Project and Innovation Finance & Accounting: Assignment 3

Diunggah oleh

Branden Oxford0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

20 tayangan10 halamanProject management

Judul Asli

Paifa Assignment

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniProject management

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

20 tayangan10 halamanProject and Innovation Finance & Accounting: Assignment 3

Diunggah oleh

Branden OxfordProject management

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 10

Project and

Innovation Finance &

Accounting

Assignment 3

A1202465

Date Due: 15/10/2010

Branden 0xford A1202465

Branden 0xford A1202465

Introduction

Surface Course Gravel for Haul Road Maintenance

Truck haulage costs can account for 10%-15% of the total costs incurred by an open

cut mining operation. Therefore there is a need for improved design technologies

encompassing the management techniques of mining haul roads appropriate for the

wheel loads of the vehicles currently in use on site. The maintenance of these haul

roads is a must to keep operations continuing economically and safely, so the best

means of obtaining the gravel for haul road maintenance needs to be evaluated.

The uppermost layer of the haul road that comes directly in contact with tires is

known as the surface course. A haul road surface is generally constructed with fine

gravel with closely controlled grading to avoid dust problems while maintaining

proper binding characteristic of the material. Apart from providing a smooth riding

surface, it also distributes the load over a larger area thus reducing stresses

experienced by the base course. When a selected waste rock layer is located under

the wearing course, road performance is significantly improved, primarily due to the

load carrying capacity of the waste rock layer which reduces the susceptibility of the

soft sub-grade and in-situ to the effects of high axle loads. It also has the added

advantage of reduced construction costs (by virtue of reduced volumetric and

compaction requirements), compared with the CBR cover-curve design approach. As

with structural designs, if local mine material can be used for construction, the costs

are all the more favourable.

The advantages haul road maintenance includes:

smooth haul roads

safer haul roads

less tyre wear

less water required on the haul road

more traction

less dust

more access time to the haul road after heavy rains and flooding

less wear and tear to suspension systems on trucks and light vehicles

haul roads can be reshaped to maintain a cross-fall for water run off

less fatigue for truck drivers

no dips, no bumps, therefore - no spillage

Project Objective

Evaluate three types of gravel crushing/screening facilities to be located on site to

provide gravel from blast waste rock. This gravel will be sold to recoup the projects

capital outlay and also be used on Bramoni EDIS own haul roads which will

eliminate current supply issues being experienced from third party contractors.

Branden 0xford A1202465

Evaluation of Crushing/Screening Plants

Smith Permanent In-line Gravel Crusher/Processor

An old erection site which has easy access to power and water has be chosen next

to the eastern blue pit dam for this module to be built. The complete crushing

process plant consists of the vibrating feeder, jaw crusher (coarse crushing), Impact

Crusher (secondary crushing), vibrating screen, belt conveyor etc. The Smith

production line is highly automated, large capacity, and high-yielding. The final size

has even particle size and grain shape that will meet the requirement of all mine

sites.

Base data for Discounted Cash Flow (DCF) Calculation

Item Value

Initial capital cost $2,200,000

Life of project 5 years

Salvage value at end of life $300,808

Production per year See table 1

Selling price $55/ton

Annual operating expenses See table 2

Depreciation rate for tax purposes 27.5%

Tax rate 35%

Discount rate 15%

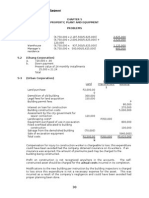

Table1: Discounted Cash Flow

0 1 2 3 4 5

Production, ton 30,000 50,000 50,000 50,000 45,000

Operating revenue at $55/ton 1,650,000 2,750,000 2,750,000 2,750,000 2,475,000

Operating expenses 742,500 1,320,000 1,430,000 1,595,000 1,930,500

Operating profit 907,500 1,430,000 1,320,000 1,155,000 544,500

Capital Expenditure 2,200,000

Tax depreciation- 27.5% of the

start-of-year value of capital 453,750 328,969 238,502 172,914 125,363

End of year written-down value

for tax purposes 1,196,250 867,281 628,779 455,865 330,502

Salvage value 300,808

Taxable profit 453,750 1,101,031 1,081,498 982,086 419,137

Income tax payable at 35% tax

rate 158,813 385,361 378,524 343,730 146,698

After tax profit 294,938 715,670 702,973 638,356 272,439

Net cash flow -2,200,000 748,688 1,044,639 941,476 811,270 698,610

Discount factor(at 15% return

on investment) 1.000 0.8696 0.7561 0.6575 0.5718 0.4972

Discounted cash flow -2,200,000 651,059 789,852 619,020 463,884 347,349

Year

Branden 0xford A1202465

Net Present Value and Internal Rate of Return Calculation

Net Present Value (NPV) = -$191,683

Internal Rate of Return (IRR) = 10.84%

Graph 1 NPV Profile

Sensitivity Analysis

An evaluation was made checking sensitivity of the base-case NPV relative to

variations +/-10% of the selling price selling price of the gravel. This was based on

previous market data history and future forecasts.

Base-case

Selling price

$55/ton

Increase 10%

Selling price

$60.5/ton

Decrease 10%

Selling price

$49.5/ton

NPV -189,488 4,085 -383,061

-$800,000

-$600,000

-$400,000

-$200,000

$-

$200,000

$400,000

$600,000

$800,000

0

.

0

0

%

2

.

0

0

%

4

.

0

0

%

6

.

0

0

%

8

.

0

0

%

1

0

.

0

0

%

1

2

.

0

0

%

1

4

.

0

0

%

1

6

.

0

0

%

1

8

.

0

0

%

2

0

.

0

0

%

2

2

.

0

0

%

2

4

.

0

0

%

2

6

.

0

0

%

2

8

.

0

0

%

3

0

.

0

0

%

Discount Rate

NPV

Branden 0xford A1202465

SBM Mobile Jaw Crusher Unit

The SBM mobile jaw crusher unit doesnt require a specific site it can be moved from

location to location which may be a benefit. The unit consists of vibrating feeder,

motor feeder, hopper feeder, jaw crusher, motor of jaw crusher, standard belt

conveyor and extended belt conveyor. SBM mobile crushing plant has high chassis

and small turning radius, which is suitable for most transportation conditions,

especially for driving to crushing sites that are difficult to access. The preparation

time of the mobile crushing plant is greatly reduced, compared with the fixed one and

reduced material transportation cost can also be achieved.

Base data for Discounted Cash Flow (DCF) Calculation

Item Value

Initial capital cost $2,100,000

Life of project 5 years

Salvage value at end of life $300,502

Production per year See table 2

Selling price $55/ton

Annual operating expenses See table 2

Depreciation rate for tax purposes 27.5%

Tax rate 35%

Discount rate 15%

Table 2: Discounted Cash Flow Summary

0 1 2 3 4 5

Production, ton 30,000 50,000 50,000 50,000 45,000

Operating revenue at $55/ton 1,650,000 2,750,000 2,750,000 2,750,000 2,475,000

Operating expenses 660,000 1,237,500 1,430,000 1,567,500 1,658,250

Operating profit 990,000 1,512,500 1,320,000 1,182,500 816,750

Capital Expenditure 2,100,000

Tax depreciation- 27.5% of the

start-of-year value of capital

453,750 328,969 238,502 172,914 125,363

End of year written-down value

for tax purposes 1,196,250 867,281 628,779 455,865 330,502

Salvage value 300,502

Taxable profit 536,250 1,183,531 1,081,498 1,009,586 691,387

Income tax payable at 35% tax

rate 187,688 414,236 378,524 353,355 241,986

After tax profit 348,563 769,295 702,973 656,231 449,402

Net cash flow -2,100,000 802,313 1,098,264 941,476 829,145 875,266

Discount factor (at 15% return on

investment) 1.000 0.8696 0.7561 0.6575 0.5718 0.4972

Discounted cash flow -2,100,000 697,691 830,397 619,020 474,105 435,182

Year

Branden 0xford A1202465

Net Present Value and Internal Rate of Return Calculation

Net Present Value (NPV) = $29,036

Internal Rate of Return (IRR) = 15.64%

Graph 2: NPV Profile

Sensitivity Analysis

An evaluation was made checking sensitivity of the base-case NPV relative to

variations +/-10% of the selling price of the gravel. This was based on previous

market data history and future forecasts.

Base-case

Selling price

$55/ton

Increase 10%

Selling price

$60.5/ton

Decrease 10%

Selling price

$49.5/ton

NPV 31,577 237,219 -174,148

-$800,000

-$600,000

-$400,000

-$200,000

$-

$200,000

$400,000

$600,000

$800,000

0

.

0

0

%

2

.

0

0

%

4

.

0

0

%

6

.

0

0

%

8

.

0

0

%

1

0

.

0

0

%

1

2

.

0

0

%

1

4

.

0

0

%

1

6

.

0

0

%

1

8

.

0

0

%

2

0

.

0

0

%

2

2

.

0

0

%

2

4

.

0

0

%

2

6

.

0

0

%

2

8

.

0

0

%

3

0

.

0

0

%

Discount Rate

NPV

Branden 0xford A1202465

PFW Hydraulic Impact Crusher

An old dragline erection site which has easy access to power and water has been

chosen next to the eastern blue pit dam. PFW series impact crushers have the

features of heavy duty rotor design, unique hammer locking system, interchangeable

wearing parts, and easy maintenance. This series hydraulic impact crushers provide

low capital cost solutions, outstanding performance, good cubical shape, lowest

operation cost per ton, and wide materials applications. Due to the cubicle shape

and sizing a greater selling price is achievable.

Base data for Discounted Cash Flow (DCF) Calculation

Item Value

Initial capital cost $2, 500,000

Life of project 5 years

Salvage value at end of life $300,456

Production per year See table 3

Selling price (per ton) $70/ton

Annual operating expenses See table 3

Depreciation rate for tax purposes 27.5%

Tax rate 35%

Discount rate 15%

Table 3: Discounted Cash Flow Summary

0 1 2 3 4 5

Production, ton 30,000 50,000 50,000 50,000 45,000

Operating revenue at $70/ton 2,100,000 3,500,000 3,500,000 3,500,000 3,150,000

Operating expenses 777,000 1,400,000 1,470,000 1,575,000 1,795,500

Operating profit 1,323,000 2,100,000 2,030,000 1,925,000 1,354,500

Capital Expenditure 2,500,000

Tax depreciation- 27.5% of the

start-of-year value of capital 577,500 418,688 303,548 220,073 159,553

End of year written-down value

for tax purposes 1,522,500 1,103,813 800,264 580,191 420,639

Salvage value 300,456

Taxable profit 745,500 1,681,313 1,726,452 1,704,927 1,194,947

Income tax payable at 35% tax

rate 260,925 588,459 604,258 596,725 418,232

After tax profit 484,575 1,092,853 1,122,194 1,108,203 776,716

Net cash flow -2,500,000 1,062,075 1,511,541 1,425,742 1,328,275 1,236,724

Discount factor (at 15% return on

investment) 1.000 0.8696 0.7561 0.6575 0.5718 0.4972

Discounted cash flow -2,500,000 923,580 1,142,876 937,425 759,508 614,899

Year

Branden 0xford A1202465

Net Present Value and Internal Rate of Return Calculation

Net Present Value (NPV) = $523,688

Internal Rate of Return (IRR) = 27.88%

Graph 3: NPV Profile

Sensitivity Analysis

An evaluation was made checking sensitivity of the base-case NPV relative to

variations +/-10% of the selling price selling price of the gravel. This was based on

previous market data history and future forecasts.

Base-case

Selling price

$70/ton

Increase 10%

Selling price

$77/ton

Decrease 10%

Selling price

$63/ton

NPV 527,107 822,351 231,868

-$800,000

-$600,000

-$400,000

-$200,000

$-

$200,000

$400,000

$600,000

$800,000

0

.

0

0

%

2

.

0

0

%

4

.

0

0

%

6

.

0

0

%

8

.

0

0

%

1

0

.

0

0

%

1

2

.

0

0

%

1

4

.

0

0

%

1

6

.

0

0

%

1

8

.

0

0

%

2

0

.

0

0

%

2

2

.

0

0

%

2

4

.

0

0

%

2

6

.

0

0

%

2

8

.

0

0

%

3

0

.

0

0

%

Discount Rate

NPV

Branden 0xford A1202465

Recommendation

After reviewing the three available gravel crushing/screening plants it is

recommended that Bramoni EDI installs the PFW Hydraulic crusher. The PFW

model had the best NPV value proving that with this project there will be more than

enough revenue generated to cover costs at the minimum rate of return. This model

also provided the best IRR which is crucial when looking at multiple investment

possibilities like on this occasion. One possible risk was the pricing of the gravel, the

resulting gravel product is high grade with a selling price some $15/ton above the

Smith and SBM plants but the sensitivity analysis showed even with a price

decrease of 10% a positive NPV can still be achieved.

Water and power issues can be eliminated by building the plant at the old dragline

erection site, power is already installed and water can be utilised from the nearby

eastern blue pit dam.

The importance of maintenance to haul roads to reduce hauling costs, provide safer

working conditions and less environmental impact is crucial to Bramoni EDIs

success. And due to the lack of availability of third party contractors to supply the

gravel needed to do this, installing the PFW crushing/screening plant on site will

eliminate this problem and as this report shows the revenue generated makes the

project worthwhile.

References

Atrill & Mclaney, 2008, Accounting An Introduction 4/E, Pearson Education Australia,

ISBN 978-0733990588

Ian C. Runge 1998 Mining Economics and Strategy Society for Mining, Metallurgy,

and Exploration, Inc ISBN 0-87335-165-7 P50-59

Anda mungkin juga menyukai

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryDari EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryBelum ada peringkat

- Managing Successful Projects with PRINCE2 2009 EditionDari EverandManaging Successful Projects with PRINCE2 2009 EditionPenilaian: 4 dari 5 bintang4/5 (3)

- Project Profile On Tyre RetreadingDokumen5 halamanProject Profile On Tyre RetreadingBinu Balakrishnan100% (2)

- Mini Cement Plant: Jaslin Singh Gyanvendra Singh Anurag AgrawalDokumen14 halamanMini Cement Plant: Jaslin Singh Gyanvendra Singh Anurag AgrawalJaslin SinghBelum ada peringkat

- Property, Plant and Equipment Problems 5-1 (Uy Company)Dokumen14 halamanProperty, Plant and Equipment Problems 5-1 (Uy Company)NaSheeng100% (1)

- Management Accounting: Page 1 of 6Dokumen70 halamanManagement Accounting: Page 1 of 6Ahmed Raza MirBelum ada peringkat

- Wheat Milling PDFDokumen7 halamanWheat Milling PDF8898surajBelum ada peringkat

- BTech 2007Dokumen246 halamanBTech 2007bhushan pawar patilBelum ada peringkat

- AssignmentDokumen7 halamanAssignmentsmmehedih008Belum ada peringkat

- CAPCOST - 2008 Ethylene Oxide B6Dokumen16 halamanCAPCOST - 2008 Ethylene Oxide B6'Arif Rukaini SufianBelum ada peringkat

- Ice Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiDokumen9 halamanIce Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiBunty RathoreBelum ada peringkat

- ClassiFormer en 200802Dokumen10 halamanClassiFormer en 200802kapokBelum ada peringkat

- Auto Pistons: NtroductionDokumen5 halamanAuto Pistons: NtroductionProfNDAcharyaBelum ada peringkat

- General Approach To Distribute Waste Rocks Between Dump Sites in Open Cast MinesDokumen11 halamanGeneral Approach To Distribute Waste Rocks Between Dump Sites in Open Cast MinesluisparedesBelum ada peringkat

- Rupees in 000: Page 1 of 6Dokumen6 halamanRupees in 000: Page 1 of 6Royal XpreSsBelum ada peringkat

- Auto Leaf SpringDokumen11 halamanAuto Leaf SpringVijayKrishnaAmaraneniBelum ada peringkat

- Gear Hobbing Dry Vs Wet Hobbing Manufacturing ProcessDokumen1 halamanGear Hobbing Dry Vs Wet Hobbing Manufacturing ProcessDhruv SutharBelum ada peringkat

- PSG College of TechnologyDokumen43 halamanPSG College of TechnologySiddharth Narayanan ChidambareswaranBelum ada peringkat

- Practise Question Chap 11Dokumen20 halamanPractise Question Chap 11SaadBelum ada peringkat

- Design Handbook MAchine DesignDokumen5 halamanDesign Handbook MAchine DesignsouravBelum ada peringkat

- Water Pump ReportDokumen15 halamanWater Pump ReportMohammed BashierBelum ada peringkat

- CH 21Dokumen5 halamanCH 21ProfNDAcharyaBelum ada peringkat

- Oil Production Water TreatmentDokumen36 halamanOil Production Water TreatmentGuido PerezBelum ada peringkat

- Basaveshwar Engineering College (Autonomous) BagalkotDokumen20 halamanBasaveshwar Engineering College (Autonomous) Bagalkotsagar sherkhaneBelum ada peringkat

- Washing Powder: Production and Cost ConceptDokumen24 halamanWashing Powder: Production and Cost Concepttinki0410Belum ada peringkat

- 326 Chapter 9 - Fundamentals of Capital BudgetingDokumen20 halaman326 Chapter 9 - Fundamentals of Capital BudgetingAbira Bilal HanifBelum ada peringkat

- Desk Break LiningDokumen15 halamanDesk Break Liningbig johnBelum ada peringkat

- Chapter 26 - Gripping IFRS ICAP 2008 (Solution of Graded Questions)Dokumen31 halamanChapter 26 - Gripping IFRS ICAP 2008 (Solution of Graded Questions)Falah Ud Din SheryarBelum ada peringkat

- 04 Theory of Production and Cost FinalDokumen21 halaman04 Theory of Production and Cost FinalNeushinth HettiarachchiBelum ada peringkat

- MaK VM32C Low Emission Engine 32305Dokumen12 halamanMaK VM32C Low Emission Engine 32305abuzer1981100% (1)

- DecommissioningDokumen7 halamanDecommissioningYong Kai MingBelum ada peringkat

- Chapter 10Dokumen89 halamanChapter 10kazimkoroglu100% (1)

- Sample Cash Flow Construction ProjectsDokumen6 halamanSample Cash Flow Construction ProjectsRoshan de Silva89% (9)

- Automobile SilencerDokumen3 halamanAutomobile SilencerHimanshu PunethaBelum ada peringkat

- 5.SH LTDDokumen4 halaman5.SH LTDDhrubajyoti PatraBelum ada peringkat

- Innovation and Improvements in Batch Centrifugal Designs.: 2.1 ReliabilityDokumen7 halamanInnovation and Improvements in Batch Centrifugal Designs.: 2.1 ReliabilityRAJKUMARBelum ada peringkat

- Evaluating Single Project: PROBLEM SET: Money-Time RelationshipsDokumen4 halamanEvaluating Single Project: PROBLEM SET: Money-Time RelationshipsAnjo Vasquez100% (1)

- 2-LCC For VEWDokumen30 halaman2-LCC For VEWحموده الساميBelum ada peringkat

- Rolling MillDokumen5 halamanRolling MillARDOVABelum ada peringkat

- Group Technology: Pgdie 41Dokumen31 halamanGroup Technology: Pgdie 41Saikat SahaBelum ada peringkat

- December 2010 TC6ADokumen7 halamanDecember 2010 TC6AAhmed Raza MirBelum ada peringkat

- Blancett b133-300Dokumen4 halamanBlancett b133-300frankurt1Belum ada peringkat

- Water ProjectDokumen5 halamanWater ProjectJayaprakash KanagarajBelum ada peringkat

- Pioneer Cement LTD.: Cost Auditors' ReportDokumen14 halamanPioneer Cement LTD.: Cost Auditors' ReportDhiren JainBelum ada peringkat

- Silicon Wafer Manufacturing ProcessDokumen8 halamanSilicon Wafer Manufacturing ProcessNur SaheerahBelum ada peringkat

- ATTOCK CEMent REPORT 29 ADokumen11 halamanATTOCK CEMent REPORT 29 AihtashamBelum ada peringkat

- 8r77r-Cybas I ConeDokumen6 halaman8r77r-Cybas I Coneturkishdjem100% (1)

- Sepax SeperatorDokumen6 halamanSepax Seperatoradanis01100% (1)

- Ready-Mix Concrete (RMC Plant) - 627631 PDFDokumen84 halamanReady-Mix Concrete (RMC Plant) - 627631 PDFPANKAJ SINGHBISHTBelum ada peringkat

- Ready-Mix Concrete (RMC Plant) - 627631 PDFDokumen84 halamanReady-Mix Concrete (RMC Plant) - 627631 PDFHarshada Hikare100% (1)

- Plant LayoutDokumen65 halamanPlant Layoutsupriya127100% (1)

- Ce 8328: Construction Management: Assignment 02Dokumen9 halamanCe 8328: Construction Management: Assignment 02Chiranjaya HulangamuwaBelum ada peringkat

- AAC Sample Project Profile Universal-Ver-2Dokumen7 halamanAAC Sample Project Profile Universal-Ver-2N Gangadhar Reddy100% (1)

- Basic Principles of Life Cycle CostingDokumen9 halamanBasic Principles of Life Cycle CostingsburckhardtBelum ada peringkat

- STP 125 KLDDokumen9 halamanSTP 125 KLDAbhay SisodiaBelum ada peringkat

- Turnaround Management for the Oil, Gas, and Process Industries: A Project Management ApproachDari EverandTurnaround Management for the Oil, Gas, and Process Industries: A Project Management ApproachPenilaian: 2 dari 5 bintang2/5 (1)

- A Practical Guide to Concrete Pavement Technology for Developing CountriesDari EverandA Practical Guide to Concrete Pavement Technology for Developing CountriesBelum ada peringkat

- Guide to Performance-Based Road Maintenance ContractsDari EverandGuide to Performance-Based Road Maintenance ContractsBelum ada peringkat

- Sustainability Footprints in SMEs: Strategy and Case Studies for Entrepreneurs and Small BusinessDari EverandSustainability Footprints in SMEs: Strategy and Case Studies for Entrepreneurs and Small BusinessBelum ada peringkat

- Carbon Capture, Utilization, and Storage Game Changers in Asia and the Pacific: 2022 Compendium of Technologies and EnablersDari EverandCarbon Capture, Utilization, and Storage Game Changers in Asia and the Pacific: 2022 Compendium of Technologies and EnablersBelum ada peringkat

- List The Circumstances Where You Would Base Your Project Management Approach On A Model-Based MethodologyDokumen5 halamanList The Circumstances Where You Would Base Your Project Management Approach On A Model-Based MethodologyBranden OxfordBelum ada peringkat

- 793c TransDokumen1 halaman793c TransBranden OxfordBelum ada peringkat

- List The Circumstances Where You Would Base Your Project Management Approach On A Model-Based MethodologyDokumen5 halamanList The Circumstances Where You Would Base Your Project Management Approach On A Model-Based MethodologyBranden OxfordBelum ada peringkat

- Trans Scavenge TC Charging Transmission Charging Transmission LubeDokumen2 halamanTrans Scavenge TC Charging Transmission Charging Transmission LubeBranden OxfordBelum ada peringkat

- Mine ManagementDokumen7 halamanMine ManagementBranden OxfordBelum ada peringkat