Aggregate

Diunggah oleh

myusuf_engineerHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Aggregate

Diunggah oleh

myusuf_engineerHak Cipta:

Format Tersedia

1. Select approximately 1200 g of saturated sand.

The sample has been soaked for at least 48 hours prior to lab.

Initial mass = g

2. Weigh two large tare cans to be used later.

Can 1: OD = g (for Oven Dry mass)

Can 2: BSG = g (for Bulk Specific Gravity)

3. Fill the volumetric flask to near the zero mark with water and record the initial reading.

Initial reading = cc

4. Spread the sample in a pan and dry with a small fan and heat lamp. Should take about 45 minutes

5. Stir the entire sample frequently for uniform drying.

6. Repeat steps 4 and 5 until the sand approaches a saturated surface dry condition.

7. Place the sand loosely in the conical mold and tamp lightly 25 times.

8. Lift the mold vertically. If free water is present, the cone of sand will retain its shape.

9. Continue steps 4 through 8 until the cone of sand slumps upon removal of the mold.

* The saturated surface dry condition has then been found.

* If the sand has become drier than saturated surface dry, add a small amount of water,

mix thoroughly and return to step 4.

10. Immediately take two samples, put in tare cans and weigh.

g (about 150 g + can weight to be put in oven overnight)

g (about 50 g + can weight to be used in BSG test)

11. Pour the sample from Can 2: BSG into the volumetric flask.

12. Gently tap the sides of the flask to remove any air bubbles.

13. Read the displaced volume (dV) of water on the calibrated neck.

dV = cc

14. Place Can 1: AC in the oven and oven dry the sample for at least 24 hours.

15. TOMORROW, remove Can 1: AC from the oven, permit it to cool,

and weigh it to find the mass of solids Movendry.

g (after drying)

g

1. Compute the absorption capacity (ACsand).

%

2. Compute the bulk specific gravity (BSGsandSSD).

density of water = 1.0 g/ml

Aggregate Lab

Bulk Specific Gravity and Absorption Capacity of Fine Aggregate

Movendry =

* Initial Preparations *

* Dry the sample to Saturated Surface Dry Condition *

Can 2: Mssd(BSG) with can =

Mssd(BSG) =

Can 1: Movendry with can =

BSGsandSSD = Mssd(BSG) / [dV * density of water] =

Data Development of Results

Procedure

ACsand = [Mssd - Movendry] / Movendry =

* Perform the Bulk Specific Gravity test *

* Set up to find the Oven Dry mass tomorrow *

Can 1: Mssd with can =

Mssd =

1. Weigh a pan large enough to hold the sample.

Can 3: gravel = g

2. Obtain 1800g of blended and saturated coarse aggregate.

Total weight = g (approximately 1800 g)

The saturated aggregate was soaked for at least 48 hours prior to the lab.

3. Weigh and record the submerged mass of the empty basket (MBsub).

MBsub = g

4. Surface dry the aggregate with a rag until all visible films of water are removed,

but do not permit evaporation to further dry the aggregate.

5. Weigh the sample to find the saturated surface dry mass (Mssd).

Mssd (with pan) = g

Mssd = g

6. Place the sample in the basket under the scale

and record the submerged mass of aggregate plus basket (MTsub).

MTsub = g

7. Calculate the submerged mass of aggregate (Msub).

g

8. Place the sample in the oven to dry.

9. TOMORROW, remove the sample from the oven, permit it to cool,

and weigh it to find the dry mass (Movendry).

g

g

1. Compute the absorption capacity (ACgravel).

%

2. Compute the bulk volume (Vb).

g = ml 1.0 g/ml density of water

2. Compute the bulk specific gravity (BSGgravelSSD).

density of water = 1.0 g/ml

* Set up to find the Oven Dry mass tomorrow *

Aggregate Lab

Bulk Specific Gravity and Absorption Capacity of Coarse Aggregate

Procedure

Msub = MTsub - MBsub =

* Initial Preparations *

* Dry the sample to Saturated Surface Dry Condition *

* Perform the Bulk Specific Gravity test *

ACgravel = [Mssd - Movendry] / Movendry =

Data Development of Results

Vb = Mssd - Msub =

BSGgravelSSD = Mssd / [ Vb * density of water ] =

Movendry (with pan) =

Movendry =

1. Weigh a 5 gallon pail to hold the sample.

Mpail = lb

2. Obtain approximately 13.6 kg (30 lb) of blended air dry coarse aggregate.

Total weight = lb

3. Weigh the 0.25 cubic foot steel proving bucket (Mbucket).

Mbucket = lb

4. Fill the bucket to one third full with the blended aggregate and rod the aggregate with 25 strokes

distributed evenly over the surface. Do not hit the container bottom.

5. Fill the bucket to two-thirds full and rod with 25 strokes penetrating just into the previous layer.

6. Fill the bucket to overflowing and rod 25 strokes penetrating only into the previous layer.

7. Strike off the surplus with a flat bar and weigh the filled bucket (Mfullbucket),

Mfullbucket = lb

8. Subtract the mass of the proving bucket to find the mass of aggregate (Mgravel).

lb

9. Weigh the bucket with the glass plate (Mempty).

Mempty = lb

10. Fill the bucket with water using the glass plate as a cover.

11. Remove all air bubbles that are trapped beneath the plate using a squirt bottle.

12. Weigh the filled container and glass plate (Mfull).

Mfull = lb

13. Subtract to find the mass of water to fill the bucket

lb

1. Calculate the actual volume of the proving bucket (V).

density of water = 62.4 lb/ft^3 or pcf

cubic feet (cf)

2. Compute the dry rodded unit weight (D).

pcf D = Mgravel / V =

Data Development of Results

Mwater = Mfull - Mempty =

V = Mwater / density of water =

* calibrate the proving bucket volume *

Aggregate Lab

Dry Rodded Unit Weight of Coarse Aggregate

Procedure

Mgravel = Mfullbucket - Mbucket =

* Initial Preparations *

* run the test *

2"

2"

1"

1"

1/2"

1/2"

#4

#4

#10

#10

#20

#20

#40

#40

#100

#100

#200

#200

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

0.01 0.10 1.00 10.00 100.00

%

p

a

s

s

i

n

g

grain diameter (mm)

Grain Size Distribution

fine aggregate (sand)

coarse aggregate (1")

No. size with pan w/o pan % retained sum(% retained) % passing

(US std) (mm) (g) (g)

2" 50.80 -- -- -- -- 100%

1" 25.00 -- -- -- -- 100%

1/2" 12.70 1159.9 1071.3 60.87% 60.87% 39.13%

3/8" 9.50 371.1 282.5 16.05% 76.92% 23.08%

#4 4.75 421.2 332.6 18.90% 95.82% 4.18%

#10 2.00 129.0 40.4 2.30% 98.11% 1.89%

#20 0.85 101.4 12.8 0.73% 98.84% 1.16%

#40 0.425 93.8 5.2 0.30% 99.14% 0.86%

#100 0.150 97.1 8.5 0.48% 99.62% 0.38%

#200 0.075 90.6 2.0 0.11% 99.73% 0.27%

pan -- 92.4 3.8 0.22% 99.95% --

Totals 1759.1 -- -- --

No. size with pan w/o pan % retained sum(% retained) % passing

(US std) (mm) (g) (g)

2" 50.80 -- -- -- -- 100%

1" 25.00 -- -- -- -- 100%

1/2" 12.70 -- -- -- -- 100%

3/8" 9.50 -- -- -- -- 100%

#4 4.75 89.8 1.2 0.11% 0.11% 99.89%

#10 2.00 230.5 141.9 13.02% 13.13% 86.87%

#20 0.85 379 290.4 26.65% 39.79% 60.21%

#40 0.425 411.1 322.5 29.60% 69.38% 30.62%

#100 0.150 352.4 263.8 24.21% 93.59% 6.41%

#200 0.075 130.9 42.3 3.88% 97.48% 2.52%

pan -- 108.6 20.0 1.84% 99.31% --

Totals 1082.1 -- -- 286.52%

2.87

Mass of soil * based on Minitial

Sieve Size and Percent passing for Fine Aggregate

Sample Size = 1089.6 grams

fineness modulus

Sieve Size and Percent passing for Coarse Aggregate

Sieve Mass of soil * based on Minitial

Sample Size = 1760.0 grams

Sieve

Standard Sieve Size data for plot

No. size % passing

(US std) (mm)

2" 50.80 0%

50.80 100%

1" 25.00 0%

25.00 100%

3/4" 19.00 0%

19.00 100%

1/2" 12.70 0%

12.70 100%

3/8" 9.50 0%

9.50 100%

#4 4.75 0%

4.75 100%

10 2.00 0%

2.00 100%

20 0.85 0%

0.85 100%

40 0.425 0%

0.425 100%

100 0.150 0%

0.150 100%

200 0.075 0%

0.075 100%

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- PW 01Dokumen1 halamanPW 01aliengineer953Belum ada peringkat

- Emaar CBK TV EW Addendum No 5 (27 Sep 21)Dokumen7 halamanEmaar CBK TV EW Addendum No 5 (27 Sep 21)aliengineer953Belum ada peringkat

- The Views Protection Pile Alternate Design Calcs-1Dokumen28 halamanThe Views Protection Pile Alternate Design Calcs-1aliengineer953Belum ada peringkat

- EMAAR PANORAMA generator set proposalDokumen10 halamanEMAAR PANORAMA generator set proposalaliengineer953Belum ada peringkat

- The Views Protection Pile Alternate Design Calcs-1Dokumen28 halamanThe Views Protection Pile Alternate Design Calcs-1aliengineer953Belum ada peringkat

- Facade Tile Cladding Works at Panorama Tower at Emaar Crescent Bay, Dha KarachiDokumen1 halamanFacade Tile Cladding Works at Panorama Tower at Emaar Crescent Bay, Dha Karachialiengineer953Belum ada peringkat

- The Views Tangent Pile-Method StatementDokumen5 halamanThe Views Tangent Pile-Method Statementaliengineer953Belum ada peringkat

- FINAL-FINAL - ADSC Secant - Tangent Pile Wall Spec - 10-19-2015 PDFDokumen20 halamanFINAL-FINAL - ADSC Secant - Tangent Pile Wall Spec - 10-19-2015 PDFpsaroudakisBelum ada peringkat

- Dewatering Method Statement for Emaar The Views ProjectDokumen3 halamanDewatering Method Statement for Emaar The Views Projectaliengineer953Belum ada peringkat

- The Views Protection PileDokumen1 halamanThe Views Protection Pilealiengineer953Belum ada peringkat

- Dewatering Method Statement for Emaar The Views ProjectDokumen3 halamanDewatering Method Statement for Emaar The Views Projectaliengineer953Belum ada peringkat

- METHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The ViewsDokumen6 halamanMETHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The Viewsaliengineer953Belum ada peringkat

- Emaar-CBK-PT-Civil Work BOQ - JoineryDokumen21 halamanEmaar-CBK-PT-Civil Work BOQ - Joineryaliengineer953Belum ada peringkat

- Equipment Deployment EmaarDokumen8 halamanEquipment Deployment Emaaraliengineer953Belum ada peringkat

- CBK-P-KP-1003 Rev-1-Master PlanDokumen1 halamanCBK-P-KP-1003 Rev-1-Master Planaliengineer953Belum ada peringkat

- RP-7 Area Detail and DimensionsDokumen1 halamanRP-7 Area Detail and Dimensionsaliengineer953Belum ada peringkat

- Update Plan in 2004-Model - PDF Rev-2Dokumen1 halamanUpdate Plan in 2004-Model - PDF Rev-2aliengineer953Belum ada peringkat

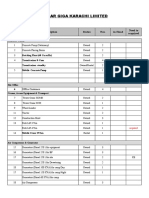

- EMAAR KARACHI LIMITED FACADE GLAZING WORKS COST SUMMARYDokumen3 halamanEMAAR KARACHI LIMITED FACADE GLAZING WORKS COST SUMMARYaliengineer953Belum ada peringkat

- Update Plan in 2004-Model - PDF Rev-1Dokumen1 halamanUpdate Plan in 2004-Model - PDF Rev-1aliengineer953Belum ada peringkat

- Project Risk Management: Dr. Muhammad Wasif, PMPDokumen2 halamanProject Risk Management: Dr. Muhammad Wasif, PMPaliengineer953Belum ada peringkat

- GROHE - Flushing Cistern GD 2 38661 000 - Search Result - SearchDokumen1 halamanGROHE - Flushing Cistern GD 2 38661 000 - Search Result - Searchaliengineer953Belum ada peringkat

- 02 Dj68-00605e PDFDokumen44 halaman02 Dj68-00605e PDFaliengineer953Belum ada peringkat

- Associated Constructors Limited: Speedy WorksDokumen1 halamanAssociated Constructors Limited: Speedy Worksaliengineer953Belum ada peringkat

- Washing Machine & Vacuum Cleaner Cargo (Karachi)Dokumen1 halamanWashing Machine & Vacuum Cleaner Cargo (Karachi)aliengineer953Belum ada peringkat

- Pakistan Post OfficeDokumen1 halamanPakistan Post Officealiengineer953Belum ada peringkat

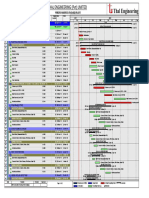

- Thal Engineering (PVT) LmitedDokumen2 halamanThal Engineering (PVT) Lmitedaliengineer953Belum ada peringkat

- GROHE Specification Sheet 37095000Dokumen1 halamanGROHE Specification Sheet 37095000aliengineer953Belum ada peringkat

- Filling VolveDokumen1 halamanFilling Volvealiengineer953Belum ada peringkat

- Pol Archives - Pakistan State OilDokumen69 halamanPol Archives - Pakistan State Oilaliengineer953Belum ada peringkat

- Vehicle Request PDFDokumen1 halamanVehicle Request PDFaliengineer953Belum ada peringkat