1000 0121 401

Diunggah oleh

TimmyJuriJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1000 0121 401

Diunggah oleh

TimmyJuriHak Cipta:

Format Tersedia

Framo

Cargo Pumps

No. 1000-0121-401

Rev.C 14Oct10/AGAa

Operation manual

SD100

SD125

SD150

SD200

SD250

SD300

SD350

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

2 of 20

14Oct10/AGAa

CONTENTS

1 GENERAL DESCRIPTION ....................................................................................................... 2

1.1 Top plate ........................................................................................................................ 2

1.2 Pipe stack ...................................................................................................................... 2

1.3 Pump head .................................................................................................................... 2

2 OPERATING INFORMATION .................................................................................................. 4

2.1 Discharging .................................................................................................................... 4

2.2 Running of pumps in parallel ......................................................................................... 6

2.3 Stripping ........................................................................................................................ 8

2.4 Purging of cofferdam ................................................................................................... 11

2.5 Precautions to be taken when handling special types of cargoes ............................... 14

2.6 Tank cleaning / cleaning of pump ................................................................................ 15

2.7 Precautions if using cargo pumps in sea water ........................................................... 16

2.8 Loading of cargo tank .................................................................................................. 17

3 MAINTENANCE INFORMATION ........................................................................................... 18

4 TROUBLE SHOOTING ........................................................................................................... 18

Reference to associated instructions

1000-0109-4: Interchange of pump control valve

1375-0027-4: Service manual for Pump control valve (STC)

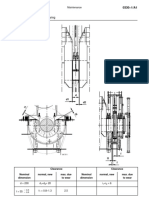

1 GENERAL DESCRIPTION

The Framo cargo pump is a hydraulically driven single stage centrifugal pump with parts exposed to

cargo in stainless steel as standard material. The pump is installed in the cargo tank with suction inlet

at the bottom of the tank.

1.1 Top plate

The cargo pump is supported by a deck trunk welded to the deck. All the connections are at the top

cover plate, to which the pump control valve STC (Speed Torque Controller) is also mounted. This

control valve for remote and local operation of the cargo pump regulates the inlet pressure to the

hydraulic motor. Thereby the pump speed can be regulated step less from 0 to max. speed.

1.2 Pipe stack

The pipe stack connects the pump head to the top plate by a cargo pipe and a hydraulic section. In

addition the stripping pipe, the check pipe and eventually temp. sensor pocket and vacuum drain pipe

are integrated in the pipe stack.

1.3 Pump head

The pump head is welded or flanged to the pipe stack/casing and supported by the bottom support.

The hydr. motor is located inside the pump head and surrounded by low pressure hydraulic oil.

The short shaft, supported by bearings lubricated by hydraulic oil, is connected to a single-stage

impeller. The hydraulic section is surrounded by a cofferdam that completely segregates the hydraulic

oil from the cargo. Leakages to the cofferdam chamber will be purged through the cofferdam check

pipe and collected in the exhaust trap when cofferdam is purged.

The seal arrangement consists of a mechanical oil seal, single cofferdam lip seal and a cargo seal.

The cargo seal is only exposed to static head from the cargo.

The backstop unit installed on the shaft enables the pump to be used as a drop line.

Wear rings are fitted between the impeller and the volute casing.

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

3 of 20

14Oct10/AGAa

Impeller

Bearings

Mechanical

oil seal

Cargo seal set

Wear rings

Volute casing

Back stop unit

Hydraulic motor

Cofferdam

surrounding

hydraulic section

Cofferdam check pipe

Hydraulic Pipestack

Cofferdam pipe

Hydraulic pressure pipe

Hydraulic return pipe

Cargo stripping pipe

Cargo pipe

Flexible suspension

Exhaust trap

Cargo

purging valve

Local control valve

Manometer

Pump control valve (STC)

Cofferdam purging connection

Stripping valve

Cargo

Discharge valve

Deck trunk

Top plate

Fig. 1

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

4 of 20

14Oct10/AGAa

300

225

150

75

0

BAR

1P

ON

Manifold

pressure

Discharge

pressure

OPEN

300

225

150

75

0

BAR

1P

ON

Reduced capacity

300

225

150

75

0

BAR

1P

ON

Reduced capacity

2 OPERATING INFORMATION

This procedure describes the normal operation of the cargo pumps. Certain cargoes require special

handling procedures for safe handling. In addition to this operation procedure charters instruction,

Material Safety Data sheet and any ATC instructions shall be taken into consideration during cargo

operation and handling.

2.1 Discharging

To get maximum lifetime of the pumps, operate

the pumps within the operation range.

100%

60% dp

H

e

a

d

H

25% 0

50%

0

75% 50%

100%

125%

Flow Q

100% dp 75%

25%

80% dp

40% dp 20% dp

125%

OPERATION

RANGE

OPTIMUM

OPERATION

RANGE

Check that the hydraulic system is started and

enough hydraulic power is available.

Operation of pump from cargo control panel:

1) Local control valve and cargo discharge valve

must be in closed position.

HP service valve, OPEN

Only to be closed when carrying

out service work on the pump.

Stripping valve, CLOSED

Cargo discharge valve, CLOSED

Local control

valve, CLOSED

Cargo purging valve

CLOSED

(Purging hose disconnected)

2) Start the pump and let it run

with hydraulic motor

pressure at approx 50 bar

for 1 minute.

3) Increase hydraulic

motor pressure

until the cargo

discharge pressure

is above cargo

manifold pressure.

4) Open cargo

discharge valve.

Note!

Avoid running pumps against closed cargo valve

with high discharge pressure for a longer period.

5) Increase hydraulic

motor pressure until

required discharge

pressure or

capacity is

achieved.

Note!

Check that the system pressure is about 20 bar

above the motor pressure of the highest

consumer.

6) End of discharging

When the tank is close to empty reduce pumping

capacity to avoid loss of suction.

This is indicated by

a hunting hydraulic

pressure, and

should be avoided.

Empty the cargo

tank at reduced

hydraulic motor

pressure.

7) When the cargo tank is empty the hydraulic

motor pressure will drop.

Close cargo

discharge valve

and stop

the pump

(handle in

minimum

position).

8) If the pump is to be restarted, relieve the

vacuum in pump cargo pipe as described in

chapter 2.3, Stripping (page 9).

300

225

150

75

0

BAR

1P

ON

Start

300

225

150

75

0

BAR

1P

ON

Manifold

pressure

Discharge

pressure

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

5 of 20

14Oct10/AGAa

OPEN

Operation of pump from local control valve:

1) Open local control valve (by turning counter

clockwise). Cargo discharge valve must be in

closed position.

HP service valve, OPEN

Only to be closed when carrying

out service work on the pump.

Stripping valve, CLOSED

Cargo discharge valve, CLOSED

Local control

valve, OPENED

Cargo purging valve

CLOSED

(Purging hose disconnected)

2) Set the remote control

handle in maximum position.

(Remote control closed)

3) Start the pump by

closing the local

control valve

(turn clockwise)

and let it run with

hydraulic motor

pressure 50 bar

for approx. 1 minute.

4) Increase hydraulic motor pressure (turn the

local control valve clockwise) until the cargo

discharge pressure is above cargo manifold

pressure.

Manifold pressure Discharge pressure

5) Open cargo

discharge valve

6) Increase hydraulic motor pressure until

required discharge pressure or capacity is

achieved.

7) End of discharging

When the tank is close to empty reduce

pumping capacity to avoid loss of suction.

This is indicated by a hunting hydraulic

pressure, and should be avoided. Empty the

cargo tank at reduced hydraulic motor

pressure.

bar 0

100

200

300

400

Reduced capacity

8) When the cargo tank is empty the hydraulic

motor pressure will drop. Close cargo

discharge valve and stop the pump by opening

the local control valve (by turning counter

clockwise).

Open local

control valve

CLOSE

9) Reset for remote control

operation:

Set the remote control

handle in minimum

position (remote control

open) and close the

local control valve.

10) If the pump is to be restarted, relieve

the vacuum in pump cargo pipe as

described in chapter 2.3, Stripping

(page 9).

bar 0

100

200

300

400

300

225

150

75

0

BAR

1P

ON

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

6 of 20

14Oct10/AGAa

300

225

150

75

0

BAR

1P

ON

Manifold

pressure

Discharge

pressure

2.2 Running of pumps in parallel

This is a general description for running pumps

in parallel.

1) Local control valve and cargo discharge valve

must be in closed position.

Local control

valve, CLOSED

HP service valve, OPEN

Only to be closed when carrying

out service work on the pump.

Stripping valve, CLOSED

Cargo discharge valve, CLOSED

Cargo purging valve

CLOSED

(Purging hose disconnected)

2) Start the hydraulic

system and set the

system pressure to

about 100-150 bar.

(Depending on piping

system, cargo sp.gr.,

visc. etc.)

Also see performance diagram for actual pump.

3) Start the first pump and

let it run with hydraulic

motor pressure at approx.

50 bar for

1 minute.

4) Increase hydraulic

motor pressure

until the cargo

discharge

pressure is above

cargo manifold

pressure.

(Ref.

fig. 31 pos. A)

5) Open cargo discharge

valve.

(Ref. fig 31, pos. A-B)

6) Start offloading and raise the hydraulic

motor pressure command to maximum

(fig.31, pos C).

300

225

150

75

0

BAR

1P

ON

Manifold pressure

Discharge pressure

Note!

Handle in

maximum

position.

7) Start the second

cargo pump against

closed cargo

discharge valve as

described in step 3.

8) Check that pump discharge pressure is

higher than manifold pressure. If necessary

adjust the motor pressure until the cargo

discharge pressure is just above cargo

manifold pressure and then open cargo

discharge valve.

300

225

150

75

0

BAR

2P

ON

Manifold pressure Discharge

pressure

Note!

Handle in

maximum

position.

9) Start offloading and raise the hydraulic motor

pressure command to maximum (the handle

in maximum position).

Verify that the ullage in the tank is increasing.

SYSTEM PRESSURE

0

100 300

200

400

bar

PRESSURE SET

300

225

150

75

0

BAR

1P

ON

Start

OPEN

300

225

150

75

0

BAR

2P

ON

Start

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

7 of 20

14Oct10/AGAa

Pressure loss

discharge system

100% 25% 0 75% 50% 125%

Flow Q

H

e

a

d

H

50%

0

100%

75%

25%

125%

20% dp

40% dp

60% dp

80% dp

100% dp

A

B C

A)

A-B)

C)

D)

E)

F)

G-I)

Increase hydraulic motor pressure.

Cargo discharge valve closed.

Open cargo discharge valve.

Increase hydraulic motor pressure.

Open cargo discharge valve - 2 pumps.

Open cargo discharge valve - 3 pumps.

Open cargo discharge valve - 4 pumps.

Increase hydraulic system pressure

(4 pumps running).

100% 25% 0 75% 50% 125%

Flow Q

H

e

a

d

H

50%

0

100%

75%

25%

125%

A

B C

D

E

F

G

H

I

Pressure loss

discharge system

Typical capacity/head diagram

for cargo pump running one

Typical capacity/head diagram for cargo pumps running four

Fig. 31

10) Start the next pumps, one by one, following

the same procedure, ref. fig. 31 pos. E-F.

Ensure that enough hydraulic power is

available for the pumps to be run in parallel.

11) Increase the hydraulic system pressure until

required discharge pressure or capacity is

achieved, ref. fig. 31 pos G-H-I.

12) During parallel pumping with differences in

tank ullage and pressure losses in deck

piping it is sometimes required to readjust

the hydraulic motor pressure on some of the

cargo pumps to adjust individual capacities.

Discharge pressure

SYSTEM PRESSURE

0

100 300

200

400

bar

300

225

150

75

0

BAR

4P

ON

300

225

150

75

0

BAR

3P

ON

300

225

150

75

0

BAR

2P

ON

300

225

150

75

0

BAR

1P

ON

Manifold pressure

13) When a cargo tank becomes empty, close

the cargo discharge valve and stop the

pump (handle in minimum position).

300

225

150

75

0

BAR

1P

ON

Stop

14) If the pump is to be restarted, relieve the

vacuum in pump cargo pipe as described

in chapter 2.3, Stripping (page 9).

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

8 of 20

14Oct10/AGAa

2.3 Stripping

Stripping is to remove remaining cargo in pump cargo

pipe upon completion of the discharge operation.

The stripping is done by running the pump locally at

reduced hydraulic motor pressure against closed

discharge valve while purging the pump cargo pipe.

The remaining cargo is then purged into the deck line

through the stripping valve.

The pump impeller acts as a non-return valve,

preventing cargo from returning to tank. If the pump

speed (hydraulic motor pressure) is too low, cargo will

flow through the impeller back to the tank.

The arrangement of deck piping must be taken into

consideration when stripping. Optimal procedure for

tank stripping to be based on experience on board.

The best stripping result is obtained when stripping

against lowest possible backpressure. At increased

back pressure cargo flow is reduced, and stripping time

is increased. High cargo viscosity will also increase

stripping time.

Examples:

Purging press. - Static head - Back press. =Available purging

pressure

I 7 bar - 2 bar - 0 bar = 5 bar

II 7 bar - 2 bar - 3 bar = 2 bar

0

1

2

3

4

5

6

7

8

Pressure (bar)

Flow

Purging

medium

pressure

Reduced stripping flow at

increased back pressure

Stripping flow at

min. back pressure

Static head Static head

Back

pressure

Available

purging

pressure

Available

purging

pressure

Fig. 33

Estimated time to empty the pump cargo pipe

(Backpressure 0 bar(g), 1cSt, spgr. 1.0) *

SD100 / SD125 / SD150 2 4 min.

SD200 / SD300 4 7 min

SD350 8 9 min

* Time will be influenced by pump length, back pressure, piping system, type of suction well, cargo,

purging medium pressure etc.

Minimum required hydraulic pressure to prevent

backflow through impeller

0

2

4

6

8

60 80 100 120

Hydr. motor pressure (bar)

P

u

r

g

i

n

g

m

e

d

i

u

m

p

r

e

s

s

u

r

e

i

n

c

a

r

g

o

p

i

p

e

(

b

a

r

g

)

Fig. 32

Static

head

Stripping pipe

Pump

cargo pipe

Stripping

valve (C)

Cargo discharge

valve (D)

Cargo deck line

back pressure

Purging medium

pressure

Local

control valve

Cargo purging valve/

connection (B)

Purging

medium

supply (A)

Fig. 34

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

9 of 20

14Oct10/AGAa

Stripping procedure

Relieving vacuum in pump cargo pipe

Stripping

Note!

Open stripping valve (C)

Open cargo purging valve (B) to start the stripping.

Continue stripping until pump cargo pipe is empty, identified by frequent speed variations

of pump.

Close stripping valve (C) and valve at cargo purging connection (B).

Stop the cargo pump.

If necessary, purge the cargo deck line and repeat the stripping sequence.

Close valve (A) and disconnect purging medium hose.

Do not run the pump unnecessary during stripping.

8)

9)

10)

11)

12)

13)

14)

Purging of cargo deck line

Purging

medium

supply OPEN

OPEN

CLOSED

CLOSED

Purge the cargo

deck line either

to terminal line,

slop tank or

other cargo tank

in accordance with

ships procedure.

Close the manifold

valve.

5)

Relieving deck line pressure

CLOSED

CLOSED

C OPEN/CLOSE

B CLOSED

CLOSED

Relieve the deck

line pressure into

the tank by open

and close

stripping valve (C).

6)

Note!

Start the pump by using the local control valve, and

increase hydraulic pump pressure to 90-120 bar.

Optimum hydraulic pressure depends on cargo specific

gravity and viscosity, purging medium pressure, static

head etc., and must be based on experience on board.

7)

Alternatively the pump can be stripped into a slop tank through a dedicated deck line.

It is also possible to strip to a cargo deck line at low manifold pressure, however

stripping time will increase with increased cargo pressure.

A

Pump running

Purging

medium

supply

CLOSED

CLOSED

CLOSED

C OPEN

A

B

Purging

medium

supply

D CLOSED

A

B

Pump

stopped

Connect purging hose

to the purging medium

supply (A) and cargo

purging valve (B).

Relieve vacuum in

pump cargo pipe by

opening valves at

purging medium supply

(valve A and B).

Close the cargo purging

valve (B).

Note!

Purging medium

pressure in the hose

must always be

higher than the

pressure in the

cargo pipe.

2)

3)

4)

Preparations

When the tank is

empty, close cargo

discharge valve(D)

and stop the pump.

1)

Fig. 35

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

10 of 20

14Oct10/AGAa

Water test procedure according to Marpol Annex II

Ensure that the cargo tank to be tested and its

associated piping have been cleaned and that

the cargo tank is safe for entry.

Provide 100kPa (1 atmosphere) back

pressure at the cargo tanks unloading

manifold, see fig. 36.

- Fill the cargo tank with water to a depth necessary to carry out normal end of discharge operation.

Water test with sea water must be followed by a thoroughly rinse with fresh water to remove

chlorides.

- Purge and relieve pressure in cargo piping according to Stripping procedure step 1 to 6.

- Follow the normal stripping procedure.

Start timing when cargo purging valve is opened, ref. step 9. Stop timing when stripping valve

is closed, ref. step 11.

- The time taken to be recorded.

- Residues to be collected and measured.

Note! Residues in cargo deck line to be measured separately.

Log the results

Tank no

Residues (liter)

In suction well On tank top

Duration (sec)

Water residues

in tank after

water test.

Fig. 37

10m

Cargo piping

Manifold

valve

Test hose

Min. 75mm

Fig. 36 Suggested back pressure manifold arrangement

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

11 of 20

14Oct10/AGAa

2.4 Purging of cofferdam

This procedure describes purging of submerged cargo

pumps with dry cofferdam. (For submerged cargo pumps

with liquid filled cofferdam, refer to instruction 1000-0102-4.)

The cargo pump cofferdam is essential for segregation of the

pump hydraulic section from the cargo and for seal

monitoring. Purging to be carried out at regular intervals for

the purpose of:

- Leakage rate detection

- Condition monitoring of the shaft seal system

- Avoid that leakages are blocking the cofferdam

How to purge the cofferdam

CAUTION:

Exhaust gas and liquid may be hazardous.

Wear safety gear and avoid contact with drain from exhaust

trap and venting line.

Preparation:

1) Place a suitable container underneath the exhaust trap to

collect the leakage.

2) Check that drain valve at bottom of exhaust trap is not

blocked.

3) Drain the purging medium supply line for condensed

water.

4) Connect purging hose (max. supply pressure 7 bar).

Purging:

5) Start the purging by opening the valve at purging medium

supply line.

Note!

A relief valve is fitted at cofferdam purging connection. This

is set at 3-3,5 bar to limit the purging pressure for protection

of the pump seals. A small leakage from the relief valve is

normal when liquid is purged from cofferdam. The valve will

also open if the cofferdam is blocked.

6) Check that exhaust gas is coming out of the exhaust trap

vent line (to verify that cofferdam is open).

CAUTION! Exhaust gas and liquid watch out !

7) Purge cofferdam in several sequences if required.

Drain exhaust trap between each sequence.

8) Disconnect purging hose.

9) Close exhaust trap drain valve.

10) Log the amount of leakage, -evaluate the result.

Note! For handling special cargoes, ref. chapter 2.5.

Cofferdam purging connection

Purging medium supply

Exhaust gas

Cofferdam

check pipe

Container to

collect the leakage

Relief valve

Exhaust trap

CLOSED

CLOSED

Purging

medium

Flexible hose with

snap-on coupling

Vent. line

Drain valve

CLOSED

CLOSED

Fig. 38

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

12 of 20

14Oct10/AGAa

Purging intervals, - logging of purging result

LOADING VOYAGE DISCHARGE

1. Shortly before

loading.

1. 1-2 days after loading. 1. Shortly before

discharging.

2. If no leakage at step 1, purge every fortnight. 2. Shortly after

discharging.

3. If leakage is detected at step 1, or at a later stage

during the voyage, purge this pump every day.

4. If pumps are used for cargo circulation during the

voyage, the cofferdam must be purged before start

and after stop.

Note! Neglecting of purging can result in a blocked cofferdam and lack of leakage control.

The purging form should be filled in with the results from every purging operation. Each horizontal

line in the form represents one cargo in one tank from loading till discharging. If a ship loads and

discharges some tanks more frequently than other, an extra form should be filled in for those

tanks.

PURGING ROUTINE FOR FRAMO SUBMERGED CARGO PUMPS

SHIP NAME:__________________________________ VOYAGE NO.: __________________________________

Electronic copy: purging@framo.no

If paper copy: FrankMohn ServicesAS

Ship owner: Electronic/ Papercopy

A B C D

NOTE:

In "Result" column:

H=hydr. oil

C=cargo

W=water condensate

In "Open cofferdam" column:

Yes=air or liquidcomingthrough

No=Blockedcofferdam

Shortly

before loading

1-2 days

afterloading

If no leakage at A go to C.

If leakage at A purge thispump

everyday

Shortly

before unloading

Shortly

afterunloading

Tank

No.

Cargo Date Result Open

coffer-

dam

Date Result Open

coffer-

dam

Date Result Open

coffer-

dam

Average

result

Date Result Open

coffer-

dam

Date Result Open

coffer-

dam

State action taken,

newpartsinstalled, etc.

Signed by: Chief Officer Chief Engineer Pumpman

Forlong voyageswith

"no leakage at A"

purge at least every

fortnight.

Tank no.

Type of

cargo

Date of

purging

Open cofferdam:

Yes=air or liquid coming through

No =blocked cofferdam

Note action taken -

new parts installed etc.

RESULT:

If no leakage, write OK.

If leakage, write amount of leakage in litres and

type of leakage.

(Example: 1H=1 litre hydraulic oil, 1C=1 litre cargo,

1 H/C=1 litre mixture of hydraulic oil and cargo).

Fig. 39 Example of FRAMO purging form

Filled in purging form to be sent to Ship owner and to Framo (purging@framo.no).

(Green copy for the ship, red copy for the Ship owner and white copy for Framo.)

Ships crew to evaluate the purging results and to take necessary action however in case the

ships crew needs advice, contact a Framo Service Station.

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

13 of 20

14Oct10/AGAa

Evaluation of the purging result

Cargo leakage

A small leakage rate of up to about 0.5 l/day

(and higher with light cargoes) during pump

operation is normal.

Acceptable leakage rate depends on the type of

cargo and possible consequences in case of

leakage.

- Risk for clogging of pump cofferdam

Cargoes like naphtha, condensate etc.

penetrates the shaft seals more easily than

lubricating oils, vegetable oils and other viscous

cargoes.

It is therefore recommended to carefully monitor

the leakage rate over a period of time,

preferable with different type of cargoes.

For critical cargoes, when the leakage rate is

about 2 litres/day or higher, the pump must be

purged a couple of times daily and service

(pressure test-repair) carried out at first

opportunity.

Intensify the purging if the leakage rate is

exceeding acceptable limits. If this is not

sufficient to keep the leakage under control it

must, depending on the nature of the cargo, be

considered to discharge the tank using the

portable pump.

Cargo leakage to cofferdam normally indicates

shaft seal leakage. But the leakage might come

from flange connections or damage (cracks/pin

holes) in pump/pipe stack (ref. chapter 4,

Trouble shooting).

The development of a cargo leakage can be

monitored if purging is done according to

instructions. Thereby maintenance work can be

planned, and unexpected shut down due to

leakage can be avoided.

Hydraulic oil leakage

Hydraulic oil in the cofferdam normally

indicates shaft seal leakage, but might come

from flange face seals in pipe stack/ pump

head or damage in the pipe stack/pump head.

A small leakage rate into the cofferdam up to

about 10 ml/h (0.25 l/day) from the mechanical

oil seal or lip seal during pump operation is

normal. For short periods of time, higher

leakage peaks can occur.

If the leakage rate is increasing above

acceptable level, the pump must be purged a

couple of times daily and inspected as soon

as possible to find the reason for the leakage.

Intensify the purging if the leakage rate is

increasing above the acceptable level. If this

is not keeping the leakage under control,

close the hydraulic service valve. Depending

of the nature of the cargo consider to use the

portable pump to discharge the cargo.

Blocked cofferdam

In general we do not recommend operating

the cargo pump with blocked cofferdam.

For advice, depending of type of cargo etc.,

contact a Framo Service Station.

Note! Always remember to pressure test the cofferdam with 3 bar to locate the leakage prior to any

dismantling of the cargo pump.

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

14 of 20

14Oct10/AGAa

Liquid

supply

Liquid

return

CLOSED

CLOSED

CLOSED

Valve for

regulation of flow

OPEN

Flexible hose with

snap-on coupling

Fig. 41

2.5 Precautions to be taken when handling special types of cargoes

The main rule is to have the cofferdam clean, dry and vented to atmosphere through the exhaust trap

vent line, in order to detect leakages easily. However, when handling certain groups of cargoes it may be

an advantage to fill the cofferdam with liquid to improve the seal lifetime and to avoid solidifying cargo

blocking the cofferdam. Recommended type of liquid to be filled into the cofferdam for some groups of

cargoes is given below.

This is a general advice, only experience can define which liquid gives the best result for the great

number of different types of cargoes.

Filling

To fill liquid in the cofferdam, disconnect the

exhaust trap piping from the pump top plate. Using

a suitable adapter, fill the liquid through the

cofferdam check pipe. Open the purging connection

to ventilate the cofferdam during filling. (Connect an

open female coupling or similar).

Circulation

A circulation of liquid through the cofferdam can

be arranged in the following way:

- Connect liquid supply to the purging connection.

The supply line must also be equipped with a

valve to regulate the liquid flow.

- Open drain valve on the exhaust trap, and

collect the return liquid here.

Note!

When filling or circulating liquid in the cofferdam,

it is important that the hydraulic oil return pressure

always is higher than the pressure in the cofferdam.

This is especially important on hydraulic systems

with non-pressurised return line.

Solidifying cargoes (in cargo tanks with heating coils)

To prevent the cargo to get solid (freeze) inside the suction well, circulate the cargo at intervals by

starting the cargo pump.

Acid cargoes

After discharging and purging is finished, it

may be an advantage to circulate fresh

water through the cofferdam to remove all

residues after a leakage.

Phenol, caustic soda etc.

A circulation of hot water through the cofferdam

can avoid clogging.

Note! Remember that some of these types of

cargoes are very hazardous.

Polymerising cargoes. (TDI, MDI)

Fill cofferdam with dioctyl phthalate(DOP) to

limit the risk of blocking the cofferdam.

Heated oil products (fuel oil, crude oil)

Fill cofferdam with diesel oil/white spirit to keep

any leakage into cofferdam in liquid form. (This is

especially important after stripping and during

tank cleaning.)

Crystallizing cargoes (molasses, etc.)

Fill cofferdam with fresh water. The

cofferdam may also be arranged with a

small water circulation.

CLOSED

Vent. line

CLOSED

CLOSED

Open purging

connection

Fig. 40

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

15 of 20

14Oct10/AGAa

2.6 Tank cleaning / cleaning of pump

For viscous/solidifying cargoes

During tank cleaning the pump should be run at

approximately the same flow rate as cleaning

water / liquid supply.

Halfway the tank cleaning time close the cargo

discharge valve, open the stripping valve and

operate pump for a short period in order to get

a good cleaning of wear rings, seal rings,

pumps parts and stripping pipe.

Then open the cargo discharge valve and run

the pump to complete the tank cleaning

operation.

Cleaning water left in pump's cargo pipe is to

be stripped as described in chapter 2.3.

For corrosive cargoes

Tanks to be cleaned should be filled with a

large amount of cleaning water to dilute the

corrosive cargo.

After tank flushing the same cleaning procedure

as for viscous / solidifying cargoes should be

followed.

Note!

Remains of cleaning water in suction well to be

removed to avoid galvanic corrosion.

Galvanic

cell

Suction well

empty

Fig. 42

Note!

If steam is used to clean the pump, the steaming

out period must not exceed 10 minutes, to avoid

damage of seals or hydraulic motor. Always

purge the cofferdam before tank washing with

steam.

Note!

If using sea water or brackish water for tank

cleaning, see chapter 2.7.

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

16 of 20

14Oct10/AGAa

2.7 Precautions if using cargo pumps in sea water

Seawater tank cleaning (Continuous circulation)

The nominal corrosion rate for stainless steel in sea

water is low. However, under certain circumstances,

local corrosive attack can take place and the corrosion

rate might be severe. High chloride concentrations and

low pH increase the probability of pitting and crevice

corrosion as do high temperatures and stagnant

solutions. Tank cleaning using sea water must

therefore be carried out according to qualified

procedure.

- In general the tank cleaning should be carried out

within limited time frame at temperature below 60C.

Higher temperature up to 80C can be used for a

shorter period. (Fig. 43, for guidance only.)

- Avoid pH values below 6,5. Check carefully if the

ship has been carrying acids.

- If hot seawater is used, cool immediately with cold

seawater until surface temp. is below 40C before

fresh water rinse. This to avoid concentration of

chlorides from evaporation on hot steel surfaces.

- Tank cleaning with seawater must be followed

by a thoroughly rinse with fresh water to remove

chlorides.

Sea water for heavy ballast

- When possible, take clean seawater in open sea

and avoid contaminated harbour water.

- Empty the tanks as soon as possible when the

ballast is no longer required or when the testing is

finished.

- Carefully clean the tank and the pump to ensure no

chlorides remain on surfaces.

Max. exposure time, hours

S

e

a

w

a

t

e

r

t

e

m

p

.

C

o

2 4

40

50

60

80

70

Tank cleaning

Fig. 43

2 4 6

10

20

30

40

8 10 12

Max. exposure time, days

Ballast

S

e

a

w

a

t

e

r

t

e

m

p

.

C

o

Fig. 44

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

17 of 20

14Oct10/AGAa

2.8 Loading of cargo tank

In general it is recommended to start the loading slowly to avoid pressure surges in the cargo pipe line

and the pump. Correct operation of valves is important. Open / close valves slowly !

If a separate drop line is installed,

it is recommended to load through

the drop line only.

If required to load through the pump,

use following procedure:

Note! For sampling procedures,

ref. charterer's requirements.

- Keep manifold valve closed until

the cargo reach the manifold.

- Open manifold valve partly to fill

cargo line on deck.

- Open cargo pump discharge valve

and drop line valve slowly.

- Open manifold valve slowly until

required pressure/capacity is reached.

Note! Maximum acceptable loading

pressure when loading through

the pump is 8 bar at the pump

top plate.

Cargo line

Cargo discharge valve

CLOSED

Drop line

OPEN valve

Loading pressure

Max. 8 bar

Fig. 45 Arrangement with separate drop line

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

18 of 20

14Oct10/AGAa

3 MAINTENANCE INFORMATION

Prior to entering a cargo tank for doing

service it is essential to become familiar

with the ship's safety rules and

requirements regarding cargo-handling

equipment. Do not enter a cargo tank before

the tank is confirmed gas free and safe.

Before doing service on pump, always close

and lock the hydraulic pressure inlet valve

and purge the cofferdam. Purge cofferdam

according to chapt.2.4.

Close the cargo discharge valve. Ensure

that the valve is in closed position until the

work/service is finished (info sign to be

placed at the control panel/computer).

Caution: Venting gas and liquid may be

hazardous.

To prevent skidding and minimize the risk of

fire it is important to remove oil spill during

maintenance and servicing work. The

operator should be confident that all flange

connections are in satisfactory condition so

as to prevent hydraulic oil and cargo spills.

4 TROUBLE SHOOTING

Warning: To prevent damage from hazardous cargoes, take necessary precautions, wear safety

gear and avoid contact with spray/gases.

Symptom: Possible reason: Remedy: *)

COP operational problem

(First it is necessary to

verify if the problem is in

the pump control system

or in the pump unit itself).

General Ref. system service manual - Trouble shooting

section

The pump will not start a) Cargo pump remote

control system failure

b) Pump control valve

failure

c) Pump impeller stuck.

c1)Frozen /solidified cargo

c2)Foreign objects stuck in

pump or other

mechanical problem

a) Ref. instruction for Pump remote control

b) Ref. Instruction for Pump control valve (STC)

c1) Heat the cargo in the pump suction well.

c2) Pump unit to be inspected.

Pump is vibrating heavily a) Control system problem

b) Rotating parts out of

balance.

a) Ref. instr. for Pump control system.

b) Impurities stuck in impeller or other

mechanical problem.

Too low pumping capacity a) Control system problem

b) Worn wear rings.

Impurities stuck in

impeller, or other

mechanical problem

a) Ref. instr. for Pump control system and instr.

for Pump control valve.

(If required interchange pump control valve

as described in instr. 1000-0109-4)

b) Pump unit to be inspected

*) Ref. instruction for maintenance and repair for actual pump.

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

19 of 20

14Oct10/AGAa

Symptom: Possible reason: Remedy: *)

Noise(non return valve)

and vibration when loading

through the pump.

Damaged back stop unit

Check hydraulic motor inlet pressure

pressure above 15-20 bar indicates

malfunctioning back stop unit.

Change back stop unit.

Contact a Framo Service Station.

Not possible to purge the

cofferdam (no air, inert gas

or liquid coming out of the

check pipe when purging)

(See also chapter 2.4)

a) No or insufficient

purging medium supply

b) Blocked cofferdam

system

Note!

In case steam is used in

attempt to clear a blockage

in pump cofferdam system

pay special attention not to

over pressurize the

pump/pipe stack

a) Check valves, hose connections and

purging medium relief valve (open at approx.

3 bar).

b) Check the exhaust trap and the piping on

deck for blockage. Open if possible.

b1) Disconnect check pipe from pump unit

(lower seal house) watch out for possible

pressurized liquid in cofferdam!!

By carefully purging check if the blockage is

located in the check pipe or in the pump/

pipe stack cofferdam.

Depending on the nature of the medium

blocking the cofferdam system use steam or

solvent to dissolve the blockage.

Dismantling of pump might be required.

Note! Pressure test pump after assembly.

Cargo leakage to pump

cofferdam.

(See also chapter 2.4)

General

Note!

Always pressure test pump

prior to and after

dismantling. This is required

to locate possible leakage

and to confirm no leakage

upon completion of repair.

a) Worn cargo seal

Note; If no leakage is

detected by pressure test

it is likely that the cargo

leakage to cofferdam is

caused by worn cargo

seal. (the upper seal lip is

sealing when pressurizing

cofferdam).

b) Leaking seal element in

flange connection

c) Crack/pinhole in piping

Pressure test pump cofferdam system at approx.

3 bar.

Check for leakage if required spray with soapy

water to locate the leakage.

a) Replace cargo seal set.

Also, carefully check ceramic sleeve for

possible damage-wear.

b) Check for loose bolts and for pitting corrosion

in seal faces in case of corrosion repair is

required.

When assemble, renew damaged seal

element.

c) Contact a Framo Service Station.

*) Ref. instruction for maintenance and repair for actual pump.

Framo Cargo Pumps

OPERATION MANUAL

No.

Date/Sign.:

Page:

Rev. C:

1000-0121-401

08J un98/AGAa

20 of 20

14Oct10/AGAa

Symptom: Possible reason: Remedy: *)

Hydraulic oil leakage to

pump cofferdam.

(See also chapter 2.4)

General

a) Leaking shaft seal

b) Leaking seal element in

flange connection.

c)Crack/pinhole in piping

Drain the pump return side prior to dismantling.

Disconnect pump head/unit from pipe

stack/casing.

Pressurize pump unit return side at approx 4 bar

and check for leakage to cofferdam side.

Pressure test pump pipe stack / casing at max 7

bar on cofferdam side and check for leakage to

return side.

a)Replace shaft seal (replaced seal to be

reconditioned if feasible)

b) Check sealing surface for possible damage

repair if damaged.

When assemble, renew damaged seal

element.

c) Contact a Framo Service Station.

*) Ref. instruction for maintenance and repair for actual pump.

Note!

Evaluate if changed parts as sleeves, mechanical seals etc. are possible to recondition.

Send these parts to a Framo Service Station and ask for an evaluation.

Anda mungkin juga menyukai

- No22 2000 Local Control Valves and Service Valves For Cargo PumpsDokumen4 halamanNo22 2000 Local Control Valves and Service Valves For Cargo PumpsTimmyJuriBelum ada peringkat

- No25 2001 Improved Stripping - Latest Standard Available As Upgrading KitsDokumen6 halamanNo25 2001 Improved Stripping - Latest Standard Available As Upgrading KitsTimmyJuriBelum ada peringkat

- No7 1992 Recondition of Components in Framo Cargo Pumping SystemDokumen5 halamanNo7 1992 Recondition of Components in Framo Cargo Pumping SystemTimmyJuriBelum ada peringkat

- E0 Survey RequirementsDokumen2 halamanE0 Survey RequirementsTimmyJuriBelum ada peringkat

- HELGA SPIRIT SealDokumen19 halamanHELGA SPIRIT SealTimmyJuriBelum ada peringkat

- O-53b Cargo Pumping SystemDokumen453 halamanO-53b Cargo Pumping SystemTimmyJuri100% (2)

- No20 1998 Reconditioning of Mechanical SealsDokumen4 halamanNo20 1998 Reconditioning of Mechanical SealsTimmyJuriBelum ada peringkat

- TD13-00019-02 Inlet Temp. Setting of LT F.W. Engine (Rev.2 Precaution Statement Edit)Dokumen2 halamanTD13-00019-02 Inlet Temp. Setting of LT F.W. Engine (Rev.2 Precaution Statement Edit)TimmyJuriBelum ada peringkat

- Pre Docking Inspection - PrimeservDokumen7 halamanPre Docking Inspection - PrimeservTimmyJuriBelum ada peringkat

- Techno News: Spray Shielding of Flammable OilDokumen3 halamanTechno News: Spray Shielding of Flammable OilTimmyJuriBelum ada peringkat

- TD13-00008 Water Leakage From O-Ring of Cylinder LinerDokumen2 halamanTD13-00008 Water Leakage From O-Ring of Cylinder LinerTimmyJuriBelum ada peringkat

- Service Note: Precautions For Operation of Fuels With Maximum 0.50% SulphurDokumen7 halamanService Note: Precautions For Operation of Fuels With Maximum 0.50% SulphurTimmyJuriBelum ada peringkat

- !!MY02 - MB10100 - PIPING DIAGRAM IN ENGINE ROOM (BOOKLET) ModificationDokumen58 halaman!!MY02 - MB10100 - PIPING DIAGRAM IN ENGINE ROOM (BOOKLET) ModificationTimmyJuriBelum ada peringkat

- Code BookDokumen207 halamanCode BookTimmyJuriBelum ada peringkat

- Atx 060Dokumen2 halamanAtx 060TimmyJuriBelum ada peringkat

- Ecospray Operators Pocket Guide 18 Apr 2019Dokumen21 halamanEcospray Operators Pocket Guide 18 Apr 2019TimmyJuri100% (1)

- Rules For Classification and Construction I Ship Technology: 1 Seagoing ShipsDokumen56 halamanRules For Classification and Construction I Ship Technology: 1 Seagoing ShipsTimmyJuriBelum ada peringkat

- Technical Bulletin WJP Operation of Aft Seal TankDokumen5 halamanTechnical Bulletin WJP Operation of Aft Seal TankTimmyJuriBelum ada peringkat

- Alpha Lubricator Emergency OperationDokumen2 halamanAlpha Lubricator Emergency OperationTimmyJuriBelum ada peringkat

- M-08) Piping Diagram in Engine RoomDokumen39 halamanM-08) Piping Diagram in Engine RoomTimmyJuriBelum ada peringkat

- pdf130 TMP PDFDokumen3 halamanpdf130 TMP PDFTimmyJuriBelum ada peringkat

- Instruction Manual For Stern Tube Seal 2015aprDokumen33 halamanInstruction Manual For Stern Tube Seal 2015aprTimmyJuriBelum ada peringkat

- Steam Traps - Impulse Type Working PrincipleDokumen3 halamanSteam Traps - Impulse Type Working PrincipleTimmyJuriBelum ada peringkat

- 08 Exhaust Valve SystemDokumen16 halaman08 Exhaust Valve SystemTimmyJuriBelum ada peringkat

- ME Engine Training Course MAN B W Diesel PDFDokumen436 halamanME Engine Training Course MAN B W Diesel PDFTimmyJuriBelum ada peringkat

- Service Bulletin RTA-75 RT-flex-04Dokumen5 halamanService Bulletin RTA-75 RT-flex-04TimmyJuriBelum ada peringkat

- 2015 Pri XLDokumen2 halaman2015 Pri XLTimmyJuriBelum ada peringkat

- Engine Room Operations 2nd EditionDokumen3 halamanEngine Room Operations 2nd EditionTimmyJuriBelum ada peringkat

- Rta 48 ClearancesDokumen17 halamanRta 48 ClearancesTimmyJuriBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)