Material Testing Cement

Diunggah oleh

Chester TomaleJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Material Testing Cement

Diunggah oleh

Chester TomaleHak Cipta:

Format Tersedia

1. Define cement.

A cement is a binder, a substance that sets and hardens independently, and can bind

other materials together. The word "cement" traces to theRomans, who used the

term opus caementicium to describe masonry resembling modern concrete that was made

from crushed rock with burnt lime as binder. The volcanic ash and

pulverized brick additives that were added to the burnt lime to obtain a hydraulic binder

were later referred to as cementum,cimentum, cment, and cement.

2. Who developed the use of cement and when?

An early version of cement made with lime, sand, and gravel was used in Mesopotamia in

the third millennium B.C. and later in Egypt. It is uncertain where it was first discovered

that a combination of hydrated non-hydraulic lime and a pozzolan produces a hydraulic

mixture, but concrete made from such mixtures was first used by the Ancient

Macedonians and three centuries later on a large scale by Roman engineers.

3. What are the materials used in the manufacturing in cement?

Examples of raw materials for Portland cement manufacture

Calcium Silicon Aluminum Iron

Limestone Clay Clay Clay

Marl Marl Shale Iron ore

Calcite Sand Fly ash Mill scale

Aragonite Shale Aluminum ore refuse Shale

Shale Fly ash Blast furnace dust

Sea Shells Rice hull ash

Cement kiln dust Slag

4. What are the different types of cement and their use?

A. Ordinary cement

This type of cement is used a lot today, and is still known as OPC (ordinary Portland

cement) ... It is ground up into a powder to form ordinary OPC

B. Rapid heat cement

They generate more heat in the early stages and can be useful in cold weather

concreting. ... as either rapid-setting or extra rapid hardening

C. Low heat cement

Low Heat Cement complies with AS 3972, Special Purpose Type LH/SR. It is

manufactured from the ingredients of specially selected cement clinker and ground

granulated blast furnace slag, that result in significantly lower heat generation during

the process of hydration than the comparable Portland Cement.

D. Portland blast furnace cement

The granulated slag made by the rapid chilling of suitable molten slags from blast

furnaces forms the basis of another group of constructional cements. A mixture of

portland cement and granulated slag, containing up to 65 percent slag, is known in the

English-speaking countries as portland blast-furnace (slag) cement

E. High alumina cement

of High Alumina Cement, Alumina Cement, Refractory Cement, Refractory Materails, ...

Density Corundum Bricks, high alumine cement ca50-G5, G7, G9, fused, ca70, ca80

F. Expanding cement

Expanding and nonshrinking cements expand slightly on hydration, thus offsetting the

small contraction that occurs when fresh concrete dries for the first time. Expanding

cements were first produced

G. Quick setting cement

Rapid cure allows for quick access to repaired areas. Garonite anchoring cement sets

and e-x-p-a-n-d-s rapidly, curing twice as strong as concrete in one hour. Use indoors

or out

H. Hydrophorbic cement

Cement is a hydraulic bonding agent used in building construction and civil

engineering. It is a fine powder obtained by grinding the clinker of a clay and

limestone mixture calcined at high temperatures. When water is added to cement it

becomes a slurry that gradually hardens to a stone-like consistency. It can be mixed

with sand and gravel (coarse aggregates) to form mortar and concrete.

I. White cement

White portland cement is readily available throughout North America. It has essentially

the same properties as gray cement, except for color, which is a very important quality

control issue in the industry.

J. Air & trading cement,

i presume this was mis understood and it shood be airentranment cement this type of

cement holds bubbles of air in it and has a porous finish so water can seep through it.

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Jo-Ellie Barrios 7TH Bill PDFDokumen1 halamanJo-Ellie Barrios 7TH Bill PDFChester TomaleBelum ada peringkat

- 6-Bridges Bored Pile Cage DetailDokumen6 halaman6-Bridges Bored Pile Cage DetailChester TomaleBelum ada peringkat

- Roadworks Safety Assestment TeamDokumen1 halamanRoadworks Safety Assestment TeamChester TomaleBelum ada peringkat

- LyricsDokumen5 halamanLyricsChester TomaleBelum ada peringkat

- 3D Truss AnalysisDokumen6 halaman3D Truss AnalysisChester TomaleBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- BHP Billiton Petroleum Contract Letter For ABDUL SATTARDokumen5 halamanBHP Billiton Petroleum Contract Letter For ABDUL SATTARAbdul SattarBelum ada peringkat

- Postoperative Care in Thoracic Surgery A Comprehensive GuideDokumen397 halamanPostoperative Care in Thoracic Surgery A Comprehensive GuideΑΘΑΝΑΣΙΟΣ ΚΟΥΤΟΥΚΤΣΗΣ100% (1)

- Safety Tips in Playing ArnisDokumen2 halamanSafety Tips in Playing ArnisDensyo De MensyoBelum ada peringkat

- Distress Manual PDFDokumen51 halamanDistress Manual PDFEIRINI ZIGKIRIADOUBelum ada peringkat

- Varioklav Steam Sterilizer 75 S - 135 S Technical SpecificationsDokumen10 halamanVarioklav Steam Sterilizer 75 S - 135 S Technical Specificationssagor sagorBelum ada peringkat

- Series RL: Standards General DataDokumen4 halamanSeries RL: Standards General DataBalamurugan SankaravelBelum ada peringkat

- Reverse Osmosis Desalination: Our Global Expertise To Address Water ScarcityDokumen16 halamanReverse Osmosis Desalination: Our Global Expertise To Address Water Scarcitynice guyBelum ada peringkat

- Dryer Regenerative Blower Purge DBP 02250195 405 R00 PDFDokumen84 halamanDryer Regenerative Blower Purge DBP 02250195 405 R00 PDFjennyBelum ada peringkat

- ANATOMY 1 NILEM and Cat FISHDokumen19 halamanANATOMY 1 NILEM and Cat FISHAnisatul Khabibah ZaenBelum ada peringkat

- 4EVC800802-LFEN DCwallbox 5 19Dokumen2 halaman4EVC800802-LFEN DCwallbox 5 19michael esoBelum ada peringkat

- Facts About Concussion and Brain Injury: Where To Get HelpDokumen20 halamanFacts About Concussion and Brain Injury: Where To Get HelpJess GracaBelum ada peringkat

- UgpeDokumen3 halamanUgpeOlety Subrahmanya SastryBelum ada peringkat

- A Cook's Journey To Japan - Fish Tales and Rice Paddies 100 Homestyle Recipes From Japanese KitchensDokumen306 halamanA Cook's Journey To Japan - Fish Tales and Rice Paddies 100 Homestyle Recipes From Japanese KitchensEthan F.100% (1)

- Unit Weight of Soil in Quezon CityDokumen2 halamanUnit Weight of Soil in Quezon CityClarence Noel CorpuzBelum ada peringkat

- Missoula County Fairgrounds Phase 2Dokumen10 halamanMissoula County Fairgrounds Phase 2Olivia IversonBelum ada peringkat

- MCQ Homework: PeriodonticsDokumen4 halamanMCQ Homework: Periodonticsفراس الموسويBelum ada peringkat

- Course Guide Pe1 PDFDokumen4 halamanCourse Guide Pe1 PDFrahskkBelum ada peringkat

- B - Cracked Tooth SyndromeDokumen8 halamanB - Cracked Tooth SyndromeDavid TaylorBelum ada peringkat

- Desigo PX SeriesDokumen10 halamanDesigo PX SeriestemamBelum ada peringkat

- Boeco BM-800 - User ManualDokumen21 halamanBoeco BM-800 - User ManualJuan Carlos CrespoBelum ada peringkat

- (Engine International Air Pollution Prevention) : EIAPP CertificateDokumen2 halaman(Engine International Air Pollution Prevention) : EIAPP CertificateTan DatBelum ada peringkat

- Method Statement For Installation of Chilled Water Pump & Condenser Water PumpDokumen14 halamanMethod Statement For Installation of Chilled Water Pump & Condenser Water Pump721917114 47Belum ada peringkat

- BCA2006 BCA GuideDokumen507 halamanBCA2006 BCA GuidePatrick LiaoBelum ada peringkat

- Lesson 49Dokumen2 halamanLesson 49Андрій ХомишакBelum ada peringkat

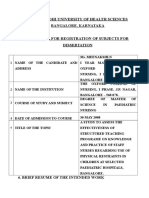

- Rajivgandhi University of Health Sciences Bangalore, KarnatakaDokumen19 halamanRajivgandhi University of Health Sciences Bangalore, KarnatakaHUSSAINA BANOBelum ada peringkat

- Chapter 7 Unemployment, Inflation, and Long-Run GrowthDokumen21 halamanChapter 7 Unemployment, Inflation, and Long-Run GrowthNataly FarahBelum ada peringkat

- Blood DonationDokumen19 halamanBlood DonationsuruthiBelum ada peringkat

- Menu Siklus RSDokumen3 halamanMenu Siklus RSChika VionitaBelum ada peringkat

- Atlas of Feline Anatomy For VeterinariansDokumen275 halamanAtlas of Feline Anatomy For VeterinariansДибензол Ксазепин100% (4)

- Experiment Number 16 Formal ReportDokumen4 halamanExperiment Number 16 Formal Reportapi-524547303Belum ada peringkat