Industrial Fans

Diunggah oleh

Alejandro AguanteDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Industrial Fans

Diunggah oleh

Alejandro AguanteHak Cipta:

Format Tersedia

Industrial Fans

Jonathan F. Hale, MPA

Air Systems Corporation

1

Air is a Fluid

Birds Swim In

It!

40,000 CFM = ? LBS.

AIR/HR.

Air

= .075

LBS.

1 CU. FT.

40,000 CFM = 90 TONS/HR.

= 3,000 LBS/MIN

FORWARD CURVED

50 - 60 % efficiency

Most Common Fan type in the world?

BACKWARDLY INCLINED

~ 79% max. efficiency

AIRFOIL (Bl)

82% max. efficiency

INDUSTRIAL EXHAUSTERS

55-70% EFFICIENCY

AXIAL (PROPELLER) FANS

UP TO 90% EFFICIENCY

INDUSTRIAL FANS

MODULE TOPICS

FAN IN AIR SYSTEM

FAN TYPES

FAN SELECTION

FAN TESTING

AIR DENSITY

FAN SAFETY

29

FANS ROLE IN AIR SYSTEM

30

The purpose of a fan is to supply an air

system with energy (in the form of pressure)

necessary to maintain airflow.

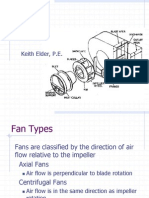

FAN TYPES

Centrifugal Fans

Air turns 90 through the fan.

Axial Fans

Air Flows straight through the fan.

Other Types

Special Design Fans.

31

CENTRIFUGAL FAN TYPES

Different Designs types are used to match System air flow and

static pressure requirements.

The Inlet and Outlet Sizes decrease relative to housing

diameter as the pressure developed increases.

32

CENTRIFUGAL FAN TYPES

Centrifugal Fans used in higher pressure lower flow, corrosive, or material

handling systems.

The Inlet and Outlet Sizes decrease relative to housing diameter as the

pressure developed increases.

Generally outlet velocity Range of 1250 to 6000 FPM Outlet Velocity

Centrifugal Fan pressure capabilities:

Backward Curved Centrifugals up to 20 SP

Industrial Exhausters up to 46 SP

Pressure Blowers up to 14 SP

Turbo Pressure Blowers up to 100 SP

33

AXIAL FAN TYPES

Different propeller types are used to match System air flow and static

pressure requirements.

The propeller hub diameter increases relative to the fan diameter as

the pressure developed increases.

34

AXIAL FAN TYPES

Axial Fans used in higher flow lower pressure systems.

Generally outlet velocity Range of 1000 to 4000 FPM Outlet

Velocity

Axial Fan Pressure capabilities:

General Ventilation Fans to 1/2 SP

Duct Fans to 1 1/4 SP

Duct Axial to 5 SP

Vane Axial to 10

35

OTHER AIR MOVING DEVICES

Special Designs

In Line Centrifugal

Mixed Flow

Centrifugal Power Roof Ventilators

Axial Power Roof Ventilators

Ejectors

36

FAN SYSTEM CALCULATION

37

ACGIH Velocity Pressure

Method Calculation

Sheet

Calculate the required

flow through the system.

Calculate the static

pressure required to

move the required flow.

CFM & SP will develop a

System Curve.

SYSTEM SP provides the Fan SP

SYSTEM CFM = FLOW

SYSTEM SP SP SP VP

out in in

= SYSTEM SP SP SP VP

out in in

=

FAN SELECTION

System Calculation

Flow or Capacity

Pressure Requirements

System Resistance Curve

System Losses Plotted

38

2

2

CFM x Constant 0.075 x

1097 x Area

CFM

C x C =

(

= = VP

System

Loss

CFM

P

r

e

s

s

u

r

e

FAN SELECTION

Select a fan which will generate the required

pressure at the desired airflow.

Airflow

Desired CFM

P

r

e

s

s

u

r

e

P

o

w

e

r

HP vs. CFM

Required SP

System Curve

SP vs. CFM

39

FAN SELECTION

Other Considerations

Airstream

Materials through the fan

Explosive or Flammable Materials

Contaminated or Corrosive

Elevated Temperature

Physical Limitations

Fan Size and Type

Belt Drive vs. Direct Drive

Mounting Arrangement

Materials

First Cost, Operating Cost, Maintenance Cost

Other Factors including color

40

RATING TABLES AND PERFORMANCE

PROGRAMS

41

Selection and rating areas are defined by the Manufacturers,

Usually only good selections are shown.

Fan Performance tables are at Standard Conditions (0.075

lb./ft.

3

air density.)

Computer Software is available to provide selections and

performance curves.

The AMCA Certified Rating Program insures manufacturers

ratings.

FAN SELECTION

Ratings will include notes

on how the fan was tested

Open or Ducted Inlet

Open or Ducted Outlet

Belt losses may not be

included in the

performance ratings.

Accessories included in the

test

42

FAN PERFORMANCE

Test Equipment

Measure Flow (indirectly)

Pitot tube traverse

Flow Nozzle

Flow Measurement Station

Measure Fan Pressure

Inlet Pressure

Outlet Pressure

Measure Fan Power

Measure Fan Speed

Measure Temperature

Dry Bulb Temp.

Wet Bulb Temp.

Barometric Pressure

System Air Temp.

43

The Aerodynamic Performance Test

AMCA Standard 210 - "Laboratory Methods of Testing Fans for Certified

Aerodynamic Performance Rating

AMCA Standard 203 - "Field Performance Measurement of Fan Systems"

FAN PERFORMANCE

Manufacturers provide fan performance at many speeds and pressures.

The Fan Laws are used to calculate performance using well established

methods.

44

All fans have one thing in common:

Accurate prediction of aerodynamic

performance requires a test at:

Constant Speed,

Known Density

THE FAN LAWS

The Fan Laws are used to calculate fan performance at:

Other Speeds, Other Densities, Other Fan Sizes

45

First Law:

Second Law:

Third Law:

THE FAN LAWS

P

r

e

s

s

u

r

e

P

o

w

e

r

Airflow

Changes in Speed

46

FAN SELECTION

Select fan for Stable Operating Point

Interaction of Fan Performance Curve and System Curve

There is only one intersection between the fan curve and system

curve.

Fans are load matching devices.

Fans handle ACFM only.

47

P

r

e

s

s

u

r

e

P

o

w

e

r

Airflow

FAN ARRANGEMENT

AMCA Standard Drive Arrangements: Centrifugal or Axial

Belt Drive, Direct Drive, and Direct Coupled Arrangements

48

STANDARD AIR

Standard air is the reference gas for:

Fan Performance Ratings

Air System Design

Standard Density is 0.075

lb.

/

ft.

3

SCFM is not equal to ACFM

49

AIR DENSITY

Density effects Fan and System

Performance.

Density at a given temperature and

barometric pressure can be calculated:

Temp. F 460

F 70 F 460

x

Hg in. 29.92

press. Abs.

x

ft

lbm

0.075

3

+

+

50

AIR DENSITY

Industrial Ventilation Manual calculates density

using Density Factors:

df df df df df

df [1 (6.73 10 )(z)]

df (407 SP) (407)

df (530) (T 460)

df (1 ) (1 1.607 )

e p T m

e

6 5.258

p

T

m

= - - -

= -

= +

= +

= + +

e e

51

FAN SAFETY

Fans contain moving parts and can be

dangerous.

Install guards.

Know the Hidden Dangers

Suction and Pressure

Windmilling

Temperature

Noise and Environment

Stroboscopic Effect

Special Purpose Fans and Systems

Have a lock out procedure.

AMCA Publication 410-96, "Recommended

Safety Practices For Users and Installers of

Industrial and Commercial Fans" is an

excellent resource.

52

CONCLUSION

Proper Fan Application, Selection, Installation, and

Maintenance will result in excellent Fan System operations.

53

INSPECTION & MAINTENANCE

Inspection and routine maintenance on a periodic schedule of fan equipment is

necessary.

Historical records of fan condition and maintenance should be maintained and

compared with current conditions as they are indicators of upcoming problems.

Monitor and record vibration levels.

Sudden changes in fan performance, noise, or vibration levels are often a

precursor to breakdown.

Fans should be inspected for condition, material buildup, and erosion.

54

Anda mungkin juga menyukai

- Fan and BlowerDokumen58 halamanFan and BlowerKAZI SIAMUL ISLAM100% (1)

- Syllabus Fans and Blowers: Types, Performance Evaluation, Efficient System Operation, FlowDokumen16 halamanSyllabus Fans and Blowers: Types, Performance Evaluation, Efficient System Operation, FlowGaurav ShrivastavaBelum ada peringkat

- Fans and Blowers: Types, Operation, and Efficiency OptimizationDokumen27 halamanFans and Blowers: Types, Operation, and Efficiency Optimizationcvkalyan100% (1)

- Understanding Fan Operation and Performance - W. HilbishDokumen34 halamanUnderstanding Fan Operation and Performance - W. HilbishJosé Pedro Casagrande TrentínBelum ada peringkat

- Overview On FansDokumen54 halamanOverview On Fansniteshnerist100% (1)

- Part 1 - Fundamentals of Airflow, Fans & DuctDokumen49 halamanPart 1 - Fundamentals of Airflow, Fans & Ductkhanh.vecBelum ada peringkat

- Fan BlowerDokumen20 halamanFan BlowerShariq AliBelum ada peringkat

- Axial Fan PerformanceDokumen17 halamanAxial Fan Performancehassan wastiBelum ada peringkat

- The Basics of Fan Performance TablesDokumen5 halamanThe Basics of Fan Performance TablesTessfaye Wolde Gebretsadik100% (1)

- Main Fans: by Daniel Brassel (Cts - TPT)Dokumen41 halamanMain Fans: by Daniel Brassel (Cts - TPT)Mahmoud MohammadBelum ada peringkat

- Aeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramDokumen4 halamanAeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramAshraf KamalBelum ada peringkat

- Specific power consumption of air compressorsDokumen12 halamanSpecific power consumption of air compressorsHeet PatelBelum ada peringkat

- Wet Scrubber Application Guide: Impingement Plate Scrubbers Venturi Scrubbers Eductor Venturi ScrubbersDokumen17 halamanWet Scrubber Application Guide: Impingement Plate Scrubbers Venturi Scrubbers Eductor Venturi ScrubbersAlvaro MathisonBelum ada peringkat

- Fan Performance CurveDokumen4 halamanFan Performance CurvemuddogBelum ada peringkat

- Basic Fan Engineering NotesDokumen5 halamanBasic Fan Engineering NotesrentboyrodriguezBelum ada peringkat

- Centrifugal Fan: Prepared byDokumen25 halamanCentrifugal Fan: Prepared bySham FerrerBelum ada peringkat

- 9.0 Dust Collection SystemsDokumen15 halaman9.0 Dust Collection SystemsNol BarandonBelum ada peringkat

- Hood Design Data - Range of Capture VelocitiesDokumen3 halamanHood Design Data - Range of Capture VelocitieszshehadehBelum ada peringkat

- Axial Fans Design PDFDokumen22 halamanAxial Fans Design PDFuuur35Belum ada peringkat

- Training DuctingDokumen20 halamanTraining Ductingpanji uteBelum ada peringkat

- BlowersDokumen58 halamanBlowersmahmad61100% (1)

- Advantages and Disadvantages : ParticlesDokumen6 halamanAdvantages and Disadvantages : Particlesbavani_84Belum ada peringkat

- Essential Guide to Compressed Air SystemsDokumen35 halamanEssential Guide to Compressed Air SystemsvmramakrishnanBelum ada peringkat

- Compressed Air System Design ManualDokumen26 halamanCompressed Air System Design ManualBadrul HishamBelum ada peringkat

- Duct Design For "Super" SupermarketDokumen47 halamanDuct Design For "Super" Supermarketkevin_thian_1100% (4)

- Duct DesignDokumen49 halamanDuct DesignabianshbaralBelum ada peringkat

- Chapter-Fans and BlowersDokumen21 halamanChapter-Fans and BlowersRathish RaghupathyBelum ada peringkat

- Cooling Fan Selection Calculations PDFDokumen1 halamanCooling Fan Selection Calculations PDFvinodsnBelum ada peringkat

- Fan Selection and Performance FactorsDokumen13 halamanFan Selection and Performance FactorstejasckBelum ada peringkat

- Fan Source BookDokumen92 halamanFan Source Bookapi-3808778100% (10)

- FanDokumen52 halamanFansahilchemBelum ada peringkat

- Fan Selection & PerformanceDokumen63 halamanFan Selection & PerformanceVishva Deepak MishraBelum ada peringkat

- Hibon PD BlowerDokumen3 halamanHibon PD BlowerAbhinav SaiBelum ada peringkat

- FA128-12 AnalysisLabExhaustDokumen4 halamanFA128-12 AnalysisLabExhaustTomy WongBelum ada peringkat

- 425-7-Fans 2006Dokumen23 halaman425-7-Fans 2006Niong DavidBelum ada peringkat

- Project Standards and Specifications Fan and Blower Systems Rev01Dokumen12 halamanProject Standards and Specifications Fan and Blower Systems Rev01vominhthaiBelum ada peringkat

- Overview On FansDokumen44 halamanOverview On FansniteshneristBelum ada peringkat

- PDH CompressorsDokumen90 halamanPDH CompressorsLawren Ignatius100% (2)

- Fan BasicsDokumen6 halamanFan BasicsPankaj Patil100% (1)

- AHU FansDokumen14 halamanAHU Fansmirali74Belum ada peringkat

- Fans Pumps Compressors and BlowersDokumen6 halamanFans Pumps Compressors and BlowersKentloyskiBelum ada peringkat

- Energy Audit Inbuilding FansDokumen91 halamanEnergy Audit Inbuilding FansPravin KumarBelum ada peringkat

- CLCH PRC008 enDokumen352 halamanCLCH PRC008 enOscar Andrés PavónBelum ada peringkat

- Chiller Ahu and Fcu SystemsDokumen67 halamanChiller Ahu and Fcu Systemsrawand adnanBelum ada peringkat

- Fan & SystemDokumen31 halamanFan & SystemAlberto FranciscoBelum ada peringkat

- CHILLER, AHU and FCU SYSTEMSDokumen67 halamanCHILLER, AHU and FCU SYSTEMSAnonymous zpy8Ea9uBelum ada peringkat

- Compressed Air Systems, PDH Course M146Dokumen91 halamanCompressed Air Systems, PDH Course M146cramerps2084Belum ada peringkat

- M 385 ContentDokumen47 halamanM 385 ContentSalmanul FareziBelum ada peringkat

- Basic Fan SelectionDokumen4 halamanBasic Fan Selectioncem_kamalBelum ada peringkat

- Selection of Fans For Thermal PDFDokumen188 halamanSelection of Fans For Thermal PDFhardik033Belum ada peringkat

- HevcaDokumen3 halamanHevcavirtechBelum ada peringkat

- Ventilation FundamentalsDokumen24 halamanVentilation FundamentalsSomnath SenBelum ada peringkat

- Industrial VentilationsDokumen47 halamanIndustrial VentilationsAta AtefBelum ada peringkat

- Fan Performance EvaluationDokumen24 halamanFan Performance EvaluationjohnBelum ada peringkat

- Fan SelectionDokumen61 halamanFan SelectionJugmohunBelum ada peringkat

- Fans, Blowers and CompressorsDokumen29 halamanFans, Blowers and CompressorsMohammed.abudi1996Belum ada peringkat

- Fans in Thermal Power PlantsDokumen3 halamanFans in Thermal Power PlantsMuhammad Nadeem RazaBelum ada peringkat

- Centrifugal FansDokumen19 halamanCentrifugal FansMark John Santos60% (5)

- Air CompressorDokumen31 halamanAir CompressorEr Bali Pandhare33% (3)

- Project Standards and Specifications Piping Design Criteria Rev1.0Dokumen15 halamanProject Standards and Specifications Piping Design Criteria Rev1.0Alejandro AguanteBelum ada peringkat

- Metraflex Expansion Joints PDFDokumen32 halamanMetraflex Expansion Joints PDFleventozenBelum ada peringkat

- Piping and Instrument Diagram (P&id) Standard Symbols Detailed DocumentationDokumen15 halamanPiping and Instrument Diagram (P&id) Standard Symbols Detailed Documentationautomationforum92% (103)

- Acoplamiento de Disco FreedomDokumen55 halamanAcoplamiento de Disco FreedomAlejandro Aguante100% (2)

- Diseño de Cimentaciones PDFDokumen134 halamanDiseño de Cimentaciones PDFAlejandro AguanteBelum ada peringkat

- Acoplamientos FalkDokumen8 halamanAcoplamientos Falkramart67% (3)

- Climaveneta Accurate Close Control Server UnitsDokumen32 halamanClimaveneta Accurate Close Control Server UnitsRobin DittoBelum ada peringkat

- For An Air-Conditioning System The Plant 170 LB of Delivered by Its Compressor Is 60Dokumen3 halamanFor An Air-Conditioning System The Plant 170 LB of Delivered by Its Compressor Is 60Rockydel MontesBelum ada peringkat

- AHRI Standard 441 SI 2019Dokumen26 halamanAHRI Standard 441 SI 2019sofyangunawanBelum ada peringkat

- Ma 110Dokumen2 halamanMa 110Jari JokipiiBelum ada peringkat

- Hisense Indoor Unit SelectionDokumen8 halamanHisense Indoor Unit SelectionSaahil KhaanBelum ada peringkat

- Contractor 1Dokumen2 halamanContractor 1lhhjklll100% (1)

- Meaco 20L Medium Home Dehumidifier Instruction Manual - December - 2011 PDFDokumen16 halamanMeaco 20L Medium Home Dehumidifier Instruction Manual - December - 2011 PDFtintucinbBelum ada peringkat

- Problem Set 2Dokumen3 halamanProblem Set 2alfa_macasaet100% (1)

- Hvac Design of HospitalDokumen9 halamanHvac Design of HospitalSaurav Verma0% (1)

- MRT (Seleksi Ac)Dokumen4 halamanMRT (Seleksi Ac)Fauzi Rahman100% (1)

- Write Up On Under Floor Air Distribution SystemDokumen7 halamanWrite Up On Under Floor Air Distribution SystemNitin GheediaBelum ada peringkat

- HC 150 Dew 150 ManualDokumen47 halamanHC 150 Dew 150 Manualpburks254647Belum ada peringkat

- 49-Working With The New Hydronic Heat Loss Short FormDokumen8 halaman49-Working With The New Hydronic Heat Loss Short Formshivas34regalBelum ada peringkat

- Catalogo Tecnico HW Triple Inv Publ69911203 Yhjke 12 To 24 ZjmexcorxDokumen2 halamanCatalogo Tecnico HW Triple Inv Publ69911203 Yhjke 12 To 24 ZjmexcorxCarlos Perez PerezBelum ada peringkat

- Handbook-RefrigerationDokumen67 halamanHandbook-RefrigerationDDCMBelum ada peringkat

- Fundamentals of RefrigerationDokumen1 halamanFundamentals of RefrigerationDheeraj KashyapBelum ada peringkat

- Quotation - RefrigDryer D600IN-A To D5400IN-ADokumen9 halamanQuotation - RefrigDryer D600IN-A To D5400IN-Abiberius100% (1)

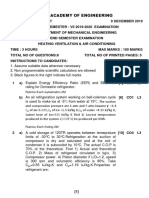

- MIT ACADEMY OF ENGINEERING COURSE CODE: ME401T END SEMESTER EXAMINATION HEATING VENTILATION & AIR CONDITIONINGDokumen5 halamanMIT ACADEMY OF ENGINEERING COURSE CODE: ME401T END SEMESTER EXAMINATION HEATING VENTILATION & AIR CONDITIONINGVishal GaikwadBelum ada peringkat

- Comparing Thai and ASHRAE Outdoor Air Supply Standards for Cold Storage FacilitiesDokumen30 halamanComparing Thai and ASHRAE Outdoor Air Supply Standards for Cold Storage FacilitiesTheerat KanthapornBelum ada peringkat

- Air-cooled solar absorption air conditioningDokumen230 halamanAir-cooled solar absorption air conditioningrezarossBelum ada peringkat

- Ac 111Dokumen1 halamanAc 111Surya LiemBelum ada peringkat

- Interklima CB1 FCUDokumen32 halamanInterklima CB1 FCUnomi1873Belum ada peringkat

- Thermodynamic Analysis of Vapour Cascade Refrigaration System Using R-12 & R-404a (Alternative Refrigarent)Dokumen34 halamanThermodynamic Analysis of Vapour Cascade Refrigaration System Using R-12 & R-404a (Alternative Refrigarent)AndresBelum ada peringkat

- Affinity R Series Chiller D5407Dokumen45 halamanAffinity R Series Chiller D5407moldprematBelum ada peringkat

- Chapter 3-2Dokumen48 halamanChapter 3-2AHMEDBelum ada peringkat

- Sez KD09 12 15 18naDokumen18 halamanSez KD09 12 15 18naErich AutomatonBelum ada peringkat

- CV Ali EzzeddineDokumen3 halamanCV Ali EzzeddineOmar RajadBelum ada peringkat

- Controls, Start-Up, Operation, Service, and TroubleshootingDokumen126 halamanControls, Start-Up, Operation, Service, and TroubleshootingindraBelum ada peringkat

- BAS Point ScheduleDokumen16 halamanBAS Point Schedulesajeevi piumikaBelum ada peringkat

- Colibri StorkDokumen4 halamanColibri Storkbruce1312Belum ada peringkat