2000 Guruprasad Mukherjee

Diunggah oleh

sachin_mane880 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

9 tayangan10 halamanResearch Paper on blast modelling experiment

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniResearch Paper on blast modelling experiment

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

9 tayangan10 halaman2000 Guruprasad Mukherjee

Diunggah oleh

sachin_mane88Research Paper on blast modelling experiment

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 10

* Corresponding author. Tel.: 091-22-576-7343; fax: 091-22-578-3480.

E-mail address: abhijit@civil.iitb.ernet.in (A. Mukherjee).

International Journal of Impact Engineering 24 (2000) 975}984

Layered sacri"cial claddings under blast loading

Part II * experimental studies

S. Guruprasad, Abhijit Mukherjee*

Research & Development Establishment (Engineers), Dighi, Pune 411 015, India

Department of Civil Engineering, Indian Institute of Technology, Bombay, Mumbai 400 076, India

Received 15 July 1999; received in revised form 15 December 1999

Abstract

This paper discusses the performance of sacri"cial layer under blast loading. A number of blast experi-

ments have been carried out on sacri"cial layered claddings. The blast overpressures were recorded by two

crystal-type blast pressure gauges. The deformations of the layers of the claddings were also recorded. The

layers collapsed successively in the same manner as predicted in the analytical studies. The collapse mode of

the unit cell was always the same as predicted in the analytical studies. However, collapse of the layers was

slower than predicted in the analytical studies. The experiments have shown the e$cacy of the layered

sacri"cial claddings in design of blast resistant structures. 2000 Elsevier Science Ltd. All rights reserved.

1. Introduction

In Part I, analytical studies of the layered sacri"cial cladding were discussed. The experimental

veri"cation is reported in this paper. Experimental studies were carried out to validate the

analytical models as reliable design tools. Experimental work involving blast loading is expensive

and requires careful planning in design of the specimens as well as the instrumentation scheme.

The specimens should cover variations of all the important parameters of study in line with the

objectives of the experiments. The instrumentation scheme should be capable of measuring the

aspects of the structural response that have a direct bearing on the objectives of the experimental

study.

In this paper, the experimental specimens, the experimental set up adopted, the instrumentation

scheme and the data acquisition and processing system are discussed in detail. The scheme of

0734-743X/00/$- see front matter 2000 Elsevier Science Ltd. All rights reserved.

PII: S 0 7 3 4 - 7 4 3 X( 0 0 ) 0 0 0 0 5 - 1

experiments and challenges faced during experiments have also been discussed. The reported

experiments on blast and impulsively loaded structures are brie#y reviewed.

The phenomenon of energy absorption through plastic deformations including the e!ects of

elasticity, strain hardening and strain rate sensitivity are similar for structures subjected to impact

or blast loads. All the literature dealing with impact loading and corresponding structural response

is relevant to blast loading also. Jones [1,2] has reviewed literature under dynamic plastic

behaviour of ductile metallic structures subjected to impact and blast loads. Field experiments

conducted on energy absorbing structures subjected to blast load are sparse. However, studies on

small-scale structural elements like plates, sti!ened plates, beams and grillages are available and

they are very useful in understanding the response of structures subjected to blast loads.

Nurick et al. [3] have carried out investigations on deformation and tearing of blast-loaded

sti!ened square plates. The plates and the sti!ener are machined out of a block of material and

hence, completely built in. Numerical studies using "nite element analysis have been carried out

including strain-rate e!ects with Cowper}Symonds relations. For blast loading a rectangular pulse

with the duration equal to burn time of the explosive is used. Ballistic pendulum has been used to

measure the impulse and the burn time of the explosive is taken as the duration. Using these two

quantities the blast pressures have been calculated.

Houlston and Slater [4] have carried out experimental and analytical studies on ship panels

subjected to air blast loading. The ship panels were sti!ened plates with box beams and were

clamped to a concrete base seated on the ground. The instrumentation in the experiments consisted

of transducers to measure blast pressures, accelerometers and strain gauges. The recordings of

pressure, acceleration and strain were analog that were subsequently digitised at 50 kHz for

pressure and acceleration and 25 kHz for strain. The "nite element model was a quarter of the

square plate with beam sti!eners. The analytical and experimental work was compared and the

experiments produced more deformations than analytically predicted.

Wierzbicki et al. [5] have studied transient response of plastic cylindrical shells using a simpli"ed

analytical model. They have also studied ring reinforced cylinders under impact and blast loading.

A comparison of the analytical results with limited experimental results [6] was also presented.

Simple formulae for ballistic limit of an unsti!ened shell subjected to a missile impact and the

critical impulse to rupture of a sti!ened shell are also presented.

Galiev [7] has carried out experimental studies on circular plates and has observed some

counterintuitive behaviour, i.e. the "nal de#ections are contrary to the direction of the impulsive

loading. The importance of considering the negative phase of the blast wave in certain conditions is

highlighted in his paper.

Li and Jones [8] have studied dynamic response of a fully clamped circular plate with

rigid-perfectly plastic material model. Theoretical solutions are obtained for a general blast loading

distributed uniformly over the entire area of the plate. The e!ects of di!erent boundary conditions,

pressure pulse loading shapes and the in#uence of the transverse shear force on the dynamic plastic

response of circular plates are studied. The critical conditions are predicted for a transverse shear

severance to occur at the supports of a circular plate when transverse shear e!ects are retained in

the yield condition. They have also investigated dynamic response of a short cylindrical shell [9]

that is made from a rigid, perfectly plastic material. The e!ect of transverse shear is studied in

particular. The theoretical results are combined with an elementary failure criterion to predict the

critical conditions for a transverse shear failure.

976 S. Guruprasad, A. Mukherjee / International Journal of Impact Engineering 24 (2000) 975}984

Nurick et al. [10] have carried out experiments for prediction of the onset of thinning (necking)

and the subsequent tearing at the boundary of clamped circular plates subjected to uniformly

loaded air blasts. They have investigated di!erent clamped edge conditions viz. sharp, round with

di!erent radii. They have compared the experimental results with analytical results obtained using

"nite element analysis.

Watson et al. [11] have carried out experimental investigations on steel claddings subjected to

blast loading. Scaled specimens were used for carrying out experimentation. Comparisons are

made between the damage produced on the scale model and on comparable full scale buildings of

similar construction.

Jiang and Olson [12] have developed a simpli"ed method of analysis to predict the nonlinear

dynamic response of submerged sti!ened plates subjected to underwater explosions. Rigid}plastic

beam and beam grillage approach is used to model the dynamic response. The mathematical

formulation of the coupled "eld system is brie#y outlined and some illustrative examples are

presented.

The experimental work carried out by di!erent investigators also highlights the di$culties faced

in instrumentation and recording of structural response. Blast pressure gauges, strain gauges and

accelerometers are the transducers generally used in measurements. Sometimes, indirect methods

have been adopted to measure certain quantities. Foe example, ballistic pendulum has been used

for measuring impulse and then calculating the blast pressure. We shall now introduce the present

experimental set-up.

2. Experiments

2.1. Specimen preparation

The sacri"cial device has been introduced in Part I. Experimental specimens consisted of the

same cellular construction. The focus of the study was on behaviour of unit cells in the sacri"cial

layers. Hence, the structure should be big enough to accommodate a few rows of unit cells with

su$cient width. Fig. 1 shows the photograph of the experimental set-up with a typical test

specimen. The cladding layers were fabricated out of 1.2 and 1.6 mm mild steel sheets. The

mechanical properties of the sheets are indicated in Section 3 of Part I. All the test specimens were

of 1 m;2 m dimension. The cladding layers were stitch welded to a rigid frame of heavy steel

channel sections.

The cells consist of 1 cover plate, 1 bottom plate and two web plates joined together by spot

welds staggered by 15 mmand with a pitch of 30 mm (Fig. 2). A few specimens with a single unit cell

of 100 mm width were fabricated and loaded until complete collapse to see adequacy of the joint

strengths. The joint strength was found adequate under gradual loading as well as impact loading.

The web plates were bent to the required shape by a plate bending machine and the geometry was

controlled by a template.

2.2. Test set-up

The experimental specimens were placed on ground with sacri"cial cladding surface on top and

horizontal. Fig. 1 shows the experimental set up adopted. Two poles were erected with a rope

S. Guruprasad, A. Mukherjee / International Journal of Impact Engineering 24 (2000) 975}984 977

Fig. 1. Experimental set-up. Fig. 2. Single unit cell specimen.

across on top. The test specimens are placed centrally below the rope. The explosive charge is hung

from the middle of the rope so that the charge is centrally above the cladding surface. This closely

simulates free air burst. The height of the charge is adjusted with the help of the rope. TNT charges

were used for all explosions as the blast parameters for TNT are well established. Since the base

frame structure on which sacri"cial cladding structure is "xed is quite heavy, no anchoring of the

specimen was required. After each explosion the rope was replaced.

2.3. Instrumentation scheme

The instrumentation consists of the blast pressure measuring devices and the response measure-

ment of the cladding. The instrumentation for blast pressure measurements consisted of crystal

type blast pressure gauges to record side on blast pressures. Two sets of pressure gauges were used,

one at the same distance as between the explosive charge and the cladding surface, the other gauge

at 0.5 m further. The gauges were mounted at right angles to each other on pedestals and at the

same height as the explosive charges. Two charges were exploded to examine the transducers and

instrumentation.

For recording the structural response usual options are to use accelerometers and strain gauges.

Under blast environment, use of accelerometers would be very expensive as the accelerometers may

get damaged. If strain gauges are used it is very di$cult to convert the strain gauge recordings to

structural response in terms of deformation history. A special arrangement was devised for

recording deformation histories of each layer in the sacri"cial cladding. This new arrangement

consists of a set of potentiometers rigged to record the deformations. Fig. 3 shows the scheme of

measuring the deformations in a cell. The potentiometer is mounted on a bracket pasted on the

978 S. Guruprasad, A. Mukherjee / International Journal of Impact Engineering 24 (2000) 975}984

Fig. 3. Arrangement for measuring deformation of layers.

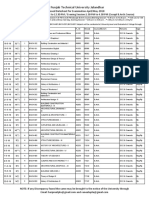

Table 1

Details of specimens and blast loads

Test no. TNT charge weight (kg) Height of charge (m) Number of layers Sheet thickness (mm)

1 2.5 1.5 1 1.6

2 4.1 1.5 3 1.2

3 4.1 1.5 1 1.6

4 5.1 1.5 3 1.6

5 5.0 1.5 3 1.5

6 4.1 2 3 Cover & base 1.2 mm,

web 1.6 mm

7 4.1 2 3 1.2

8 2.5 2 3 1.2

9 4.1 2 1 1.6

10 2.5 2 1 1.6

base plate using a quick setting resin. A slotted arm is "xed to the shaft of the potentiometer and

the slot is engaged with a pin on the top bracket pasted to the cover plate. When the cover plate

deforms the arm and the potentiometer shaft rotates causing a change in the potential across the

potentiometer. This change is recorded in a data acquisition system. The deformation of the cover

plate and the change in potential are calibrated before hand for each potentiometer.

2.4. Tests and results

Table 1 gives the details of the experiments carried out. All the TNT charges used were

cylindrical in shape with an aspect ratio of approximately 1. Table 1 of Part I details the peak

pressure and duration for each blast.

S. Guruprasad, A. Mukherjee / International Journal of Impact Engineering 24 (2000) 975}984 979

Fig. 4. Deformed shape Test 6. Fig. 5. Analytical deformed shape.

Fig. 4 shows the deformed specimen for Test 6. The "rst layer has completely collapsed,

whereas the second layer has not fully collapsed, the third layer has undergone marginal plastic

deformations. The analytical simulation of this experiment is presented in Case 3 of Part I. The

predicted deformation is presented in Fig. 5. The analytical and experimental deformations the "rst

and the third layers compare favourably. The second layer has undergone less deformation than

predicted in the analysis. The analysis does not include a few modes of energy dissipation such as

rubbing of web plates with cover and joint deformations at the spot welds. As a result, it

overpredicts deformation. Moreover, the analytical snap shot is taken before the elastic recovery.

The upward bend of the top plate is the result of elastic recovery. Figs. 6 and 7 show the

comparison of deformation histories for Test 6. The agreement between the analytical and the

experimental results is very good. The analysis, however, has predicted a slightly faster collapse of

both layers. The analysis absorbs the blast through plastic deformation only, while in experiment

some additional modes of energy dissipation take place.

Figs. 8 and 9 compare the experimental and analytical deformations for Test 7. Figs. 10}12 show

deformation histories of the three layers and compares them with analytical results corresponding

to Case 4 in Part I.

Figs. 8 and 9 show that there is a good agreement between experimental and analytical "nal

deformed shapes. The comparison of deformation histories is also reasonably good. The

di!erences are mainly due to exclusion of some of the dissipating agents from the analytical study.

Other tests also produced similar results. These tests validate the analytical technique and con"rm

that the goals of a sacri"cing layer have been met in the design.

One of the vital di!erences between the analysis and the experiments was that in some

experiments wherein the distance between the cladding surface and the explosive charge is small

(1.5 m) the cover plate of the "rst layer was torn and this damage was not analytically predicted.

980 S. Guruprasad, A. Mukherjee / International Journal of Impact Engineering 24 (2000) 975}984

Fig. 6. Deformation history of layer 1 (Test 6). Fig. 7. Deformation history of layer 2 (Test 6).

Fig. 8. Deformed shape Test 7. Fig. 9. Analytical deformed shape.

The re#ected overpressure at the initial moments seems to have shot up for small charge distances.

The theoretical curve did not include this initial peak. Moreover, for small charge distances the

pressure generated over the surface area of the plate is not uniform. As a result, the area under

higher pressure undergoes plastic deformation and in the process pulls the plate that is under lesser

S. Guruprasad, A. Mukherjee / International Journal of Impact Engineering 24 (2000) 975}984 981

Fig. 10. Deformation history of layer 1 (Test 7). Fig. 11. Deformation history of layer 2 (Test 7).

Fig. 12. Deformation history of layer 3 (Test 7).

pressure. That generates a lot of membrane forces in the cover plate. This is contrary to the

assumption of uniform pressure made in the analysis. However, in the successive layers the cover

plates remained intact and the overall design is successful.

982 S. Guruprasad, A. Mukherjee / International Journal of Impact Engineering 24 (2000) 975}984

3. Conclusions

The experimental results have validated the design and the basic observation made through

analytical studies. The analysis marginally overpredicted the deformation and underpredicted the

collapse time. This is due to the absence of some dissipating agents from the analytical model. If the

distance of the explosive charge is small, the re#ected overpressures may be very high and the "rst

layer cover plate may tear but the internal layers are not torn. The experiments have adequately

validated the analytical models and established the layered sacri"cial claddings as an e!ective

energy absorbing device for design of structures under blast loads.

Observations on the performance of a sacri"cial cladding structure under blast loading are as

follows:

E The sacri"cial cladding is very e$cient in dissipating blasts.

E The cells of sacri"cial cladding have prede"ned plastic zones; this makes the collapse behaviour

consistent.

E The behaviour of the cells in the sacri"cial cladding is predictable over the whole range of blast

loads.

E The layered cladding consisting of several layers of cells collapses sequentially.

E Transfer of impulse through the sacri"cial layer is marginal, allowing elastic design of non-

sacri"cial layer.

E The experimental scheme proposed in this paper is successful in measuring the blast pressures

and the corresponding collapse behaviour of the cladding.

E The experimental and theoretical results are in good agreement. The analysis marginally

underpredicts collapse time and overpredicts deformation due to exclusion of some modes

of dissipation.

E In case of short charge distances the top cover plate in some cases was torn due to high peak

re#ected overpressure.

References

[1] Jones N. Recent studies on the dynamic plastic behaviour of structures. Appl Mech Rev 1989;42(4):95}115.

[2] Jones N. Recent studies on the dynamic plastic behaviour of structures * an update. Appl Mech Rev 1996;

49(10):5112}7.

[3] Nurick GN, Olson MD, Fagnan JR, Levin A. Deformation and tearing of blast-loaded sti!ened square plates.

Int J Impact Eng 1995;16(2):273}91.

[4] Houlston R, Slater JE. On analysis of structural response of ship panels subjected to air blast loading. Comput

Struct 1985;21(1/2):273}89.

[5] Wierzbicki T, Hoo Fatt MS. Damage assessment of cylinders due to impact and explosive loading. Int J Impact

Eng 1993;13(2):215}41.

[6] Stronge W. Impact on metal tubes: indentation and perforation. In: Jones N, Wierzbicki T, editors. Structural

crashworthiness and failure. Amsterdam: Elsevier, 1993.

[7] Galiev ShU. Experimental observations and discussion of counterintuitive behavior of plates and shallow shells

subjected to blast loading. Int J Impact Eng 1996;18(7, 8):783}802.

[8] Li QM, Jones N. Blast loading of fully clamped circular plates with transverse shear e!ects. Int J Solids Struct

1994;31(14):1861}76.

S. Guruprasad, A. Mukherjee / International Journal of Impact Engineering 24 (2000) 975}984 983

[9] Li QM, Jones N. Blast loading of a `Shorta cylindrical shell with transverse shear e!ects. Int J Impact Eng

1995;16(2):331}53.

[10] Nurick GN, Gelman ME, Marshall NS. Tearing of blast loaded plates with clamped boundary conditions.

Int J Impact Eng 1996;18(7, 8):803}27.

[11] Watson AJ, Hobbs B, Wright SJ. Experimental modelling of explosive blast e!ects on structural steel cladding.

Struct Under Shock Impact.

[12] Jiang J, Olson MD. Rigid}plastic analysis of underwater blast loaded sti!ened plates. Int J Mech Sci

1995;37(8):843}59.

984 S. Guruprasad, A. Mukherjee / International Journal of Impact Engineering 24 (2000) 975}984

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- GMP Audit in Pharmaceutical Companies-Review ArticleDokumen6 halamanGMP Audit in Pharmaceutical Companies-Review Articleraju1559405Belum ada peringkat

- Final Na Talaga ToDokumen54 halamanFinal Na Talaga ToJoy ManguneBelum ada peringkat

- Christine Hine - Virtual EthnographyDokumen25 halamanChristine Hine - Virtual Ethnographylightmana100% (1)

- Prposed Date Sheet Upload Web SiteDokumen154 halamanPrposed Date Sheet Upload Web SiteShaheer ShafatBelum ada peringkat

- Critical Quarterly Volume 50 Issue 1-2 2008 (Doi 10.1111/j.1467-8705.2008.00811.x) SIMON FRITH - Why Music MattersDokumen15 halamanCritical Quarterly Volume 50 Issue 1-2 2008 (Doi 10.1111/j.1467-8705.2008.00811.x) SIMON FRITH - Why Music MatterssebastianmunoztBelum ada peringkat

- Descriptive Research Design: By: Prateek KakkarDokumen9 halamanDescriptive Research Design: By: Prateek KakkarCarms YasayBelum ada peringkat

- HR001123S0011Dokumen57 halamanHR001123S0011Ahmed LaajiliBelum ada peringkat

- Functionalist Theories of ReligionDokumen19 halamanFunctionalist Theories of ReligionHimanshu KapkotiBelum ada peringkat

- Viral Markers Screening: King Khalid Hospital, NajranDokumen1 halamanViral Markers Screening: King Khalid Hospital, NajranCristal TannerBelum ada peringkat

- Lyceum of The Philippines University Cavite Campus DOA Coecsa A.Y. 2020-2021Dokumen7 halamanLyceum of The Philippines University Cavite Campus DOA Coecsa A.Y. 2020-2021Learnce MasculinoBelum ada peringkat

- Full Details Chromite Mining and ProcessingDokumen12 halamanFull Details Chromite Mining and ProcessingSameen BaberBelum ada peringkat

- WK01. S2 - WMC201Dokumen30 halamanWK01. S2 - WMC201tr.hjieu0708Belum ada peringkat

- Introduction To Statistics ModuleDokumen101 halamanIntroduction To Statistics ModuleBelsty Wale KibretBelum ada peringkat

- Planning, Forecasting and Decision MakingDokumen8 halamanPlanning, Forecasting and Decision MakingDipen MandaliyaBelum ada peringkat

- T4 Rapid Quantitative Test COA - F23216309ADDokumen1 halamanT4 Rapid Quantitative Test COA - F23216309ADg64bt8rqdwBelum ada peringkat

- Cleaner and Responsible Consumption: Nguyen Thi Khanh ChiDokumen9 halamanCleaner and Responsible Consumption: Nguyen Thi Khanh ChiThu ThảoBelum ada peringkat

- Research MethodolgyDokumen4 halamanResearch MethodolgyRizwan BalouchBelum ada peringkat

- Correlational Research - Group 2Dokumen9 halamanCorrelational Research - Group 2Elisa HairaniBelum ada peringkat

- MakalahDokumen16 halamanMakalahNurul FajarrahayuBelum ada peringkat

- Cognitive Emotion Regulation Questionnaire - Development of A Short 18-Item Version (CERQ-short)Dokumen9 halamanCognitive Emotion Regulation Questionnaire - Development of A Short 18-Item Version (CERQ-short)leonardBelum ada peringkat

- Diana HornoiuDokumen2 halamanDiana HornoiuAlexandra DorobanţuBelum ada peringkat

- Cost of To Being Nice !!Dokumen9 halamanCost of To Being Nice !!Himanshu Sharma100% (1)

- Test Bank For What Is Life A Guide To Biology With Physiology 1st Edition PhelanDokumen25 halamanTest Bank For What Is Life A Guide To Biology With Physiology 1st Edition PhelanChester Gildea100% (24)

- The Legend of The Seven WhalesDokumen1 halamanThe Legend of The Seven WhalesSue WestBelum ada peringkat

- Biostatistics For BiotechnologyDokumen128 halamanBiostatistics For Biotechnologykibiralew DestaBelum ada peringkat

- Abstract and Intro Acid-Base TitrationsDokumen2 halamanAbstract and Intro Acid-Base TitrationsZhyra Alexis Anda0% (1)

- Unit 1 - Lesson IDokumen9 halamanUnit 1 - Lesson Imalaaileen6Belum ada peringkat

- Mental Health of Medical Workers DuringDokumen8 halamanMental Health of Medical Workers DuringlokBelum ada peringkat

- Humanities 1 SyllabusDokumen6 halamanHumanities 1 SyllabusEder Aguirre CapangpanganBelum ada peringkat

- Natural Resource Management DissertationDokumen8 halamanNatural Resource Management DissertationCustomCollegePaperCanada100% (1)