Rail Conf

Diunggah oleh

ภาคใต้โพสต์ southernpostJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Rail Conf

Diunggah oleh

ภาคใต้โพสต์ southernpostHak Cipta:

Format Tersedia

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 1/16

Geological Engineering Engineering Professional Development Civil & Environmental Engineering

James Tinjum, PE, PhD

Tuncer Edil, PE, PhD

Damien Hesse, MS Candidate

Tolga Dolcek, MS Candidate

Ben Warren, MS Candidate

Remediating Fouled Ballast and

Enhancing Rail Freight Capacity

by Polyurethane Technology

UW-Madison Rail Substructure Research Program

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 2/16

Background: Railway Track Components

Ballast

Tie

Subballast

Rail

Tie

Shoulder

Compacted Subgrade

Natural Subgrade

Subgrade S

u

b

s

t

r

u

c

t

u

r

e

S

u

p

e

r

-

s

t

r

u

c

u

t

u

r

e

Fastening

System

Deterioration in the substructure leads to permanent deformation in

the track, threatening rail operations

Prevent track deformation while enhancing rail operations

Ballast layer deteriorates under numerous loading repetitions

Problem:

Objective:

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 3/16

Motivation: Track Maintenance Costs

Maintenance of ballast is $500M/ year

For 150,000 km of Class 1 freight rail in the US,

(Chrismer and Davis 2000)

Fouling Level Increases During Service Life of Track

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 4/16

Types of Fouling

Coal Fouling Mineral Fouling

Clay Fouling

Non-Cohesive Fouling (i.e., between P4 & P200)

Clay/Cohesive Fouling

(i.e., P200)

Frac Sand

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 5/16

Frac Sand Industry

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 6/16

Large-Scale Cyclic Triaxial (LSCT)

600-mm

Cyclic loading machine

to simulate railway traffic

Automated data acquisition

system (LabVIEW)

Axle load: 20, 30, and 40 tons

Equivalent to:

Deviator Stress, = 300 kPa

Confining Stress, = 90 kPa

(Ebrahimi 2011)

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 7/16

Ebrahimi, A., Tinjum, M. J., Edil, T. B., 2010, LARGE-SCALE, CYCLIC TRIAXIAL TESTING OF RAIL BALLAST, AREMA 2010 Annual Conference, Orlando, FL.

Example Results

Deformational Characteristics of Ballast

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 8/16

Permanent Deformation with Moisture

w= % of moisture

FI= Fouling Index (%)= P4+P200

GT= Gross Tones for Traffic

6

10

30 N

MGT

Million Gross Tones =

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 9/16

0.0%

0.5%

1.0%

1.5%

2.0%

2.5%

3.0%

1 100 10,000 1,000,000

P

l

a

s

t

i

c

S

t

r

a

i

n

(

%

)

Number of Cycles

Igneous Ballast, 70/140 Frac Sand

w=0

w=4

w=14

EPD Short Course

J.M. Tinjum

Slide 9

Mitigating and Monitoring Railway Ballast

Fouling Mechanisms

September 24, 2013

0.0%

1.0%

2.0%

3.0%

4.0%

5.0%

6.0%

7.0%

8.0%

1 100 10,000 1,000,000

P

l

a

s

t

i

c

S

t

r

a

i

n

(

%

)

Number of Cycles

Dolomite Ballast, 20/40 Frac Sand

w=0

w=4

w=14

0.0

0.1

0.2

0.3

0.4

0.5

0.6

1 100 10,000 1,000,000

R

a

t

e

o

f

P

l

a

s

t

i

c

S

t

r

a

i

n

Number of Cycles

Dolomite Ballast, 20/40 Frac Sand

w=0

w=4

w=14

0.00

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0.09

0.10

1 100 10,000 1,000,000

R

a

t

e

o

f

P

l

a

s

t

i

c

S

t

r

a

i

n

(

%

)

Number of Cycles

Igneous Ballast, 70/140 Frac Sand

w=0

w=4

w=14

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 10/16

Leading to the Dip in the Track

Mile marker 74.7 part of the Dayton Dip located near Ottowa, IL

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 11/16

UW-Madison Railroad Research

Mitigating Ballast Fouling Impact and Enhancing Rail

Freight Capacity

Prevent ballast layer deterioration and track deformation

Enhance railway track capacity and maintained capabilities

Polyurethane reinforcement of ballast layer is proposed

Steve

Reed

Dr. Randy Brown Andrew Keene

Ben

Warren

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 12/16

Uretek Polyurethane

Uretek Polyurethane:

High density expanding thermoset resin system

Reaches 90% of full compressive and tensile strength in

15 minutes

Research Involves Use of Technology With Rail Ballast

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 13/16

Materials: Uretek USA Inc. Polyurethane

Uretek Polyurethane: Rigid-Polyurethane Foam

High density, expanding, thermoset, resin system

Reaches 90% of full compressive and tensile strength in

15 minutes

Research Involves Use of Technology With Rail Ballast

Rigid-Polyurethane Foam (RPF)

Polyurethane-Stabilized Ballast (PSB)

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 14/16

Methods: Large-Scale Cyclic Triaxial (LSCT)

600-mm

Cyclic loading machine

to simulate railway traffic

Automated data acquisition

system (LabView)

Axle load: 20, 30, and 40 tons

Equivalent to:

Deviator Stress, = 300 kPa

Confining Stress, = 90 kPa

(Ebrahimi 2011)

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 15/16

Flexural Beam Testing

L = 0.4 m

Unconfined Compressive Strength Testing

L = 0.76 m

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 16/16

0

0.5

1

1.5

2

2.5

3

3.5

300 350 375 400

C

u

m

u

l

a

t

i

v

e

P

l

a

s

t

i

c

S

t

r

a

i

n

,

P

(

%

)

Deviator Stress,

d

(kPa)

Fouled Ballast, FI 5% & MC 15%

Clean Ballast

PS-Clean Ballast

PS-Fouled Ballast, FI 25% & MC 15%

PS-Recycled Ballast, P25.4 mm & R19 mm

Results: Stabilized and Un-stabilized

MC = % Moisture Content

FI = Fouling Index (%)= P4+P200

Clean Ballast Reference Line

PS = Polyurethane Stabilized

P4 = 4.75 mm

P200 = 0.075 mm

Tested over 200,000 loading repetitions in cyclic triaxial compression

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 17/16

PSB and Constituent Mechanical Properties

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

C

o

m

p

r

e

s

s

i

v

e

F

l

e

x

u

r

a

l

T

e

n

s

i

l

e

C

o

m

p

r

e

s

s

i

v

e

F

l

e

x

u

r

a

l

T

e

n

s

i

l

e

C

o

m

p

r

e

s

s

i

v

e

F

l

e

x

u

r

a

l

T

e

n

s

i

l

e

PSB RPF Ballast

M

e

c

h

a

n

i

c

a

l

S

t

r

e

n

g

t

h

s

(

k

P

a

)

0

50

100

150

200

250

300

350

400

450

500

C

o

m

p

r

e

s

s

i

v

e

F

l

e

x

u

r

a

l

T

e

n

s

i

l

e

C

o

m

p

r

e

s

s

i

v

e

F

l

e

x

u

r

a

l

T

e

n

s

i

l

e

C

o

m

p

r

e

s

s

i

v

e

F

l

e

x

u

r

a

l

T

e

n

s

i

l

e

PSB RPF Ballast

E

l

a

s

t

i

c

M

o

d

u

l

i

(

M

P

a

)

RPF

= 200 kg/m

3

b

= 1,580 kg/m

3

RPF = Rigid Polyurethane Foam

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 18/16

Material Property Summary

Mechanical Properties

PSB plastic deformational behavior far less than clean

ballast, recycled ballast, and fouled ballast

PSB elastic moduli typically less than ballast

Further Considerations and Restated Questions:

Effect of lower modulus on overall track response?

Fatigue lifecycle for PSB layers?

Next Step: Modeling PSB in Track-Substructure

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 19/16

PSB Model Percolation-Injection

RPF = Rigid Polyurethane Foam

Concept: Model percolation-

injection method for PSB

stabilization

Goal: Determine track elastic

response

Result: Areas of lower modulus

did not have negative impact

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 20/16

3DView

Longitudinal View

Lateral View

PSB Trackbed Layer

PSB Model Subsurface-Injection

Concept: Model subsurface-injection method

for PSB trackbeds

Goal: Determine strain at base of layer for

input into analytical fatigue model

Result: Strain measured would give PSB

fatigue lifecycle at 500-1000 MGT

RPF = Rigid Polyurethane Foam

t

= Flexural Strain

(Rose & Konduri 2006)

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 21/16

Conclusions

Mechanical Properties

PSB outperforms other track-substructure materials

PSB had typically higher elastic deformational behavior

Feasibility of Stabilization in Track-Substructure

Stabilization does not have negative impact on elastic response

Injection methods are feasible for track stabilization

PSB can greatly increase track mechanistic lifecycle

2013 WisDOT Freight Railroad Conference November 13, 2013 Tinjum and Edil

Crowne Plaza Hotel Slide 22/16

Questions?

Acknowledgements

Center for Freight Infrastructure

Research and Education (CFIRE)

Uretek USA Inc.

UW-Madison Laboratory Staff:

William Lang

Xiaodong Buff Wang

Special Thanks To:

Dr. Ali Ebrahimi

Zhipeng Su

References

ASTM Standards, Annual Book of ASTM Standards, ASTM

International, West Conshohocken, PA

Ebrahimi, A. (2011). Deformational Behavior of Fouled Railway

Ballast. PhD thesis, Department of Civil and Environmental

Engineering, University of Wisconsin, Madison.

Ebrahimi, A. and Keene, A.K. Maintenance Planning of Railway Ballast,

In proceedings of the AREMA 2011 Annual Conference,

Minneapolis, Minnesota, September 18-22.

Keene, A. (2012). Mitigating ballast fouling and enhancing rail-freight

capacity. MS thesis, Dept. of Civil and Env. Eng., University of

Wisconsin-Madison.

Rose, J.G. & Konduri, K.G. (2006). "KENTRACKA Railway Trackbed

Structural Design Program." AREMA 2006 Annual Conference,

Louisville, Kentucky, September 17-20.

Gizem Bozkurt

Ben Warren

Anda mungkin juga menyukai

- College of Engineering 2009 Annual ReportDokumen36 halamanCollege of Engineering 2009 Annual ReportSandy Knisely BarnidgeBelum ada peringkat

- Su, Fratta, Tinjum, EdilDokumen23 halamanSu, Fratta, Tinjum, Edilภาคใต้โพสต์ southernpostBelum ada peringkat

- Pavement Ch2 CompressedDokumen81 halamanPavement Ch2 Compressedภาคใต้โพสต์ southernpostBelum ada peringkat

- University of Wisconsin System Solid Waste Research Program: Student Project ReportDokumen22 halamanUniversity of Wisconsin System Solid Waste Research Program: Student Project Reportภาคใต้โพสต์ southernpostBelum ada peringkat

- Railway SubstructureDokumen16 halamanRailway Substructureภาคใต้โพสต์ southernpostBelum ada peringkat

- Ref Paper For Soil EngineeringDokumen36 halamanRef Paper For Soil Engineeringภาคใต้โพสต์ southernpostBelum ada peringkat

- Su, Fratta, Tinjum, EdilDokumen23 halamanSu, Fratta, Tinjum, Edilภาคใต้โพสต์ southernpostBelum ada peringkat

- College of Engineering 2009 Annual ReportDokumen36 halamanCollege of Engineering 2009 Annual ReportSandy Knisely BarnidgeBelum ada peringkat

- Pavement Design Good Ref.Dokumen68 halamanPavement Design Good Ref.ภาคใต้โพสต์ southernpost100% (2)

- Railway SubstructureDokumen16 halamanRailway Substructureภาคใต้โพสต์ southernpostBelum ada peringkat

- Railway SubstructureDokumen17 halamanRailway Substructureภาคใต้โพสต์ southernpostBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Biomedical Applications of Composite MaterialsDokumen30 halamanBiomedical Applications of Composite MaterialsRita Singh50% (2)

- Technical Data 30RH040-240Dokumen16 halamanTechnical Data 30RH040-240Jhair Diaz AranaBelum ada peringkat

- 120201Dokumen56 halaman120201dharwin apBelum ada peringkat

- LFA Glass and AluminumDokumen51 halamanLFA Glass and AluminumClef GonadanBelum ada peringkat

- Secco Hd5401Aa: High Density PolyethyleneDokumen2 halamanSecco Hd5401Aa: High Density PolyethyleneDarko KuroBelum ada peringkat

- Natural Gas Engineering StudentsDokumen35 halamanNatural Gas Engineering StudentsMahmoud Elaraby100% (1)

- Masonry Performance GuideDokumen5 halamanMasonry Performance GuideShivanan SinghBelum ada peringkat

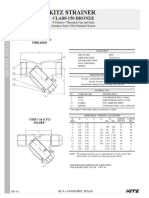

- Filtro FI180 Marca KitsDokumen1 halamanFiltro FI180 Marca KitsDianalys ArriecheBelum ada peringkat

- Piping Daily Progrss Report MMGP: Gulf Asia Contracting Company LLCDokumen3 halamanPiping Daily Progrss Report MMGP: Gulf Asia Contracting Company LLCAbdul raheem syedBelum ada peringkat

- Paper 1 3-D Analysis of Building Frame Using Staad-ProDokumen2 halamanPaper 1 3-D Analysis of Building Frame Using Staad-ProAnonymous CaemA1Belum ada peringkat

- Alun Thomas ArticleDokumen10 halamanAlun Thomas ArticleTansel YılmazBelum ada peringkat

- Solef PVDF 6008Dokumen2 halamanSolef PVDF 6008topteam123Belum ada peringkat

- Rothoblaas Terralock Technical-Data-Sheets en PDFDokumen5 halamanRothoblaas Terralock Technical-Data-Sheets en PDFCristina GhigheanuBelum ada peringkat

- Rapid depressurization of pressure vessels: predicting hazardous behaviorDokumen4 halamanRapid depressurization of pressure vessels: predicting hazardous behaviorthlim19078656Belum ada peringkat

- Circuits Education Presentation in Blue Yellow Flat Cartoon StyleDokumen14 halamanCircuits Education Presentation in Blue Yellow Flat Cartoon StyleMa Angelica BañariaBelum ada peringkat

- KMT - GLOBE - Manual (Ver0.2) - Eng - 16-2026 (2016.08.16)Dokumen21 halamanKMT - GLOBE - Manual (Ver0.2) - Eng - 16-2026 (2016.08.16)Ozi Fawzi100% (1)

- Sheet Metal. GaugeDokumen1 halamanSheet Metal. GaugeVinu VenkidachalamBelum ada peringkat

- Project Execution PlanDokumen60 halamanProject Execution PlanJohn MichaelBelum ada peringkat

- Mid If ItDokumen4 halamanMid If ItsncomputerBelum ada peringkat

- TRB 01 21 Rooftop Ductwork Round or RectangularDokumen4 halamanTRB 01 21 Rooftop Ductwork Round or Rectangularagb71c2478Belum ada peringkat

- 3 Distortion Energy Theory DerivationDokumen6 halaman3 Distortion Energy Theory DerivationVaisakh FSzBelum ada peringkat

- Data Sheet Purgador PT65-40Dokumen2 halamanData Sheet Purgador PT65-40Douglas Tondello100% (1)

- And Thermal Conductivity and Uses The VBA Functions For Those PropertiesDokumen6 halamanAnd Thermal Conductivity and Uses The VBA Functions For Those PropertiesselisenBelum ada peringkat

- IG Seismic Design HousesDokumen36 halamanIG Seismic Design HousesmarkBelum ada peringkat

- Cvg2140 - Tutorial 2 (SFDBMD)Dokumen2 halamanCvg2140 - Tutorial 2 (SFDBMD)Fadey FaridBelum ada peringkat

- Parallel Plate Flow EquationsDokumen1 halamanParallel Plate Flow EquationsS.A. BeskalesBelum ada peringkat

- CMV Fracture Toughness ArticleDokumen10 halamanCMV Fracture Toughness ArticleFlo RenceBelum ada peringkat

- Assignment One SolvedDokumen9 halamanAssignment One Solvedabebawabiyu100% (1)

- Quality Assurence Büscher 2006Dokumen71 halamanQuality Assurence Büscher 2006mustafBelum ada peringkat

- CONCRETE MIX DESIGN DETAILSDokumen18 halamanCONCRETE MIX DESIGN DETAILSInhinyero SibilBelum ada peringkat