingSutableModellimara65Belum ada peringkat

- GTL Geosynthetics Application 131031Dokumen14 halamanGTL Geosynthetics Application 131031limara65Belum ada peringkat

- Geogrids Isochronous CurvesDokumen12 halamanGeogrids Isochronous Curveslimara65Belum ada peringkat

- EngPhin Julius MomentDataDokumen1 halamanEngPhin Julius MomentDatalimara65Belum ada peringkat

- GTL Geosynthetics Application 131031Dokumen14 halamanGTL Geosynthetics Application 131031limara65Belum ada peringkat

- Keruntuhan Galian DalamDokumen16 halamanKeruntuhan Galian Dalamlimara65Belum ada peringkat

- SettlementDokumen22 halamanSettlementlimara65Belum ada peringkat

- 050322-MRT Tunnelling - Predicted Vs Rel MovementDokumen11 halaman050322-MRT Tunnelling - Predicted Vs Rel Movementlimara65Belum ada peringkat

- Ground Improvment On Reclaimed Land - Indonesian ExperiencesDokumen22 halamanGround Improvment On Reclaimed Land - Indonesian Experienceslimara65Belum ada peringkat

- Gravity Wall Verification Manual enDokumen26 halamanGravity Wall Verification Manual enradem3Belum ada peringkat

- Konstanta Pegas Dan Interaksi Struktur TanahDokumen10 halamanKonstanta Pegas Dan Interaksi Struktur Tanahlimara65Belum ada peringkat

- Konstanta Pegas Dan Interaksi Struktur TanahDokumen10 halamanKonstanta Pegas Dan Interaksi Struktur Tanahlimara65Belum ada peringkat

- Terowongan Galian Dalam Tanah Lunak: Aplikasi Untuk Dan DiDokumen24 halamanTerowongan Galian Dalam Tanah Lunak: Aplikasi Untuk Dan Dilimara65Belum ada peringkat

- CH-12-063-001-Pile DynamicsDokumen10 halamanCH-12-063-001-Pile Dynamicslimara65Belum ada peringkat

- Vacuum Preloading Soil Improvement For A Vietnam Power Plant Project-2012-Dec-HattiDokumen0 halamanVacuum Preloading Soil Improvement For A Vietnam Power Plant Project-2012-Dec-Hattilimara65Belum ada peringkat

- 2013 PIT ScheduleDokumen3 halaman2013 PIT Schedulelimara65Belum ada peringkat

- 100312-Soil Stiffness For Jakarta Silty and Clayey SoilsDokumen5 halaman100312-Soil Stiffness For Jakarta Silty and Clayey Soilslimara65Belum ada peringkat

- 010307-Spring Constants & SSI - 2001Dokumen11 halaman010307-Spring Constants & SSI - 2001limara65Belum ada peringkat

- CAD/CAM Ceramic Restorative Materials For Natural Teeth: F.A. Spitznagel, J. Boldt, and P.C. GierthmuehlenDokumen10 halamanCAD/CAM Ceramic Restorative Materials For Natural Teeth: F.A. Spitznagel, J. Boldt, and P.C. GierthmuehlenlimemBelum ada peringkat

- Act 2 Fatigue Some Famous Accidents and Some Less FamousDokumen10 halamanAct 2 Fatigue Some Famous Accidents and Some Less Famousbbv89100% (1)

- SN017 (NCCI - Shear Resistance of A Fin Plate Connection)Dokumen13 halamanSN017 (NCCI - Shear Resistance of A Fin Plate Connection)Hamati Rami100% (2)

- Akira Furusaki - Topological InsulatorsDokumen33 halamanAkira Furusaki - Topological InsulatorsPo48HSD100% (1)

- GO-PANI Conductive MembraneDokumen13 halamanGO-PANI Conductive MembraneMadalinaBelum ada peringkat

- Survey of Temperature Sensors Used in Various Thermal SystemsDokumen3 halamanSurvey of Temperature Sensors Used in Various Thermal SystemsRavi PatilBelum ada peringkat

- Practice Problem FinalDokumen12 halamanPractice Problem FinalAfaq AhmadBelum ada peringkat

- Molecular DynamicsDokumen8 halamanMolecular DynamicsSourav SahaBelum ada peringkat

- Ball Milling-1Dokumen4 halamanBall Milling-1Muhammad Akhtar-U-ZamanBelum ada peringkat

- Progress and Perspective of Refractory Technology: Technical ReviewDokumen5 halamanProgress and Perspective of Refractory Technology: Technical ReviewFredBelum ada peringkat

- Limit State Design of Shallow Foundations: Pridniprovska State Academy of Civil Engineering and Architecture, UkraineDokumen6 halamanLimit State Design of Shallow Foundations: Pridniprovska State Academy of Civil Engineering and Architecture, UkraineJessica TangBelum ada peringkat

- Pipe Stress AnalysisDokumen7 halamanPipe Stress AnalysisTushar NaikBelum ada peringkat

- Input Parameters - Hardening Soil / Hssmall Model: Determination of Hs Parameters For ClayDokumen14 halamanInput Parameters - Hardening Soil / Hssmall Model: Determination of Hs Parameters For ClayNadeem AbbasiBelum ada peringkat

- Konsep StressDokumen26 halamanKonsep StressaliBelum ada peringkat

- Homework 4 Heat TransferDokumen3 halamanHomework 4 Heat TransferDoug MasekBelum ada peringkat

- Polymer Processing With Super Critical Fluids by SG KazarianDokumen24 halamanPolymer Processing With Super Critical Fluids by SG KazarianLia NashBelum ada peringkat

- Fluid Mechanics FormulaDokumen3 halamanFluid Mechanics FormulaKamran ZafarBelum ada peringkat

- Tarea 2 GeodinamicaDokumen11 halamanTarea 2 GeodinamicaCarlos David Valencia0% (1)

- X-Ray Diffraction BasicsDokumen18 halamanX-Ray Diffraction BasicsAlexandre DVulcanBelum ada peringkat

- Percdc Cns Geas 1Dokumen9 halamanPercdc Cns Geas 1Charles Adrian CBelum ada peringkat

- Estimation of Load and Torque Hot Rolling Process: by Green and JDokumen7 halamanEstimation of Load and Torque Hot Rolling Process: by Green and JAnonymous yjzIf6Belum ada peringkat

- The Structure of Atom 2Dokumen11 halamanThe Structure of Atom 2Dania NatashaBelum ada peringkat

- Chapter 10 Buckling and Stress Stiffening 1Dokumen9 halamanChapter 10 Buckling and Stress Stiffening 1Quân TrịnhBelum ada peringkat

- Chemical Engineering LawsDokumen4 halamanChemical Engineering LawsAbhijit MoreBelum ada peringkat

- Dynatest Pastii and Sopt GaugesDokumen1 halamanDynatest Pastii and Sopt GaugesbloomdidoBelum ada peringkat

- Nanoworld of Science and TechnologyDokumen8 halamanNanoworld of Science and TechnologyAurelia Marie Aguinaldo TactacBelum ada peringkat

- Viscoelasticity RGDokumen28 halamanViscoelasticity RGManu HegdeBelum ada peringkat

- Eas 326-06 M eDokumen7 halamanEas 326-06 M erodolfoBelum ada peringkat

- Lecture16 Drude-Sommerfield ModelDokumen4 halamanLecture16 Drude-Sommerfield ModelSteel BeingBelum ada peringkat

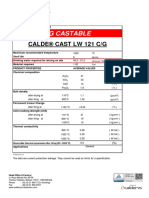

- Tds Calde Cast LW 121 CGDokumen1 halamanTds Calde Cast LW 121 CGAfronie Cepoz D'nextBelum ada peringkat