Laser Imaging Devices

Diunggah oleh

simpletun0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

49 tayangan50 halamanLaser printing

Judul Asli

Laser Imaging Devices - Copy

Hak Cipta

© © All Rights Reserved

Format Tersedia

PPSX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniLaser printing

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPSX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

49 tayangan50 halamanLaser Imaging Devices

Diunggah oleh

simpletunLaser printing

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PPSX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 50

Imaging Technologies

Lscher future-proof CtP for plate Production

Colin Price

Lscher

Plan:

u Lscher Info

u Imaging Technologies in Graphic Arts

u Lscher Flex Solution

u Lscher Multi-DX

u Summary

Originally a Family business, founded in 1946

Head office in Gretzenbach, Switzerland

New production plant opened

Software Development team

Sell world-wide either Direct or through partners

Purchased Jan 2007 by PAInvest

Focus on precision engineering & reliability

Lscher: Company Profile

Canada

USA

Mexico

Costa Rica

Venezuela

Ecuador

Uruguay

Columbia

Chile

Peru

Brasil

Argentina

Finland

Sweden

Norway

Denmark

Lithuania

Great Britain

Ireland

South Africa

Czech

Republic

Croatia

Hungary

Slovenia

Bulgaria

Romania

Turkey

Cyprus

Egypt

Jordan

Pakistan

Azerbaijan

Kazakhstan

Syria

Japan

China

Hong Kong

South Korea

Vietnam

India

Bangladesh

Taiwan

Thailand

Philippines

Malaysia

Singapore

Australia

Netherlands

Belgium

Luxembourg

Germany

France

Swiss

Italy

Spain

Portugal

Russia

Belarus

Ukraine

UAE

Kuwait

Iran

in more than 60 countries

Global Presence

Lscher: Company Profile

Successful products over more than 60 years

Offset Printing

XPose! thermal

XPose! UV conventional

Over 2000 worldwide

Flexo and Hybrid

Flex *new

T-Flex *new

UV-Flex *new

Hybrid machine for different

plate options

CT....X

Multi-DX

X= many applications

Imaging Technologies in

Graphic Arts

Materials & Lasers:

u Most graphic Arts materials were developed for UV light

o Polymer flexo plates

o Polymer letterpress plates (dry offset)

o Liquid polymers

o Screens

o Offset plates

o Etching plates with a photo-resist

u No lasers existed that could expose these materials, so CtP had

to find another way. Thermal lasers were available since late 80s

and many materials were developed / adapted, often with a

compromise in performance. Flexo used the ablation mask.

u Around 1995, UV Lasers started to become available, so CtP

with conventional materials started to become theoretically

viable.

In non-flexo print:

u UV lasers are now being used to expose many 2D conventional

materials:

u Offset plates, Pad plates, Hot foil dies,

Framed screens, rotary screens

u Any type of plate with a photo-resist

u CtP increases quality (using digital polymer plates)

u The image is still created with an intermediary mask:

u Black mask ablation using CtP for digital polymer plates

u Film for conventional flexo plates and liquid polymers

u High resolution film & further steps (lamination) can do similar

u UV Image exposure is still analog (even digital plates)

u UV frame exposure is used to control the required 3D dots

In Flexo and Letterpress (polymers):

Lscher has been working on directly

exposing conventional polymers, using

UV lasers, with 3D control over dot

structure

polymerisation

polymerization

u First polymerisation product commercially

released Accent coating plate, from MacDermid

u Late beta stages for conventional dry offset plates.

Anticipated commercial release Q2 2013. Toray and

Flint to start with, Toyobo approval will follow.

u Not yet for Flexo but in R&D.

Status..

Polymerisation

12

Direct UV imaging (Polymerisation)

Plate making steps :

1. The polymer is directly cross linked with modulated UV Laser light

2. Wash out and drying

3. Light finishing

Challenges (Polymerisation)

3D direct imaging of Letterpress relief plates is challenging:

Small positive elements need shoulders in order to be in a position to be

printed

Negative elements must remain open with deep reverses

Lscher has developed X!Direct software that solves this equation:

Small positive elements get optimized shoulders

Mid tones and shadows have deep relief

Reverses are open

A whole set of independent imaging parameters can be called on for

achieving this result

The single points

are sticking

together

The imaging energy is applied in a defined number of

scans (or passes), the imaging information can therefore

be specific for each scan.

Requirement for high rotation speed of plate (or optic).

More precisely:

A black pixel means 100% of the energy is applied locally. This is

corresponding to the original Tiff file.

Pixels in grey are imaged with an adjustable fraction of the overall

energy.

The gradient of energy around

positive elements is used to shape

the shoulders.

Imaging (Polymerisation)

15

Imaging overview (Polymerisation)

100 % of the total energy

40 % of the total energy

15 % of the total energy

10 % of the total energy

No energy applied

Spatial distribution of energy controlled by software.

Example of imaging strategy:

Direct UV imaging workflow (4/4)

Imaging of positive line work:

Imaging of highlight dots:

Imaging of reverses:

17

Benefits of polymerisation..

Truly digital imaging

No loss of details due to mask. Pixel accurate

reproduction.

Fewer production steps (simplicity and reliability)

No mask and no mask processing issues (developing &

chemicals contamination)

Possibility to image conventional plates (lower cost?)

Broader range of plates and plate technologies

Photochemical processes are the most efficient in nature,

and nature shows us the way (green features).

Potential to boost imaging quality with a whole new set

of parameters that can be called on for optimization.

18

Conventional Letterpress plates (UV light sensitive) can be imaged

directly and digitally with UV laser diodes

A whole range of new software parameters are at our disposal for

the optimization of imaging

UV lasers are continually developing, due to high investment in R&D

by laser manufacturers, because of the data storage applications

(BluRay etc smaller wavelength = higher density storage)

Direct imaging has the potential to be better than mask ablation

with a more cost effective, more energy efficient process

This is a possible future path for flexo

Outlook..

Product Presentation -Lscher Flex

Unique Architecture

Imaging Technologies - External Drum

Laser diode Technology

Multi-Beam/laser for speed

power needed at plate surface

Fighting physics

Stop / Start operation

Plate load/unload management

Pros

Cons

Stationary Target

No balancing problem

Highly Accurate (target not moving)

Historically used for light sensitive substrates

(imagesetters)

Not suitable for thermal imaging

Not enough power at the plate surface

for most plate types

Pros

Cons

Imaging Technologies Internal Drum

Lscher incorporates Both internal and external drum technology!

External drum Imaging Head Containing laser diodes, Perfectly balanced

Imaging Optic close to plate

Internal drum with

stationary

Printing plate(s)

Heart of our technology.

Perfectly balanced Imaging drum, driven

by in-line torque motor

Imaging Optic close to plate

Up to 8

Laser modules,

containing

Laser diodes

Unique Architecture

Internal drum advantages

Easy loading

Plate size independence

Accuracy (image and registration)

No balancing Issues

External drum advantages

Power at the plate

Scalable

Range Of

Machines

Flexo plates to 35

x 47

Flexo plates to 52

x 80

Flexo plate sizes up

to up to 54 x 114

(2900mm x

1370mm)

Big Plate Handling

http://www.youtube.com/watch?v=J35T8vgY6xo

Aluminum / Steel / Polyester / Screens

Multiple jobs on 1 large plate

Plate-size independent workflow

Multiple plate loading

Pin Registration = ABSOLUTE FIT

Small plates / Off-cuts = less waste

Flexibility

http://www.youtube.com/watch?v=Ng5a7bpo3VY

Equipment Installation and Support

Service

USA Based engineers

Supported by Lscher dedicated Technical Support department

Customer Technician Training in Training School

On-site Spares Kits available

Pre-Scheduled PM visits based on equipment usage

Legendary up-time from Lscher

Solid Build

Modularity of components

Superb remote diagnostics

XPose monitors and calibrates itself

Unique Features

Laser modules

Unique Hybrid Optic

Screeny system

UV lasers

Flexo & coating plates

Carbon layer

Thermal lasers

Conventional offset plates

UV lasers

Thermal ablation offset plates

IR lasers

Thermal offset plates 830Nm

Letterpress plates IR lasers

Accent Varnish plate UV

Diazo film

Process control

u By Design

u Continuous Calibration Technology (CCT) for perfect consistency

u because Lasers by their nature will vary

u All machine parameters can be monitored and consistency maintained

u Needed to Satisfy Banknote Printers Lscher is market leader

Modular Design

- adaptable to change

u Lasers can be added = more speed

u Laser Types can be changed for new materials

u All plate types can be loaded

u Modular Electronics = swift repairs

u EPROM based software remotely upgradable

u Full Remote Diagnostics

Future Proof

Accuracy and Movement

u Linear Motor

u For moving the optics

u accurate to 0.0004mm

u Swift Movement

u Maintenance free

u Combines with X!Skip s/w for production gains

u Torque Motor

u Inline for vibration-free rotation of optics

Resolution

Resolution

Depending on the Application:

2400 is a standard in Offset, Screen & Flexo

New Industry Trends driving quality in Flexo

High Definition (HD) in Flexo @ 4000dpi

Higher resolution gives rounder highlight dots

Depending on the Market:

Security market needs higher resolutions

For Wet and Waterless Offset ( 6,000, 8,000, 9,000, 10,000)

For Letterpress / dry Offset (up to 10,000 dpi)

Lasers..

Lasers..

Flexo Laser Possibilities

u All brands of digital flexo plates

u Either solvent or water washout

u All brands of digital dry offset plates

u 4800dpi, 5080dpi, 6000, 8000, 10,000dpi

u Coating or Varnishing plates

u Steel backed plates: no magnetic drum needed!

u Ablative film (but expensive option)

u Continuous Calibration

technology for perfect

consistency

u Diazo Film

u High Quality, Tough, fast imaging

u Half the price of imagesetter film

u Can be imaged with supercell patterning for

better ink transfer

u Conventional Offset Plates

u Rotary Screens (Gallus Screeny, Stork, K&B)

u Pin registered precision

u NEW LUSCHER IMAGING TECHNOLOGY

Blue (405 Nm UV) Laser Possibilities

Also now available 375Nm UV lasers.

imaging conventional dry offset plates

- Used with Lscher X!Direct 3D imaging software

further development in flexo plate imaging

405nm

375nm

405nm

375nm

Summary

u One Machine: multiple plate types

u Swiss Quality engineering

u Continuous Calibration Technology CCT (process control)

u Thermal lasers for

u digital flexo & letterpress today

u But UV lasers are revolutionising

u Diazo film (available now)

u Offset ctp (available now)

u Rotary Screens (available now)

u Coating plates (available now)

u Dry Offset/Letterpress (available soon)

u Flexo potential digital flexo of the future

u Customers can change lasers to meet market needs

And..

http://www.youtube.com/watch?v=FTAWO8SUwjo

Multi-DX Flatbed architecture

u SAME FUNCTIONALITY with a FlatBed Architecture

u Offers new direct imaging opportunities (rigid materials)

50

Together we are strong

Thank you very much for your attention.

Herzlichen Dank fr Ihre Aufmerksamkeit.

Merci de votre attention.

La ringraziamo per la vostra attenzione.

Muchas gracias por su atencin.

Muito obrigado por sua ateno.

Anda mungkin juga menyukai

- Kksgklsdgjlsjs Lakkcsakpeakd VKJZ LSK Agk FDSK:LSKLV Ldsa:Fl' F'SL'GL'P AgdlfssgdDokumen1 halamanKksgklsdgjlsjs Lakkcsakpeakd VKJZ LSK Agk FDSK:LSKLV Ldsa:Fl' F'SL'GL'P AgdlfssgdsimpletunBelum ada peringkat

- For RefDokumen1 halamanFor RefsimpletunBelum ada peringkat

- Test 199cDokumen1 halamanTest 199csimpletunBelum ada peringkat

- United Nations: or Print in Ink. Read CarefullyDokumen4 halamanUnited Nations: or Print in Ink. Read CarefullysimpletunBelum ada peringkat

- Syllabi Compilation - University of Pittsburgh - Managing Threats Emerg and DisastersDokumen6 halamanSyllabi Compilation - University of Pittsburgh - Managing Threats Emerg and DisasterssimpletunBelum ada peringkat

- Testing FileDokumen1 halamanTesting FilesimpletunBelum ada peringkat

- Laser PDokumen16 halamanLaser PsimpletunBelum ada peringkat

- คู่มือการวิเคราะห์ทางเทคนิคDokumen240 halamanคู่มือการวิเคราะห์ทางเทคนิค878Belum ada peringkat

- Guide To Color-Matching: Using Agfa Calibrator4.x With The Kodakapproval Digital Proofing SystemDokumen18 halamanGuide To Color-Matching: Using Agfa Calibrator4.x With The Kodakapproval Digital Proofing SystemsimpletunBelum ada peringkat

- Guide To Color-Matching: Using Agfa Calibrator4.x With The Kodakapproval Digital Proofing SystemDokumen18 halamanGuide To Color-Matching: Using Agfa Calibrator4.x With The Kodakapproval Digital Proofing SystemsimpletunBelum ada peringkat

- Syllabi Compilation - University of Pittsburgh - Managing Threats Emerg and DisastersDokumen6 halamanSyllabi Compilation - University of Pittsburgh - Managing Threats Emerg and DisasterssimpletunBelum ada peringkat

- Building Strong BrandDokumen32 halamanBuilding Strong BrandsimpletunBelum ada peringkat

- Revised Technology of Printing InksDokumen13 halamanRevised Technology of Printing Inkssherifamer85Belum ada peringkat

- GravureDokumen6 halamanGravureamiit_agBelum ada peringkat

- Final Report of 3D OPC Seismic Data Processing by WGDokumen93 halamanFinal Report of 3D OPC Seismic Data Processing by WGsimpletunBelum ada peringkat

- 06 2 PrestonDokumen10 halaman06 2 PrestonsimpletunBelum ada peringkat

- Earthquake Planning For BusinessDokumen29 halamanEarthquake Planning For BusinesssimpletunBelum ada peringkat

- Earthquake Planning For BusinessDokumen29 halamanEarthquake Planning For BusinesssimpletunBelum ada peringkat

- GravureDokumen6 halamanGravureamiit_agBelum ada peringkat

- อะไรDokumen1 halamanอะไรsimpletunBelum ada peringkat

- กล่องโฟมDokumen1 halamanกล่องโฟมsimpletunBelum ada peringkat

- Printing Ink Testing AstmDokumen11 halamanPrinting Ink Testing Astmsimpletun50% (2)

- Printing Inks - Issues, Guidance and RegulationsDokumen93 halamanPrinting Inks - Issues, Guidance and RegulationsDinesh RajputBelum ada peringkat

- Guyana TFO PKG W'SHP Session 6 - PrintingDokumen30 halamanGuyana TFO PKG W'SHP Session 6 - PrintingsimpletunBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Teaching Quantum Mechanics On An Introductory Level PDFDokumen10 halamanTeaching Quantum Mechanics On An Introductory Level PDF24263537Belum ada peringkat

- Turbomachineries School of Mechanical and Industrial Engineering Debre Markos UniversityDokumen58 halamanTurbomachineries School of Mechanical and Industrial Engineering Debre Markos UniversitybirlieBelum ada peringkat

- Li 2017 IOP Conf. Ser. Mater. Sci. Eng. 232 012084Dokumen10 halamanLi 2017 IOP Conf. Ser. Mater. Sci. Eng. 232 012084Yu An ShihBelum ada peringkat

- Cooling PDFDokumen656 halamanCooling PDFTrầnNgọcCườngBelum ada peringkat

- EL MOSSALLAMY Modelling The Behaviour of Piled Raft PDFDokumen4 halamanEL MOSSALLAMY Modelling The Behaviour of Piled Raft PDFera210Belum ada peringkat

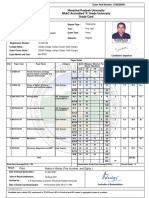

- Serial Number:1920110212668 Exam Roll Number Grade CardDokumen2 halamanSerial Number:1920110212668 Exam Roll Number Grade Cardsimran vaidBelum ada peringkat

- (ISRM Book Series) Shunsuke Sakurai - Back Analysis in Rock Engineering-Routledge - CRC Press (2016) PDFDokumen241 halaman(ISRM Book Series) Shunsuke Sakurai - Back Analysis in Rock Engineering-Routledge - CRC Press (2016) PDFJorge Cortez CampañaBelum ada peringkat

- BKI Vol2 - Section38Dokumen5 halamanBKI Vol2 - Section38Erwin Paulian SihombingBelum ada peringkat

- Lukac Perkowski Book Introduction and Quantum MechanicsDokumen104 halamanLukac Perkowski Book Introduction and Quantum MechanicsSitalk TeresBelum ada peringkat

- Panel Dual Polarization Half-Power Beam Width Fixed Electrical DowntiltDokumen2 halamanPanel Dual Polarization Half-Power Beam Width Fixed Electrical DowntiltEmmersonLisboaBelum ada peringkat

- Siniloan Integrated National High SchoolDokumen4 halamanSiniloan Integrated National High SchoolKimberlyn VelascoBelum ada peringkat

- 1 BelzonaDokumen41 halaman1 BelzonashakeelahmadjsrBelum ada peringkat

- Laser Flash Photolysis Purpose A Reactive Free Radical Ketyl IsDokumen16 halamanLaser Flash Photolysis Purpose A Reactive Free Radical Ketyl IspathinfoBelum ada peringkat

- Volumes by Cylindrical ShellsDokumen7 halamanVolumes by Cylindrical Shellseomer1968Belum ada peringkat

- M.A.M College of Engineering: Department of Electrical and Electronics EnggDokumen16 halamanM.A.M College of Engineering: Department of Electrical and Electronics EnggKrishna ChaitanyaBelum ada peringkat

- Magnetism and Electromagnetism - Electrical Multiple Choice Questions and AnswersDokumen10 halamanMagnetism and Electromagnetism - Electrical Multiple Choice Questions and AnswersNagesh GillBelum ada peringkat

- Mendocino Motor Control ApproachesDokumen6 halamanMendocino Motor Control ApproachesAngélica María CastrillónBelum ada peringkat

- Optimising Design and Power Management in Energy Efficient Marine Vessel Power SystemsDokumen11 halamanOptimising Design and Power Management in Energy Efficient Marine Vessel Power SystemshamadiBelum ada peringkat

- Torque NotesDokumen3 halamanTorque NotesKudzai MashayaBelum ada peringkat

- FFT window and transform lengthsDokumen5 halamanFFT window and transform lengthsNguyen Quoc DoanBelum ada peringkat

- 2 Stage GearboxDokumen47 halaman2 Stage GearboxSanad Shajahan0% (1)

- Egyptian FractionsDokumen80 halamanEgyptian Fractionsmyasweet22Belum ada peringkat

- Computer Simulation For Large Scale Bioprocess Design: S.A. Rouf, P.L. Douglas, M. Moo-Young, J.M. ScharerDokumen6 halamanComputer Simulation For Large Scale Bioprocess Design: S.A. Rouf, P.L. Douglas, M. Moo-Young, J.M. Scharerdaimon_pBelum ada peringkat

- Induction MotorDokumen27 halamanInduction MotorNandhini SaranathanBelum ada peringkat

- 100 Years Werner HeisenbergDokumen308 halaman100 Years Werner Heisenbergmvmbapple100% (3)

- Bagh Bon BondukDokumen105 halamanBagh Bon BondukAdnan RahmanBelum ada peringkat

- Physical Computing NotesDokumen2 halamanPhysical Computing NotesAnonymous W9MgRBVtYCBelum ada peringkat

- Spe163887 PDFDokumen11 halamanSpe163887 PDFCarlos Ulises LeonidasBelum ada peringkat

- KIN 335 - Biomechanics: Part 1. Reaction Board MethodDokumen9 halamanKIN 335 - Biomechanics: Part 1. Reaction Board MethodandyimoodeyBelum ada peringkat

- Last Minute Review MCQDokumen34 halamanLast Minute Review MCQIB Experts for 7on7 Pvt. Ltd.Belum ada peringkat