Report of Industrial Training

Diunggah oleh

munnayadav5550 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

68 tayangan15 halamanSchneider electric report on industrial training.

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniSchneider electric report on industrial training.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

68 tayangan15 halamanReport of Industrial Training

Diunggah oleh

munnayadav555Schneider electric report on industrial training.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 15

Page 1 of 15

Report of Industrial Training

On

1. Process Capability of Industrial Control Products.

2. Studying the MCCB line, identifying the causes for

rejections and measures taken to overcome them.

At

HYDERABAD WORKS

Submitted by

RAMAN PRATAP SINGH,LAJWANT PRAJPAT

12STUHHME0219,ME0091

In partial fulfilment of the requirements for the award of the degree of

BACHELOR OF TECHNOLOGY

IN

MECHANICAL ENGINEERING

DEPARTMENT OF MECHANICAL ENGINEERING

IFHE - FST

(A Constituent College of ICFAI University)

HYDERABAD , INDIA

Page 2 of 15

ACKNOWLEDGEMENT

__________________________________________________________________________________

First of all I would like to thank Schneider Electric India Private Limited for giving me this

opportunity to learn, share my ideas, views, and thoughts on various subjects through this

project, undertaken as a part of my curriculum requirements.

This project could not have been completed, if not for the help and encouragement from

various people. Words are inadequate in offering our thanks to the Project mentors

Mr. nilesh sir, for their guidance and cooperation throughout my internship.

1. COMPANY PROFILE

Schneider Electric is a French global company, founded in 1836 by two brothers, Eugene

and Adolph Schneider. It a global specialist in energy management with operations in 130

countries, Schneider Electric offers integrated solutions across multiple market segments,

including leadership positions in energy and infrastructure, industrial processes, building

automation, and data centres/networks, as well as a broad presence in residential applications.

Schneider Electric offers solutions to make energy safe, reliable, efficient, productive and

green from plant to plug.

3. SCHNEIDER ELECTRIC INDIA

22.4bn

Global Sales in 2011

39% of sales in new economies

2 compared to 2004

130,000+ people

In more than 100 countries

4-5%

Sales devoted to R&D

170 years

of history through innovation

and leading brands

Page 3 of 15

Schneider Electric entered India in 1963 through a first joint venture with Tata group.

In 1995, Schneider Electric established a 100% fully owned subsidiary Schneider Electric

India Pvt. Ltd.

In the year 2000, Schneider Electric further consolidated its position in the Indian market by

acquiring S&S Switchgear and Crompton Greaves LV division.

Hyderabad Factory

Fig: 2.3

Land: 40000 sq.mts Built up area: 12500 sq.mts

Schneider Electric India has added to its manufacturing capacities establishing another state-

of-the-art Plant at Hyderabad. Sprawling over 10-acre land, the plant has 12,500 Sq.m built-

up area. It boasts of machines equipped with cutting edge technologies, and manufactures

world-class Air Circuit Breakers, Medium Voltage (RN2C, RM6), Contactors and Push

Buttons, and caters to the requirements of domestic as well as worldwide markets

Products of Hyderabad plant are

Page 4 of 15

Table: 2.1

Products manufactured in Hyderabad factory are:

Fig: 2.4 Master pact Circuit Breakers

Fig: 2.5

RN2C Ringmaster

Fig: 2.6 RM6 Ring Main unit Fig:2.7 Tesys Range of Contactors

Tesys D

EasyPact TVS

Page 5 of 15

Fig: 2.8 Harmony range of push buttons & pilot lamps Fig: 2.9 Tesys-E Range of Contactors

WHAT

IS A

CONTACTOR?

The contactor is a mechanical switching device controlled by an electromagnet; it is able to

make or break high currents by energizing or de-energizing a coil in which a relatively low

current flows its operating mode is discrete (on/off).

Contactor operation:

Page 6 of 15

Fig 3: Functional diagram of a contactor

About TeSys :

Tesys is a range of contactors manufactured at Schneider Electric Hyderabad Plant.

Tesys comes in two varieties :

1) Tesys D,

2) Tesys-E.

3) Definition -Process: Process refers to any system of causes; any combination of

conditions which work together to produce circuit breaker is an automatically

operated electrical switch designed to protect an electrical circuit from damage caused

by overload or short circuit. Its basic function is to detect a fault condition and

interrupt current flow. The circuit breakers are divided into two types based on their

rating:

Low-Voltage circuit breaker

High- voltage circuit breaker

What is an M.C.C.B?

Page 7 of 15

A relatively light, fast-acting electrical circuit breaker assembled as an integral unit in a

supporting and enclosing housing of moulded insulating material.

EasyPact CVS- MCCB with adjustable settings .

Fig: 5.1 Easy Pact CVS

Compact NSX

Also called the next generation Circuit Breaker

Fig: 4.5 Compact NSX 250A

with 2.5A micro logic

Easy Pact (Molded Circuit breaker from 15 to 400A

Page 8 of 15

Fig: 4.6 Easy Pact (15-400A)

Page 9 of 15

6. Manufacture of Molded case Circuit Breaker (M.C.C.B)

Fixed contact Arc Splitters Spark Production

Moving contact

Insulation Disc

Breaking Cell Assembly

Sensor Testing

Riveting Assembly Station

Manual Checking

Mechanism assembly

Resistance Test

Base Assembly

Trip Circuit Assembly

Function Test Machine

Label Pasting

Front Cover Assembly

MCCB Laser Marking

Machine

Page 10 of 15

Breaking Cell Assembly:

Fig: 6.1 Lower segment of the Breaker cell showing fixed

And moving contacts

Fig: 6.2 Components in the lower part of the breaking cell.

Riveti ng Asse mbly

station:

Moving contact

Fixed contact (Upstream)

Lower part of the cell

Fixed contact (downstream)

Spark production

Insulation disc

Arc Splitters (6- pin)

Page 11 of 15

Fig: 6.3 Riveting Assembly Station Fig: 6.4 Barcode Label printing

Station

Mechanism Assembly:

Fig: 6.5 A Breaker Mechanism Fig: 6.6 the Mechanism Assembly

Steel and Copper Testing:

Fig: 6.7 The Steel and copper

Testing machine

Base Assembly:

At this station the Screw presence and proper

tightening is tested. And once done is sent to the trip unit

assembly.

Machine to be tested is to be

inserted here.

Indictors that test if the metal

used is steel or copper

Page 12 of 15

Fig: 6.8 Screw presences being tested and tightened

Trip unit Assembly

Fig: 6.9 Fig: 6.10 Fig: 6.11

Fig: 6.12 Fig: 6.13

Function Test Machine (F.T.M)

The product is sent to the FTM (Function test Machine) after the trip unit assembly where it

is tested for different aspects such as continuity, dielectric, resistance, screwing and the

presence of mechanism lever/ right OF/ left OF.

Page 13 of 15

Fig: 6.14 Fig: 6.15 Fig: 6.16

MCCB Laser Marking Machine:

Once the FTM tested, the breaker which passes the test is sent to the laser marking machine

where the references are printed on the slip according to the breaker. .

Fig: 6.17 MCCB laser marking M/C Fig: 6.18 Reference concerned to the

circuit breaker is printed on this slip.

Front cover Assembly:

Reference and

details are printed

by the laser printer

here.

Page 14 of 15

Fig: 6.19 Front cover Assembly Station Fig: 6.20 Appearance of the breaker after

The front cover.

Fig: 6.21 Primary Packing Fig: 6.22 Secondary Packing

7. Analysis on the parts that are rejected and scope for improvement

Page 15 of 15

Fig: 7.1 Fig: 7.2 Fig: 7.3

Defects in moving

contact after assembly

Rust formations on moving contacts.

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- XTZ Class-Ap 100: User ManualDokumen13 halamanXTZ Class-Ap 100: User ManualSotara RenBelum ada peringkat

- Optimal Design of Electrical MachinesDokumen10 halamanOptimal Design of Electrical MachinesShammi Shekhar ParmarBelum ada peringkat

- Battery Ignition System Definition Parts Working Principle Applications Advantages and DisadvantagesDokumen5 halamanBattery Ignition System Definition Parts Working Principle Applications Advantages and DisadvantagesSatya NarayanaBelum ada peringkat

- ST250 Ratemeter Instruction ManualDokumen10 halamanST250 Ratemeter Instruction ManualDeyvid Chambi TBelum ada peringkat

- Charge Redistribution AdcDokumen74 halamanCharge Redistribution AdcAnonymous eWMnRr70qBelum ada peringkat

- 4u Physics Equations Formula SheetDokumen2 halaman4u Physics Equations Formula SheetAngelica FilipeBelum ada peringkat

- Grundfos Multi-R Variable Speed Booster SystemDokumen4 halamanGrundfos Multi-R Variable Speed Booster SystemlaaliBelum ada peringkat

- Sr. No. Equipment Equipment ID Location Calibration Due DateDokumen16 halamanSr. No. Equipment Equipment ID Location Calibration Due DateGURIBelum ada peringkat

- Kannur University: Examination BranchDokumen3 halamanKannur University: Examination BranchPraveen PavithranBelum ada peringkat

- LM340K 12 7812P+Dokumen18 halamanLM340K 12 7812P+abrap_delBelum ada peringkat

- OPMS Trip Report AnalysisDokumen4 halamanOPMS Trip Report AnalysisAnuragBelum ada peringkat

- Program ATP EMTP in Overvoltage EducationDokumen4 halamanProgram ATP EMTP in Overvoltage Educationrodrigoct88Belum ada peringkat

- VariableDokumen85 halamanVariableme10b031Belum ada peringkat

- D D D D D D D D: TLC556, TLC556Y Dual Lincmos TimersDokumen24 halamanD D D D D D D D: TLC556, TLC556Y Dual Lincmos Timerselfak.2000Belum ada peringkat

- 22 Calculated Magnetic Properties of Co Doped CdTe V P - 2017 - Computational CondDokumen4 halaman22 Calculated Magnetic Properties of Co Doped CdTe V P - 2017 - Computational CondMounia El YousfiBelum ada peringkat

- Pae Receiver Type t6r Maintenance HandbookDokumen80 halamanPae Receiver Type t6r Maintenance Handbookcmge_200580% (5)

- DiodeDokumen16 halamanDiodeGilberto ManhattanBelum ada peringkat

- Advance Xitanium SR Bridge Design-In Guide (PAd-1704DG)Dokumen20 halamanAdvance Xitanium SR Bridge Design-In Guide (PAd-1704DG)DanielBelum ada peringkat

- Indian Standard: Methods of Test For CablesDokumen3 halamanIndian Standard: Methods of Test For CablesBilal AhmadBelum ada peringkat

- Reliability 1Dokumen71 halamanReliability 1AyoBelum ada peringkat

- Ac and DC BridgeDokumen33 halamanAc and DC BridgeArijit KaranBelum ada peringkat

- Optical Communication 2017,2018,2020 and 2021 Past Questions and SolutionsDokumen42 halamanOptical Communication 2017,2018,2020 and 2021 Past Questions and SolutionsMelsougly BryceBelum ada peringkat

- Convergence 36Dokumen3 halamanConvergence 36Furqan WarisBelum ada peringkat

- Instrument Ass. 2Dokumen14 halamanInstrument Ass. 2Chaudhry Salman Gujjar89% (35)

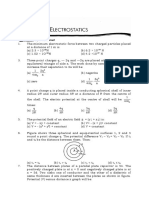

- 14 ElectrostaticsDokumen38 halaman14 ElectrostaticskumarBelum ada peringkat

- Sample Questions NAC Tech Part BDokumen5 halamanSample Questions NAC Tech Part Brachelkrrish100% (1)

- ASTM E1571-01 Ferromagnetic Steel Wire Rope PDFDokumen5 halamanASTM E1571-01 Ferromagnetic Steel Wire Rope PDFDanny Milton Silva Vasquez100% (2)

- WilsonDokumen51 halamanWilsonbedip20200Belum ada peringkat

- Chapter 2 - Waveguide PDFDokumen38 halamanChapter 2 - Waveguide PDFHiroshi RayBelum ada peringkat

- Electricity at Work Regulations 1989.Dokumen52 halamanElectricity at Work Regulations 1989.kagkaggBelum ada peringkat