Fuel System: Performance

Diunggah oleh

Denis JimenezDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Fuel System: Performance

Diunggah oleh

Denis JimenezHak Cipta:

Format Tersedia

Fuel System

Page 1 of 3

Fuel System

Various fuel, water, and steam systems can be selected for the LM2500 engine to fit a particular

installation. The selection will depend on fuel availability and NOx suppression requirements, with

either water or steam injection. Table 1 provides a summary matrix of LM2500 engine configurations

which are offered for specific Purchaser requirements. The engine model designations are also

provided.

This Section specifies operational/interface limits and requirements for the fuel, water, and steam

systems, which are included as standard equipment for a particular gas turbine model. The gas turbine

hardware includes fuel nozzles and fuel/water/steam manifold systems mounted externally on the gas

turbine.

The fuel, water, and/or steam flow rates are determined from performance data which is described in

Performance. The supply pressure requirements at the engine interface connection points can be

determined with fuel flow, water or steam flow, and engine pressure level (PS3) from the performance

data, and flow-pressure characteristics described in this section. Generally the estimated fuel flow rates

should be increased at least 5% and the water/steam flow rates increased by 20% when calculating

pressure requirements and system sizing to account for engine variations and deterioration.

Specific Installation data for each fuel system are provided by selecting the desired fuel system in Table

1. Additional general requirements are provided in Table 2.

Table 1. LM2500 Fuel Systems

NOx

Suppression

Power

Enhance

m

Gas only

No

Gas and water

Gas/Water

Yes

Gas/Steam

PreMix

Gas

Steam

Premix nozzle

Yes

Gas/Steam

Direct Injection

Gas

NOx steam

CDP steam (purge)

Dual gas nozzle

(gas and steam)

Yes

Gas/Water/ Steam

Gas/Water

CDP (steam)

Gas/water nozzle

Yes

Gas/Steam

(STIG)

Gas

NOx steam

CDP steam

Dual gas nozzle

(gas and steam)

Yes

Gas/CDP Steam

Gas

CDP steam

Gas only

No

No.

Fuel System

Manifolds

Fuel Nozzle Type

Gas

Gas

Gas/Water

http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/LM25bssac/sec08.h... 19/11/2005

Fuel System

Page 2 of 3

Liquid

Single liquid fuel

Liquid fuel only with

integral flow divider

valves

No

Liquid/Water

Primary, secondary and

water mixing tee

Liquid/water with off

engine fuel pressurizing

valve

Yes

10

Liquid/ Water/ Steam

(Mixed Mode)

Same as liquid/water,

plus CDP steam

Liquid/water with off

engine pressurizing

valve

Yes

11

Liquid/ CDP Steam

Single liquid fuel

CDP steam

Liquid fuel only with

integral flow divider

valves

No

12

Dual Fuel

Same as liquid/water

plus gas

Dual fuel with offengine

liquid fuel pressurizing

valve

No

13

Dual Fuel/ Water

Same as liquid/water

plus gas

Dual fuel with offengine

liquid fuel pressurizing

valve

Yes

14

Dual Fuel/ Water/

Steam

Same as liquid/water

plus Gas

CDP steam

Dual fuel with offengine

liquid fuel pressurizing

valve

Yes

15

Dual Fuel/

CDP Steam

Same as dual fuel

CDP steam

Dual fuel with offengine

liquid fuel pressurizing

valve

No

16

Dual Fuel/ Steam PreMix

Same as dual fuel plus

steam

Dual fuel-Steam with

offengine liquid fuel

pressurizing valve

Yes

17

Dual Fuel/ Steam PreMix plus CDP Steam

Same as dual fuel plus

steam

CDP Steam

Dual fuel-Steam with

offengine liquid fuel

pressurizing valve

Yes

Table 2 - General Requirements

Gas Fuel Requirements

Liquid Fuel Requirements

NOx Abatement Water Requirements NOx Abatement Steam Requirements

,1'(;

%$&. 72 723

+20(

http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/LM25bssac/sec08.h... 19/11/2005

Fuel System

Page 3 of 3

http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/LM25bssac/sec08.h... 19/11/2005

Anda mungkin juga menyukai

- Sb-Lm2500-Ind-305 R3Dokumen7 halamanSb-Lm2500-Ind-305 R3Daniil SerovBelum ada peringkat

- E79000-2-04-13 FS Buch WWWDokumen291 halamanE79000-2-04-13 FS Buch WWWDenis JimenezBelum ada peringkat

- Combustion InspectionsDokumen81 halamanCombustion InspectionsPhong leBelum ada peringkat

- Sample Email Policy TemplateDokumen7 halamanSample Email Policy TemplateSonia Vinod100% (1)

- Fuel System Pressure - TestDokumen7 halamanFuel System Pressure - TestHamilton MirandaBelum ada peringkat

- MAN L21 31 PowerPlantDokumen248 halamanMAN L21 31 PowerPlantSmart Lau100% (4)

- APA DOC No. 2014 PDFDokumen67 halamanAPA DOC No. 2014 PDFThanapaet RittirutBelum ada peringkat

- Nigeria Gas Specification - GACNDokumen1 halamanNigeria Gas Specification - GACNOlusegun OyebanjiBelum ada peringkat

- Ge F-Class Gek111895Dokumen2 halamanGe F-Class Gek111895gopinathsampath0% (2)

- WTUI - NewUserPrestentation TM2500 GEDokumen35 halamanWTUI - NewUserPrestentation TM2500 GEjoravicaBelum ada peringkat

- 4 - Inspection - Interval - Extension W5015DA PDFDokumen12 halaman4 - Inspection - Interval - Extension W5015DA PDFEDBBelum ada peringkat

- SBLM2500 Ind 217Dokumen5 halamanSBLM2500 Ind 217Daniil SerovBelum ada peringkat

- Psib 20160225aDokumen6 halamanPsib 20160225aJhonathan RodriguezBelum ada peringkat

- 01 Master SOP FinDokumen6 halaman01 Master SOP FinPramod Athiyarathu100% (1)

- Tm2500+ Mobile Gas Turbine Package Including SCOPE OF SUPPLYDokumen10 halamanTm2500+ Mobile Gas Turbine Package Including SCOPE OF SUPPLYMuhammad FazriansyahBelum ada peringkat

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionDokumen4 halamanGE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionAndrea CupelloBelum ada peringkat

- Gas Turbine Performance Based On Inlet ADokumen82 halamanGas Turbine Performance Based On Inlet Afateh1982Belum ada peringkat

- 04 - LM2500 OverviewDokumen27 halaman04 - LM2500 OverviewLudovic LeroyBelum ada peringkat

- Compressor WashingDokumen10 halamanCompressor Washingsamil68100% (1)

- Stag 300Dokumen16 halamanStag 300liviucatalinBelum ada peringkat

- Psib 20160225a-R3Dokumen6 halamanPsib 20160225a-R3Léandre Ettekri NdriBelum ada peringkat

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Hydraulic Start System DescriptionDokumen5 halamanGE Energy LM2500+ G4 Operation and Maintenance Manual: Hydraulic Start System DescriptionAndrea Cupello100% (1)

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Water Wash System DescriptionDokumen2 halamanGE Energy LM2500+ G4 Operation and Maintenance Manual: Water Wash System DescriptionAndrea Cupello100% (1)

- Scope of Supply Titan130Dokumen32 halamanScope of Supply Titan130danferreiro8318Belum ada peringkat

- Psib 20160225a-R2Dokumen7 halamanPsib 20160225a-R2Léandre Ettekri NdriBelum ada peringkat

- GE MS6001B - EmissionDokumen33 halamanGE MS6001B - EmissionMohamad AfifBelum ada peringkat

- Dynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDokumen3 halamanDynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDenis JimenezBelum ada peringkat

- IPL Saturn 20Dokumen56 halamanIPL Saturn 20Ranjan Shankar100% (3)

- Thermal Peaking PDFDokumen26 halamanThermal Peaking PDFkhozaqiBelum ada peringkat

- Testing and Commissioning Procedure For Earthing System Method StatementDokumen2 halamanTesting and Commissioning Procedure For Earthing System Method StatementHumaid ShaikhBelum ada peringkat

- Gek105060 File0060 PDFDokumen12 halamanGek105060 File0060 PDFHelton OliveiraBelum ada peringkat

- Optional: Service BulletinDokumen5 halamanOptional: Service BulletinDaniil SerovBelum ada peringkat

- T48 SpreadDokumen1 halamanT48 SpreadKarim MuhammedBelum ada peringkat

- Compresor TITAN 130 (Solar)Dokumen86 halamanCompresor TITAN 130 (Solar)Martínez Rodriguez DiegoBelum ada peringkat

- Lampiran 1 Standar InspectionDokumen7 halamanLampiran 1 Standar InspectionFitra SBelum ada peringkat

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDokumen4 halamanList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZBelum ada peringkat

- LM2500 50Hz Fact Sheet 2016Dokumen2 halamanLM2500 50Hz Fact Sheet 2016joseomarlmBelum ada peringkat

- Siemens Typhoon V1 CH01 PDFDokumen48 halamanSiemens Typhoon V1 CH01 PDFbvq1987100% (3)

- Sb-Lm2500-Ind-303 R1Dokumen11 halamanSb-Lm2500-Ind-303 R1Daniil SerovBelum ada peringkat

- Quality Management Case StudyDokumen26 halamanQuality Management Case StudyJim Juan Osman100% (1)

- Gas Turbines and Turbocompressors For LNG ServiceDokumen35 halamanGas Turbines and Turbocompressors For LNG ServiceRiza Agung NugrahaBelum ada peringkat

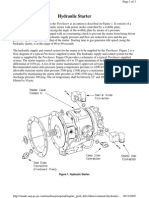

- Figure 1. Hydraulic StarterDokumen3 halamanFigure 1. Hydraulic StarterDenis JimenezBelum ada peringkat

- Turbo Power Services Company ProfileDokumen50 halamanTurbo Power Services Company Profilesomasekharch100% (1)

- Vol 01Dokumen153 halamanVol 01chandrasingh4564Belum ada peringkat

- AUTOSAR SWS DiagnosticEventManagerDokumen511 halamanAUTOSAR SWS DiagnosticEventManagerchinna0% (1)

- GE LM6000 1275-GryDokumen1 halamanGE LM6000 1275-GryuzairmughalBelum ada peringkat

- 2.3.8 Liquid FuelDokumen16 halaman2.3.8 Liquid FuelSarah CohenBelum ada peringkat

- Spare Parts For Gas Turbine F9E For Instrument & Control - RehabDokumen1 halamanSpare Parts For Gas Turbine F9E For Instrument & Control - RehabhakimsalimiBelum ada peringkat

- Technical Paper - SGT400 ASME 2002Dokumen9 halamanTechnical Paper - SGT400 ASME 2002usaid saifullahBelum ada peringkat

- Contracts ManagementDokumen87 halamanContracts Managementarabi2222Belum ada peringkat

- General Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Dokumen13 halamanGeneral Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Ibilola IbisankaleBelum ada peringkat

- Service Bulletin: PurposeDokumen3 halamanService Bulletin: PurposejussmeeeBelum ada peringkat

- Gas Turbine Engines Characteristics and Performance Combustion ChamberDokumen2 halamanGas Turbine Engines Characteristics and Performance Combustion ChamberNicolas Guatibonza LBelum ada peringkat

- Caterpillar Power Generation Systems: Bangladesh 8 X 16Cm43Dokumen3 halamanCaterpillar Power Generation Systems: Bangladesh 8 X 16Cm43Boonchai AralmBelum ada peringkat

- Lm2500 ManifoldDokumen2 halamanLm2500 ManifoldDenis JimenezBelum ada peringkat

- EPS GT Base PrinciplesDokumen32 halamanEPS GT Base PrinciplescdbeardsallBelum ada peringkat

- Startup of A Gas TurbineDokumen1 halamanStartup of A Gas TurbineMohammad Ibnul HossainBelum ada peringkat

- Systems Description For PGT 25 (LM2500)Dokumen2 halamanSystems Description For PGT 25 (LM2500)KALPUSHBelum ada peringkat

- 7EA Experience With Water Cooled Liquid FuelDokumen5 halaman7EA Experience With Water Cooled Liquid FuelJJBelum ada peringkat

- 07 Gas Turbine Valves - 0Dokumen14 halaman07 Gas Turbine Valves - 0VILAS VIJAYANBelum ada peringkat

- GEK 97310 GEK 97310 Addendum I Addendum IDokumen32 halamanGEK 97310 GEK 97310 Addendum I Addendum IJacky WuBelum ada peringkat

- GE Frame 7EA Loss of FlameDokumen6 halamanGE Frame 7EA Loss of Flamenabil160874Belum ada peringkat

- 6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFDokumen1 halaman6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFLenin RamonBelum ada peringkat

- Gea32081a LM6000 - Pa - Us - R1 - LRDokumen1 halamanGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenBelum ada peringkat

- Computation of Engine Output Characteristics For A 4-Stroke Turbocharged Diesel EngineDokumen35 halamanComputation of Engine Output Characteristics For A 4-Stroke Turbocharged Diesel EngineAlexBelum ada peringkat

- 6 7 Diesel Fuel System Contamination Diagnosis and Service Procedure Job AidDokumen13 halaman6 7 Diesel Fuel System Contamination Diagnosis and Service Procedure Job AidMicheal ThomasBelum ada peringkat

- Hydac SCADokumen6 halamanHydac SCADenis JimenezBelum ada peringkat

- 3612tale Jgd6 DesignDokumen1 halaman3612tale Jgd6 DesignDenis JimenezBelum ada peringkat

- 460-119 Hoja de Especificaciones.Dokumen2 halaman460-119 Hoja de Especificaciones.Denis JimenezBelum ada peringkat

- Dse4610 Dse4620 Data SheetDokumen2 halamanDse4610 Dse4620 Data SheetDenis Jimenez0% (1)

- E7700 10 10 13 - Prozesstechnik - WebDokumen24 halamanE7700 10 10 13 - Prozesstechnik - WebDenis JimenezBelum ada peringkat

- E7710 1 06 11 - Leitungsfilter ProzessDokumen8 halamanE7710 1 06 11 - Leitungsfilter Prozessvikram_007Belum ada peringkat

- Ac-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDokumen12 halamanAc-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDenis JimenezBelum ada peringkat

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDokumen20 halamanBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezBelum ada peringkat

- 1303-1512 SSPF Final InoxidableDokumen16 halaman1303-1512 SSPF Final InoxidableDenis JimenezBelum ada peringkat

- Inline Process FiltersDokumen7 halamanInline Process FiltersDenis JimenezBelum ada peringkat

- Filter Bound CatalogDokumen248 halamanFilter Bound CatalogDenis JimenezBelum ada peringkat

- Filter Bound CatalogDokumen248 halamanFilter Bound CatalogDenis JimenezBelum ada peringkat

- E2000 0 03 11 - SYSTEMTECHNIK - WWWDokumen8 halamanE2000 0 03 11 - SYSTEMTECHNIK - WWWDenis JimenezBelum ada peringkat

- Fluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsDokumen12 halamanFluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsDenis JimenezBelum ada peringkat

- E5601 13 04 07 - PT Neu2Dokumen5 halamanE5601 13 04 07 - PT Neu2Denis JimenezBelum ada peringkat

- Ac-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDokumen12 halamanAc-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDenis JimenezBelum ada peringkat

- E18061 2 0 11 13 - HNS3000Dokumen2 halamanE18061 2 0 11 13 - HNS3000Denis JimenezBelum ada peringkat

- E5601 PTKDokumen4 halamanE5601 PTKDenis JimenezBelum ada peringkat

- 105388Dokumen4 halaman105388Denis JimenezBelum ada peringkat

- E2902 4 03 13 - Pumpen Uebersicht - LQDokumen20 halamanE2902 4 03 13 - Pumpen Uebersicht - LQDenis Jimenez0% (1)

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDokumen20 halamanBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezBelum ada peringkat

- E831BDokumen4 halamanE831BDenis JimenezBelum ada peringkat

- E7113 4 03 12 - NFD KatalogversionDokumen8 halamanE7113 4 03 12 - NFD KatalogversionDenis JimenezBelum ada peringkat

- E7113 4 03 12 - NFD KatalogversionDokumen8 halamanE7113 4 03 12 - NFD KatalogversionDenis JimenezBelum ada peringkat

- 1403013194Dokumen1 halaman1403013194Denis JimenezBelum ada peringkat

- 1403013194Dokumen1 halaman1403013194Denis JimenezBelum ada peringkat

- E831BDokumen4 halamanE831BDenis JimenezBelum ada peringkat

- E7109 4-03-12 RFLD Guss KatalogversionDokumen8 halamanE7109 4-03-12 RFLD Guss KatalogversionDenis JimenezBelum ada peringkat

- Pastillas HSH 1v 1t 5wDokumen1 halamanPastillas HSH 1v 1t 5wDenis JimenezBelum ada peringkat

- Data Sheet Level Gauge: GeneralDokumen5 halamanData Sheet Level Gauge: GeneralJKKBelum ada peringkat

- Priority Ceiling Protocols: Today's Topic: Resource/Data Sharing and SynchronizationDokumen20 halamanPriority Ceiling Protocols: Today's Topic: Resource/Data Sharing and SynchronizationBasti DBelum ada peringkat

- Smart Manual ThomsonDokumen32 halamanSmart Manual ThomsonJeevaBelum ada peringkat

- TYPOGRAPHY PRACTICAL FILE New PnsDokumen21 halamanTYPOGRAPHY PRACTICAL FILE New PnsPiyushBelum ada peringkat

- Victory Solution For Technical ConsultationsDokumen4 halamanVictory Solution For Technical Consultationsamul prakashBelum ada peringkat

- CT S 941tx16u+Dokumen453 halamanCT S 941tx16u+Joel BorenBelum ada peringkat

- V08-DC32e INSTRUCTION MANUAL (OPERATION)Dokumen103 halamanV08-DC32e INSTRUCTION MANUAL (OPERATION)Data IBTBelum ada peringkat

- Systematic Mapping Studies in Software Engineering PDFDokumen10 halamanSystematic Mapping Studies in Software Engineering PDFElena Rodríguez MéndezBelum ada peringkat

- 00040900Dokumen30 halaman00040900asperfudBelum ada peringkat

- Tutoriel 2 - Shape and Combine Data in Power BI DesktopDokumen19 halamanTutoriel 2 - Shape and Combine Data in Power BI DesktopLahmar AkramBelum ada peringkat

- Qualys Big Shift To Cloud Based SecurityDokumen9 halamanQualys Big Shift To Cloud Based SecurityKayode MoriwawonBelum ada peringkat

- Fedex Online Remote Pickup Userguide en TWDokumen21 halamanFedex Online Remote Pickup Userguide en TWTovapeBelum ada peringkat

- At Commands Interface Guide For at X41bDokumen461 halamanAt Commands Interface Guide For at X41bEuuE2008Belum ada peringkat

- 03 v.I.P. System Services Volume 2 0853BDokumen531 halaman03 v.I.P. System Services Volume 2 0853BlabbihiBelum ada peringkat

- FAQs - Touch ID - Quick BalanceDokumen3 halamanFAQs - Touch ID - Quick BalanceAnonpcBelum ada peringkat

- WMS Bluebird RetrofitDokumen12 halamanWMS Bluebird RetrofitMalorin CifuentesBelum ada peringkat

- N3 HV Series User ManualDokumen21 halamanN3 HV Series User ManualRati Gabisonia100% (1)

- Java Fundamentals Section 7 Part 2: Creating An Inventory Project ProjectDokumen4 halamanJava Fundamentals Section 7 Part 2: Creating An Inventory Project ProjectnaniBelum ada peringkat

- ResearchDokumen9 halamanResearchKYRAH MAE NICOLE DELACIONBelum ada peringkat

- Electrical Equipment Check ListDokumen3 halamanElectrical Equipment Check ListPuran Singh LabanaBelum ada peringkat

- JVC KD-R820BTDokumen51 halamanJVC KD-R820BTmark752Belum ada peringkat

- BDLO Labsii Fandii Daandii 224 Bara 2012Dokumen10 halamanBDLO Labsii Fandii Daandii 224 Bara 2012Freesun AbbasBelum ada peringkat

- Genco Syllabus For EEE BranchDokumen2 halamanGenco Syllabus For EEE BranchMansa ManuBelum ada peringkat

- Deep Learning Approach For Object Detection Using CNN: AbstractDokumen7 halamanDeep Learning Approach For Object Detection Using CNN: AbstractAYUSH MISHRABelum ada peringkat

- A Survey On Odia Handwritten Character RecognitionDokumen2 halamanA Survey On Odia Handwritten Character RecognitionIJARTESBelum ada peringkat