LaTeX Example

Diunggah oleh

Bon BonDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

LaTeX Example

Diunggah oleh

Bon BonHak Cipta:

Format Tersedia

Industrial production of ethylene oxide

How is ethylene oxide produced on an industrial

scale and how does the ethylene oxide process

qualitatively compare to the production of propylene

oxide?

Hans David Wendt, Lars Heuvels, Eline van Daatselaar and Tim van Schagen

(Group B)

April 3, 2014

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Ethylene oxide production . . . . . . . . . . . . . . . . . . . . 3

2.1 Reaction . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Chlorohydrin process . . . . . . . . . . . . . . . . . . . 3

3 Distillation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Determination of the adiabatic temperature rise . . . 7

3.2 Temperature rise in the reactor . . . . . . . . . . . . . 9

3.3 Constant reactor temperature . . . . . . . . . . . . . . 9

1

1 Introduction

In this project we researched the production process of ethylene oxide (ab-

breviated EtO, C

2

H

4

O). Ethylene oxide is a frequently used intermediate in

the chemical industry. The reason for this is the easily broken ring (Figure

1), because the breaking of these bonds releases a lot of energy. So ethylene

oxide is a very reactive and much used compound. Because of this, very

much ethylene oxide is produced on a yearly basis. In earlier times, the

production process involved a chlorohydrin process, which was less ecient

then the oxidation process that is used presently. We focussed on the direct

oxidation process, with pure oxygen and not with air. We made this choice,

since the process with pure oxygen is more often used and has a higher pro-

duction rate. For this process we evaluated mass balances, where dierent

variables are discussed, like the inuence of the conversion, selectivity and

feed rate. We also had a look at the separator units, mainly the distillation

column. Those columns are important for these kind of processes, because

these units improve the purity of the nal product. At the end, the en-

ergy balance is computed. To evaluate these three processes, we have used

calculation programs like Matlab and Microsoft Excel.

Our research questions are:

How is the mass balance of the production of EtO arranged?

How does the distillation column work for this process?

How are the energy ows in the system set up?

Besides the production process of ethylene oxide, the production of propy-

lene oxide (abbreviated PO, C

3

H

6

O) also is evaluated. We qualitatively

compare this process to the production process of EtO. The dierences and

similarities will be discussed with the following question:

How much diers the production of PO from that of EtO?

O

Figure 1: The molecular structure of ethylene oxide

2

2 Ethylene oxide production

We will start with discussing the production of ethylene oxide in a chemical

factory.

2.1 Reaction

The reaction we are evaluating is the production of ethylene oxide from

ethylene and oxygen. The reactions that occur in the reactor are depicted

in Figure 2, Figure 3 and Figure 4. The reaction in Figure 2 is the desired

reaction to produce ethylene oxide. Unfortunately, there is a side reaction.

Ethylene oxide reacts further to carbon dioxide and water (Figure 3). The

reaction in Figure 4 is the sum of 2 and 3 and so the total reaction equation

for the byproducts.

2 H

2

C CH

2

+ O

2

Ag

2

O

Figure 2: The formation of ethylene oxide out of ethylene and oxygen cat-

alyzed by a silver catalyst

2

O

+ 5 O

2

4 CO

2

+ 4 H

2

O

Figure 3: Combustion reaction of ethylene oxide.

H

2

C CH

2

+ 3 O

2

2 CO

2

+ 2 H

2

O

Figure 4: Combustion reaction of ethylene.

The process in which ethylene oxide is produced, is schematically represented

in Figure 5. In this gure, all mass ows and separators are pointed out and

will be computed in following paragraphs.[1]

2.2 Chlorohydrin process

The process to make propylene oxide by using chlorohydrins consists basi-

cally of three steps: chlorohydration, epoxidation and purication. In the

chlorohydration step, propylene gas and chlorine gas are mixed stoichiomet-

ric, while reacting as following to a chloronium ion intermediate (Figure

6):

This intermediate can react in three ways to dierent products. The de-

sired products are two isomers of propylene chlorohydrin, namely 1-chloro-

2-propanol (Figure 7) and 2-chloro-1-propanol (Figure 8), which arise from

a reaction with water:

3

Figure 5: Schematic representatation of the ethylene oxide process.

CH

3

CH

2

+ Cl Cl

CH

3

Cl

+

Cl

Figure 6: The reaction of propylene with chorine to form the chloronium

ion.

CH

3

Cl

+ H

O

H +

Cl

H

3

C

OH

Cl

+ HCl

Figure 7: Reaction of the chloronium ion with water to form 1-chloro-2-

propanol.

CH

3

Cl

+ H

O

H +

Cl

H

3

C

Cl

O H

+ HCl

Figure 8: Reaction of the chloronium ion with water to form 2-chloro-1-

propanol.

1-chloro-2-propanol emerges for about 85%, because this isomer is formed via

a secondary carbocation, while 2-chloro-1-propanol is formed via a primary

carbocation. Usually this desired main reaction represents 90% or more

of the yield. Besides, there are two side reactions, which together emerge

for up to 10%. The intermediate can react with the chloride ion to form

1,2-dichloropropane (Figure 9). The other side reaction produces isomers of

4

dichloro-dipropyl ether out of a reaction with propylene chlorohydrin (Figure

10).

CH

3

Cl

+

Cl

H

3

C

Cl

Cl

Figure 9: Reaction of the chloronium ion with chloride to form 1,2-

dichloropropanol.

CH

3

Cl

+ H

3

C

O H

Cl

+

Cl

H

3

C

Cl

O

CH

3

Cl

+ HCl

Figure 10: The formation of dichloro-dipropyl ether.

The next step can be called epoxidation, dehydrochlorination or saponica-

tion. The chloropropanol reacts with a base, which is added in excess. This

could be calcium hydroxide or sodium hydroxide, dissolved in water. The

reaction is as following (Figure 11):

CH

3

OH

Cl

+ HCl + 2OH

CH

3

O

+ 2Cl

+ 2H

2

O

Figure 11: Reaction of chloropropanol with a base to form propylene oxide.

The issue with the saponication is that the propylene oxide decomposes

when a base is present. Therefore...[3]

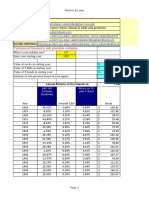

3 Distillation

Changing the Antoine parameters makes no sense in the nal version, but

we will discuss that later. The parameters are only present to show us the

Antoine parameters. The boiling temperatures are valid for 1 bar, but we

solved the assignment for 4.428 bar, since we could only nd Vapor Liquid

Equilibrium (VLE) data for water and ethylene oxide at this pressure. We

made a plot and polynomial approximation of a VLE graph.[9] This graph

can be seen in Figure 12.

5

Figure 12: VLE graph of EtO and water.

Next, we want to evaluate the temperature of the feed. This can be done

by solving equation 1.[10]

X

eto

p

0

eto

+X

water

p

0

H

2

O

= 4.428 (1)

This can be done...

Therefore, we made a polynomial approximation of the Antoine parametes of

ranges of temperatures we could nd. Then we extrapolated these. We put

this approximation in equation 1 to solve it. This makes a better polynomial

approximation than using only one set of parameters. The parameters used

are displayed in table 1.[11]

Ethylene oxide 1 Ethylene oxide 2 Water

A 4.386 5.48696 4.6543

B 1115.1 2022.83 1435.264

C -29.015 62.656 -64.848

Temperature range 185-280 K 280-305 K 256-373 K

Table 1: Antoine parameters of water and ethylene oxide

6

3.1 Determination of the adiabatic temperature rise

Because the oxidation of ethylene to ethylene oxide is an exothermal reac-

tion, there is a lot of energy that is released in the reaction. We want to

know what the temperature rise of the reactor is when we dont let any heat

ow in or out (adiabatic). Weve used an enthalpy balance to determine the

adiabatic temperature rise. We use the steady-state open-system energy

balance (equation 2).[7]

H +

E

k

+

E

p

=

Q

W

s

(2)

E

k

(kinetic energy) and

E

p

(potential energy) can be neglected because

these terms are very small in comparison to

H (internal energy). In our

process the

W

s

(work) term is approximately zero and because we want the

adiabatic temperature rise, the

Q (heat ow) term is also zero. So we get

H = 0, which means:

H

in

=

H

out

(3)

We use the heat of formation method to calculate the enthalpy balance. So

we can rewrite equation 3 to:

in

H

in

=

out

H

out

(4)

In this equation we just take the sum of the enthalpy of each individual

component, which can be calculated by multiplying the molar ow with the

enthalpy per mol. In the mass balance section, we already calculated the

molar ows of every single compound in our spreadsheet. These values are

displayed in Table 2.

Compound

in

(mol/s)

out

(mol/s)

Ethylene (g) 2114.286 1902.857

Oxygen (g) 185.0 0

Methane (g) 6147.692 6147.692

Carbon dioxide (g) 287.8681 351.2967

Water (g) 0 63.42857

Ethylene oxide (g) 0 179.7143

Table 2: Molar ows over the reactor

To calculate the enthalpy per mole we need the heat of formation for the

dierent compounds. The heat of formation is given at 298 K and 1 atm.

Weve used the data of the NIST Webbook[11] (Table 3).

Because we arent working at standard temperatures, we also have to know

the heat capacities of the compounds, and because these arent constant

at dierent temperatures we need the heat capacities as a function of the

temperature. Its true that we also didnt work at standard pressures, but

because we work with gases and our working pressure isnt very extreme

7

Compound Heat of formation

f

H (kJ/mol)

Ethylene (g) 52.47

Oxygen (g) 0

Methane (g) -74.87

Carbon dioxide (g) -393.52

Water (g) -241.83

Ethylene oxide (g) -52.64

Table 3: Heat of formation at p

0

and T

0

of the compounds in the reactor.

Compound A B C D E

Ethylene (g) -6.387880 184.4019 -112.9718 28.49593 0.315540

Oxygen (g) 31.32234 -20.23531 57.86644 -36.50624 -0.007374

Methane (g) -0.703029 108.4773 -42.52157 5.862788 0.678565

Carbon dioxide (g) 24.99735 55.18696 -33.69137 7.948387 -0.136638

Water (g) 30.09200 6.832514 6.793435 -2.534480 0.082139

Ethylene oxide (g) -23.25802 275.6997 -188.9729 51.03350 0.386930

Table 4: Parameters for the Shomate equation.

(compared to p

0

), we can neglect the

V P term. We use the Shomate

equation to express the heat capacity as a function of temperature (Equation

5)

C

p

= A+B t +C t

2

+D t

3

+E/t

2

(5)

t is dened in Equation 6, where T is the temperature in Kelvin.

t = T/1000 (6)

A, B, C, D and E are constants. These constants are compound specic.

The constants for the compounds in our reactor are in Table 4.[11]

H =

f

H +

T

2

T

1

C

p

dT (7)

The adiabatic temperature rise depends also on the T

in

, we set T

in

= 523

K[1] and want to calculate T

out

. So T

out

is our variable in equation 4. We

used our Matlab code Determination_of_adiabatic_Temperature_rise.m

and the data above to calculate T

out

. When we ll in the data with T

in

= 523 K we get T

out

= 628.385 K, so the adiabatic temperature rise =

105.385 K.

8

3.2 Temperature rise in the reactor

If the temperature in the reactor rises, the single pass conversion will rise,

because the reaction will occur faster. When the conversion rises the selec-

tivity will decrease. So a temperature rise will lead to a lower selectivity.

This means that we produce more by-products. When our selectivity de-

creases the production cost will increase so we dont want the selectivity to

decrease. The temperature is allowed when the reactor is strong enough to

hold these circumstances, but economically we dont want a temperature

rise in our reactor.

3.3 Constant reactor temperature

Because we want a constant temperature in our reactor and the reaction is

exothermal we have to cool down the reactor. To calculate the amount of

heat we have to absorb we again use an enthalpy balance. This time the

Q

(heat ow) isnt zero so we get the equation:

in

H

in

out

H

out

=

Q (8)

In table 2 we can nd the

in

and

out

again, because these dont change

when we let the heat ow out. The

H

in

and

H

out

can be calculated because

temperature in reactor is constant = 523 K. We just use equation 7 again

(calculations done with Matlab le: Energybalance_ethyleenoxide.m). The

results are in table 5.

Compound

H

in

(kJ/mol)

H

out

(kJ/mol)

Ethylene (g) 64.6064 64.6064

Oxygen (g) 6.8060 6.8060

Methane (g) -65.5838 -65.5838

Carbon dioxide (g) -384.4319 -384.4319

Water (g) -234.0780 -234.0780

Ethylene oxide (g) -38.3405 -38.3405

Table 5:

H

in

and

H

out

of the compounds in the reactor.

in

H

in

= 4.8666 10

5

kJ/s (9)

out

H

out

= 5.3835 10

5

kJ/s (10)

This gives a heat ow

Q = 5.1687 10

4

kJ/s So we have to absorb 5.1687 10

4

kJ per second. We use water at room temperature (298 K) to cool down

the reactor, because this is a cheap substance with very few risks. Another

advantage of cooling down the reactor with water is, that we can re-use the

9

steam for heating up other streams of the process. To calculate the amount

of steam at 373 K that we can produce, we need the heat of vaporization

and the heat capacity of liquid water. To express the heat capacity as a

function of the temperature, we use the Shomate equation again (Equations

5 and 6). The constants for liquid water are depicted in table 6.[11]

A -203.6060

B 1523.290

C -3196.413

D 2474.455

E 3.855326

Table 6: Shomate parameters for liquid water.

The heat of vaporization of water H

vap

= 40.68 kJ/mol. To calculate the

amount of heat needed to vaporize 1 mol of water at room temperature we

use:

H

vap

+

373

298

C

p

dT = 46.3401 kJ/mol (11)

When we divide Q by this amount we get the amount of water, we can

vaporize by cooling down the reactor = 1.1154 10

3

mol/s.

10

Bibliography

[1] Siegfried Rebsdat, Dieter Mayer, Ullmans Encyclopedia of Industrial

Chemistry - Article Ethylene Oxide. DOI: 10.1002/14356007.a10_117.

published: 15-03-2001, consulted: 21-01-2014.

[2] J. P. Dever, K. F. George, W. C. Homan, H. Soo, Kirk-Othmer:

Encyclopedia of Chemical Technology - Artice Ethylene Oxide. DOI:

10.1002/0471238961.0520082504052205.a01.pub2. published: 14-03-

2004, consulted: 21-01-2014.

[3] David L. Trent, Kirk-Othmer: Encyclopedia of Chem-

ical Technology - Artice Propylene Oxide. DOI:

10.1002/0471238961.1618151620180514.a01.pub2. published: 4-01-

2001, consulted: 21-01-2014.

[4] Dietmar Kahlich, Uwe Wiechern, Jrg Lindner, Ullmans Ency-

clopedia of Industrial Chemistry - Article Propylene Oxide. DOI:

10.1002/14356007.a22_239.pub2. published: 15-10-2012, consulted:

21-01-2014.

[5] Prof. Dr. Rainer Herges and Dr. Torsten Winkler, Epoxidation

of Alkenes with Peracids. URL: http://www.chemgapedia.de/

vsengine/vlu/vsc/en/ch/2/vlu/oxidation_reduktion/epxo_per_

1.vlu/Page/vsc/en/ch/2/oc/reaktionen/formale_systematik/

oxidation_reduktion/oxidation/addition_sauerstoff/

epoxidierung_mit_persaeuren/mechanismus.vscml.html. pub-

lished: 2000, consulted: 21-01-2014.

[6] Shell Oil Company, Patent Preparation Method SMPO Process. Publi-

catio number: US6989469 B2. published: 24-01-2006, consulted: 21-01-

2014.

[7] Richard M. Felder, Ronald W. Rousseau, Elementary Principles of

Chemial Reactions, 2005 edition. ISBN: 987-0-471-68757-3. published:

2005, consulted: 21-01-2014.

[8] University of Alicante, Conversion: Fundamentals and the dier-

ence between single pass and overall conversion. URL: http://

11

www.youtube.com/watch?v=Wgkv8uqQ3wk. published: 14-03-2004, con-

sulted: 21-01-2014.

[9] Y.-L. Huang , T. Merker , M. Heilig , H. Hasse , and J. Vrabec, Molec-

ular Modeling and Simulation of Vapor-Liquid Equilibria of Ethylene

Oxide, Ethylene Glycol, and Water as Well as their Binary Mixtures.

DOI: 10.1021/ie300248z. published: 30-04-2012, consulted: 22-01-2014.

[10] A.B. de Haan, H. Bosch, Fundamentals of Industrial Separations, Edi-

tion 2. ISBN: 9789081097321. published: 2007, consulted: 21-01-2014.

[11] National Institute of Standards and Technology, NIST Chemistry Web-

Book. URL: http://webbook.nist.gov/. published: dierent dates,

consulted: 21-01-2014.

12

Anda mungkin juga menyukai

- Simulation of Reactors and Heaters Coolers Using HYSYSDokumen21 halamanSimulation of Reactors and Heaters Coolers Using HYSYSVonbait100% (2)

- CLL703 Process Engineering - Tut Sheet 1: C H C H + H C H (1/2) C H + CHDokumen2 halamanCLL703 Process Engineering - Tut Sheet 1: C H C H + H C H (1/2) C H + CHshakshiBelum ada peringkat

- Report Simulation PDDokumen18 halamanReport Simulation PDAtika Mohd YatimBelum ada peringkat

- Styrene Production Plant Dwsim FlowsheetDokumen11 halamanStyrene Production Plant Dwsim FlowsheetmurtadaBelum ada peringkat

- Reactor ModelDokumen12 halamanReactor ModelTanuja ThanuBelum ada peringkat

- Contoh Report WritingDokumen22 halamanContoh Report WritingWan A HarisBelum ada peringkat

- Ethanol 5ad Aafsdfastfwqfas Sacaxvava AxcvvvvvvvvvvvvvvvvasdddddddddddDokumen7 halamanEthanol 5ad Aafsdfastfwqfas Sacaxvava AxcvvvvvvvvvvvvvvvvasdddddddddddNiko Ava DaaBelum ada peringkat

- Group 3 - Acetone Production Via The Dehydrogenation of IPADokumen7 halamanGroup 3 - Acetone Production Via The Dehydrogenation of IPAQuỳnh Như PhạmBelum ada peringkat

- Project 4 Ethylene OxideDokumen12 halamanProject 4 Ethylene OxideNhan Nguyen Van100% (4)

- PFD Diagram of Benzoic Acid FormationDokumen5 halamanPFD Diagram of Benzoic Acid FormationShailesh LahotiBelum ada peringkat

- CRE (Stage 3) GROUP A6Dokumen13 halamanCRE (Stage 3) GROUP A6Danish MughalBelum ada peringkat

- Mass Balance Tutorial 2 - 2021 Fin-StuDokumen2 halamanMass Balance Tutorial 2 - 2021 Fin-StuToanique HeadmanBelum ada peringkat

- Design of An Plant For Manufacturing of AcetaldehydeDokumen4 halamanDesign of An Plant For Manufacturing of AcetaldehydeClaudio Martinez BernalBelum ada peringkat

- Trabaj Oxido D EtilenoDokumen3 halamanTrabaj Oxido D EtilenoJuan M LariosBelum ada peringkat

- Experiment 10 Chem 223Dokumen7 halamanExperiment 10 Chem 223azinthepantsBelum ada peringkat

- Design (Ch.1 Problems)Dokumen5 halamanDesign (Ch.1 Problems)John UnkBelum ada peringkat

- Hydrogen Production ProcessesDokumen73 halamanHydrogen Production ProcessesThitikorn Wassanarpheernphong100% (2)

- Lecture 14Dokumen6 halamanLecture 14Yahya ArdianBelum ada peringkat

- Lab 5Dokumen11 halamanLab 5Alif AizadBelum ada peringkat

- Assignment ReactiveDokumen2 halamanAssignment ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET01940% (1)

- Theoretical and Actual CombustionDokumen14 halamanTheoretical and Actual CombustionErma Sulistyo R100% (1)

- CHM3103 Lab Experiment 2Dokumen15 halamanCHM3103 Lab Experiment 2husnaBelum ada peringkat

- Proceso Etilbenceno 311280Dokumen26 halamanProceso Etilbenceno 311280ItzelBelum ada peringkat

- Proceso Etilbenceno 311280Dokumen26 halamanProceso Etilbenceno 311280itzelefavBelum ada peringkat

- Austrian 25Dokumen13 halamanAustrian 25Vo Tung LamBelum ada peringkat

- Assignments 4SY2015 2016Dokumen6 halamanAssignments 4SY2015 2016Carlito H. Monasque Jr.Belum ada peringkat

- AS HydroDokumen3 halamanAS HydroNaeemMushtaqBelum ada peringkat

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasDari EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasBelum ada peringkat

- SKKK1113 Tutorial Assignment-04-ReactiveDokumen2 halamanSKKK1113 Tutorial Assignment-04-ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET0194Belum ada peringkat

- Flowsheet Development and Simulation of Ethane Production From Synthesis Gas by Using HysysDokumen9 halamanFlowsheet Development and Simulation of Ethane Production From Synthesis Gas by Using HysysazimBelum ada peringkat

- ErwerDokumen9 halamanErwerPriska Jesika MonanginBelum ada peringkat

- 1263 3507 1 PBDokumen5 halaman1263 3507 1 PBJohn TorrezBelum ada peringkat

- Ethylene Production Via Partial Oxidation and Pyrolysis of Ethane - M. Dente, A. Berettal, T. Faravelli, E. Ranzi, A. Abbr, M. Notarbartolo PDFDokumen6 halamanEthylene Production Via Partial Oxidation and Pyrolysis of Ethane - M. Dente, A. Berettal, T. Faravelli, E. Ranzi, A. Abbr, M. Notarbartolo PDFAlejandro HernandezBelum ada peringkat

- Jasmin Malhotra Enthalpy Report - FinalDokumen9 halamanJasmin Malhotra Enthalpy Report - Finalapi-2876652020% (1)

- Ethylene PropyleneDokumen40 halamanEthylene PropyleneSiva KumarBelum ada peringkat

- Process DesignDokumen6 halamanProcess DesignSwathi NiraleBelum ada peringkat

- Detailed Solutions To ExercisesDokumen123 halamanDetailed Solutions To Exerciseslutfi awn100% (4)

- Laboratory Exercise 3 - AdU1sAY2223 - ANIESDokumen2 halamanLaboratory Exercise 3 - AdU1sAY2223 - ANIESRhean Rheign VergaraBelum ada peringkat

- TOURTON-páginas-37-124-73-88 PDFDokumen16 halamanTOURTON-páginas-37-124-73-88 PDFJesús David González CañasBelum ada peringkat

- FF PDFDokumen19 halamanFF PDFSyed Shamsul ArefinBelum ada peringkat

- Simulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationDokumen9 halamanSimulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationHaris Surya HidayatBelum ada peringkat

- Uj 36637+SOURCE1+SOURCE1.1Dokumen7 halamanUj 36637+SOURCE1+SOURCE1.1pulezanele11Belum ada peringkat

- 2020 UKChO ASDAN FinalDokumen16 halaman2020 UKChO ASDAN FinalXuBelum ada peringkat

- Chapter 11: Combustion: David BaylessDokumen19 halamanChapter 11: Combustion: David BaylessHopeBelum ada peringkat

- Ekc 336 Chemical Reaction Engineering: Reactor Design of Ethylene Oxide (Eo) ProductionDokumen24 halamanEkc 336 Chemical Reaction Engineering: Reactor Design of Ethylene Oxide (Eo) ProductionYou Jin JieBelum ada peringkat

- UDEC1134 Chemistry UDEC1134 Chemistry Laboratory I Laboratory I Bachelor of Science Bachelor of Science (HONS) Chemistry (HONS) ChemistryDokumen7 halamanUDEC1134 Chemistry UDEC1134 Chemistry Laboratory I Laboratory I Bachelor of Science Bachelor of Science (HONS) Chemistry (HONS) ChemistryWENDY NATHALIA ROJAS ARCEBelum ada peringkat

- SC 2005 2317Dokumen8 halamanSC 2005 2317alirezamman20Belum ada peringkat

- UEMK1103 AssignmentDokumen12 halamanUEMK1103 AssignmentHan Chuan ChuanBelum ada peringkat

- Tutorial Sheet 1: Chem 2002 - Process Systems Analysis - 2016-2017Dokumen20 halamanTutorial Sheet 1: Chem 2002 - Process Systems Analysis - 2016-2017ajali1957Belum ada peringkat

- T10 QuestionsDokumen20 halamanT10 Questionsleafar96100% (4)

- As Expt 2.1 (4) - Enthalpy of Formation of CaCO3Dokumen4 halamanAs Expt 2.1 (4) - Enthalpy of Formation of CaCO3Diddled_skittles100% (1)

- Assignment 1 Organic ChemistryDokumen9 halamanAssignment 1 Organic ChemistryAnotidaishe MugadzaBelum ada peringkat

- Enthalpy Formation CaCO3Dokumen7 halamanEnthalpy Formation CaCO3saBelum ada peringkat

- 03 - Trích IChO 32nd - Dap AnDokumen25 halaman03 - Trích IChO 32nd - Dap AnTạ Đình TrungBelum ada peringkat

- Organic ChemistryDokumen24 halamanOrganic ChemistryNivas KaruppananBelum ada peringkat

- Selected Constants: Oxidation–Reduction Potentials of Inorganic Substances in Aqueous SolutionDari EverandSelected Constants: Oxidation–Reduction Potentials of Inorganic Substances in Aqueous SolutionBelum ada peringkat

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesDari EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesBelum ada peringkat

- Efficiency of Biomass Energy: An Exergy Approach to Biofuels, Power, and BiorefineriesDari EverandEfficiency of Biomass Energy: An Exergy Approach to Biofuels, Power, and BiorefineriesBelum ada peringkat

- A Modern Course in Statistical PhysicsDari EverandA Modern Course in Statistical PhysicsPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- StructureDokumen9 halamanStructureRafael SouzaBelum ada peringkat

- Chapter 09 Solutions Physics PDFDokumen14 halamanChapter 09 Solutions Physics PDFBon Bon100% (1)

- Chapter 09 Solutions Physics PDFDokumen14 halamanChapter 09 Solutions Physics PDFBon Bon100% (1)

- Uses of Styrene MonomerDokumen4 halamanUses of Styrene MonomerBon BonBelum ada peringkat

- Port Neches Groves ISD No267 Huntsman Petrochemical LLC Supplemental MaterialDokumen15 halamanPort Neches Groves ISD No267 Huntsman Petrochemical LLC Supplemental MaterialBon BonBelum ada peringkat

- Nitric AcidDokumen31 halamanNitric AcidBon Bon100% (1)

- Nitric Acid Plant DetailsDokumen21 halamanNitric Acid Plant DetailsBon BonBelum ada peringkat

- LeachingDokumen21 halamanLeachingBon Bon100% (1)

- LeachingDokumen21 halamanLeachingBon Bon100% (1)

- Applying The: Taking Care of The World's WaterDokumen8 halamanApplying The: Taking Care of The World's WaterBon BonBelum ada peringkat

- 1 KineticsDokumen5 halaman1 KineticsBon BonBelum ada peringkat

- PVP Glass TransitionDokumen10 halamanPVP Glass TransitionEric SandoukBelum ada peringkat

- Chapter 7. Electron Delocalization and ResonanceDokumen44 halamanChapter 7. Electron Delocalization and ResonancethanhnguyenhhvnBelum ada peringkat

- My Crusade To Fend Off: Antal E. FeketeDokumen12 halamanMy Crusade To Fend Off: Antal E. FeketelarsrordamBelum ada peringkat

- Bond Valuation With PluginsDokumen23 halamanBond Valuation With PluginsHu-Jean RussellBelum ada peringkat

- Answer Key: Chemistry 206 First Hour ExaminationDokumen9 halamanAnswer Key: Chemistry 206 First Hour Examinationsudipta88Belum ada peringkat

- 11 - Topic 20 Organic Chemistry AnswersDokumen60 halaman11 - Topic 20 Organic Chemistry AnswersNeen NaazBelum ada peringkat

- Chen Feb 07Dokumen9 halamanChen Feb 07Debdeep RayBelum ada peringkat

- Financial Asset at Amortized CostDokumen4 halamanFinancial Asset at Amortized Costramir maglangitBelum ada peringkat

- Coordination Compounds Multiple C. QuesDokumen6 halamanCoordination Compounds Multiple C. QuesShivam KumarBelum ada peringkat

- Quiz 3Dokumen131 halamanQuiz 3afeeraBelum ada peringkat

- Current State and Future Outlook of The Construction Administration Practices in KenyaDokumen38 halamanCurrent State and Future Outlook of The Construction Administration Practices in KenyaIzo SeremBelum ada peringkat

- Basic Features of BondsDokumen1 halamanBasic Features of Bondspmaina100% (1)

- Practica Organica 3Dokumen6 halamanPractica Organica 3Manuel Giraldo VelasquezBelum ada peringkat

- Functional GroupsDokumen5 halamanFunctional GroupsGian Austin R. AngelesBelum ada peringkat

- Unit 15 - Reaction Rates and EquilibriumDokumen68 halamanUnit 15 - Reaction Rates and EquilibriumGarett Berumen-RoqueBelum ada peringkat

- Adhesive Technology & Formulations (Technology Book)Dokumen18 halamanAdhesive Technology & Formulations (Technology Book)Vijay Gupta46% (13)

- ChecklistDokumen18 halamanChecklistAdzcer HadullaBelum ada peringkat

- Observations On The Deprotection of Pinanediol and Pinacol Boronate Esters Via Fluorinated IntermediatesDokumen4 halamanObservations On The Deprotection of Pinanediol and Pinacol Boronate Esters Via Fluorinated IntermediatesSilvanaMedhatBelum ada peringkat

- PC No.19 Updated 1Dokumen661 halamanPC No.19 Updated 1Amalina YaniBelum ada peringkat

- Customized Geometric Risk Premium EstimatorDokumen40 halamanCustomized Geometric Risk Premium EstimatorVíctor GómezBelum ada peringkat

- Chapter 13 Introduction To Polymer (Edited)Dokumen36 halamanChapter 13 Introduction To Polymer (Edited)Clementz WS100% (1)

- Fort Bliss Job Order ContractDokumen446 halamanFort Bliss Job Order ContractNick AndrewsBelum ada peringkat

- An Introduction To Infrared and UV-Visible SpectrosDokumen45 halamanAn Introduction To Infrared and UV-Visible SpectrosArvandz_tea100% (1)

- Investment Management: We Shall Cover: Equity Portfolio Management Debt Portfolio ManagementDokumen14 halamanInvestment Management: We Shall Cover: Equity Portfolio Management Debt Portfolio ManagementsidhanthaBelum ada peringkat

- SN1, SN2, 1Dokumen66 halamanSN1, SN2, 1Muhsin Mukhtar S. Farm100% (1)

- Starch Cross LinkingDokumen217 halamanStarch Cross LinkingMark VicsonBelum ada peringkat

- Chap2 IR LectureNote DRK 110929Dokumen28 halamanChap2 IR LectureNote DRK 110929Aby JatBelum ada peringkat

- Atoms, Molecules & Stoichiometry RedoxDokumen189 halamanAtoms, Molecules & Stoichiometry RedoxPriscilla TjjBelum ada peringkat

- Acid Hydrolysis of DNA Isolated From Allium Cepa and Analysis of DNA Components Using Qualitative Color Reaction TestDokumen6 halamanAcid Hydrolysis of DNA Isolated From Allium Cepa and Analysis of DNA Components Using Qualitative Color Reaction Testmissy_macy11100% (1)