Work Instruction - Transformers

Diunggah oleh

kumarvishal07Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Work Instruction - Transformers

Diunggah oleh

kumarvishal07Hak Cipta:

Format Tersedia

:

ELECTROSTEEL STEELS LTD

DOC. NO

: ESL-BM-EE-TR-WI01

PAGE NO : 01

OF: 02

ISSUE NO :

DATE:

REV.

NO

:

00

DATE:

Distribution Transformer-1

01.01.2013

BAR MILL ELECTRICAL MAINTENANCE

WORK INSTRUCTION

TITLE: 6.6kV/415V

1. PURPOSE: Preventive Maintenance of Distribution Transformer -1

2. SCOPE: Applicable for the personnel working in E&A Department

of BAR MILL unit of EELECTROSTEEL STEELS LTD.

3. DOCUMENT REFERENCE: Maintenance Procedure of 6.6kV/415V

transformers-Doc. No.

4. INSTRUCTION :

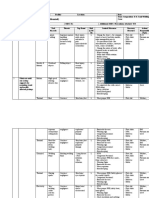

Sl.

NO

FREQUENC

Y

ACTIVITY

DURATION: 12hrs.

MANPOWER REQUIRED: 4no.

INFORMATION: Inform operation HOD & shift I/C and

Mechanical HOD & I/C about job and time required for

the job.

MATERIAL:

As and

when

required

.

RESPONSIBILI

TY &

AUTHORITY

Shift

Incharge.

TOOLS, CONSUMABLES & SERVICES

1. Flat & ring spanner size 2. Adjustable spanner (18,36,)

3. Screw Driver-set.

4. Air Blower, Vaccume Cleaner.

5. Multimeter, Meggar (500V, 2000V, 5000V), Clamp

Meter, Test Lamp, Earth Tester, Oil Filtering Machine,

BDV Testing Kit, Secondary Injection Kit.

6. Electrical Cleaners, Antitracking

spray, HT Tape 12kV , PVC Tape.

7. Cadmium coated or GI Nut, Bolts and Washerssize/Length 8. Old Clothes, Markin Clothes.

ISOLATION PROCEDURE:

1. After Taking Shut Down Permit, Take Changeover Of

PREPARED BY

CHECKED BY

APPROVED BY

ISSUED BY

SECTION I/C

HOD

MR

ELECTROSTEEL STEELS LTD

DOC. NO

: ESL-BM-EE-TR-WI01

PAGE NO : 01

OF: 02

ISSUE NO :

DATE:

REV.

NO

:

00

DATE:

Distribution Transformer-1

01.01.2013

BAR MILL ELECTRICAL MAINTENANCE

WORK INSTRUCTION

TITLE: 6.6kV/415V

LV me /C of PCC-1.First Switch Off the LV I/C-1 ACB,Rack

out the Breaker and Switch off the Control supply of its

Control transofmer.

2.Switch Off The HT Power Supply From VCB of

FeederPanel No. 2. Rack out the Circuit Breaker and Apply Earth Switch

after that Switch off All Control Supply.

3. Switch off the LV I/C Supply From the

Breaker,Rackout the ACB Then Switch off the Control

Transformer Supply

Procedure of the job.

1. Disconnect the cantilever roller motor

2. Stop the G-1 grease system and Remove the grease

pipes on Plummer block.

3. Remove apron plate fix on furnace wall.

4. Remove the Plummer block foundation bolts.

5. Remove gear box holding bolt.

6. Fix the sling at gear box side Plummer block.

7. Stop the water and Remove the hoses of rotary

union.

8. Tilt the roller slightly and remove the roller by using

crane

(Castable blocks will come out while removing

roller).

9. Place ceramic fiber glass wool at place of removed

roller for protection of heat.

10. Place the bottom castable block.

11. Bring the new roller and place it.

PREPARED BY

CHECKED BY

APPROVED BY

ISSUED BY

SECTION I/C

HOD

MR

ELECTROSTEEL STEELS LTD

DOC. NO

: ESL-BM-EE-TR-WI01

PAGE NO : 01

OF: 02

ISSUE NO :

DATE:

REV.

NO

:

00

DATE:

Distribution Transformer-1

01.01.2013

BAR MILL ELECTRICAL MAINTENANCE

WORK INSTRUCTION

TITLE: 6.6kV/415V

12. Adjust the holes of Plummer block foundation and

place the bolts.

13. Fix the rotary union hose pipe and start the water.

14. Fix the gear box holding bolt.

15. Place the upper castable block on roller shaft.

16. Tight the bolts diagonally and check the freeness of

roller rotation.

17. Fix the grease pipes and start the grease system G1

18. Electrical connection of motor. Fix the apron.

KEY POINT

1.

Ensure cooling water flow after giving all

connections.

2. Ensure freeness of roller.

3. Take trail run before handing over.

STARTUP

1. Remove all men & tools from their job on the work

place.

2. Clear shutdown permit and ensure power

3. Inform operation shift I/C for availability of

equipment.

PREPARED BY

CHECKED BY

APPROVED BY

ISSUED BY

SECTION I/C

HOD

MR

ELECTROSTEEL STEELS LTD

DOC. NO

: ESL-BM-EE-TR-WI01

PAGE NO : 01

OF: 02

ISSUE NO :

DATE:

REV.

NO

:

00

DATE:

Distribution Transformer-1

01.01.2013

BAR MILL ELECTRICAL MAINTENANCE

WORK INSTRUCTION

TITLE: 6.6kV/415V

PREPARED BY

CHECKED BY

APPROVED BY

ISSUED BY

SECTION I/C

HOD

MR

Anda mungkin juga menyukai

- PTW No.: - : Excavation PermitDokumen1 halamanPTW No.: - : Excavation PermitbhaskarBelum ada peringkat

- Jsa Worksheet Appendix 1: A-2401 Cooling Tower Pond CleaningDokumen4 halamanJsa Worksheet Appendix 1: A-2401 Cooling Tower Pond CleaningAmmadRehmanBelum ada peringkat

- 7.electrical LOTO Check List InspectionDokumen1 halaman7.electrical LOTO Check List Inspectionfitri widyaBelum ada peringkat

- PPM Check List: Floor: Wing: Room No: DateDokumen3 halamanPPM Check List: Floor: Wing: Room No: DateMdrahaman MithuBelum ada peringkat

- Tool Box TalkDokumen2 halamanTool Box TalkTwin BullsBelum ada peringkat

- Boom BarrierDokumen2 halamanBoom BarrierRamkumar KumaresanBelum ada peringkat

- Lockout Tagout Annual Inspection and Training Assessment ChecklistDokumen1 halamanLockout Tagout Annual Inspection and Training Assessment Checklistmelike sultan açıkBelum ada peringkat

- Stacker Preventive Maintenance Weekly: Clean and InspectDokumen1 halamanStacker Preventive Maintenance Weekly: Clean and InspectFabio Gonzalez100% (1)

- Part Submission WarrantDokumen4 halamanPart Submission WarrantSam AnuBelum ada peringkat

- HSE-FM-05 Check List pERALATANDokumen5 halamanHSE-FM-05 Check List pERALATANyudaBelum ada peringkat

- SOP Maintenance ACDokumen2 halamanSOP Maintenance ACArieBelum ada peringkat

- Form 13Dokumen4 halamanForm 13Jayendra NaiduBelum ada peringkat

- Loto Emergency Removal FormDokumen2 halamanLoto Emergency Removal FormdauxomBelum ada peringkat

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Dokumen11 halamanJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanBelum ada peringkat

- Poshs Metal Industries PVT - LTD: SR - No. Inspection Area Remark Required Lux Level (Min) Actual Lux LevelDokumen2 halamanPoshs Metal Industries PVT - LTD: SR - No. Inspection Area Remark Required Lux Level (Min) Actual Lux LevelSafety Dept100% (1)

- Work PermitDokumen17 halamanWork PermitRiccar303Belum ada peringkat

- Attendance ListDokumen2 halamanAttendance ListYusup MulyanaBelum ada peringkat

- Grating Decking and Floor Removal FormDokumen2 halamanGrating Decking and Floor Removal FormMohamed Abd ElhaleemBelum ada peringkat

- Elcb Checking Format-TDokumen1 halamanElcb Checking Format-TGyanendra Narayan NayakBelum ada peringkat

- JSA For Purging NitrogenDokumen1 halamanJSA For Purging Nitrogenlina ekawatiBelum ada peringkat

- STR GL Hal Hse SQ 501Dokumen12 halamanSTR GL Hal Hse SQ 501jose gregorio mata cabezaBelum ada peringkat

- Permit To DigDokumen3 halamanPermit To DigMarco DonatiBelum ada peringkat

- SOP-08 Thermocouple - DTC CalibrationDokumen9 halamanSOP-08 Thermocouple - DTC CalibrationPandu BirumakovelaBelum ada peringkat

- SOP Workshop Hy FinalDokumen4 halamanSOP Workshop Hy FinalanbuBelum ada peringkat

- HSE Induction - Attendance FormDokumen1 halamanHSE Induction - Attendance FormSyed Mohammad NeezarBelum ada peringkat

- P-007 Electrical Isolation PermitDokumen1 halamanP-007 Electrical Isolation PermitSatheesh Kumar PBelum ada peringkat

- R-20 Two Way Communication FormDokumen1 halamanR-20 Two Way Communication FormSandeep KumarBelum ada peringkat

- Drill Report On Emergency Treatment of Electric Shock: Low Voltage Portable Electrical ToolDokumen3 halamanDrill Report On Emergency Treatment of Electric Shock: Low Voltage Portable Electrical ToolRAJESHBelum ada peringkat

- Form - 37 - Register Containing Particulars of Monitoring of Working EnvironmentDokumen1 halamanForm - 37 - Register Containing Particulars of Monitoring of Working Environmenthdpanchal86Belum ada peringkat

- PPI - Personal Protective Equipment Issue - Version 3 September 2014Dokumen2 halamanPPI - Personal Protective Equipment Issue - Version 3 September 2014chelios20% (1)

- ECO - Electrical Shock Emergency Mock DrillDokumen4 halamanECO - Electrical Shock Emergency Mock DrillBoluwatife Elisha100% (1)

- ChecklistDokumen14 halamanChecklistInstrument SCIBelum ada peringkat

- PP-HSE-FORM-005 PTW-Confined SpaceDokumen2 halamanPP-HSE-FORM-005 PTW-Confined SpaceDimas Dwi SwarnaBelum ada peringkat

- Batching Plant Permit Rev-00Dokumen3 halamanBatching Plant Permit Rev-00cuteboom1122Belum ada peringkat

- Eil Permit For Energy Isolation & De-IsolationDokumen1 halamanEil Permit For Energy Isolation & De-IsolationAvesh ChauahanBelum ada peringkat

- JSA E&I 1.instrument Installation (Stand Mounted)Dokumen5 halamanJSA E&I 1.instrument Installation (Stand Mounted)AmyBelum ada peringkat

- Daily Checklist For DGDokumen2 halamanDaily Checklist For DG7Days Facility ManagementBelum ada peringkat

- Radiator Cleaning of Instrument Air Compressor-3: Lock Out Tagout OrderDokumen1 halamanRadiator Cleaning of Instrument Air Compressor-3: Lock Out Tagout OrderZeeshan RehmanBelum ada peringkat

- Checklist ERDMP 100919Dokumen3 halamanChecklist ERDMP 100919varunkumar415Belum ada peringkat

- Hazardous Energy Control Procedure: Lockout/Tagout SheetDokumen3 halamanHazardous Energy Control Procedure: Lockout/Tagout SheetPaul HymanBelum ada peringkat

- 7 QC ToolsDokumen155 halaman7 QC Toolswintoday01Belum ada peringkat

- Permit To Work Audit Checklist OctoberDokumen3 halamanPermit To Work Audit Checklist OctoberefeBelum ada peringkat

- Hot Work PermitDokumen1 halamanHot Work PermitKlyneRamirezBelum ada peringkat

- Work Permit Format - Jul 2014Dokumen2 halamanWork Permit Format - Jul 2014NilamSanjeev Kumar SinghBelum ada peringkat

- SHEM-SP-08.10 Work Permits ProcedureDokumen74 halamanSHEM-SP-08.10 Work Permits ProcedureAjith Kumar AjithBelum ada peringkat

- 06-F03 Ohs Introduction & Induction: Safety Induction Training Check-ListDokumen2 halaman06-F03 Ohs Introduction & Induction: Safety Induction Training Check-ListSn AhsanBelum ada peringkat

- Lockout/Tagout (Loto) Checklist: 1. Scope of WorkDokumen3 halamanLockout/Tagout (Loto) Checklist: 1. Scope of WorkPutri UnaBelum ada peringkat

- Shiva Enterprises: Accident & Incident LogDokumen1 halamanShiva Enterprises: Accident & Incident LogRahul KumarBelum ada peringkat

- A.C Motor ReplacementDokumen1 halamanA.C Motor ReplacementReda BoualiBelum ada peringkat

- JSA PRE-TEST Upload ContohDokumen2 halamanJSA PRE-TEST Upload ContohDenny Kurniawan PrawiraBelum ada peringkat

- List of MachineDokumen11 halamanList of Machinemohitsharmagzb09Belum ada peringkat

- Bar Bending Checklist: Contractor NameDokumen1 halamanBar Bending Checklist: Contractor NameAfroz AlamBelum ada peringkat

- 18A - FO - Permit To Work LogDokumen2 halaman18A - FO - Permit To Work Lograjesh_rathBelum ada peringkat

- PTW LiftingDokumen4 halamanPTW LiftingAhmedAhmedBelum ada peringkat

- Lockout/tagout Inspection FormDokumen2 halamanLockout/tagout Inspection Formerofik72Belum ada peringkat

- JSA Fiber Tank LiftingDokumen4 halamanJSA Fiber Tank LiftingEngismail KhanBelum ada peringkat

- JSA of Charging UnitDokumen3 halamanJSA of Charging UnitMuhammad AliBelum ada peringkat

- HSE 13 Lifting Operation PermitDokumen1 halamanHSE 13 Lifting Operation PermitBa N Nhim100% (1)

- Hitachi RAS-10KH2 - Manual Service - Lb. Engleza PDFDokumen68 halamanHitachi RAS-10KH2 - Manual Service - Lb. Engleza PDFnoidforall100% (2)

- Jawaharlal Nehru Technological University Anantapur AndhrapradeshDokumen30 halamanJawaharlal Nehru Technological University Anantapur AndhrapradeshJagaBelum ada peringkat

- Technology in Society: SciencedirectDokumen10 halamanTechnology in Society: SciencedirectVARGAS MEDINA ALEJANDRABelum ada peringkat

- 20 Ijrerd-C153Dokumen9 halaman20 Ijrerd-C153Akmaruddin Bin JofriBelum ada peringkat

- 42ld340h Commercial Mode Setup Guide PDFDokumen59 halaman42ld340h Commercial Mode Setup Guide PDFGanesh BabuBelum ada peringkat

- How Do I Predict Event Timing Saturn Nakshatra PDFDokumen5 halamanHow Do I Predict Event Timing Saturn Nakshatra PDFpiyushBelum ada peringkat

- Unit 2 Module 2 Combined-1Dokumen14 halamanUnit 2 Module 2 Combined-1api-2930012170% (2)

- "Prayagraj ": Destination Visit ReportDokumen5 halaman"Prayagraj ": Destination Visit ReportswetaBelum ada peringkat

- Manual de Utilizare HUMAX DIGI TV RDSDokumen116 halamanManual de Utilizare HUMAX DIGI TV RDSenamicul50Belum ada peringkat

- Enzymatic Hydrolysis, Analysis of Mucic Acid Crystals and Osazones, and Thin - Layer Chromatography of Carbohydrates From CassavaDokumen8 halamanEnzymatic Hydrolysis, Analysis of Mucic Acid Crystals and Osazones, and Thin - Layer Chromatography of Carbohydrates From CassavaKimberly Mae MesinaBelum ada peringkat

- Vicente BSC2-4 WhoamiDokumen3 halamanVicente BSC2-4 WhoamiVethinaVirayBelum ada peringkat

- C7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesDokumen13 halamanC7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesBhat SaqibBelum ada peringkat

- 1 s2.0 S0378432004002465 MainDokumen20 halaman1 s2.0 S0378432004002465 MainMuhammad JameelBelum ada peringkat

- Advantages of The CapmDokumen3 halamanAdvantages of The Capmdeeparaghu6Belum ada peringkat

- Human Aspect Issues After Mergers and AcquisitionsDokumen4 halamanHuman Aspect Issues After Mergers and AcquisitionsA B100% (1)

- July 2014Dokumen56 halamanJuly 2014Gas, Oil & Mining Contractor MagazineBelum ada peringkat

- By Vaibhav Pandya S R.information Security Consultant M.Tech Solutions (India) PVT - LTDDokumen22 halamanBy Vaibhav Pandya S R.information Security Consultant M.Tech Solutions (India) PVT - LTDtsegay.csBelum ada peringkat

- Form PersonalizationDokumen5 halamanForm PersonalizationSuneelTejBelum ada peringkat

- Aits 2122 PT I Jeea 2022 TD Paper 2 SolDokumen14 halamanAits 2122 PT I Jeea 2022 TD Paper 2 SolSoumodeep NayakBelum ada peringkat

- STAB 2009 s03-p1Dokumen16 halamanSTAB 2009 s03-p1Petre TofanBelum ada peringkat

- 3-CHAPTER-1 - Edited v1Dokumen32 halaman3-CHAPTER-1 - Edited v1Michael Jaye RiblezaBelum ada peringkat

- Corporate Members List Iei Mysore Local CentreDokumen296 halamanCorporate Members List Iei Mysore Local CentreNagarjun GowdaBelum ada peringkat

- Mufti ReligionMilitancy WebDokumen0 halamanMufti ReligionMilitancy WebAyaz Ahmed KhanBelum ada peringkat

- ADP G2 Spreadsheet Loader Data Entry: End-User GuideDokumen48 halamanADP G2 Spreadsheet Loader Data Entry: End-User Guideraokumar250% (2)

- D2E133AM4701 Operating Instruction UsDokumen9 halamanD2E133AM4701 Operating Instruction UsMohamed AlkharashyBelum ada peringkat

- Al-Farabi Fusul Al MadaniDokumen107 halamanAl-Farabi Fusul Al MadaniDaniel G.G.100% (1)

- TM9-1904 - Ammunition Inspection Guide - 1944 PDFDokumen414 halamanTM9-1904 - Ammunition Inspection Guide - 1944 PDFhodhodhodsribdBelum ada peringkat

- The Evolution of Knowledge Management Systems Needs To Be ManagedDokumen14 halamanThe Evolution of Knowledge Management Systems Needs To Be ManagedhenaediBelum ada peringkat

- Duties and Responsibilities - Filipino DepartmentDokumen2 halamanDuties and Responsibilities - Filipino DepartmentEder Aguirre Capangpangan100% (2)

- Pharmacy System Project PlanDokumen8 halamanPharmacy System Project PlankkumarBelum ada peringkat

- 02 Laboratory Exercise 1Dokumen2 halaman02 Laboratory Exercise 1Mico Bryan BurgosBelum ada peringkat

- NHD Process PaperDokumen2 halamanNHD Process Paperapi-122116050Belum ada peringkat