Attagel - BASF

Diunggah oleh

ketchito100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

356 tayangan12 halamanColloidal clays disperse easily in aqueous and solvent-borne systems. Attagel products need no special solvents, activators, or modifiers. Manufacturers use them in place of more expensive rheology agents.

Deskripsi Asli:

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniColloidal clays disperse easily in aqueous and solvent-borne systems. Attagel products need no special solvents, activators, or modifiers. Manufacturers use them in place of more expensive rheology agents.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

356 tayangan12 halamanAttagel - BASF

Diunggah oleh

ketchitoColloidal clays disperse easily in aqueous and solvent-borne systems. Attagel products need no special solvents, activators, or modifiers. Manufacturers use them in place of more expensive rheology agents.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 12

Attagel

Rheology modiers

Helping Make Products Better

Forming a colloidal network

Unique rheology modication

Attagel

attapulgite rheology modiers by BASF offer a wide range of

performance benets in many liquid systems.

During formulation, Attagel colloidal clays disperse easily in

aqueous and solvent-borne systems.

Attagel products provide wide latitude in formulating as they are

essentially inert and compatible with most additives and tolerate

most physical and chemical environments.

Attagel products need no special solvents, activators, or modiers,

except in solvent-borne systems where a surfactant is recommended.

In end-use applications, Attagel rheology modiers assist in

syneresis control, sag resistance, lm build, leveling, spatter

resistance, spreadability, feathering, tint strength, and hiding.

During storage, Attagel products reduce liquid separation

(syneresis), do not swell, are stable over wide pH and temperature

ranges, are insoluble in organic liquids, and generally resist settling.

Attagel rheology modier is an ultra-ne mineral containing bundles

of sub-micron particles. When the bundles are well dispersed in liquid

systems, the colloidal particles interact to form a network that entraps

liquid and smaller particles and suspends larger particles (Figure 1).

Attagel rheology modiers are exceptionally effective gellants, thixotropes

and suspending agents that provide consistent performance over a

wide range of liquid systems. Manufacturers use them in place of more

expensive rheology agents, wholly or partially, to gain the many benets

they offer during a products life cycle. Attagel products have distinct

advantages over other commonly used thickening and suspending agents.

Figure 1. Photomicrograph showing particles in a slurry suspended by a colloidal network of Attagel.

Attagel rheology modiers

Performs in water and solvent-borne systems

Provides syneresis control

Consistent performance

Thixotropic viscosity modication

Low amount of energy needed to disperse

Cost effective

Attagel products offer an excellent balance of cost and performance

over a broad pH and temperature range and are compatible with

almost all other additives. They are not subject to bacterial attack nor

affected by salts, acids or basesexcept in extreme cases. They do not

swell nor need special solvents, activators or modiers. Organic liquid

systems do sometimes need surfactants.

The thixotropy added by Attagel rheology modiers is invaluable in

a wide variety of aqueous and organic liquid systems (Table 1). For

instance, it enables paints, inks, adhesives and other products coated

on surfaces to spread easily when rolled, sprayed or brushed, and

then stiffen at a controlled rate to prevent sags and drips. It can

also improve lm build, tint strength, hiding, leveling and spatter

resistance, while reducing water sensitivity and preventing syneresis.

As suspending agents, Attagel products can hold relatively large or

dense particles in liquids for an extended time. They are especially

useful where mixing capability is limited. If settling does occur, the

sediment formed tends to be soft and easily resuspended. Typical

applications include liquid soaps, pigment and ceramic slurries,

refractory coatings, foundry wash, fertilizers and liquid animal feed.

What are Attagel rheology modiers?

Attagel thickeners and suspending agents are made from specially

processed attapulgite, a hydrated magnesium aluminosilicate and a

principal member of the fullers earth family of clay minerals having

the ideal formula: 3MgO 1.5Al

2

O

3

8SiO

2

9H

2

O. Attapulgite

occurs as tightly packed bundles of submicron particles whose lathe-

like structure gives it unique colloidal and sorptive properties.

Attagel thickeners and suspending agents provide benets, including

easy dispersion, formulating latitude and long-term stability. The

02 03

Adhesives and Sealants Attagel thickeners provide superior thickening, sag resistance, and ease of application, especially in highly lled

systems.

T

a

b

l

e

1

.

B

r

o

a

d

r

a

n

g

e

o

f

a

p

p

l

i

c

a

t

i

o

n

s

Asphalt Coatings Attagel 30 provides for easy application (especially spray application), excellent storage stability and syneresis control

in roof coatings, underbody coatings, driveway sealers and other asphalt cutbacks and emulsions.

Chemical Suspensions Attagel 50 provides easy and stable suspensions of insoluble additives in a wide range of solutions, including biocides,

ceramic glazes, fertilizers, household cleaners, paint remover and veterinary medicines.

Paints and Coatings Attagel 40 and 50 are used in latex and other general waterborne formulations. Attagel 50 is used in more demanding

aqueous and solventborne coatings, such as primers, topcoats, maintenance coatings, marine nishes, and semigloss

and gloss enamels. Both products work as co-thickeners with cellulosic, associative and alkali swellable thickeners.

Pesticides and Herbicides Attagel 50 stabilize and suspend ingredients in wet-owable and suspension concentrates in pesticide and herbicide

formulations, even at high loadings.

Plastics Attagel 50 controls viscosity to aid ow and prevent sag upon deposition in vinyl plastisol and epoxy systems. It also

helps prevent settling and oat out in lightweight ller compounds.

Tape Joint Compounds Attagel 30 provides for smooth, scratch-free application in these thick lms, as well as for sag resistance, viscosity

control, spreadability and excellent feathering at low cost.

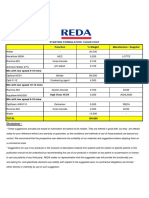

Typical physical and chemical properties Attagel 30 Attagel 40 Attagel 50

Physical appearance Micronized Powders

T

a

b

l

e

2

.

T

y

p

i

c

a

l

p

h

y

s

i

c

a

l

a

n

d

c

h

e

m

i

c

a

l

p

r

o

p

e

r

t

i

e

s

o

f

A

t

t

a

g

e

l

3

0

,

4

0

a

n

d

5

0

t

h

i

c

k

e

n

e

r

s

Average particle size (m) 0.1 0.1 0.1

Residue, +325 mesh wet, % max. 3.5 0.15 0.01

Hegman neness of grind (in dioctyl phthalate) <5 5+ 6+

Oil absorption (ASTM D281) 100 110 115

Free moisture, as produced (% wt. loss at 650C) 12 12 12

Volatile matter, as produced (% wt. at 650C, moisture-free basis) 10 10 10

Ignition loss, as produced (% wt. loss at 1000C) 24 24 24

Bulking value Attagel 30 Attagel 40 Attagel 50

lb./gal. 19.7 (2.36 kg/l) 19.7 (2.36 kg/l) 19.7 (2.36 kg/l)

gal./lb. 0.0507 (0.42 l/kg) 0.0507 (0.42 l/kg) 0.0507 (0.42 l/kg)

pH (ASTM D 1208) 8.5 8.5 8.5

Color Light cream Light cream Light cream

Specic gravity 2.4 2.4 2.4

Density (tamped volume wt.), lb./cu. ft. 35 30 23

B.E.T surface area, m/g (moisture-free basis) 150 150 150

Chemical analysis (volatile and moisture-free basis) Attagel 30 Attagel 40 Attagel 50

Major constituents exist as complex silicates rather than as free oxides.

Silicon (SiO

2

) 65.2% 65.2% 65.2%

Aluminum (Al

2

O

3

) 12.7% 12.7% 12.7%

Magnesium (MgO) 12.3% 12.3% 12.3%

Iron (Fe

2

O

3

) 3.5% 3.5% 3.5%

Calcium (CaO) 3.9% 3.9% 3.9%

Phosphorus (P

2

O

5

) 1.0% 1.0% 1.0%

Potassium (K

2

O) 0.8% 0.8% 0.8%

Titanium (TiO

2

) 0.5% 0.5% 0.5%

Trace elements 0.1% 0.1% 0.1%

Dispersion characteristics

Setting up a network

04 05

colloidal network forms a thixotropic gel that if undisturbed, is stable

indenitely. Under modest shear, however, the structure breaks down

and the liquid becomes thin and owable. When agitation ceases, the

scattered particles realign to reform the colloidal network and thicken

the liquid. The cycle of thinning and thickening, by changes in shear,

can be repeated endlessly.

As a leader in attapulgite technology, BASF manufactures Attagel

products using methods we pioneered and continue to develop. We

engineer quality into these products by starting with a high-grade

attapulgite mineral and processing it under strict control. The mineral is

mined from our holdings in southwestern Georgia and northern Florida,

USA which contain some of the purest attapulgite available. We then

unlock the potential of this versatile mineral by purifying the crude

and manufacturing a variety of products through well-controlled heat

treatment and particle-size processing.

Attagel rheology modiers are hydrated grades made by low-

temperature drying. They are specially processed to create

submicron-size particles with selected residue and moisture

specications for optimal dispersing and gelling capability.

The Attagel 30 and 40 grades work well in most aqueous applications.

The Attagel 50 grade is a premium product with less residue, smaller

particle size (Table 2) and uniquely rounded particle edges. It is most

desired in applications where neness, surface smoothness and

sprayability of the end-use product are critical. In organic or solvent-

borne applications, where dispersion can be more difcult, Attagel 50

particles can wet-out more quickly and completely, providing a more

consistent and stable dispersion and thickening.

Optimal formulation and mixing methods

When to add Attagel rheology modiers

Attagel thickeners develop high viscosity when they are well dispersed.

This involves breaking up the attapulgite aggregates and distributing

the particles evenly in the uid. In water-based coatings, Attagel

products are usually added at the end of the pigment-grind step to

prevent absorption of surfactants that can cause over-dispersion and

hinder gel formation, see Figure 2. The mix should have enough water

so it remains in the proper viscosity zone, for near maximum shear,

as viscosity increases. In solvent-based systems, where a surfactant

is needed to disperse the hydrophillic Attagel particles, the Attagel

product should be added early to ensure capture of the surfactant.

Mixing speed

High-speed mixing creates rapid thickening. Intensive, slow-speed

mixing, such as with a double planetary-type mixer, may take longer

to develop near maximum viscosity and may require higher solids

to generate adequate shear. For example, Figure 3 shows the time

difference, between low- and high-speed mixing, to reach near

maximum viscosities is less in a 20% aqueous dispersion than in one

at 10%. This occurs because higher solids create higher shear, which

aids dispersion. Since shear rate is more critical than mixing speed,

low-speed mixers can be used with the proper order of addition, or

with a pregel.

Figure 2. Processing effects on dispersion characteristics of Attagel rheology

modiers

GEL

UNDER DISPERSION OVER DISPERSION

DRY ATTAGEL THICKENER POWDER

Attagel thickener in

water with mild shear

gives partial

dispersion and

moderate thickening.

Attagel thickener in water

with high shear plus a

dispersant gives over

dispersion and slight

thickening.

A magnifed view of idealized Attagel thickener dispersions, this demonstrates that over

dispersing or under dispersing of the attapulgite will results in undesirable properties.

We recommend that experiments be carried out in the laboratory using your proposed

formulas to determine the optimum dispersion parameters.

Schematic of Attagel Thickening

Attagel thickener in water

with high shear gives

optimum dispersion &

maximum thickening to

form a gel.

Thixotropic development

Pregelling

Pregelling Attagel products take advantage of the shear inherent

in particle crowding. Manufacturers often use pre-made Attagel

concentrates if not enough shear can be applied to the main mix

batch. Pregels are especially useful in formulations that foam when

mixed rapidly or if high-speed mixers are unavailable. They are also

added to systems with abundant liquid and relatively small amounts

of pigment and vehicle.

Many processes use Attagel pregels that contain 10% to 15% solids.

These are formed under low-to-moderate mixing. A typical pregel

formula is: 10 to 15 lb. Attagel thickener/10.2 to 10.8 gallons water

(10 to 15 g Attagel per 85 to 90 ml water).

Liquid demand

Although much of the viscosity developed with Attagel thickener

depends on the concentration and degree of dispersion, other

ingredients can affect viscosity because the liquid demand

determines the liquid available to be thickened. More crowded

systems mean that viscosity change for a given amount of Attagel is

more noticeable (Figure 4). In most cases, viscosity increases slowly,

as concentration rises to about 8%, but increases rapidly above 8%.

Dispersion

Care should be taken to avoid over-dispersion or under-dispersion

as shown in Figure 2. Over-dispersion, often caused by overuse

of tetrasodium pyrophosphate (TSPP) and other dispersants or

surfactants, scatters and separates particles so much they cannot

form a strong gelling network. Under-dispersion, due to insufcient

mixing shear or time, does not free enough particles to form a

strong network. Another undesirable effect can occur, as viscosity

can increase slowly as bundles wet-out and separate into individual

particles and cause post-thickening. This occurs in aqueous Attagel

systems that are under-dispersed because Attagel products wet-out

naturally over time in water.

Figure 3. Effect of mixing speeds and Attagel concentration on gel development

Figure 4. Effect of Attagel thickener concentration on the viscosity of water

dispersions

06 07

Aqueous applications

How much to use

The amount of Attagel rheology modier used depends on the

consistency desired, other pigments or additives present, the solids of

the system, and the free water available. Attagel product can be used

as the sole thickener only if thixotropic rheology is needed, as is often

the case with adhesives, liquid detergents, Portland cement mortars,

and polishes. Such systems do not have high viscosity at high shear

and, therefore, ow easily during application.

In smooth-brushing coatings that use Attagel product as a co-

thickener, manufacturers usually start with 3 to 10 lb. Attagel per 100

gal. (4 to 12 g/l or 0.3 to 1.0%). Levels as high as 25 lb. per 100 gal.

(30 g/l) are used in high-viscosity coatings, caulks, detergents and

tape joint compounds (Table 3).

Aqueous applications

Partial replacement of cellulose thickeners

When using Attagel to reduce cellulosic thickeners in emulsion coating

systems, at least 3 lb. cellulosic per 100 gal. (3.5 g/l) must remain

in the formulation to provide freeze-thaw stability and open-time. In

reducing cellulosic, in an existing formulation, 3 to 4 parts of Attagel

(by weight) per part of cellulosic are generally used. The optimal level of

Attagel product in these applications is usually 5 to10 lb. per 100 gal.

(6 to 12 g/l), which helps to improve spattering and sag resistance.

Attagel thickeners work best with high-viscosity cellulosics like

hydroxyethyl cellulose (HEC) and hydroxypropyl methyl cellulose

(HPMC). If a ropey or livered appearance occurs with HEC, replace it

with HPMC. Ropiness can also be prevented by avoiding phosphate

dispersants, using a blend of polyacrylate and AMP-95

(1)

dispersants, or lowering replacement ratio to less than 5 parts

Attagel per part of cellulosic.

Concentration

T

a

b

l

e

3

:

T

y

p

i

c

a

l

l

o

a

d

i

n

g

l

e

v

e

l

s

o

f

A

t

t

a

g

e

l

p

r

o

d

u

c

t

s

i

n

a

q

u

e

o

u

s

a

p

p

l

i

c

a

t

i

o

n

s

Application lb./100 gal. (g/l) wt%*

Soft settling or suspension 1-5 (1.2-6) 0.1-0.5**

Flat and semi-gloss latex paint***, exographic ink, shampoo, hair conditioner, adhesive, polish 3-10 (4-12) 0.3-1.0

Ready-mix tape joint compound, liquid dishwashing detergent 10-25 (12-30) 1.0-2.5

Latex texture paint 15-25 (12-30) 1.5-2.5

Cinderblock surfacer, caulk 20-25 (24-30) 2.0-2.5

* Based on a 10 lb./gal. or 1.2 kg/l product.

** Systems with large particles may need up to 2.0 wt.%.

*** Used as co-thickener in latex paints.

(1)

AMP-95 is a trademark of Angus Chemical Corporation.

Solvent applications

Adding value to associative thickener systems

Attagel products are used as co-thickening thixotropes in paints

together with urethane-based rheology modiers. These associative

thickeners provide excellent leveling and improved gloss. They keep

viscosity high at high shear, as with roller application, so paints

spatter less and have excellent lm build for improved one-coat

hiding. Manufacturers often use Attagel thickeners to overcome

problems with syneresis, pigment settling, organic pigment ooding

and oating, hiding, color development and sag resistance that can

occur with associative thickeners, at a rate of 3 to 5 lb./100 gal. (4

to 6 g/l) in semigloss paints and 3 to 7 lb./100 gal. (4 to 8.5 g/l) in

interior at paints. Attagel products are also used as co-thickening

thixotropes, with alkali swellable and hydrophobically modied HEC

thickeners to remedy sag resistance, pigment settling and dripping

problems. Typical addition levels are 3 to 5 lb./100 gal. (4 to 6.0 g/l).

Easy, consistent and stable suspensions

Attagel rheology modier provides long-term stability to liquid

systems, is essentially chemically inert, and is stable over a wide

range of pH and with most known additives. Particles remain

suspended indenitely. The gels formed can suspend relatively large

or dense pigment or extender particles. If particles do settle, they

usually form soft sediment that is easily re-suspended. The amount

of Attagel needed is reduced as solids rise. Pigmented systems may

need less than 0.5% for suspension or soft-settle, and those with

large particles may need 0.5% to 2.0%.

Organic liquid applications

Attagel 50 rheology modier provides good thixotropic thickening and

suspension in many organic liquids, including mineral oils, mineral

spirits, naphthas, vegetable oils, aromatic solvents, synthetic oils,

synthetic lubricants, polyesters, epoxy resins, plasticizers, alkyds and

many other systems. Since attapulgite particles are organophobic,

in many organic liquids a surfactant is often needed to wet them so

they can disperse fully and form stable gel structures. In waterborne

systems, a surfactant is not needed.

Surfactants

Surfactant molecules act by attaching a hydrophilic portion to the

attapulgite surface and extending a long-chained organophilic portion

into the organic liquid. Cationic surfactants usually work best with

Attagel 50 grade, providing for the most efcient thickening and the

greatest water resistance. Non-ionic surfactants also work efciently,

but tend to reduce water resistance. Anionic surfactants normally are

ineffective and give poor water resistance and poor thickening.

The qualities of the liquid to be thickened, specically the polarity and

level of hydrogen bonding, affect the need for a surfactant and the

nature of the gel formed.

The following is a guideline for Attagel 50 in certain organic liquids:

Highly polar liquids with strong hydrogen bonds permit Attagel 50

grade to disperse readily and form a strong gel. Surfactants are

often not needed in these liquids.

Medium polarity liquids with medium hydrogen bonding permits

Attagel 50 grade to form modest gels by itself and excellent gels

when used with a surfactant.

Low polarity liquids with poor hydrogen bonding need higher

loadings of Attagel 50 and a surfactant. Addition of a polar liquid

can strengthen gels in low polarity liquids. Surfactants usually are

not needed if the organic liquid contains at least 5% water.

Desiccating liquids that remove free surface moisture from

Attagel 50 particles usually gel well without a surfactant, but the

gel may be unstable. Addition of compatible polar liquids (e.g.,

5% to 10% water, higher alcohols or glycols) is recommended to

improve gelling and stability.

Surfactant ratio

The surfactant and its concentration depend on the liquid being

thickened, the amount of surfactant adsorbed by other solids, and the

presence of surface-active agents. Each organic liquid has Attagel 50/

surfactant weight ratio that gives high viscosity and viscosity stability,

low syneresis and efcient use of Attagel 50 modier (Figure 5).

Surfactant levels below this level generally have poorer thickening and

viscosity stability, and greater liquid bleed. Higher surfactant levels

generally have poorer thickening and/or viscosity stability, although

suspension may remain high. Higher surfactant levels also increase

cost and water sensitivity.

08 09

When formulating with Attagel 50 rheology modier select a starting

thickener/surfactant ratio for the liquid and experiment with higher

and lower ratios to nd the best level for your application.

Example: Optimizing surfactant ratio

To thicken toluene with Attagel 50 thickener and the surfactant

PA-14* acetate, the recommended starting ratio is 9:1. As a rst step

in nding the optimum surfactant level, measure viscosities of a 100

gm batch at varying ratios of 8:1 to 10:1 as shown in Table 4.

How much Attagel rheology modier to use

Attagel 50 thickener loading required to gel a pure organic liquid is

typically 10 to 20% weight. The more viscous the liquid, however, the

less thickener is needed. Higher solids concentrations also decrease

the amount of Attagel 50 product required, because the solids reduce

the amount of liquid to be thickened. High solids content also makes

Attagel 50 thickener more efcient because the particles interact with

the modiers structure and strengthen the gel.

Other thickening agents or bers also reduce the amount of Attagel

50 product required. In the presence of such co-thickeners, Attagel

rheology modiers are needed to produce thixotropy, sag resistance

and syneresis control which many co-thickeners do not provide.

Attagel 50 rheology modier produces stable suspensions of solids

in organic liquids. If the suspended particles settle, they tend to

form soft sediment that is easily redispersed. The amount of Attagel

50 product needed should be determined empirically because the

optimum concentration depends on such factors as percent solids

present, size and density of the particles, the type and viscosity of the

organic liquid, and the surfactant used.

Dispersion

Attagel 50 rheology modier is dispersed best in organic liquids as a

pregel. This involves combining some of the liquid with the thickener

and surfactant to form a 15% to 20% concentrate that disperses

rapidly at low shear. Pregels can be formed in two ways Pregel

Batch Method and Pregel Concentrate Method.

Attagel 50/Surfactant ratio 8:1 9:1 10:1

T

a

b

l

e

4

.

O

p

t

i

m

i

z

i

n

g

s

u

r

f

a

c

t

a

n

t

r

a

t

i

o

Toluene, gm 77.5 77.8 78.0

Surfactant, gm 2.5 2.2 2.0

Attagel 50, gm 20.0 20.0 20.0

Figure 5. Typical curves: Viscosity vs. surfactant concentration

V

i

s

c

o

s

i

t

y

Surfactant Concentration

Liquid A Optimum

Liquid B Optimum

*PA-14 is a trademark of Tomah products.

Formulation assistance

Were here to help

Pregel batch method

In this technique, Attagel 50 rheology modier is added directly into

the mixing vessel during the grinding stage.

1. Add a portion of the organic liquid. If no other solids will be added,

use only the portion of the organic liquid in the formula sufcient

to yield a 15 to 20% Attagel 50 concentration after Step 3. If other

solids will be added, use a predetermined portion of the organic

liquid that gives a viscosity range for optimum shear in Step 4.

2. Mix all the surfactant into the liquid.

3. Add all Attagel 50 product and mix to adequate dispersion.

4. Add all other solids and additives. Mix together at high shear until

gelling occurs.

5. Add the balance of the organic liquid and mix to homogenize.

Pregel concentrate method

Prepare a 15% to 20% Attagel 50 concentrate separately from the

production batch (Steps 1 to 3 above) for use in multiple batches or

to be stored for future use. High-speed/high-shear mixing or milling

usually is needed to make this concentrate. When using pregels in

a formulation, the usual order of addition is organic liquid, pregel

concentrate (mix to homogenize) and then all other materials (mix to

adequate dispersion).

Care should be taken to avoid over- or under-dispersion, see Figure

2. Over-dispersion occurs if too much surfactant is present. Particles

are scattered and separated so much that they cannot form a strong

network. Under-dispersion, due to insufcient mixing shear or time,

does not free enough particles to form a strong network. Under-

dispersion can also allow viscosity to increase slowly over time as the

attapulgite bundles wet-out and separate into individual particles.

Effect of heat and moisture

Heating the components or the mixture before or during processing

can help dissolve the surfactant so it is more available for dispersion

of Attagel 50 modier. Heat can also improve gelling by reducing the

secondary bonding forces that hold Attagel 50 particles together and

by lowering the viscosity of waxes, asphalts and other thick systems.

Too much heat can cause problems, however. It can make medium-

viscosity organic liquids so thin that not enough energy can be

added to the system during mixing for proper dispersion. It can also

evaporate volatile organic liquids which alters concentrations or

drives off surface water on Attagel 50 particles. This free surface

moisture on Attagel 50 particles aids their dispersion in organic

liquids, particularly in low-polarity liquids. Gels lose strength if too

much surface water is removed. Excessive loss of surface water can

be corrected by adding small amounts of water to systems that can

tolerate it, or by adding polyhydroxy compounds, such as glycerine,

glycols, mannitol, sorbitol or pentaerythritol.

Processing

Proper dispersion of Attagel 50 modier usually requires medium-

and high-shear mixing equipment, such as a Cowles Dissolver.

Low-speed mixers can be used with the proper order of addition,

especially if a pregel is used.

Manufacturers also use high-speed mixers, homogenizers, and colloid,

roll and ball mills, to disperse Attagel 50 modier in organic liquids.

With high-speed mixers, it is best to dissolve the surfactant in the

liquid (using heat, if necessary) before adding the Attagel 50 product

and mixing until gelling occurs. With a homogenizer or colloid or roll

mill, it is best to prepare a blended feed containing the organic liquid,

Attagel 50 (at 15 to 20% concentration) and the surfactant. With a

slow-speed paddle mixer or ribbon blender, it is best to use a pregel

for enhanced thickening.

Stability of gels

Organic liquids gelled with Attagel 50 product and a suitable surfactant

show good temperature stability, unlike other inorganic thickeners, such

as some oganoclays. Organic gels can be prepared that show no melting

point and exhibit only minor consistency changes over wide temperature

ranges. Greases made with Attagel 50 rheology modier and a surfactant

demonstrate excellent mechanical properties and storage stability.

Despite the excellent gel stability of organic liquids thickened with

Attagel 50, there are a few conditions which can hinder this stability.

Thinning can occur in organic liquids gelled with Attagel 50 thickener

that contain water if the pH exceeds 11. Also, the presence of soaps,

naphthenates, or other surface-active materials in an organic liquid

can thin gels. In some cases, decreasing the amount of surfactant or

adding small amounts of 85% phosphoric acid can overcome this.

The latter is particularly effective with imidazoline surfactant.

The viscosity of gels made with Attagel 50 thickener usually increases

to a stable level within 12 to 24 hours of preparation. It is best to age

gels for at least 24 hours before evaluating them to allow thickening

to stabilize. Be sure to check viscosity and gel stability of the nal

product formula at the temperature and duration in which the product

will be stored.

10 11

A review of the steps to optimize Attagel product performance

1. Attagel rheology modiers concentration and degree of dispersion

are critical for optimizing its rheological properties.

2. Dispersion is strongly inuenced by the following:

a. Surfactants They aid dispersion but an excess will over-

disperse particles and hinder gel formation. Surfactants are

not generally recommended for aqueous systems.

b. Shear rate of mixing Dispersion improves with higher shear

rate and is aided by higher solids. Shear rate is more critical

than mixing speed (Figure 3). Under-dispersion gives poor gel

formation and, in aqueous systems, post-thickening can occur

as the undispersed particles wet-out naturally over time and

develop a stronger gel network. A low shear process requires

pregel, higher solids, or longer mixing time.

3. Pregelling Attagel products takes advantage of the shear inherent

in particle crowding. Pregels are best used when there is low

shear mixing, the formulation foams when mixed rapidly, high-

speed mixers are unavailable, or the formulation has abundant

liquid and relatively small amounts of pigment and vehicle.

4. Liquid demand of other ingredients can affect viscosity as it

determines the liquid available to be thickened. More crowded

systems mean that viscosity change for a given amount of Attagel

is more noticeable (Figure 4).

Aqueous applications

1. It is best to add Attagel modiers at the end of the pigment-

grind step to prevent absorption of surfactants intended for

other pigments. This can cause over-dispersion and hinder gel

formation.

2. The dosage of Attagel product depends on the consistency

desired, the presence of other pigments or additives, the solids of

the system, and the available free water. Table 3 provides typical

dosages in several major applications.

3. Attagel thickener can be used as the sole thickener only if

thixotropic rheology is needed. Such systems do not have high

viscosity at high shear so they ow easily during application.

4. Attagel can be used to partially replace cellulose thickeners to

improve spattering and sag resistance. They are best used with

high viscosity cellulosics like HEC and HPMC. It is recommended

that at least 3 lbs. cellulosic per 100 gallons (3.5g/l) be retained

in the formulation to provide freeze-thaw stability and open-time.

5. Attagel products co-thickened with associative thickeners

(urethane-based rheology modiers) improve syneresis, pigment

settling, organic pigment ooding and oating, hiding, color

development and sag resistance.

6. Attagel products co-thickened with alkali swellable and

hydrophobically modied HEC thickeners remedy sag resistance,

pigment settling, and dipping problems.

Organic liquid applications

1. Attagel 50 is the preferred grade as the ner particles wet-out

better in organic liquids.

2. To gel pure organic liquids, 10 to 20% by weight of Attagel 50

thickener is typically added. The more viscous the liquid the less

thickener needed. Also, the amount of thickener is reduced with

higher solids concentrations and the addition of other thickening

agents or bers.

3. Select a surfactant specic to the organic liquid to be thickened.

A surfactant is not usually needed in highly polar liquids. Cationic

surfactants are best.

4. Determine the optimum Attagel 50/surfactant ratio to achieve the

highest viscosity and least syneresis.

5. Evaluate Attagel 50/surfactant ratios with all additives present.

6. When a surfactant is required, Attagel should be added early to

ensure capture of the surfactant.

7. Pregelling is usually the best way to disperse the Attagel 50

modier, especially if low-shear mixing is used.

8. A few formulation and process conditions can hinder gel stability

and cause thinning, such as heat, moisture, pH above 11, and

certain soaps, naphthenates, and other surface-active materials.

9. The gels should be allowed to stabilize for at least 24 hours

before evaluating.

10. Check the storage stability of the nal formula at the temperature

and duration of typical storage.

For more information about Attagel rheology modiers or any of

BASFs attapulgite, kaolin, or mica products, please contact your

BASF representative.

North America

BASF Corporation

Tel: +800 962 7829

+973 245 7399

Fax: +800 971 1123

+864 332 5080

email:

ColorsEffectsCustomerCare@basf.com

BASF Corporation, headquartered in New Jersey, is the North American afliate of BASF AG,

Ludwigshafen, Germany. BASF is the worlds leading chemical company, with a portfolio that ranges

from chemicals, plastics, performance products, agricultural products and ne chemicals to crude oil

and natural gas. As a reliable partner to virtually all industries, BASFs intelligent solutions and high-

value products help customers to be more successful. BASF develops new technologies and uses

them to open up additional market opportunities. We combine economic success with environmental

protection and social responsibility, thus contributing to a better future. Further information on BASF is

available on the Internet at www.basf.com.

While the descriptions, designs, data and information contained herein are presented in good faith

and believed to be accurate, it is provided for your guidance only. Because many factors may affect

processing or application/use, we recommend that you make tests to determine the suitability of a

product for your particular purpose prior to use. NO WARRANTIES OF ANY KIND, EITHER EXPRESS OR

IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE MADE REGARDING PRODUCTS DESCRIBED OR DESIGNS, DATA OR INFORMATION SET FORTH, OR

THAT THE PRODUCTS, DESIGNS, DATA OR INFORMATION MAY BE USED WITHOUT INFRINGING THE

INTELLECTUAL PROPERTY RIGHTS OF OTHERS. IN NO CASE SHALL THE DESCRIPTIONS, INFORMATION,

DATA OR DESIGNS PROVIDED BE CONSIDERED A PART OF OUR TERMS AND CONDITIONS OF SALE.

All trademarks are owned by BASF AG, BASF Corporation, or BASF Catalysts LLC

Copyright 2007 BASF Corporation.

BF8851

Visit us online at www.basf.com/usa

BASF Corporation

100 Campus Drive

Florham Park, NJ 07932

Regulatory

FDA Status

All Colloidal Hydrated Magnesium Alumino-Silicate products, attapulgite, have the

following FDA and EPA CFR approvals:

21 CFR Part 175 Indirect Food Additives: Adhesives & Components of Coatings

Part 175.105 Adhesives

Part 175.125 Pressure Sensitive Adhesives

Part 175.300 Resinous and Polymeric Coatings

21 CFR Part 176 Indirect Food Additives: Paper & Paperboard Components

Part 176.170 & 176.180 Components of Paper & Paperboard

21 CFR Part 177 Indirect Food Additives: Polymers

Part 177.1200 Cellophane

Part 177.1210 Closures with Sealing Gaskets for Food Containers

Part 177.2600 Rubber Articles intended for Repeated Use

21 CFR Part 178 Indirect Food Additives: Adjuvants, Production Aids & Sanitizers

Part 178.3297 Colorants for Polymers

21 CFR Part 186 Indirect Food Substances Afrmed as Gras

Part 186.1256 Clay

21 CFR Part 582 Indirect Substances that are generally recognized as safe

Part 582.1 Anti-Caking agent and pelleting aid

Part 582.1 Suspension aid in liquid feed supplement

40 CFR Part 180 Tolerances and exemptions

Part 180.920 Inert ingredients used pre-harvest

Please refer to the listed paragraphs in the CFR or contact

BASF Regulatory directly at ehs_p_info_center@basf.com or

at 704-398-5012 for details on restrictions and limitations.

Anda mungkin juga menyukai

- FoamStar ST 2412 August 2018 R3 ED2Dokumen2 halamanFoamStar ST 2412 August 2018 R3 ED2APEX SONBelum ada peringkat

- LoVOCoat - For Low VOC High Performance Solvent Borne CoatingsDokumen4 halamanLoVOCoat - For Low VOC High Performance Solvent Borne CoatingskarlaBelum ada peringkat

- A New APEO-free Surfactant Solution For The Paint - SolvayDokumen24 halamanA New APEO-free Surfactant Solution For The Paint - Solvayichsan hakimBelum ada peringkat

- Talc in Polyester Putties - Mondo Minerals PDFDokumen10 halamanTalc in Polyester Putties - Mondo Minerals PDFJuanan LopezBelum ada peringkat

- Jo GradeDokumen40 halamanJo GradeEvonne TanBelum ada peringkat

- Brochure Matting Agents EDokumen60 halamanBrochure Matting Agents Efrox123Belum ada peringkat

- 2015 Montan Waxes and Special Wax Blends For Car Polish Base Formulations enDokumen11 halaman2015 Montan Waxes and Special Wax Blends For Car Polish Base Formulations enMohsen GolmohammadiBelum ada peringkat

- Brand+Acronal Brochure Resins+Industrial+Coatings+Selection+Guide EnglishDokumen15 halamanBrand+Acronal Brochure Resins+Industrial+Coatings+Selection+Guide Englishgemm88Belum ada peringkat

- 24 391 01 Coatings and Inks Additive Selection GuideDokumen16 halaman24 391 01 Coatings and Inks Additive Selection GuideLong An DoBelum ada peringkat

- EvonikDokumen20 halamanEvonikMohit Singhal0% (1)

- Economic Paint RedaDokumen1 halamanEconomic Paint RedaForeverBelum ada peringkat

- 07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiDokumen62 halaman07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiForeverBelum ada peringkat

- Aluminium PasteDokumen16 halamanAluminium PasteAndreas Widjaja100% (1)

- 7020P Version 7thDokumen1 halaman7020P Version 7thDuc NguyenBelum ada peringkat

- Croda How To LoVOCoatDokumen6 halamanCroda How To LoVOCoatkarla100% (1)

- Li Edaplan Metolat Dispersing TechnologyDokumen15 halamanLi Edaplan Metolat Dispersing TechnologyPulbere NeagraBelum ada peringkat

- TDS - Panax Yellow 3RDokumen1 halamanTDS - Panax Yellow 3RRio AndriyantoBelum ada peringkat

- AkzoNobel Paint Eng Tcm54-18194Dokumen20 halamanAkzoNobel Paint Eng Tcm54-18194a2009sBelum ada peringkat

- Ecrylic KDA 790 - Die Ecronova Polymer GMBHDokumen8 halamanEcrylic KDA 790 - Die Ecronova Polymer GMBHLong An ĐỗBelum ada peringkat

- Use of Soya Lecithin in Making PaintDokumen1 halamanUse of Soya Lecithin in Making PainttunlajiBelum ada peringkat

- Munzing Masterbatch AdditivesDokumen8 halamanMunzing Masterbatch AdditivesThea Athalia CandraBelum ada peringkat

- Can Coating Formulations (Sheet 1 To 4)Dokumen3 halamanCan Coating Formulations (Sheet 1 To 4)No NameBelum ada peringkat

- UC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFDokumen24 halamanUC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFchayanunBelum ada peringkat

- Water Repellent CoatingDokumen90 halamanWater Repellent Coatingmoses_cBelum ada peringkat

- Clear CoatDokumen1 halamanClear CoatForeverBelum ada peringkat

- Additives, Driers, Accelerators and Catalysts: For Coatings, Paints, Composites, Printing Inks and AdhesivesDokumen16 halamanAdditives, Driers, Accelerators and Catalysts: For Coatings, Paints, Composites, Printing Inks and AdhesivesAnanthanarayananBelum ada peringkat

- Diagram 1: Gibbs Equation On ElasticityDokumen8 halamanDiagram 1: Gibbs Equation On ElasticityManoj Lalita GoswamiBelum ada peringkat

- FP Pigments - Opacity Pigments, Cost Saving Opportunities in Architectural Coatings Paul DietzDokumen22 halamanFP Pigments - Opacity Pigments, Cost Saving Opportunities in Architectural Coatings Paul DietzHiếu Mai ĐứcBelum ada peringkat

- Technical Data Sheet: Rexin DP 127Dokumen1 halamanTechnical Data Sheet: Rexin DP 127sriatul2006Belum ada peringkat

- Waterborne Additives Brochure 2022 enDokumen13 halamanWaterborne Additives Brochure 2022 enHelene Di marcantonioBelum ada peringkat

- EDM - 012 Additives For Wood and Furniture Coatings PDFDokumen8 halamanEDM - 012 Additives For Wood and Furniture Coatings PDFEugene PaiBelum ada peringkat

- Dow Performance Solvents: - Your Choice of Coalescent in Waterborne CoatingsDokumen4 halamanDow Performance Solvents: - Your Choice of Coalescent in Waterborne CoatingsAPEX SONBelum ada peringkat

- Acronal - Plus - 7023 - Jan 2020Dokumen3 halamanAcronal - Plus - 7023 - Jan 2020Nikhil GoyalBelum ada peringkat

- How To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry PaintsDokumen45 halamanHow To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry Paintssriatul2006Belum ada peringkat

- Acrysol rm-8w 3Dokumen4 halamanAcrysol rm-8w 3Forever0% (1)

- Soyol Polyol FormulationsDokumen3 halamanSoyol Polyol FormulationsurethanBelum ada peringkat

- AIR PRODUCTS Agrochemical Adjuvants GuideDokumen8 halamanAIR PRODUCTS Agrochemical Adjuvants GuideRomán M Martín del CBelum ada peringkat

- Rheology Modifiers Product Recommendations For EuropeDokumen2 halamanRheology Modifiers Product Recommendations For EuropeHamood AbdoBelum ada peringkat

- Supreme: Premium Opacifying Mineral For Titanium Dioxide ExtensionDokumen2 halamanSupreme: Premium Opacifying Mineral For Titanium Dioxide Extensionkensley oliveiraBelum ada peringkat

- Oxylink - Technical Product Information: Additive For Waterborne Resin SystemsDokumen32 halamanOxylink - Technical Product Information: Additive For Waterborne Resin SystemsAPEX SONBelum ada peringkat

- BYKDokumen4 halamanBYKlqiroxitaBelum ada peringkat

- Kumho KTR 401: ® Technical Data SheetDokumen2 halamanKumho KTR 401: ® Technical Data Sheetjulio sierraBelum ada peringkat

- WaxAdditives EN PDFDokumen24 halamanWaxAdditives EN PDFAmm MarakataBelum ada peringkat

- Architectural EN-VINAVIL PDFDokumen36 halamanArchitectural EN-VINAVIL PDFSeafar YachtingBelum ada peringkat

- RosinDokumen42 halamanRosinVingiu Katre100% (1)

- Acronal Ps 713 APDokumen2 halamanAcronal Ps 713 APCarlos100% (1)

- Automotive Coatings Product Guide: Resins, Polymers, Dispersants & AdditivesDokumen7 halamanAutomotive Coatings Product Guide: Resins, Polymers, Dispersants & AdditivesAmado ElzBelum ada peringkat

- Manufacturing Technology Formulations Hand BookDokumen10 halamanManufacturing Technology Formulations Hand BookAhmed HassanBelum ada peringkat

- Clariant Brochure Emulsion Polymerization Portfolio 2017 EN PDFDokumen4 halamanClariant Brochure Emulsion Polymerization Portfolio 2017 EN PDF幸福100% (1)

- Tds Eterac 73626-S-70 (En)Dokumen1 halamanTds Eterac 73626-S-70 (En)Liliana Higuera NítolaBelum ada peringkat

- OMG Americas - Additives BrochureDokumen8 halamanOMG Americas - Additives BrochureUsama AwadBelum ada peringkat

- Dirt-Pickup Resistance Inlowt Elastomeric Coatings: Robert Sandoval, PH.DDokumen31 halamanDirt-Pickup Resistance Inlowt Elastomeric Coatings: Robert Sandoval, PH.Dichsan hakimBelum ada peringkat

- Paten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenDokumen4 halamanPaten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenSepvan ValeriBelum ada peringkat

- Wanhua Interior Coating SolutionsDokumen28 halamanWanhua Interior Coating SolutionsThanh Vu100% (1)

- Resins For: Vehicle Refinish & Commercial Transportation CoatingsDokumen6 halamanResins For: Vehicle Refinish & Commercial Transportation CoatingsEmilio HipolaBelum ada peringkat

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Dari EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Belum ada peringkat

- Handbook of Vinyl FormulatingDari EverandHandbook of Vinyl FormulatingRichard F GrossmanPenilaian: 3 dari 5 bintang3/5 (1)

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachDari EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudPenilaian: 5 dari 5 bintang5/5 (1)

- Darwin, C. R. Darwin, EmmaDokumen12 halamanDarwin, C. R. Darwin, EmmaketchitoBelum ada peringkat

- Hydrotherapy Vs Gym Exercises For OADokumen7 halamanHydrotherapy Vs Gym Exercises For OAketchitoBelum ada peringkat

- Drug Type Mechanism For Relief of These SymptomsDokumen2 halamanDrug Type Mechanism For Relief of These SymptomsketchitoBelum ada peringkat

- 27 1147 01Dokumen8 halaman27 1147 01ketchitoBelum ada peringkat

- Aculyn 22Dokumen12 halamanAculyn 22Carlo DuranBelum ada peringkat

- Ecosurf SA 9Dokumen2 halamanEcosurf SA 9ketchitoBelum ada peringkat

- Lahcen Achy Jawad KerdoudiDokumen2 halamanLahcen Achy Jawad KerdoudiketchitoBelum ada peringkat

- Preservatives in Cosmetic ProductsDokumen35 halamanPreservatives in Cosmetic Productsketchito100% (2)

- Experiment 4 Palvi FinalDokumen8 halamanExperiment 4 Palvi FinalSara AliBelum ada peringkat

- PW1. Javel WaterDokumen3 halamanPW1. Javel WaterFariz AbdullayevBelum ada peringkat

- Biological MacroDokumen49 halamanBiological MacroChristine De San JoseBelum ada peringkat

- Boiler Troubles: Prepared by S.I.Davis PresleyDokumen26 halamanBoiler Troubles: Prepared by S.I.Davis PresleyAbinav Narayanan100% (1)

- Form Six Chemistry 1Dokumen6 halamanForm Six Chemistry 1abubakarimuyanaBelum ada peringkat

- Balancing Chemical Equations WorksheetDokumen99 halamanBalancing Chemical Equations Worksheetkhaled_behery9934100% (4)

- Supermix PC450 PDFDokumen2 halamanSupermix PC450 PDFmanavBelum ada peringkat

- Wet Compounding With Pyrolytic Carbon Black From Waste Tyre For Manufacture of New TyDokumen11 halamanWet Compounding With Pyrolytic Carbon Black From Waste Tyre For Manufacture of New TyDimpi PatelBelum ada peringkat

- Oouchi 2019Dokumen7 halamanOouchi 2019Victor Hugo GuzmánBelum ada peringkat

- Stok 03082022Dokumen22 halamanStok 03082022Andika SulistiawanBelum ada peringkat

- How Do You Make A Potassium Iodide (KI) SolutionDokumen7 halamanHow Do You Make A Potassium Iodide (KI) SolutionK AnjaliBelum ada peringkat

- Bitumen Lecture NotesDokumen10 halamanBitumen Lecture NotesIbrahim Tanko AbeBelum ada peringkat

- Experiment #1Dokumen7 halamanExperiment #1Lakani Tindiwi YangalaBelum ada peringkat

- LM6 AluminiumDokumen4 halamanLM6 AluminiumRajaSekarsajjaBelum ada peringkat

- Domino Reaction: First Report: Angew. Chem. 1937, 50, 779-787Dokumen15 halamanDomino Reaction: First Report: Angew. Chem. 1937, 50, 779-787Priya GoleBelum ada peringkat

- Aerospace MaterialsDokumen21 halamanAerospace MaterialsrkneyveliBelum ada peringkat

- QueenOfGreen Green Cleaning RecipesDokumen2 halamanQueenOfGreen Green Cleaning RecipesJeelo100% (1)

- Sea Water DistillationDokumen1 halamanSea Water DistillationRed one67% (3)

- Lab Report 3-Investigating Plant Mineral DeficienciesDokumen18 halamanLab Report 3-Investigating Plant Mineral DeficienciesMaisarah Zainuddin100% (1)

- Answer Across Across: Nurture CourseDokumen24 halamanAnswer Across Across: Nurture CourseMayank SharmaBelum ada peringkat

- UF Membrane ProcessDokumen9 halamanUF Membrane ProcessAFRIZABelum ada peringkat

- Triple Science Chemistry Chemical Analysis Revision QuestionsDokumen32 halamanTriple Science Chemistry Chemical Analysis Revision QuestionsShakira MaribaoBelum ada peringkat

- Asme Sa 240 PDFDokumen16 halamanAsme Sa 240 PDFqaBelum ada peringkat

- 9 TH Class CBSEDokumen51 halaman9 TH Class CBSEramanji1021Belum ada peringkat

- 14D f08 E01Dokumen4 halaman14D f08 E01vincent_tang_30Belum ada peringkat

- Intermolecular Forces,, And: LiquidsDokumen72 halamanIntermolecular Forces,, And: LiquidsGlenn ClementeBelum ada peringkat

- Aramco Reference StandardDokumen49 halamanAramco Reference Standardessence1100% (1)

- 10 Science Mid Term PaperDokumen6 halaman10 Science Mid Term PaperAnishika100% (1)

- Nitrogen CompoundsDokumen20 halamanNitrogen Compoundsapi-3734333Belum ada peringkat

- MFDokumen29 halamanMFRayhan AdhaBelum ada peringkat