Basics of Flexible Bellows Couplings

Diunggah oleh

j.emmett.dwyer1033Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Basics of Flexible Bellows Couplings

Diunggah oleh

j.emmett.dwyer1033Hak Cipta:

Format Tersedia

PRECISION BELLOWS COUPLINGS

Bellows couplings are used where precise rotation, high speeds, and

dynamic motion must be transmitted. They exhibit zero backlash and

a high level of torsional stiffness, offering distinct performance

advantages. But proper sizing and handling are critical to their

successful implementation.

background

Bellows couplings first began to be widely used by machine tool builders in the mid-to-late 20

th

century.

With the advent of CNC technology, machine engineers started looing to improve upon some of the

negative influences traditional power transmission couplings can have on a precision rotary ! linear

motion system. "or those seeing to enhance CNC machine performance, the fle#ible metal bellows

offered a combination of attractive features, including natural balance, continuous symmetry, high

torsional stiffness, and a low moment of inertia. "or many, using the fle#ible bellows as a transmission

element meant not only that mechanical stiffness could be increased, but it also facilitated more

aggressive servo tuning, helping machines become faster and more accurate. $hroughout the %&'0(s

and %&&0(s a number of manufacturers, mostly in )ermany, began applying the formed metal bellows

into an increasing variety of baclash free fle#ible coupling systems, ranging in si*es corresponding to

tor+ue ratings from roughly 0.0, to %00,000 Nm. -reas of application for the bellows coupling also

e#panded into servo drive systems for printing, converting, and pacaging machinery, to name a few.

While bellows couplings are still considered by many to be a .uropean style technology, the worldwide

maret has grown significantly over the years, and they are becoming increasingly popular in North

-merica for a still growing range of high performance applications.

construction

With some e#ceptions, most bellows used in shaft coupling applications are made from one or more

layers of high grade stainless steel sheet, formed and plasma welded into a seamless tube, and either

rolled or hydroformed to produce the deep corrugations /convolutions0 which provide its fle#ibility. $he

resulting shape is one which is continuously symmetrical, and highly rigid about its rotational a#is, while

remaining fle#ible across all three other a#es1 parallel, angular and a#ial. Bellows are 2oined to the hubs

by crimping, welding, or bonding. $he end hubs and bellows are mounted onto a single mandrel during

assembly, with the ends of the mandrel matching the respective bore diameters of the coupling hubs,

guaranteeing concentricity. Bonding came into common practice in the late %&'0(s, with the advantage

being that it allows for the bellows to be floated between the two hubs, free of stress, until the bonding

agent cures. $his helps to avoid deformation or stress

concentration on the bellows, ensuring that it will run

smoothly, with consistent output rotation, once

installed. 3n cases where the coupling will be deployed in

corrosive environments or be sub2ected to temperature

e#tremes, either of which can cause the bond to brea

down, welded bellows-hub connections are preferred.

misalignment

Bellows couplings are often selected in place of low cost

2aw couplings and disc pac couplings by engineers

looing to benefit from their well documented

performance advantages. But they will only wor well to

those ends if shaft misalignment is addressed. Bellows couplings do not typically handle as much

misalignment as traditional fle#ible couplings, but impart relatively low restoring loads onto ad2acent

shafts and bearings while compensating for the levels of misalignment they are designed to handle.

When properly aligned, typically within 0.2-0.4mm parallel, they are fatigue resistant for an infinite

service life, with no maintenance re+uired. But if shaft alignment, especially parallel misalignment, is

not considered before replacing other types of couplings with bellows couplings, failures can result.

While reduced misalignment ratings can be viewed

as a drawbac, most e#perts in power transmission

would agree that, regardless of the coupling style

being used, proper shaft alignment always results in

longer life and smoother rotation for all drive line

components. Bellows couplings are not typically

intended to compensate for gross offsets /though

special high misalignment versions do e#ist0 but

rather to mitigate restoring forces between

reasonably well aligned shafts, while also remaining

as stiff as possible in rotation.

where they are used

high precision positioning1 When it comes to rotational positioning the benefits of *ero baclash and

high torsional stiffness are normally fairly obvious. 5ost motion from baclash is eliminated, and

torsional deflection /twisting0 between the input and the output of the coupling is minimi*ed. Bellows

couplings generally have the highest torsional stiffness of commercially available fle#ible shaft couplings.

-nother benefit results from its continuous symmetry. 6ost fle#ible power transmission elements have

some ind of asymmetry, which means that, due to misalignment, the coupling is under different stress

profiles at different points around a single rotation. $o varying degrees they build up and release energy

while rotating under misalignment, and have slight variations in their output speeds. 3n most

applications this is scarcely noticeable. 7owever in precision applications, where positional accuracy is

to be optimi*ed, the continuous symmetry of the bellows offers a measurable advantage.

highly dynamic motion: Bellows couplings are also well suited to highly dynamic motion profiles. $he

high torsional stiffness translates into shorter settling times when loads are abruptly started, stopped,

and reversed. -s the wea lin in most direct drive systems, the fle#ible coupling normally determines

the stiffness of the entire drive a#is. - coupling with higher torsional stiffness increases system natural

fre+uency and decreases oscillation amplitude, enabling faster moves. When properly si*ed, bellows

couplings allow designers to increase cycle rates in camming and reversing applications. 8ince bellows

couplings also tend to be offered in low mass moment of inertia configurations, they also play their part

in minimi*ing load inertia.

high rotational velocity: "or high rotational speeds, the same geometric characteristics come into play.

5ight weight, continuous symmetry, and uniform stress distribution all lend themselves to smooth,

stable running at high speeds. 8tandard bellows couplings are rated to run at %0,000 rpm, with the

limiting factor being the clamping hubs. 6uch higher speeds become possible through balancing of the

coupling assembly. 3n some instances, bellows couplings can be made to run at speeds in e#cess of

%00,000 rpm.

resistance to temperature extremes: When machinery will be sub2ected temperature e#tremes,

metallic couplings are normally favored over elastomeric couplings, as their mechanical properties

remain largely unchanged, even over a wide range of temperatures. When bonded 2oints are replaced

with welded 2oints, the bellows coupling meets this re+uirement. $he uni+ue advantage of bellows

couplings is that, unlie other types of maintenance free metallic couplings /i.e. fle#ible disc couplings0,

bellows couplings have a high tolerance for a#ial movement. $his allows them to absorb the a#ial

movement which can result from thermal growth in drive shafting and other structural changes in the

framewor of the machine. "or this reason, high tor+ue bellows couplings are often used in drive shaft

configurations for heavy e+uipment installed in remote areas.

sizing and selection

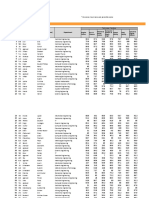

Bellows coupling si*ing is generally guided by 93N :40, which is comprised of four different formulas.

;<W offers a si*ing calculator to help simplify the si*ing process. "or reference, following is an

e#planation of the four ey si*ing formulas.

uniform load: 1x non-uniform load: 2x highly dynamic / reversing load: 3-x

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

selection according to tor"ue: Because they are normally installed in servo drive systems, bellows

couplings are si*ed for the pea tor+ue to be regularly transmitted. $he pea tor+ue of the application

should not e#ceed the rated tor+ue of the coupling. $he following calculation provides a safe

appro#imation of the minimum re+uired coupling si*e, and allows for the ma#imum speed and

misalignment to e#ist in the application.

selection according to acceleration tor"ue: - more detailed calculation taes acceleration and the

driving and driven moments of inertia into account. 8hoc ! load factors ranging from %-4 are applied,

depending on the dynamics of the application. "actors in the range of =-4 are normal for highly

dyanamic applications with multiple inde#es per second or fre+uent load reversals. - favorable driving

to driven inertia ratio diminishes the effect of the shoc ! load factor in the si*ing calculation.

selection according to torsional deflection: 8ince bellows couplings are often applied in situations

where positioning accuracy is critical, the following calculation is useful in determining the transmission

error as a result of torsional stress.

selection according to resonant fre"uency: $here are some rare cases in which the drive can pulse the

load in such a way as to e#cite the natural fre+uency of the mechanical system. 3n order to avoid this,

the torsional natural fre+uency of the mechanical system must be significantly higher or lower than that

of the e#citation fre+uency of the drive. 3n the case of torsionally stiff bellows couplings, the torsional

natural fre+uency should generally be significantly higher than the oscillation fre+uency from the motor.

$he torsional stiffness of the coupling generally determines the torsional natural fre+uency of the

complete system. $herefore the torsional stiffness of the coupling becomes a critical factor in

determining the natural fre+uency of the mechanical system. 3n the following two mass system

calculation, a value of fe > 2fer helps to ensure ade+uate stiffness for smooth, stable running.

$he ;<W bellows coupling si*ing program can be downloaded here1

info#rw-america#com/bellows-coupling-sizing-program

installation and handling

shaft alignment: When properly aligned,

theoretically infinite service life. 6any types of commercial electromechanical e+uipment have features

included in the frames to help guarantee precision alignment during installation. 6ost commonly these

are round centering pilots on motors, gearbo#es and linear actuators,

and highly concentric to their respective shafts and

male centering pilot, and driven e+uipment typically has a

frames are bolted together, these centering pilots hold everything

bellows coupling compensates for the slight misalignment that remains

e+uipment will be mounted to separate surfaces without

additional steps must be taen. -lignment between shafts

alignment tools, and ad2ustments made accordingly until the target alignment level has been reached.

3n those cases, bellows couplings with fully split clamping

hubs are often used, since they can be installed

after the shafts have been aligned. 3n cases where

precision shaft alignment is simply not practical, special

high misalignment bellows couplings are available which

can accommodate a parallel shaft misalignment of up to

%mm.

shaft locking: Because they tend to be used in high

performance applications, most bellows couplings are

mounted to their respective shafts and flanges by frictional clamping systems. $his helps to avoid the

baclash and stress concentrations

many cases eyways are still broached into the clamping hubs for a positive form fit connection

guarantee good shaft locing, most precision coupling bores are

7:, which allows for *ero undersi*ing, and oversi*ing by anywhere from 0.0% to 0.04mm, with the

tolerance range increasing with larger

gearbo#es, and linear actuators mae

and slight undersi*ing. $his helps to

installation. When installing couplings with clamping systems, it is important to follow the installation

guidelines for screw strength and tighte

screws, allowing for the ma#imum tor+ue and tension to be applied, helping to guarantee a secure loc

onto the shaft.

llation and handling

When properly aligned, ade+uately si*ed bellows couplings are fatigue resistant for a

6any types of commercial electromechanical e+uipment have features

to help guarantee precision alignment during installation. 6ost commonly these

centering pilots on motors, gearbo#es and linear actuators, which are of a precise diameter,

ntric to their respective shafts and bearing 2ournals. 9riving e+uipment typically has a

male centering pilot, and driven e+uipment typically has a matching female centering pilot.

frames are bolted together, these centering pilots hold everything within sufficient alignment

ompensates for the slight misalignment that remains. 3n cases where the coupled

e+uipment will be mounted to separate surfaces without integral features to help guarantee alignment,

-lignment between shafts must be checed with dial indicators or laser

, and ad2ustments made accordingly until the target alignment level has been reached.

bellows couplings with fully split clamping

are often used, since they can be installed laterally

er the shafts have been aligned. 3n cases where

precision shaft alignment is simply not practical, special

high misalignment bellows couplings are available which

can accommodate a parallel shaft misalignment of up to

end to be used in high

performance applications, most bellows couplings are

mounted to their respective shafts and flanges by frictional clamping systems. $his helps to avoid the

which result from connections made by eyway only

many cases eyways are still broached into the clamping hubs for a positive form fit connection

ost precision coupling bores are made to a diameter tolerance of 38?

ersi*ing, and oversi*ing by anywhere from 0.0% to 0.04mm, with the

larger shaft diameters. 3n turn, most manufacturers of motors,

mae the shafts to a diameter tolerance which allows for *ero

to create a slip fit between the shafts and couplings during

. When installing couplings with clamping systems, it is important to follow the installation

guidelines for screw strength and tightening tor+ue values. 6ost bellows couplings use high grade

screws, allowing for the ma#imum tor+ue and tension to be applied, helping to guarantee a secure loc

bellows couplings are fatigue resistant for a

6any types of commercial electromechanical e+uipment have features

to help guarantee precision alignment during installation. 6ost commonly these

which are of a precise diameter,

9riving e+uipment typically has a

female centering pilot. -s the

alignment, and the

. 3n cases where the coupled

features to help guarantee alignment,

d with dial indicators or laser

, and ad2ustments made accordingly until the target alignment level has been reached.

mounted to their respective shafts and flanges by frictional clamping systems. $his helps to avoid the

way only @ though in

many cases eyways are still broached into the clamping hubs for a positive form fit connection. $o help

diameter tolerance of 38?

ersi*ing, and oversi*ing by anywhere from 0.0% to 0.04mm, with the

. 3n turn, most manufacturers of motors,

the shafts to a diameter tolerance which allows for *ero oversi*ing

the shafts and couplings during

. When installing couplings with clamping systems, it is important to follow the installation

ning tor+ue values. 6ost bellows couplings use high grade

screws, allowing for the ma#imum tor+ue and tension to be applied, helping to guarantee a secure loc

dial indicator

mounting options: ?ver the past three decades a very wide variety of si*es and mounting attachments

have been developed for bellows couplings. "or small and medium si*es, the most common drive

attachment is the single screw clamping collar. $his allows for +uic and easy installation with *ero

baclash. "or larger si*es, typically transmitting tor+ue levels of %,000 Nm or more, conical clamping

bushings become more common, as they provide larger clamping pressure between the shaft and hub.

"langes are another popular way of attaching bellows couplings, since they tend to be very compact,

and also allow for good stress distribution and a high level of frictional holding force.

clamping collar hubs are most common for small and medium sizes

conical clamping hubs are used to transmit higher tor"ue levels

flanges offer a compact precision installation

blind mate systems allow for $plug-in% assembly

expanding shafts help add bellows to otherwise "uill mounted systems

line shaft versions span long distances between components

conclusion

"or transmitting dynamic precision motion between two fi#ed shafts, fle#ible bellows couplings offer the

benefits of high torsional stiffness, low moment of inertia, continuous symmetry, and low reaction

forces under slight misalignment. When si*ing, misalignment tolerances, and proper handling are

addressed, they can help machines run faster and more accurately. "or assistance with si*ing, selection,

customi*ation and any other +uestions, please feel free to contact ;<W at

applications&rw-america#com to get the right connection.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Hard SAT Math Problems II - BookDokumen130 halamanHard SAT Math Problems II - BookParul AggarwalBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- SmartForm - Invoice TutorialDokumen17 halamanSmartForm - Invoice TutorialShelly McRay100% (5)

- Mil-Std-1629a FmeaDokumen80 halamanMil-Std-1629a FmeaE278738Belum ada peringkat

- Learning To Program in Visual Basic and GadgeteerDokumen125 halamanLearning To Program in Visual Basic and GadgeteerpganoelBelum ada peringkat

- Antennas 101 5ppDokumen5 halamanAntennas 101 5ppj.emmett.dwyer1033Belum ada peringkat

- Application of EXCEL in Teaching FEMDokumen10 halamanApplication of EXCEL in Teaching FEMj.emmett.dwyer1033Belum ada peringkat

- Palais - Symmetries of Solitons 65ppDokumen65 halamanPalais - Symmetries of Solitons 65ppj.emmett.dwyer1033Belum ada peringkat

- Encoder Measurements: How-To Guide: 1. Encoder and Applications OverviewDokumen4 halamanEncoder Measurements: How-To Guide: 1. Encoder and Applications Overviewj.emmett.dwyer1033Belum ada peringkat

- Collomb-Tutorial On Trigonometric Curve FittingDokumen15 halamanCollomb-Tutorial On Trigonometric Curve Fittingj.emmett.dwyer1033Belum ada peringkat

- Maths IntgrationDokumen153 halamanMaths IntgrationLI DiaBelum ada peringkat

- Systems Engineering For DummiesDokumen76 halamanSystems Engineering For DummiesGreenMentor50% (2)

- Computer Models Used To Track HurricanesDokumen2 halamanComputer Models Used To Track Hurricanesj.emmett.dwyer1033Belum ada peringkat

- TERAHERTZ DETECTORS Q Dots Enable Integrated THZ ImagerDokumen3 halamanTERAHERTZ DETECTORS Q Dots Enable Integrated THZ Imagerj.emmett.dwyer1033Belum ada peringkat

- Laloux Et Al - RANDOM MATRIX THEORY AND FINANCIAL CORRELATIONSDokumen7 halamanLaloux Et Al - RANDOM MATRIX THEORY AND FINANCIAL CORRELATIONSj.emmett.dwyer1033Belum ada peringkat

- SNMP TutorialDokumen20 halamanSNMP Tutorialalexwongks6118Belum ada peringkat

- Scarani - Quantum CryptographyDokumen20 halamanScarani - Quantum Cryptographyj.emmett.dwyer1033Belum ada peringkat

- Top Five Essentials of Electronic DesignDokumen23 halamanTop Five Essentials of Electronic Designj.emmett.dwyer1033Belum ada peringkat

- Elements of Fpgas-What Design Engineers Need To KnowDokumen29 halamanElements of Fpgas-What Design Engineers Need To Knowj.emmett.dwyer1033Belum ada peringkat

- Fluid-Power Actuators BasicsDokumen5 halamanFluid-Power Actuators Basicsj.emmett.dwyer1033Belum ada peringkat

- Anopositionin: Linear - Rotary - Vertical Lift and Z - GoniometerDokumen6 halamanAnopositionin: Linear - Rotary - Vertical Lift and Z - Goniometerj.emmett.dwyer1033Belum ada peringkat

- Motor SizingDokumen10 halamanMotor SizingrafecarBelum ada peringkat

- Random Matrix TheoryDokumen2 halamanRandom Matrix Theoryj.emmett.dwyer1033Belum ada peringkat

- How Random-Matrix Theory Found Its Way Into A Promising AIDS StudyDokumen1 halamanHow Random-Matrix Theory Found Its Way Into A Promising AIDS Studyj.emmett.dwyer1033Belum ada peringkat

- Scarani - Quantum Physics With PolarizationDokumen21 halamanScarani - Quantum Physics With Polarizationj.emmett.dwyer1033Belum ada peringkat

- Motor SizingDokumen10 halamanMotor SizingrafecarBelum ada peringkat

- Conditions For A Class of Entanglement Transfor..Dokumen4 halamanConditions For A Class of Entanglement Transfor..j.emmett.dwyer1033Belum ada peringkat

- De Test+Eval Program '10Dokumen9 halamanDe Test+Eval Program '10j.emmett.dwyer1033Belum ada peringkat

- CAAM 353 - Solving Syst of NL EquationsDokumen32 halamanCAAM 353 - Solving Syst of NL Equationsj.emmett.dwyer1033Belum ada peringkat

- Von Neumann - On Measure and Ergodic TheoryDokumen9 halamanVon Neumann - On Measure and Ergodic Theoryj.emmett.dwyer1033Belum ada peringkat

- CAAM 353 - Errors and Floating Point Notation 17ppDokumen17 halamanCAAM 353 - Errors and Floating Point Notation 17ppj.emmett.dwyer1033Belum ada peringkat

- Ervina Ramadhanti 069 Ptn17aDokumen12 halamanErvina Ramadhanti 069 Ptn17aMac ManiacBelum ada peringkat

- Forecasting The Return Volatility of The Exchange RateDokumen53 halamanForecasting The Return Volatility of The Exchange RateProdan IoanaBelum ada peringkat

- Tga Kinetic ValueseDokumen3 halamanTga Kinetic ValueseCarlos ChavezBelum ada peringkat

- Solar Water Pump Supreme RevDokumen22 halamanSolar Water Pump Supreme RevBelayneh TadesseBelum ada peringkat

- Exp#4-Gas TurbineDokumen9 halamanExp#4-Gas TurbineLilo17xiBelum ada peringkat

- Questions: Comma PlacementDokumen8 halamanQuestions: Comma PlacementZarbibi Hussain khelBelum ada peringkat

- Skripsi Tanpa Bab Pembahasan PDFDokumen67 halamanSkripsi Tanpa Bab Pembahasan PDFaaaaBelum ada peringkat

- Natural Law and The Theory of Society 1500 To 1800 (Scan Perso) PDFDokumen508 halamanNatural Law and The Theory of Society 1500 To 1800 (Scan Perso) PDFjcfichte100% (1)

- D062/D063/D065/D066 Service Manual: (Book 1 of 2) 004778MIU MainframeDokumen1.347 halamanD062/D063/D065/D066 Service Manual: (Book 1 of 2) 004778MIU MainframeevpsasaBelum ada peringkat

- Innoventure List of Short Listed CandidatesDokumen69 halamanInnoventure List of Short Listed CandidatesgovindmalhotraBelum ada peringkat

- Yoga Nidra - Text PDFDokumen265 halamanYoga Nidra - Text PDFVinod Kumar100% (1)

- Business Decision MakingDokumen5 halamanBusiness Decision MakingShafiya CaderBelum ada peringkat

- Hawk RoostingDokumen11 halamanHawk RoostingMOKIBUL ISLAM MOKIPSBelum ada peringkat

- Quotient Tool An Holistic Assessment Tool For An Individual's Fit To A Specific Organizational RoleDokumen1 halamanQuotient Tool An Holistic Assessment Tool For An Individual's Fit To A Specific Organizational RoleCarina CovaBelum ada peringkat

- How To Use SQL Servers Extended Events and Notifications White Paper 24902Dokumen20 halamanHow To Use SQL Servers Extended Events and Notifications White Paper 24902Santosh KadamBelum ada peringkat

- Leadership in 21st CenturyDokumen17 halamanLeadership in 21st Centuryraisandeep2006100% (1)

- استخدام الشبكة الإدارية في السلوك القيادي بحث محكمDokumen22 halamanاستخدام الشبكة الإدارية في السلوك القيادي بحث محكمsalm yasmenBelum ada peringkat

- Diamondfreezemel32r E82eenDokumen11 halamanDiamondfreezemel32r E82eenGILI RELIABILITYBelum ada peringkat

- Ubd Food ChainDokumen5 halamanUbd Food Chainapi-313687749Belum ada peringkat

- Retail Analysis WalmartDokumen18 halamanRetail Analysis WalmartNavin MathadBelum ada peringkat

- 9-12 Lesson PlanDokumen3 halaman9-12 Lesson Planapi-364700795Belum ada peringkat

- Nonverbal Communication (BAS105 UNIT-4)Dokumen16 halamanNonverbal Communication (BAS105 UNIT-4)sachinnonofficialmailBelum ada peringkat

- Oakwood, Ub CityDokumen18 halamanOakwood, Ub CityAfreen BandayBelum ada peringkat

- IMS - General MBA - Interview QuestionsDokumen2 halamanIMS - General MBA - Interview QuestionsRahulSatputeBelum ada peringkat

- Synthesis of Isoamyl AcetateDokumen3 halamanSynthesis of Isoamyl AcetateClaire TiongsonBelum ada peringkat

- The FlirterDokumen2 halamanThe Flirterdddbbb7Belum ada peringkat

- French DELF A1 Exam PDFDokumen10 halamanFrench DELF A1 Exam PDFMishtiBelum ada peringkat

- Exalted 2e Sheet2 Mortal v0.1Dokumen2 halamanExalted 2e Sheet2 Mortal v0.1Lenice EscadaBelum ada peringkat

- Exalted Signs Sun in AriesDokumen6 halamanExalted Signs Sun in AriesGaurang PandyaBelum ada peringkat