Linear Control

Diunggah oleh

Kuying KunyitDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Linear Control

Diunggah oleh

Kuying KunyitHak Cipta:

Format Tersedia

TITLE: POSITION CONTROL (PV LINEAR MOTION)

INTRODUCTION

The IP01 or the IP02 linear motion servo plants serve as the base unit for Quanser's linear

family of products. Both plants are ideal platforms to introduce fundamental control concepts

and theories on an easy to use and intuitive platform. They consist of a cart driven by a DC

motor, via a rack and pinion mechanism to ensure consistent and continuous traction. The

cart is also equipped with a rotary joint to which a free turning rod (or pendulum) can be

attached. In the case of the IP01, both cart position and pendulum angle are sensed via

potentiometers. By contrast, the IP02 system has two encoders, which allow for multiple

turns. As a result, the IP02 pendulum can suspend in front of the cart to perform the self-

erecting and gantry experiments

OBJECTIVES:

1. To become familiar with fundamentals of control system design using PID-type of

compensators.

2. To get to know the effect of K

v

and K

p

toward the t

p,

and P

0

in linear motion control

system design.

3. To study the application of theory in the real life using control system design.

4. To run the simulation simultaneously, at every sampling period, in order to compare

the actual and simulated responses

5. To implement with WinCon the previously designed PV controller in order to

command your IP01 and IP02 servo plant

6. To simulate with a simulink diagram the IP01 or IP02 model and to close the servo

loop by implementing a proportional-plus-Velocity(PV) position controller

7. To tune PV controller gains and their effect on the closed-loop system dynamic

response

8. To design and simulate a Proportional-Velocity (PV) position controller to meet the

required design specifications

APPARATUS

Power Module : Quanser UPM 1503/2405

Data Acquisition Board : Quanser MultiQ PCI/MQ3

Linear Motion Servo Plant : Quanser IP01 and IP02

Real-Time Control Software : the WinCon-Simulink-RTX configuration, as detailed in

reference.

Figure above show the equipment

THEORY

The IP01 and 1P02 are fundamental modules for the linear motion experiment. They consist

of a precisely machined solid aluminium cart driven by a higher quality DC motor equipped

with a planetary gearbox. The cart slides along a stainless steel shaft using linear bearing. The

cart is driven via a rack and pinion mechanism as opposed to belts or wheels, in order to

eliminate slippage, belt stretching and other undesirable. This, therefore ensure consistent and

continuous traction.

IP01

In the case of the IP01, the cart position is sensed via a ten-turn potentiometer. The IP01 cart

is also equipped with a rotary joint with ball bearing to which a free turning erected rod can

be attached. This rod functions as an inverted pendulum in subsequent experiment. The

angle of the rod is sensed using a conductive plastic potentiometer.

IP02

The IP02 pendulum can suspend in front of the cart to perform self-erecting and gantry

experiment. Consistently, the IP02 system has encoder, as opposed to potentiometers as in the

IP01, to allow for multiple turns.

The IP02 cart position is sensed via a quadrature incremental encoder whose shaft meshes

with the track via an additional pinion. The IP02 is also equipped with a rotary joint to which

a free swinging rod can be attached and suspends in front of the cart. This rod functions, in

subsequent experiments, as an inverted pendulum, but more precisely as a self-erecting

inverted pendulum as well as a regular inverted pendulum. The angle of the rod inclination

about the vertical axis is also measured using a quadrature incremental encoder and is

therefore unlimited and continuous over the entire range of motion. The pendulum in itself is

a module and can be mounted on or moved from the cart

CONTROL DESIGN SPECIFICATION

i. The Percent Overshoot(i.e. PO) should be less than 10% i.e;

PO * 10%

ii. The time to first peak should be 150 ms, i.e.;

T = 0.15 s

EXPERIMENTAL PROCEDURE

Linear motion position control equipment was set and ready for trial and error simulation.

The software involved in simulating the plant was MATLAB-Simulink. We observed the

effects of varying the controllers proportional-plus-velocity (PV) gains.

1. MATLAB-Simulink software along with corresponding programming and functions

was loaded.

2. Set the value of K

p

in the block diagram of Simulink to be fixed. K

p

= 500

3. Insert any value of K

v

in the block diagram. Run the Simulink simulation.

4. Observe the graph pattern. Record the value of Y

TP

and Y

ss

.

5. Calculated the percentage of overshoot based on formula given and tabulate the result

in the table. Percentage of overshoot must be less than 10%.

Repeat the step 1 to 5 by change the value of K

v

PRE LAB ASSIGNMENT

OPEN-LOOP TRANSFER FUNCTI ON

Kirchhoffs voltage law, we obtain the following equation:

[B.3]

However, since L

m

R

m

we can disregard the motor inductance leaving us with:

[B.4]

Since we know that the back-emf voltage created by the motor, E

emf

is proportional to the

motor shaft velocity I

m

, we have:

[B.5]

Moreover, in order to account for the DC motor electrical losses, the motor efficiency is

introduced to calculated the torque generated by the DC motor:

[B.6]

Substituting Equation [B.5] and [B.6] into equation [B.2] leads to:

[B.7]

By considering the rack and pinion and the gearbox mechanisms, the motor angular

velocity can be written as a function of the cart linear velocity, as expressed by:

[B.8]

Therefore, substituting equation [B.8] into equation [B.7] and rearranging leads to :

[B.9]

Finally, substituting equation[B.9] into equation [B.1], applying the Laplace Transform

and rearranging yields the desired open-loop transfer function for the IP01 and

IP02system, such that:

[B.10]

[B.13]

Moreover, the mechanical configuration of the carts rack-pinion system gives the following

relationship:

[B.14]

Substituting equation [B.13] and [B.14] into equation [B.12] provide the following

expression for the armature inertial force:

[B.15]

Finally, substituting equation [B.9]and [B.15] into equation [B.11, and rearranging result

in the dynamic equation for the system:

[B.16]

Finally, applying the Laplace transform and rearranging yields the desired open-loop

transfer function for the IP01 and IP02 system, such that:

[B.17]

Assignment 2 : Open Loop Model Block Diagram

Following the obtaining of the IP01 or IP02 open-loop transfer function, G(s), in

Assignment 1, derive a block diagram to represent such a transfer function. In other

words, represent as individual blocks the basic mechanical and electrical equations

that you use to determine G(s).The resulting block diagram should have an overall

closed-loop transfer function identical to the one found in Assignment 1.

Finally, using the IP01 or IP02 model parameter values listed in Reference [2], evaluate the

IP01 or IP02 open-loop transfer function, G(s), that you previously found. Determine the

plant's pole(s), zero(s), and DC gain

Assignment 3 : PV Controller Design

In order to determine and calculate Kp and Kv, answer the following questions:

Perform block diagram reduction of the PV control scheme applied to G(s), as

presented in if Appendix C has been supplied with this handout. Obtain the overall

closed-loop transfer function of your IP01 or IP02 system by replace G(s) by its

expression, as found in Assignment 1.

Extract from the previously obtained closed-loop transfer function the system's

characteristic equation.

Fit the obtained characteristic equation to the standard form (seen in Equation [C.3], if

available), by identifying the parameters w

n

and . Thus, you should obtain 2

equations expressing w

n

and as functions of K

p

and K

v

as these are the only 2

variables (i.e. controller parameters) in your system.

Using your newly obtained formulae and referring to your in-class notes, what

changes to yourIP01 or IP02 response would you expect to see by varying the values

of K

p

and K

v

? Keep your answers simple (i.e. will w

n

and increase or decrease?).

How would this translate in terms of changes in t

p

and Percent Overshoot (PO)? Also

relate these changes to the physical behaviour of your closed-loop system. Hint: You

can use Equations [23] and [24], presented in the next subsection.

Specifically:

i) Assuming Kv constant, what happens to w

n

and when you

increase/decrease Kp?

ii) Assuming Kp constant, what happens to w

n

and when you

increase/decrease Kv?

Using the formulae previously obtained, determine the analytical expressions and

numerical values for Kp and Kv in order to meet the previously specified time

requirements.

The following hint formulae are provided.

Anda mungkin juga menyukai

- Control of DC Motor Using Different Control StrategiesDari EverandControl of DC Motor Using Different Control StrategiesBelum ada peringkat

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorDari EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorBelum ada peringkat

- Linear ExperimentDokumen4 halamanLinear ExperimentJaafar UdinBelum ada peringkat

- Adaptive Backstepping Control of Separately Excited DC Motor With UncertaintiesDokumen6 halamanAdaptive Backstepping Control of Separately Excited DC Motor With UncertaintiesEngr XamirBelum ada peringkat

- Magnetic Levitation PDFDokumen8 halamanMagnetic Levitation PDFAman MathurBelum ada peringkat

- Pendulum Positioning System Actuated by Dual Motorized PropellersDokumen4 halamanPendulum Positioning System Actuated by Dual Motorized Propellerspatmos666Belum ada peringkat

- First Steps Towards An Open Control Architecture For A PUMA 560Dokumen6 halamanFirst Steps Towards An Open Control Architecture For A PUMA 560Rajeev GargBelum ada peringkat

- LQG - LTR Controller Design Quanser Rotary Inverted PendulumDokumen6 halamanLQG - LTR Controller Design Quanser Rotary Inverted PendulumGeovani BondoBelum ada peringkat

- MP - GRP - 2 - PPTDokumen26 halamanMP - GRP - 2 - PPTAASISH KUMAR JENABelum ada peringkat

- Experiment 3 PDFDokumen8 halamanExperiment 3 PDFPrateek NyatiBelum ada peringkat

- Tut 1Dokumen4 halamanTut 1Chaxu MistryBelum ada peringkat

- Experiment No.: - 1: To Study The DC Servomotor CharacteristicsDokumen50 halamanExperiment No.: - 1: To Study The DC Servomotor CharacteristicsNobita NobiBelum ada peringkat

- Design and Simulation of PI Control For Positive Output Triple Lift Luo ConverterDokumen3 halamanDesign and Simulation of PI Control For Positive Output Triple Lift Luo ConverterIJMERBelum ada peringkat

- Design of Permanent Magnet Synchronous Motor Speed Control System Based On SVPWMDokumen6 halamanDesign of Permanent Magnet Synchronous Motor Speed Control System Based On SVPWMRedkit ofFootHillBelum ada peringkat

- c4 3rdyearDokumen4 halamanc4 3rdyearMark Chow Khoon Keat0% (1)

- LQG/LTR Controller Design For Rotary Inverted Pendulum Quanser Real-Time ExperimentDokumen7 halamanLQG/LTR Controller Design For Rotary Inverted Pendulum Quanser Real-Time Experimentgogu vasileBelum ada peringkat

- Pi-Controllers Determination For Vector Control MotionDokumen7 halamanPi-Controllers Determination For Vector Control MotionlalitbickBelum ada peringkat

- Space Engineering Lab Manual MDokumen43 halamanSpace Engineering Lab Manual Mmanikandan_murugaiahBelum ada peringkat

- PID Controller For DC MotorDokumen6 halamanPID Controller For DC MotorjayaseelanBelum ada peringkat

- Antenna AzimuthDokumen6 halamanAntenna AzimuthDavePascualBelum ada peringkat

- 1 SMDokumen7 halaman1 SMaswardi8756Belum ada peringkat

- PID Practical PDFDokumen18 halamanPID Practical PDFJose Luis HurtadoBelum ada peringkat

- DESIGNING THE PROPORTIONAL (P) AND PROPORTIONAL-INTEGRAL (PI) CONTROLLERS Control SystemDokumen7 halamanDESIGNING THE PROPORTIONAL (P) AND PROPORTIONAL-INTEGRAL (PI) CONTROLLERS Control SystemjayxcellBelum ada peringkat

- Grid Imposed Frequency VSC SystemDokumen27 halamanGrid Imposed Frequency VSC SystemTshibain TshibunguBelum ada peringkat

- Self Balancing Two Wheeled Robot ReportDokumen11 halamanSelf Balancing Two Wheeled Robot Reportnetlvr0Belum ada peringkat

- ECEN 2270 CU Boulder 2013, Electronics Design Lab, Lab2, WIPDokumen8 halamanECEN 2270 CU Boulder 2013, Electronics Design Lab, Lab2, WIPNunjaBelum ada peringkat

- DC Control MethodDokumen22 halamanDC Control MethodSyed Haidar Ali ZaidiBelum ada peringkat

- Design of An Antenna Azimuth Position Control SystemDokumen12 halamanDesign of An Antenna Azimuth Position Control SystemUche PaulBelum ada peringkat

- Inverted Pendulum IeeeDokumen3 halamanInverted Pendulum Ieeechaitu2403Belum ada peringkat

- Active Damping Control of Hybrid Stepping Motor: Sheng-Ming Yang, Member, IEEE and Pei-Der SuDokumen6 halamanActive Damping Control of Hybrid Stepping Motor: Sheng-Ming Yang, Member, IEEE and Pei-Der Su01689373477Belum ada peringkat

- Dien Co Ban May BayDokumen102 halamanDien Co Ban May Baykhanh nguyenBelum ada peringkat

- Gantry Crane SystemDokumen17 halamanGantry Crane SystemTarmizi KembaliBelum ada peringkat

- Simulation work on Fractional Order PIλ Control Strategy for speed control of DC motor based on stability boundary locus methodDokumen7 halamanSimulation work on Fractional Order PIλ Control Strategy for speed control of DC motor based on stability boundary locus methodseventhsensegroupBelum ada peringkat

- Pi Control System Based Speed Control of DC Motor Using MicrocontrollerDokumen13 halamanPi Control System Based Speed Control of DC Motor Using MicrocontrollerAnkit BhardwajBelum ada peringkat

- SY203 DocumentDokumen9 halamanSY203 DocumentSyer Khomainie Mohamad YakopBelum ada peringkat

- Analysis of Boost Converter Using PI Control AlgorithmsDokumen3 halamanAnalysis of Boost Converter Using PI Control AlgorithmsTrương Văn TrọngBelum ada peringkat

- CSDDokumen19 halamanCSDSaurabh MishraBelum ada peringkat

- EE 392: Control Systems & Their Components: Lab 2: DC Motor Speed: Frequency Domain Methods For Controller DesignDokumen4 halamanEE 392: Control Systems & Their Components: Lab 2: DC Motor Speed: Frequency Domain Methods For Controller DesignAbdalla FathyBelum ada peringkat

- Research On Servo Motor Motion Control System BaseDokumen8 halamanResearch On Servo Motor Motion Control System BaseAhmed AliBelum ada peringkat

- Advanced Control System Lab PDFDokumen15 halamanAdvanced Control System Lab PDFarpitg2208Belum ada peringkat

- Inverted PendulumDokumen60 halamanInverted PendulumMauricio OrtegaBelum ada peringkat

- Qualitative PI ControlDokumen4 halamanQualitative PI ControlAbeer ChaudhryBelum ada peringkat

- Four Switch Three Phase Inverter Control of BLDC MotorDokumen6 halamanFour Switch Three Phase Inverter Control of BLDC MotorBhargav Cho ChweetBelum ada peringkat

- Antenna Azimuth Controller DesignDokumen17 halamanAntenna Azimuth Controller DesignNisa Ien100% (5)

- Dynamic Output Feedback Linearizing Control of Doubly-Fed Induction MotorDokumen5 halamanDynamic Output Feedback Linearizing Control of Doubly-Fed Induction Motorpower8990Belum ada peringkat

- Control Systems Lab ManualDokumen67 halamanControl Systems Lab ManualRockstar Rich100% (1)

- Fuzzy Control Based Solar Tracker Using Arduino Uno: ISO 9001:2008 CertifiedDokumen9 halamanFuzzy Control Based Solar Tracker Using Arduino Uno: ISO 9001:2008 CertifiedDavidleonardo GalindoBelum ada peringkat

- MATLABSimulink, Stepper Motor, Vector ControlDokumen5 halamanMATLABSimulink, Stepper Motor, Vector ControlDobai SzilardBelum ada peringkat

- Buck Converter SimulinkDokumen6 halamanBuck Converter SimulinkfrankersinatBelum ada peringkat

- Chapter 1 Introduction A. Background: Full Speed, Torque Acceleration Deceleration. Power ConsumptionDokumen13 halamanChapter 1 Introduction A. Background: Full Speed, Torque Acceleration Deceleration. Power ConsumptionfirmanBelum ada peringkat

- 888490.4292-PI Controller For DC Motor Speed Realized With Arduino and SimulinkDokumen5 halaman888490.4292-PI Controller For DC Motor Speed Realized With Arduino and Simulinkwang Chen YuBelum ada peringkat

- DSP-Based Speed Adaptive Flux Observer of Induction MotorDokumen5 halamanDSP-Based Speed Adaptive Flux Observer of Induction MotorthavaselvanBelum ada peringkat

- Lab V - PDFDokumen4 halamanLab V - PDFZakBelum ada peringkat

- EM Final Project ReportDokumen6 halamanEM Final Project ReportShameen MazharBelum ada peringkat

- Me2142-2 Speed/Position Control of A DC Motor: Department of Mechanical Engineering National University of SingaporeDokumen9 halamanMe2142-2 Speed/Position Control of A DC Motor: Department of Mechanical Engineering National University of SingaporeDeepak RainaBelum ada peringkat

- Documentation For The Bytronic Pendulum Control System: (Version 2.1)Dokumen37 halamanDocumentation For The Bytronic Pendulum Control System: (Version 2.1)Mohamed Elsayed HasanBelum ada peringkat

- Design and Simulations of Sliding Mode Controller For DC-DC Buck ConverterDokumen8 halamanDesign and Simulations of Sliding Mode Controller For DC-DC Buck ConverteryoucefBelum ada peringkat

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlDari EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlPenilaian: 5 dari 5 bintang5/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDari EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetPenilaian: 2 dari 5 bintang2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDari EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetBelum ada peringkat

- Shibaura Diesel Engine S773L - Tier4 XXDokumen28 halamanShibaura Diesel Engine S773L - Tier4 XXMihai PopaBelum ada peringkat

- CV6312 S1 OverviewDokumen6 halamanCV6312 S1 Overviewlim kang haiBelum ada peringkat

- Engineering Guide Custom Battery PacksDokumen16 halamanEngineering Guide Custom Battery PacksAndrew PBelum ada peringkat

- Fixture Units Sizing ChartDokumen4 halamanFixture Units Sizing ChartAfrooz Momeni100% (1)

- Ford Egr ValvesDokumen4 halamanFord Egr ValvesTravis SincombBelum ada peringkat

- CG Drive SGDokumen1 halamanCG Drive SGmanchem sreeram sanjay67% (3)

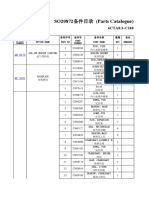

- 6CTA8.3-C240 FRO CLG862 40c0273en Parts CatalogueDokumen80 halaman6CTA8.3-C240 FRO CLG862 40c0273en Parts CataloguePurnama AbhieBelum ada peringkat

- JF-10 X-Ray Unit - User and Service ManualDokumen13 halamanJF-10 X-Ray Unit - User and Service ManualSergio MontesBelum ada peringkat

- The Dark Side of NTPC PDFDokumen50 halamanThe Dark Side of NTPC PDFCFA IndiaBelum ada peringkat

- 3 CombustionDokumen30 halaman3 CombustionCllyan ReyesBelum ada peringkat

- Bono Thermal Oil HeatersDokumen10 halamanBono Thermal Oil HeatershendraBelum ada peringkat

- OTS60SX2 UG en-medidorRigidezDielectrica PDFDokumen14 halamanOTS60SX2 UG en-medidorRigidezDielectrica PDFblancaBelum ada peringkat

- ElectricityDokumen11 halamanElectricityi919647Belum ada peringkat

- Tugas Ii ThermodinamicsDokumen7 halamanTugas Ii ThermodinamicsAdi Dangan MuktiBelum ada peringkat

- SS 1.4122Dokumen2 halamanSS 1.4122Bipin Sadasivan100% (2)

- APGCL-Petition FY 2006-07 PDFDokumen70 halamanAPGCL-Petition FY 2006-07 PDFRahul RoyBelum ada peringkat

- Del Cos 3000Dokumen12 halamanDel Cos 3000aryluck77Belum ada peringkat

- Akon Thesis PDFDokumen116 halamanAkon Thesis PDFKant SantosBelum ada peringkat

- LKP CatalogDokumen3 halamanLKP Catalogvikas_ojha54706Belum ada peringkat

- DowsingDokumen76 halamanDowsingBacean Aurel IoanBelum ada peringkat

- Chapter25 PDFDokumen8 halamanChapter25 PDFElizabeth DouglasBelum ada peringkat

- Abb LV139Dokumen20 halamanAbb LV139Ahmad Shaikh NooruddinBelum ada peringkat

- Meralco AnalysisDokumen7 halamanMeralco AnalysisjemBelum ada peringkat

- 144S... - PCB Series: Signal Conditioned Precision Pressure TransducersDokumen4 halaman144S... - PCB Series: Signal Conditioned Precision Pressure TransducersAnish KumarBelum ada peringkat

- 06-DC ChopperDokumen26 halaman06-DC ChopperTuhin ShahBelum ada peringkat

- Motor Cd20Dokumen152 halamanMotor Cd20Maciej Sobczyński100% (1)

- Technical Report 1 1999Dokumen34 halamanTechnical Report 1 1999Sinan YıldızBelum ada peringkat

- Electrostatic Field Energy: Project PHYSNET Physics Bldg. Michigan State University East Lansing, MIDokumen6 halamanElectrostatic Field Energy: Project PHYSNET Physics Bldg. Michigan State University East Lansing, MIEpic WinBelum ada peringkat

- Plastic WeldingDokumen8 halamanPlastic WeldingMichelleAdanteMorongBelum ada peringkat

- Data SheetDokumen2 halamanData SheetFarid AfifiBelum ada peringkat