How To Start Combined Cycle Power Plant

Diunggah oleh

Bv RaoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

How To Start Combined Cycle Power Plant

Diunggah oleh

Bv RaoHak Cipta:

Format Tersedia

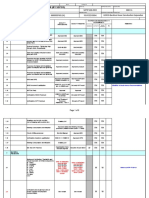

START up preparation Schedule 31 30 29 28 27 26 25 24 23 22 21

31 30 29 28 27 26 25 24 23 22 21

BALANCE OF PLANT

CW pumps A , B , C Pump and motor coupling work.

CT makeup water filling line dummy removing in CT Forebay.

Cooling tower system filling

ACW header lines manways closing work.

CW header lines manways closing work.

ACW System charging

Air compressors temporary cooling water lines connections removing work.

Cooling Water circuit charging

Instrument air compressor normalisation

CO2 system checks - CCR, PCC#1A&1B

Gas skid-1 & 2 normalisation

Side Stream filter normalisation

SWAS Coolers & Chiller Units normalisation

GAS TURBINE

GT-1A combustion chamber and diffuser visual inspection.

GT-1A combustion chamber and diffuser visual inspection.

GT-1A & GT-1B Generator Dehumidifiers hoses connections removing and

dummy's re fixing work.

Put GT-1A on turning gear

GT-1A complete check up

GT-1B complete check up

GT-1A Water Wash

GT-1B Water Wash

All NG valves stroke checking at GT skid

IGV operation & Compressor shut off valves operation

STEAM TURBINE

STG turning gear

Condenser hotwell makeup

CEP-A & B Pump and motor coupling work.

STG condenser hot well man way closing work.

Condensate circuit normalisation

CEP Pumps trial run

STG MOVs & Pnematic Control valves stroke checks

Steam Bypass system valves stroke checking

STG generator dehumidifier hose connections removing and dummy's re fixing

work.

Governing oil pumps trial & ST control and stop valves stroke checks

STG LP Turbine casing front & Rear manways closing work after silicagel trays

removal.

HRSG

HRSG#1A HP/IP/LP/CPH/Deaerator circuit N2 venting and normalisation

HRSG-1A Flue gas path silica gel removing,Guillotine Damper, Weather damper

HRSG-1A Control valves stroke checks

HRSG-1A All MOVs Open/Close test

HRSG-1A Deaerator top side vent lines NRV gates fixing work.

HRSG-1A HP drum (BFP-1A side) man way gasket replacement work.

HRSG-1A Weather damper area putty removing and cleaning work.

HRSG-1A Diverter damper & Guillotine dampers man ways closing work.

HRSG-1A Guillotine damper locking to be done after opening the damper.

HRSG-1A Chemical dosing pumps discharge lines dummies removing work.

HRSG-1A HP start up pump coupling guard fixing work.

HRSG#1A filling

HP BFP-1A1 & 1A2 pumps and motors coupling work. HP BFP-1A1 Pump suction

strainer fixing work.

HRSG-1A HP/IP/LP start up pumps and CPH RCP Pumps trial

HRSG-1A HP/IP/LP BFPs trial

HRSG-1A Furnace Bottom dummy fixing work.

HP BFP-1B1 & 1B2 pumps and motors coupling work.

1B HP/IP/LP/CPH/Deaerator circuit N2 venting and normalisation

HRSG-1B Flue gas path silica gel removing,Guillotine Damper, Weather damper

HRSG-1B Diverter damper & Guillotine dampers man ways closing work.

HRSG-1B Chemical dosing pumps discharge lines dummies removing work.

HRSG-1B Weather damper area putty removing and cleaning work.

HRSG-1B Control valves stroke checks

HRSG-1B Deaerator top side vent lines NRV gates fixing work.

HRSG-1B All MOVs Open/Close test

HRSG-1B HP start up pump coupling guard fixing work.

HRSG#1B filling

HRSG-1B HP/IP/LP start up pumps and CPH RCP Pumps trial

HRSG-1B HP/IP/LP BFPs trial

HRSG-1B Furnace Bottom dummy fixing work.

ELECTRICAL SYSTEM

GT#1A stator water circuit normalisation

GTG#1A H2 filling

GTG#1B stator water circuit normalisation

GTG#1B H2 filling

STG stator water circuit normalisation

STG H2 filling

All SWITCHGEARS & MCCs inspection

Cylinders requirement H2 CO2

GT#1A 100 20

GT#1B 100 20

STG 100 20

Total 260 60

OPS

MMD

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

SR NO MATERIAL DESCRIPTION INDENT DETAILS

1 Raw water Feed pump-A spare parts MECH/300/2011,Dt 2-1-2011

2 ACW Pump-B spare parts MECH/16/2012,Dt 2-5-2012

3 STG Lube oil Servo Prime 32 MECH/86/2011,Dt 8-8-2011

4 ServoPrime 46 (GT Lube oil) Indent to be raised for 2100Ltr

5 GTs Coalescer pads MECH/128/2012,Dt 27-11-2012

6 CT Fan-16 Gear box spares MECH/23/2012,Dt 19-5-2012

7 SWAS Chiller unit compressor-1 to be procured. MECH/15/2012,Dt 2-5-2012

8 Hyspin AWS 32SC lube oil for HP BFPs MECH/20/2012,Dt 18-5-2012

9 Air compressor-B spare parts MECH/130/2012,Dt 30-11-2012

10 GT-1B Turbine blades as per the indent. MECH/149/2011,Dt 8-12-2011

11 HRSG HP MSSV Spares

MECH/167A,168 & 169/,Dt 22-4-

2010

12

Fabric Expansion bellow of size

6100X6100X525mm, For HRSG-1A FG inlet duct MECH/9/2012,Dt 16-4-2012

Fabric Expansion bellow of size

6100X6100X525mm, For HRSG-1B DD bypass

stack duct. MECH/8/2012,Dt 16-4-2012

13 STG Vaccum pump spares MECH/37/2012,Dt 4-6-2012

14 NON Sparking tools as per the indent

MECH/83A,83B/2012,Dt 16-8-

2012 & 14-8-2012

15 GT Prefilters MECH/148/2013,Dt 7-1-2013

16 Gaskets for GT Prefilters MECH/145/2013,Dt 7-1-2013

17 GT Fine(F9) & Pre(F7) Filters MECH/30/2012,Dt 29-5-2012

SR No Worker Designation Existing Manpower

TECHNICIANS REQUIRED FOR PLANT MAINTENANCE ACTIVITIES

CRITICAL INDENTS DETAILS FOR SPARES PROCUREMENT

1 Millwright Fitter 1

2 Fitter Nil

3 Asst Fitter 2

4 welder 2

5 Gas Cutter Nil

6 Rigger 1

7 Crane Operator 1

8 Scaffolder Nil

9 HVAC Technician Nil

7 TOTAL MEMBERS

REMARKS CRITICALITY

Required for Plant start-up

Required for Plant start-up

Out of 20 barrels,only 15 nos were

received. Required for Plant start-up

Required for Plant start-up

Not Required for Plant start-

up,during plant running must

be made available

Required for Plant start-up

Indent was earlier kept on hold by

Komaraiah sir. Required for Plant start-up

Out of 6 barrels,only 2 nos were

received. Required for Plant start-up

Required for Plant start-up

Required for Plant start-up

These spares are pending since too

long.

Not Required for Plant start-

up,during plant running must

be made available

It is better to replace this

bellow before plant startup.As

it was earlier replaced partially

and the remaining area has

some minor

damages.Subjected to

material availability,job will be

taken up.

Not Required for Plant start-

up,during plant running must

be made available

Not Required for Plant start-

up,during plant running must

be made available

Required for Plant start-up

F9- 785 nos(2sets),F7- 1570

nos(4sets)

Required Manpower

TECHNICIANS REQUIRED FOR PLANT MAINTENANCE ACTIVITIES

CRITICAL INDENTS DETAILS FOR SPARES PROCUREMENT

2

3

4

1

1

1

Nil

1

1

14

INDENT NO.

INDENT

DATE

DESCRIPTION

QUANTIT

Y

ORDERE

D

Mech-205/11-12 19.03.12 SERVO GEM EPO Grease 20 Kgs.

M12 Gr.8.8 Nuts 300 Nos.

M12 8.8 Gr.washers 800 Nos.

M12X65mm long 8.8 Gr.Bolts 200 Nos.

Mech-201/11-12 12.03.12

Split AC Compressor, Model No. AW 1500F F15 Z0 4H

3237 R-22, 230Volts, 50 Hz - RLA - 7.8, LRA-51

(TECHUMSEH)

1 No.

Mech-195/11-12 28.02.12

CEP Expansion Bellow both ends fixed Flanges, Size:

DN450, Type: 1101 Installation (shipping length: 300mm)

2 Nos.

Mech-190/11-12 15.02.12

STG Vacuum Pumps Plate Heat Exchanger spares.

Plates and Gaskets (Make: FUNKE), Type: FP-14-31-1-N,

S.No.504383

1 No.

Filter Element 2.5 microns (HC 8300 fkz 16z) 2 Nos.

Filter Element 5 microns (HC 8300 fkz 16z) 2 Nos.

Mech-188/11-12 13.02.12 GT Diffusion Burner Ignition Gas Line Connector 8 Nos.

Mech-184/11-12 10.02.12

Gate Valves, 4", 600 / 300 Class, 30bar pr., Buttweld,

ON/OFF MOV Operated Valve

1 No.

Mech-177/11-12 17.01.12

CW Side Stream Filter Strainers (Model No. VAG 39),

Flow Rate: 124 M

3

/ Hr., Design Temp: 50 Deg.C

300 Nos.

Synthetic Oilimpregnated Coalescer Pad, Size: 1720mm

X 3200 x 25mm thk

36 Nos.

Synthetic Oilimpregnated Coalescer Pad, Size: 24000mm

X 3200 x 25mm thk

12 Nos.

Mech-172/11-12 06.01.12

Auxiliary Systems Re-assembly Mandatory material for

Major Overhaul (List attached)

As per list

Mech-171/11-12 06.01.12

Auxiliary Systems spare parts for Minior Inspection & day

to day (List attached)

As per list

Mech-170/11-12 06.01.12

Auxiliary Systems Potential replacement material for Major

Overhaul (List attached)

As per list

Mech-168/11-12 29.12.11 GT Potential Replacement Material (List attached) As per list

Mech-166/11-12 28.12.11 Pre Filters Holding Latch (Spring type) 500 Nos.

Mech-163/11-12 27.12.11 Combustion Chamber Cone 1 No.

Mech-157/11-12 15.12.11

GT Re-assembly mandatory material Major overhaul (list

attached)

As per List

Insert / Comp 8 Nos.

GTG Secondry Air Damper Blind Plate Seal Ring 2 No.

Mech-155/11-12 15.12.11 GT Re-assembly material Major overhaul (list attached) As per List

Spacer Sleeve (Inlet) 1 No.

Spacer Sleeve (Outlet) 1 No.

Spacer Sleeve 1 No.

Spacer Sleeve 1 No.

Spacer Bush 1 No.

Adaptor Sleeve 1 No.

Lubrication Ring 2 Nos.

Bearing Nut 1 No.

Shaft 1 No.

Impeller 5 Nos.

MECHANICAL INDENTS FOR THE YEAR 2011-12

Mech-202/11-12 12.03.12

Mech-189/11-12 15.02.12

Mech-173/11-12 09.01.12

Mech-156/11-12 15.12.11

MECH-151B / 11-

12

10.12.11

MECH-151A / 11-

12

10.12.11

Flat Gasket 4 Nos.

Flat Gasket 1 No.

O Ring 1 No.

O Ring 2 Nos.

O Ring 2 Nos.

O Ring 4 Nos.

O Ring 2 Nos.

Wearing Ring 10 Nos.

Splash Ring 2 Nos.

Oil Thrower 1 No.

Stage Sleeve 4 Nos.

Shaft Protection Sleeve (Inlet) 1 No.

Shaft Protection Sleeve (Outlet) 1 No.

Mech-146/11-12 05.12.11

Port Glass, Type: SGC-3008 (Containing Cushion Gasket,

Gauge Glass, packing strip, Mica Gasket, Protect Gasket,

Sealing Gasket)

12 Nos.

Mech-144/11-12 12.12.11

Pilot Valve recommended Spare Parts, Make: ARGUS,

Type: FKK-79, Material: SS / SS-SS-TFE, Pressure: 36

bar at 26

0

C, Size: PN-40, DN-40, S.No.791225, Fabr.No.:

116942003

2 Sets

Mech-142/11-12 02.12.11

Skid Mounted Motorized Hydro Test Pump, Max.Pressure:

300 to 350 Kg./CM2, Capacity: 110 LPH, Complete with

presure relief and setting valve, Pressure Gaauge, NRV,

Needle Valve along with accessories like Hydraulic Hose

etc.

1 Unit

Mech-133/11-12 10.11.11

1" Flanged Safety Relief Valve, Flange PCD: 85mm,

No.Holes: 4 Nos., Size: 14mm, Set Pressure: 10 Kg/cm

2

Medium Compressed Air, Make: Fluid Tech Valves

1 No.

M15B CH Plate Gasket NBRP CO, A-Type 45 Nos.

M15B CH Plate Gasket NBRP CO, BA-Type 45 Nos.

M15B2 EP 1 316/0.6/HT/NBRP CO RI 1 No.

M15B2 EP 2 316/0.6/HT/NBRP CO RI 1 No.

M15B2 CH PL 2 316/0.6/HT/NBRP CO RI 4 Nos.

M15B2 CH PL 2 316/0.6/HT/NBRP CO RI 6 Nos.

Line Shaft 1 No.

Shaft Coupling 2 Nos.

HX.HD.Bolt with Nut 8 Nos.

Gasket 1 No.

Disch Case Bearing 1 No.

HX.HD.Bolt with Nut 4 Nos.

Inter Bowl 7 Nos.

Bowl Bush 7 Nos.

Impeller Lock Collet 7 Nos.

Impeller 7 Nos.

HX.HD.Cap Screw 21 Nos.

Brg.Inter Bowl 7 Nos.

Pump Shaft 1 No.

Sand Cap 1 No.

Allen Set Screw 2 Nos.

Brg.Suction 1 No.

HX.HD.Cap Screw 3 Nos.

MECH-151A / 11-

12

10.12.11

Mech-129/11-12 29.10.11

MECH-123-C / 11-

12

31.10.11

Pipe Plug 1 No.

Adjusting Nut 1 No.

Allen Set Screw 1 No.

Water Slinger 1 No.

Packing Gland 1 No.

Packing Box 1 No.

Stud Bolt with Nut 6 Nos.

Gasket 1 No.

Packing Box Bush 1 No.

Top Shaft Sleeve 1 No.

HX.HD.Cap Screw 12 Nos.

HX.HD.Bolt with Nut 8 Nos.

Bearing Spider 1 No.

Line Shaft Brg. 1 No.

Line Shaft Sleeve 1 No.

Gib Key 1 No.

Top Shfat Bus 1 No.

Wearing Ring For Impeller 7 Nos.

Brg. Retainer 1 No.

Gasket 2 Nos.

Spring Loading Grease Cup Assy 1 No.

Water Seal Ring 1 No.

Packing Pieces 8 Nos.

Stud Bolt with Nut 2 Nos.

Top Shaft 1 No.

Line Shaft Sleeve 1 No.

Line Shaft 1 No.

Shaft Coupling 2 Nos.

HX.HD. Bolt with Nut 8 Nos.

Gasket 1 No.

Disch Case Bearing 1 No.

Hx.HD. Bolt with Nut 12 Nos.

Inter Bowl 7 Nos.

Bowl Bush 7 Nos.

Impeller Lock Collet 7 Nos.

Impeller 7 Nos.

HX.HD.Cap Screw 84 Nos.

BRG. Inter Bowl 7 Nos.

Pump Shaft 1 No.

Sand Cap 1 No.

Allen Set Screw 2 Nos.

BRG. Suction 1 No.

HX.HD. Cap Screw 6 Nos.

Pipe Plug 1 No.

Adjusting Nut 1 No.

Allen Set Screw 1 No.

Water Slinger 1 No.

Packing Gland 1 No.

Packing Box 1 No.

Stud Bolt with Nut 8 Nos.

Mech-123-B / 11-

12

31.10.11

MECH-123-A / 11-

12

31.10.11

MECH-123-C / 11-

12

31.10.11

MECH-122C / 11-

12

15.10.11

MECH-122b / 11-

12

15.10.11

Gasket 1 No.

Packing Box Bush 1 No.

Top Shaft Sleeve 1 No.

Stud Bolt with Nut 8 Nos.

HX.HD. Bolt with Screw 12 Nos.

HX.HD. Bolt with Nut 8 Nos.

Bearing Spider 1 No.

Wearing Ring Impeller 7 Nos.

BRG Retainer 1 No.

Gasket 1 No.

Spring Loading Grease Cup Assy 2 Nos.

Watear Seal Ring 1 No.

Packing Pieces 4 Nos.

Stud Bolt with Nut 2 Nos.

HX.HD. Bolt with Nut 8 Nos.

Thrust Stand Assy 1 No.

HX.HD. Bolt with Nut 4 Nos.

Top Shaft 1 No.

Line Shaft Brg. 4 Nos.

Line Shaft Sleeve 4 Nos.

Line Shaft 4 Nos.

Pump Shaft Coupling 1 No.

Gasket 1 No.

HX.HD.Bolt with Nut 8 Nos.

Pump Shaft 1 No.

BRG Inter Bowl 7 Nos.

Impell Lock Collect 7 Nos.

Impeller 7 Nos.

Inter Bowl 7 Nos.

Sand Cap 1 No.

HX.HD.Cap Screw 6 Nos.

Strainer B/T 1 No.

Suction BRG 1 No.

HX.HD. Bolt with Nut 4 Nos.

Stud Bolt with Nut 2 Nos.

Packing Gland 1 No.

Water Seal Ring 1 No.

Packing PCS 4 Nos.

Grease Cut Assy. With NRV 1 No.

Packing Box 1 No.

Packing Box Bush 1 No.

Top Shaft Sleeve 1 No.

Gasket 1 No.

Stud Bot with Nut 4 Nos.

HX.HD.Cap Screw 8 Nos.

Bearing Spider 4 Nos.

Impeller Wearing Ring 7 Nos.

BRG BRG Retainer 4 Nos.

HX.HD Bolt with Nut 32 Nos.

Top Shaft 1 No.

MECH-122b / 11-

12

15.10.11

MECH-121B / 11-

12

15.10.11

MECH-122a / 11-

12

15.10.11

MECH-121A / 11-

12

15.10.11

MECH-121C / 11-

12

15.10.11

Allen Set Screw 2 Nos.

Gasket 2 Nos.

HX.HD Bolt cap Screw 6 Nos.

Water Slinger Assy 1 No.

Thrust Stand Assy. 1 No.

HX.HD.Bot with Nut 4 Nos.

HX.HD Bolt with Nut 4 Nos.

Packing end ring for Pump Model: PN-M16A 8 Nos.

Packing for Pump Model: PN-M16A 8 Sets

Ball for Pump Model: PN-M16A 4 Nos.

Ball Guide for pump Model: PN-M16A 4 Nos.

Plunger for Pump Model: PN-M16A 2 Nos.

Packing end ring for Pump Model: PN-K16A 8 Nos.

Packing for Pump Model: PN-K16A 8 Sets

Ball for Pump Model: PN-k16A 4 Nos.

Ball Guide for pump Model: PN-K16A 4 Nos.

Plunger for Pump Model: PN-K16A 2 Nos.

Mech-108/11-12 18.10.11 HYSPIN AWS 32 SC Lube Oil 1200 Ltrs.

PALL Filter Element - RO50480 YL60 8 Nos.

pall Coreless Filter Element B>= 1000 12 8 Nos.

Mech-86/11-12 08.08.11 Servo Prime-32 Lube Oil 20 Barrels

Mech-85/11-12 08.08.11 Reo Lube (OMTI-46) Control Oil 5 Barreks

Seat Ring for 300 Class Cast Steel Gate Valve of Size:

250mm

1 No.

Disc for 300 Class Cast Steel Gate Valve of Size: 250mm 1 No.

Stem for 300 Class Cast Steel Gate Valve of Size: 250mm 1 No.

Bonnet Gasket for 300 Class Cast Steel Valve of Size:

250mm

1 No.

1 1/2" schedule 80 CPVC Pipe 100 Mtrs.

2" CPVC Socket Tee Schedule 80 4 Nos.

1 1/2 x 2" Socket Reducer Sch 80 4 Nos.

1 1/2" 90 Deg Socket Elbow sch 80 10 Nos.

1 1/2" straight couplings Sch.80 20 Nos.

1 1/2" CPVC Pipe Flange Sch.80 10 Nos.

2" Schedule 80 CPVC Pipe 50 Mtrs.

3" CPVC Socket Tee Schedule-80 4 Nos.

1 1/2" CPVC Socket Tee Schedule-80 4 Nos.

2x3" Socket Reducer Sch.80 4 Nos.

2" 90Deg. Socket Elbow Sch.80 10 Nos.

2" Strainght Coupling Sch.80 20 Nos.

2" CPVC Pipe Flange Sch.80 20 Nos.

3" Sch.80 CPVC Pipe 50 Mtrs.

3" 90 Deg. Socket Elbow Sch.80 20 Nos.

3" straight Coupling Sch.80 30 Nos.

3" CPVC Pipe Flange Sch.80 20 Nos.

CPVC Solvent Cement - 500 Ml. 2 Nos.

Gasket Set according DGSLV-560398 suitable for Valve

with Order No.760499

2 Nos.

MECH-121A / 11-

12

15.10.11

Mech-96/11-12 24.08.11

Mech-118/11-12 02.06.11

Mech-117/11-12 13.10.11

Mech-75/11-12 27.07.11

Mech-76/11-12 29.07.11

Mech-72/11-12 26.07.11

Valve Ball suitable for Valve with Order No. 760499 2 Nos.

Mech-58/11-12 04.07.11

Bellow Sealved Valve DN-15 both side external threaded

with 1/4 inch hole and 8mm outer pipe PA type fitting,

Union thread is 36x2mm pitch

6 Nos.

Mech-51/11-12 15.06.11 HP BFP Balance Disc Seat (Counter Balancing Disc) 3 Nos.

Inproseal (Item No. IS1), Material: EN1982 : CuSn12 1 No.

Inproseal (Item No. IS2), Material: EN1982 : CuSn12 1 No.

Mech-43/11-12 06.06.11

42X6.6M Wire Rope Sling. Both side soft eye. Eye length

is 650mm, capapcity: 175000 Kgs.

2 Nos.

Servo 320 Gear Oil 220 Ltrs.

GR-140 Gear Oil 100 Ltrs.

General Oil GR-90 100 Ltrs.

General Grease 50 Kgs.

Servo Grease MP 50 Kgs.

Servo Coat 120 Grease 100 Kgs.

Servomesh SP 320 Gear Grease 50 Kgs.

Mech-36/11-12 31.05.11 Servo Friz - 68 Oil 50 Ltrs.

O-Ring for sleeve in Viton, Part No.7 2 Nos.

O-Ring for Seal face in Viton, Part No. 1.2 2 Nos.

O-Ring for Seat in Viton, Part No.3 2 Nos.

O-Ring for Gland Plate in Viton, Part No.5 2 Nos.

Set of Screws, {Part No. 1.6 (1 Set = 2 Nos.), Part No. 12a

(1 Set = 2 Nos., Part No. 12b (1 Set = 4 Nos.)}

2 Sets

Set of Spring Sleeve in 1.4401 (1 Set = 8 Nos.), Part No.-

1.7

2 Sets

Set of Springs in 1.4401 (1 Set = 8 Nos.), Part No.1,5 2 Sets

Seal Face in Buko 03+1.4162, Part No.1 2 Nos.

Seat in Buka 22, Part No.2 2 Nos.

Shaft (Part No. 210.01) 2 Nos.

Impeller (Part No. 230.01) 2 Nos.

Bearing NU 308 (Part No. 320.01) 2 Nos.

Bearing 7308 BECBP (Part No. 320.02) 2 Nos.

Gasket (Part No. 400.02) 2 Nos.

Gasket (Part No. 400.03) 2 Nos.

O-Ring (Part No. 412.01) 2 Nos.

O-Ring (Part No. 412.02) 2 Nos.

Throat Bush (Part No. 456.01) 2 Nos.

Wear Ring Stationary (Part No. 502.01) 2 Nos.

Impeller Wear Ring (Part No. 502.01) 2 Nos.

Constant Level Oiler (Part No. 638.01) 2 Nos.

Gasket (Part No. 400.10) 2 Nos.

Gasket (Part No. 400.05) 4 Nos.

Circlip (Part No.932.01) 2 Nos.

Gasket-Gland in PTFE, P.No.5 1 Nos.

Set of Set Screws in 1.4401 (1 Set = 6 Nos.), P.No. 1.6,

12b & 14

1 Set

Set of O-Rings in EPDM (1 Set=3 Nos.). P.Nos.7, 3, & 12 2 Sets

Sleeve in SS316, P.No.6 1 No.

Set in Buka22, P.No.2 1 No.

Mech-47/11-12 07.06.11

Mech-72/11-12 26.07.11

Mech-24/11-12 10.05.11

Mech-41/11-12 03.06.11

Mech-14/11 14.04.11

Mech-20/11-12 10.05.11

Rotory Head Assembly in Buko 03 + 1.4462 includes

P.Nos.1.1 to 1.7

1 No.

Gasket-Gland in PTFE, P.No.5 2 Nos.

Set of Set Screws in 1.4401 (1 Set = 6 Nos.), P.No. 1.6,

12b & 14

2 Sets

Set of O-Rings in EPDM (1 Set=3 Nos.). P.Nos.7, 3, & 12 4 Sets

Pumping Ring in 1.4401, P.No.13 2 Nos.

Sleeve in SS361, P.No.6 2 Nos.

Set in Buka 22, P.No.2 4 Nos.

Rotory Head Assembly in Buko 03 + 1.4462 includes

P.Nos.1.1 to 1.7

4 Nos.

Gasket-Gland in PTFE, P.No.5 1 Nos.

Set of Set Screws in 1.4401 (1 Set = 6 Nos.), P.No. 1.6,

12b & 14

1 Set

Set of O-Rings in EPDM (1 Set=3 Nos.). P.Nos.7, 3, & 12 2 Sets

Sleeve in SS316, P.No.6 1 No.

Seat in Buka22, P.No.2 1 No.

Rotory Head Assembly in Buko 03 + 1.4462 includes

P.Nos.1.1 to 1.7

1 No.

Mech-06/11 07.04.11 CW Pump Spares, Make: Kirloskar 1 Set

Assembly body Seals 2 Sets

Assmbly Inner Set 1 set

Assembly Seals Inner Seat 2 Sets

Assembly Stuffing Box packing 1 set

Metall bellow 1 set

Assembly body Seals 2 Sets

Assmbly Inner Set 1 set

Assembly Seals Inner Seat 2 Sets

Assembly Stuffing Box packing 1 set

Metall bellow 1 set

INDENT NO.

INDENT

DATE

DESCRIPTION

QUANTIT

Y

ORDERE

D

Mech-168/12-13 11.02.13 20 NB CS Pipe SCH-40 30 Mtrs.

Multi-layer Expansion Bellow Fabric to withstand operating

temp 750 Deg, Make: Hi-Tech

12 Mtrs.

Aluminized Fiber Glass Tape, 4" X 1mm X 30 Mtrs, Item

Code: HT-ALGL, Make: Hi-Tech

1 No.

Silicon Glue Tube 3 Nos.

Mech-166/12-13 11.02.13

8 Mtrs. Long Gas Cooled Tig Torch, Model: GC-20, Make:

SAP

1 No.

1" GI Pipe SCH 40 both side threaded 100 Mtrs.

1" Female Threded Brass NRV #800 1 No.

1" GI Threded Union 1 No.

80 NB CS Gate Valve #150 Flange type, Make: AUDCO /

VALTECH

2 Nos.

Mech-14/11 14.04.11

Mech-12/11 14.04.11

Mech-13/11 14.04.11

Mech-001/11 05.04.11

Mech-002/11 05.04.11

Mech-164/12-13 09.02.13

MECHANICAL INDENTS FOR THE YEAR 2012-13

Mech-167/12-13 30.03.13

Mech-158/12-13 06.02.13

100 NB CS Gate Valve #150, Flange type, Make: AUDCO

/ VALTECH

2 Nos.

150NB CS Gate Valve #150, Flange type, Make: AUDCO

/ VALTECH

2 Nos.

Filter Element UE 219 AP08H (MAH 580), F 137155,

Make: PALL

2 Nos.

Filter Element (040417), Make: BOLL & KRICH, Length of

the Filter Element: 510mm, Material of Construction: Wire

Mesh Steel (SS), Micron Rating of Filter: 12 Microns

4 Nos.

Mech-150/12-13 21.01.13

Oil Mist Separator Filter Tubes (Filter type: FF2-

166.30012)

46 Nos.

Mech-148/12-13 07.01.13

Pre Filters type CAM-FLOW X MGT-7 (CFSS-F7-592 /

592 / 640-10-25)

60 Nos.

Mech-145/12-13 07.01.12 Gaskets for Pre-Filters 500 Nos.

Mech-134/12-13 08.12.12 EP-2 Grease, Make: Castrol 60 Kgs.

HP Piston Rings - 2480035851 4 Nos.

HP Endless Guide Rings - 2480038750 4 Nos.

Filter Element - 910071250 3 Nos.

HP Cusion Plates - 2460065450 30 Nos.

LP Cusion Plates - 2460060450 36 Nos.

Oil Wiper Rings - 2480031350 8 Nos.

Packing Assy.3pcs - 2460102150 6 Nos.

Packing Assy.6pcs - 2460102050 6 Nos.

Packing 1.6th - 2460010750 4 Nos.

Packing 1.6th - 2460010550 4 Nos.

Packing (Cylinder to Valve Assly)-2460011850 24 Nos.

Packing (Cylinder to Valve Assly)-2460021850 16 Nos.

Stud M12x1.75x25L (Cyl to Valve Cover) - 9990364850 30 Nos.

Stud M12x1.5x45L (Cyl to Valve Cover) - 9990363650 30 Nos.

Mech-128/12-13 27.11.12

Glass Fibre pads, Make: CAMFIL, Size: 620 x 620 x

100mm (Coalerser Pads)

780 Nos.

Filler Wire UTP A 6170 Co (Size: 1.6 X 1000mm) 5 Kgs.

Filler Wire Thyssen Thermanit 617 (Size: 2.4 X

1000mm)

5 Kgs.

Filler Wire Bohler DMO-IG (Size: 2.4 X 1000mm) 5 Kgs.

Filler Wire Bohler CN 16/13 (Size: 2.4 X 1000mm ) 5 Kgs.

UTP 6170 Co. (Size: 3.2 X 350) Electrode 2 Packets

Bohler FOX CN 16/13 (Size: 3.2 X 350) Electrode 2 Packets

Bohler DMD kb (Size: 3.25 X 350) Electrode 2 Packets

Stem, MOC: AISI 410 1 No.

Disc, MOC: AISI 410 Stellited 1 No.

Mech-121/12-13 09.11.12 GI Beam 250X125, Web thk: 8mm 18 Mtrs.

Mech-103/12-13 18.09.12 Servo Mesh SP 460 Oil 210 Ltrs.

Mech-89/12-13 22.08.12 Scoop Tube Shaft for Fluid Coupling, Model: MR 600 1 No.

28mm SS 304L Ferrule Fitting Elebow 32 Nos.

28mm 304L 90 Deg. Ferrule Connector 32 Nos.

28mm SS 304L 3000# Socket weld Union 32 Nos.

3/4" NPT male thread X 28mm Ferrule fitting SS 304L

Connector

32 Nos.

Mech-152/12-13 22.01.13

Mech-158/12-13 06.02.13

Mech-130/12-13 30.11.12

Mech-124/12-13 20.11.12

Mech-126/12-13 26.11.12

Mech-88/12-13 16.08.12

3/4" SS 304L, Pipe U-Clamp 80 Nos.

28mm 304L, Pipe OD:28mm, ID: 24mm, thk: 2.015mm 120 Mtrs.

1/2" SS 304L Ferrule 90 Deg. Elbow (One side male NTP

Thread)

16 Nos.

25NB, SW, 3000#, CS Equal Tee with one side BSP

Thread

6 Nos.

Mech-75/12-13 26.07.12 Servo Gem EP0 Grease 20 Kgs.

Lube Oil Filter Element 4 Nos.

Fuel Oil Filter 2 Nos.

Element and Ring 2 Nos.

Coolant Additive 1 No.

O-Ring Set 2 Nos.

Engine Lube Oil Pepremium Blue SAE 15W40 210 Ltrs.

High Focus Torch Lights 1 No.

EP-2 Lubrication Grease 60 Kgs.

Toothed Gear for Flud Coupling, Model: Mr 600 2 Nos.

Gear Rack for Fluid Coupling, Model MR 600 2 Nos.

Spring for Flud Coupling Model: MR 600 2 Nos.

Scoop Tube for Fluid Coupling, Model: MR 600 2 Nos.

Servo System 68 Oil 210 Ltrs.

Castrol 20/40 Oil 50 Ltrs.

Servo Press 68 Oil 210 Ltrs.

Servo System 220 Oil 100 Ltrs.

Shaft - S821145001 1 No.

Impeller & Shaft Shrink fitted 1 No.

Gland Packing - 1551000011 1 Set

Lock Ring - 1440000001 1 No.

Key - 140000004 1 No.

O-Ring - 1960000063 2 Nos.

Distribution Ring - 1922000001 1 No.

Flat Gasket - 1940000130 2 Nos.

Floating DE - 1493000002 2 Nos.

Shaft Seal Ring - 1530000008 2 Nos.

Rolling Contact Bearing SKF 32313 B / Q / U2 / CL7A 1 No.

Rolling Contact Bearing SKF 32312 BJ2 / QCL /7C 1 No.

Rolling Contact Bearing SKF 32024 X D720 1 No.

Rolling Contact Bearing SKF 32224 J2 1 No.

Rolling Contact Bearing SKF 32315/Q 2 Nos.

Bevel Pinion Shaft L ZY 290, 0/3, 22 1 No.

Rolling Contact Bearing 32313 B /Q/U2/CL7A 1 No.

Rolling Contact Bearing 32312 BJ2/1CL7C 1 No.

Rolling Contact bearing 32024 XD720 1 No.

Rolling Contact Bearing 32224 J2 1 No.

Pinion Shaft RP 250, 0/3, 53 1 No.

Bevel Gear R ZY 290, 0/3. 15 1 No.

Rolling Contact Bearing 32315 /Q 2 Nos.

Mech-32/12-13 02.06.12 Frame / Bearing Housing 1 No.

High Efficiency F9 Fine Filters CGT-HF-P-F9-

592x592x292-01

785 Nos.

Mech-63/12-13 04.06.12

Mech-88/12-13 16.08.12

Mech-50/12-13 05.07.12

Mech-52/12-13 07.07.12

Mech-37/12-13 04.06.12

Mech-43/12-13 12.06.12

Mech-36/12-13 02.06.12

Mech-35/12-13 02.06.12

Mech-30/12-13 29.05.12

Pre Filters Type: CAM-Flow XMGT-7 (CFSS-F7-

592X592X640-10-25)

1570 Nos.

Cam Vane 3X5 along with Holding Strips 3 Sets

Cam Vane 3X4 along with Holding Strips 5 Sets

Holding Strips 3X5 and 3X4

Each 10

Sets

Mech-24/12-13 21.05.12

Pressure Sealed Bonnet NRV, Size: 200mm, 1500 Class,

Body Material: ASTM A216 GR WCB, Butt Weld ends,

Sch120, Make: AUDCO

1 No.

Bevel Pinion Shaft L ZY 290, 0/3, 22 2 Nos.

Shaft Seal 065x085x08 CRW1-R 25420 64 Nos.

Rolling Contact Bearing 32313 BD 720 8 Nos.

Rolling Contact Bearing 32312 BD 720 8 Nos.

Shhaft 135X0684 2 Nos.

Gear Wheel LP 250, 0/3, 53 2 Nos.

Shaft Seal 120x150x12, CRW 1-R 47250 32 Nos.

Rolling Contact bearing 32024 XD720 8 Nos.

Rolling Contact Bearing 32224 X 720 8 Nos.

Pinion Shaft RP 250, 0/3, 53 2 Nos.

Bevel Gear R ZY 290, 0/3. 15 3 Nos.

Rolling Contact Bearing 32315 D720 8 Nos.

Impeller Seal Ring (AL.BRONZE AB1) 2 Nos.

Impeller Key (SSA276 TP 410) 1 No.

Pump Shaft (SS A276 TP 410) 1 No.

Pump Line Shaft ( SS A276 TP 410) 2 Nos.

Shaft Sleeve (SS A276 TP 410) 2 Nos.

Head Shaft (SS A276 TP 410) 1 No.

Bush (THORDON)

Each 2

Sets

Cutless Buss (Bronge + NITRLE RUB.)

Each 2

Sets

Gasket Sets

Each 3

Sets

Water Deflector (Neoprene Rubber) 3 Nos.

Mech-15/12-13 02.05.12

Chiller Unit Compressor Unit, Model No.: KCG 554 HAE

D512 SR No: EWK 2836 05F, 400V, 50 Hz, 3P, LRA44-R-

22, Kirloskar Copeland Ltd., Karad, India

1 No.

Fabric Expansion Bellow, Size: 6100X6100X525mm to

withstand for hot flue gas temperature of 850 Deg.C

26 Mtrs

length X 1

No.

M12X65mm, 8.8 Gr Bolts & Nuts with Washer 450 Nos.

Fabric Expansion Bellow, Size: 6100X6100X350mm to

withstand for hot flue gas temperature of 850 Deg.C

26 Mtrs

length X 2

Nos.

M12X65mm, 8.8 Gr Bolts & Nuts with Washer 450 Nos.

Fabric element assly, Material: UFV-100 (as per attached

Drawing)

26 Mtrs

length X

0.350

Mtrs.

Width

Dome seal, Materia: DS-CR (as per attached Drawing)

As per

attached

Drawing

Mech-30/12-13 29.05.12

Mech-29/12-13 29.05.12

Mech-23/12-13 19.05.12

Mech-09/12-13 16.04.12

Mech-16/12-13 12.12.12

Mech-06/12-13 10.04.12

Mech-08/12-13 16.04.12

Fabric element assly, Material: UFV-100 (as per attached

Drawing)

20 Mtrs

length X

0.350

Mtrs.

Width X 2

Dome seal, Materia: DS-CR (as per attached Drawing)

As per

attached

Drawing

INDENT NO.

INDENT

DATE

DESCRIPTION

QUANTIT

Y

ORDERE

D

Manual Steel Strapping Tool, Item Code: HMT-19-32,

Strap Gauge Range (0.023 to 0.031), Strap Width Range:

5/8" to 1

1

/

4

"

1 No.

Steel Strap Roll, Width: 2mm, Thickness: 0.6mm 200 Mtrs.

GI Packing Clips to suit 25mm wide Steel Strap 100 Nos.

Mech-44/13-14 23.09.13

216 Coal Tar Epoxy Coating with its recommended

Thinner, Color: Black

3000 Ltrs.

Enamel Black Paint (Berger) 40 Ltrs.

Thinner 130 Ltrs.

ETCH Primer 40 Ltrs.

Signal Red Paint (Berger) 650 Ltrs.

Impeller, Part No.8 5 Nos.

Impeller Lock Collet, Part No.9 6 Nos.

BRG. Inter Bowl, Part No.10 6 Nos.

Pump Shaft, Part No.11 1 No.

Line Shaft, Part No.16 3 Nos.

Line Shaft Sleeve, Part No.17 4 Nos.

Line Shaft BRG, Part No.18 4 Nos.

Bearing Retainer, Part No.20 4 Nos.

Top Shaft Sleeve, Part No.27 2 Nos.

Top Shaft, Part No.44 1 No.

Line Shaft Coupling, Part No.47 2 Nos.

Impeller Wearing Ring, Part No.50 4 Nos.

Casing Wearing Ring - 51 4 Nos.

Impeller 1 No.

Bearing Sleeve 2 Nos.

Wear Ring - Casing - 001 2 Nos.

Wear Ring - Stuffing Box - 002 2 Nos.

Shaft Sleeve - 021 2 Nos.

Water Seal Cage - 028 1 No.

Shaft - 050 1 No.

Gasket - A01 2 Nos.

Gasket - A02 2 Nos.

Gasket - A03 2 Nos.

Gasket - A09 2 Nos.

Gasket - N/A 2 Nos.

MECHANICAL INDENTS FOR THE YEAR 2013-14

Mech-49/13-14 16.10.13

Mech-01/12-13 02.04.12

Mech-28/13-14 16.07.13

Mech-42/13-14 07.09.13

Mech-18/13-14 03.06.13

Packing - A30 2 Nos.

Gasket - A60 4 Nos.

Gasket - A61 2 Nos.

Oil Seal - PE - A66 2 Nos.

Ball Bearing - A67 2 Nos.

Roller Bearing - A68 2 Nos.

Angular Contact Ball Bearing - A69 2 Nos.

Oil Seal - ME - A70 2 Nos.

Constant Level Oiler - A71 2 Nos.

Lock Washer - A72 2 Nos.

KSB MAKE WK 65/3 PUMP

Casing Wearing Ring - 1502 3 Nos.

Gland - 1452 2 Nos.

Gland Packing Set - 1461 4 Sets

SP Sleeve Suction - 1524 2 Nos.

SP Sleeve Discharge - 1524 2 Nos.

Spacer Sleeve Suction - 1525.01 2 Nos.

Stage Sleeve - 1521 4 Nos.

Splash Ring - 1507 2 Nos.

Oil Seal Set - 1421 6 Sets

Constant Level Oiler - 1638 2 Nos.

Impeller - 1230 3 Nos.

Spacer Sleeve Discharge - 1525.02 2 Nos.

Shaft - 1210 2 Nos.

Set of Gasket & O-Ring - NA 2 Sets

KSB MAKE WK 65/4 PUMP

Casing Wearing Ring - 1502 3 Nos.

Gland - 1452 2 Nos.

Gland Packing Set - 1461 4 Sets

SP Sleeve Suction - 1524 2 Nos.

SP Sleeve Discharge - 1524 2 Nos.

Spacer Sleeve Suction - 1525.01 2 Nos.

Stage Sleeve - 1521 4 Nos.

Splash Ring - 1507 2 Nos.

Oil Seal Set - 1421 6 Sets

Constant Level Oiler - 1638 2 Nos.

Impeller - 1230 3 Nos.

Spacer Sleeve Discharge - 1525.02 2 Nos.

Shaft - 1210 2 Nos.

Set of Gasket & O-Ring - NA 2 Sets

LP Piston, 2480030150 1 No.

LP Piston Rod 2480030250 1 No.

HP Piston Rod 2480035250 1 No.

Crosshead Nut 2460030450 2 Nos.

Piston Washer 2480030550 2 Nos.

Main Bearing Set 2460032250 & 2460032350 3 Sets

Big End Bearing Assy (CR Bearing) 2460032450 2 Sets

Connection Rod Bushings 950030300 2 Sets

Pin 950036600 2 Sets

Oil Seal 2410110550 2 Nos.

Mech-17/13-14 15.05.13

Mech-18/13-14 03.06.13

Mech-14/13-14 07.05.13

Spider 9992701011 2 Nos.

Lift Washer 2460071250 20 Nos.

Circlip 2460061150 10 Nos.

Assly of 3-Piece packing 2480102150 12 Nos.

Assly of 6-Piece packing 2480102050 12 Nos.

5H66 Crank Shaft 1 Assy 1 No.

5H46 Aluminum Piston 6 Nos.

Conn Rod Assy 5H 6 Nos.

Valve Plate 5H 3 Nos.

Main BRG Pump End 5H66 1 No.

Main BRG S.E. for 5H66 1 No.

Pair of Con Rod BRG for 5H 6 Nos.

5H CYL Sleeve 6 Nos.

Piston Pin 1" 6 Nos.

Comp Ring 5H46/66 12 Nos.

Oil Ring 5H 6 Nos.

Dis Valv Guid Assy 6 Nos.

SV Disc 5H 6 Nos.

Gasket Set 5H60/66 1 No.

Oil Relif Valve Asy 5H 1 No.

SV Spring 5H 36 Nos.

Pin Valve Lifter 5H 24 Nos.

Valve Lifter Pin Spring 24 Nos.

DV Seal Lock Washer 18 Nos.

Oil Pump Bush M/C 5h/5F 1 No.

Oil Pump Package 1 5H40/46/66/86 1 No.

SE BRG Washer 5H 1 No.

Thrust Washer 5H 1 No.

PE BRG Washer 5H 1 No.

Oil Filter Screen 5H 1 No.

Nylock Nuts 8 Nos.

Lock Ring 5H Piston Pin 12 Nos.

Suction Strainer Assy. 1 No.

Cranckcase Heater 6" 1 No.

Bush Con Rod 5H 6 Nos.

Carboline Multibond 2000 Primer Chlorinated Rubber

Paint (Dark Grey Color)

40 Ltrs.

Carboline Multibond 2001 MID Chlorinated Rubber Paint

(Dark Grey Color)

40 Ltrs.

Carboline Multibond 3000 Finish Chlorinated Rubber Paint

(Dark Violet Color)

40 Ltrs.

Thiiner #25 20 Ltrs.

Island Green Epoxy Paint (Code No.207) 160 Ltrs.

Epoxy Paint Thinner 25 Ltrs.

Island Green Epoxy Paint (Code No.207) 45 Ltrs.

Paint Brushes - 3" 10 Nos.

Red Oxide Paint 150 Ltrs.

Enamel Black Paint - 800 150 Ltrs.

Thinner 40 Ltrs.

Wire Brushes 20 Nos.

Rough Emery Papers 20 Nos.

Mech-13/13-14 07.05.13

Mech-14/13-14 07.05.13

Mech-12/13-14 06.05.13

Mech-11/13-14 06.05.13

Mech-09/13-14 07.05.13

Mech-10/13-14 06.05.13

INDENT

FOR

SYSTEM

NATURE

OF

INDENT

PRIORITY

HRSG Gen 7 Days

General

STG Gen 4 Days

STG Prop 15 Days

STG Prop 15 Days

GTG Prop 1 Week

STG General 7 Days

BOP Prop 7 Days

GTG Prop. ASAP

GTG Prop. ASAP

GTG Prop. ASAP

GTG Prop. 2 Months

GTG Prop. 1 Week

GTG Prop 1 Month

GTG Prop ASAP

GTG Prop. ASAP

MECHANICAL INDENTS FOR THE YEAR 2011-12

REMARKS

BOP

Prop.

Immediate

requireme

nt

As instructed by the GM (O&M) sent to HO

on 14.03.12

HOLD by CGM

Sent to HO on 14.03.12

Sent to HO on 27.02.12

GT / STG

/ BOP

Prop 15 Days Sent to HO on 07.03.12

Sent to HO by CGM on 15.02.2012

Sent to HO on by 06.03.12

Sent to HO on 27.03.2012

GT General ASAP Sent to HO on 10.01.2012

Sent to HO on 31.12.11

GTG Prop ASAP Sent to HO on 16.12.11

Sent to HO on 25.01.12

Sent to HO on 25.01.12

Sent to HO on 25.01.12

Sent to HO on 05.01.2012

Sent to HO on 31.12.11

Sent to HO on 25.01.12

Prop 1 Month

Sent to HO on 31.12.11

BOP Prop 1 Month

Sent to HO on 07.06.12

BOP

BOP Prop 25 Days

GTG Prop 15 Days

BOP General 30 Days

BOP General Urgent

Prop 1 Month

Sent to HO on 01.08.12

Sent to HO on10.02.12

Sent to HO on 03.02.12

KGPL / Doc-257 (11-12) / Mech-133 (11-12) /

211, dt.26.11.11 cancelled and Docket sent

to HO on 06.03.2012

Sent to HO on 07.06.12

BOP

Sent to HO on 28.12.11

BOP Prop 30 Days Sent to HO on 07.11.11

BOP Prop 30 Days

Sent to HO on 28.12.11

BOP Prop 30 Days

BOP Prop 30 Days

BOP Prop 30 Days

BOP Prop 30 Days

Sent to HO on 28.12.11

BOP Prop 30 Days

Sent to HO on 28.12.11

BOP Prop

Sent to HO on 28.12.11

BOP Prop

30 Days

BOP Prop 30 Days

30 Days

BOP Prop 30 Days

BOP Prop 30 Days

BOP Prop 15 Days

STG Proprietory 7 Days

STG Proprietory 7 Days

Sent to HO on 28.12.11

BOP Prop 30 Days

25 Days

Sent to HO on 25.11.11

STG Prop 15 Days Sent to HO on 01.12.11

BOP Prop 25 Days

Sent to HO on 29.10.11

BOP Prop

BOP General 1 Month Sent to HO on 22.08.11

Sent to HO on 16.08.11

HRSG-1A

Proprietor

y

15 Days Sent to HO on 12.09.11

GTG Prop 15 Days Sent to HO on 27.07.2011

GTG General 10 Days

BOP Prop 15 Days

BOP General 10 Days

BOP General 1 Week

Sent to HO on 12.09.11

Sent to HO on 12.09.11

HRSGs Prop 25 Days Sent to HO on 27.08.11

GTG Prop 15 Days Sent to HO on 27.07.2011

Sent to HO on 22.06.11

HRSGs Prop 25 Days Sent to HO 18.05.11

Sent to HO on 12.09.11

BOP / GT

/ ST

General 1 Week Sent to HO on 22.06.11

HRSG Prop 25 Days Sent to HO

HRSG- 1A

& 1B

Prop 25 Days Sent to HO on 23.07.11

BOP Prop 1 Month

INDENT

FOR

SYSTEM

NATURE

OF

INDENT

PRIORITY

BOP General 15 Days

BOP Prop 15 Days

STG /

BOP

HRSG Prop 25 Days Sent to HO

HRSG Prop 25 Days Sent to HO

HRSG Prop 25 Days Sent to HO

GTG PROP 1 Month Sent to HO on 16.04.2011

Sent to HO on 25.06.11

GTG PROP 1 Month Sent to HO on 16.04.2011

Hold by GM

BOP General 5 Days Hold by GM

MECHANICAL INDENTS FOR THE YEAR 2012-13

REMARKS

Hold by GM

HRSG /

GTs

Prop 15 Days Hold by GM

General 15 Days Sent to HO on 08.03.2013

GT Prop At earliest

GTG Prop 1 Month

GT's Prop At earliest

BOP Prop 2 Days

GT Prop 15 Days

BOP General 15 Days

BOP General 1 Week

HPBFPs Prop 30 Days

Sent to HO on 06.02.2013

Sent to HO on 06.02.2013

General 15 Days Sent to HO on 08.03.2013

GT / STG

/ BOP

Sent to HO on 24.01.2013

Sent to HO on 08.04.2013

Sent to HO on 08.01.2013

Sent to H.O. on 24.12.2012

BOP Prop 15 Days Docket sent to 03.01.2013

BOP Prop 15 Days

Sent to HO on 08.12.2012

GT Prop 7 Days Sent to HO on 08.12.12

Sent to HO on 21.09.12

Sent to HO on 11.10.12

BOP General 15 Days Sent to HO on 22.10.12

BOP General 7 Days

BOP Prop 10 Days

Sent to H.O. on 24.12.2012

EDG Prop 1 Week Sent to HO on 16.08.2012

BOP General 15 Days Sent to HO on 22.10.12

HRSG

BOP

Prop 25 Days Sent to HO on 11.10.12

GT / ST /

STG /

BOP

General 1 Day

Local cash purchased on 07.07.12

Sent to H.O. on 09.07.2012 & 24.12.12

STG Prop 30 Days Sent to HO on 11.06.2012

BOP General 10 Days Sent to HO on 16.06.2012

BOP General 5 Days

Sent to HO on 07.06.12

BOP Prop At earliest

Sent to HO on 11.06.2012

GTG Prop 2 Month

Sen to HO on 31.05.12

BOP Prop 30 Days

BOP General 14 Days

GTG Prop 2 Month

Sen to HO on 31.05.12

GTG Prop ASAP

Spare Gaskets were arranged for NRV. No

need to procure entire NRV by AGM (O&M)

on 26.11.12.

BOP Prop

Immediatel

y

Sent to HO on 01.08.2012

KGPL / Doc-346 (12-13) / Mech-28 (12-13) /

263, dt.22.01.13

HOLD by CGM

BOP General

Immediate

requireme

nt

Sen to HO on 20.04.12

BOP Prop 1 Month Sent to HO on 14.12.2012

BOP General 10 Days Sent to HO on16.05.2012

BOP General

Immediate

requireme

nt

Sen to HO on 20.04.12

INDENT

FOR

SYSTEM

NATURE

OF

INDENT

PRIORITY

BOP General 15 Days

BOP

General

BOP

BOP

MECHANICAL INDENTS FOR THE YEAR 2013-14

REMARKS

BOP Prop. 5 Days

BOP General 10 Days Sent to HO on16.05.2012

BOP

(Service

Water

Pump)

Prop. Sent to HO 23.08.2013

Sent to HO on 26.09.2013

BOP ASAP Sent to HO on 26.09.2013

BOP /

CCR

HVAC

System

Prop. 1 Month Sent to HO on 27.06.2013

GT-1A .

GT-1B /

STG Seal

Oil Pumps

Prop. 1 Month Sent to HO on 31.05.2013

BOP /

CCR

HVAC

System

Prop. 1 Month Sent to HO on 27.06.2013

BOP / Air

Compress

or Spares

Prop. 1 Month Sent to HO on 27.06.2013

BOP /

CCR

HVAC

Prop. 30 Days Sent to HO on 16.05.2013

BOP / Air

Compress

or Spares

Prop. 1 Month Sent to HO on 27.06.2013

BOP Prop. 15 Days

Sent to HO on 31.08.2013

BOP Prop.

BOP General 10 Days

15 Days

BOP Prop. 15 Days

Anda mungkin juga menyukai

- Shuaiba North HRSG ManualDokumen91 halamanShuaiba North HRSG Manualmartinp17171100% (7)

- Dehydration and Combined Cycle Power Plant of 50 MMSCFD Low BTU Natural GasDokumen42 halamanDehydration and Combined Cycle Power Plant of 50 MMSCFD Low BTU Natural GasShaikh BilalBelum ada peringkat

- P G E C Technical Specifications: Appendix N2 P A Combined CycleDokumen212 halamanP G E C Technical Specifications: Appendix N2 P A Combined Cyclepavan100% (2)

- Thermax HRSGDokumen12 halamanThermax HRSGrevenk100% (1)

- C1 CCPPDokumen109 halamanC1 CCPPSubrahmanyan Edamana100% (1)

- 15 Combined Cycle Power Plant OperationDokumen21 halaman15 Combined Cycle Power Plant OperationParmeshwar Nath Tripathi100% (3)

- 220021enc Combined Cycle Power Plant OverviewDokumen27 halaman220021enc Combined Cycle Power Plant OverviewBalajirao Samatham100% (4)

- HRSG StartupDokumen19 halamanHRSG Startuptpplant100% (1)

- 00 Ta - S 41 002 001Dokumen136 halaman00 Ta - S 41 002 001BALACHITRA100% (1)

- MAA Refinery - Daelim - Training - I&CDokumen106 halamanMAA Refinery - Daelim - Training - I&Cbezzel100% (1)

- Combine Cycle Power Plant Design InformationDokumen47 halamanCombine Cycle Power Plant Design Informationkalasivan0% (1)

- Reliability Test For The CCPPDokumen3 halamanReliability Test For The CCPPRakesh MishraBelum ada peringkat

- HRSG 2011 BrochureDokumen12 halamanHRSG 2011 BrochureAndry SetiawanBelum ada peringkat

- CCPP Plant Operating Procedures PDFDokumen123 halamanCCPP Plant Operating Procedures PDFReda Nari100% (1)

- At "CCPP Training Services" Bahria Town, LahoreDokumen2 halamanAt "CCPP Training Services" Bahria Town, LahoreFazalur Rehman Babar0% (1)

- CC Power PlantsDokumen48 halamanCC Power PlantsSamBelum ada peringkat

- SEC A Bekasi Design SpecDokumen20 halamanSEC A Bekasi Design Speccharleselitb92Belum ada peringkat

- Combined Cycle Power Plant OperationDokumen21 halamanCombined Cycle Power Plant OperationEgit Bobyarta100% (5)

- Turbine University: GE Power SystemsDokumen34 halamanTurbine University: GE Power SystemsĐặng Trung AnhBelum ada peringkat

- HRSG StartupDokumen20 halamanHRSG StartupKvvPrasad100% (1)

- T07073-LBH-SY-M001 Rev.A PDFDokumen43 halamanT07073-LBH-SY-M001 Rev.A PDFRanjanaWajeBelum ada peringkat

- Ge F-Class Gek111895Dokumen2 halamanGe F-Class Gek111895gopinathsampath0% (2)

- 1 汽机运维规程 Steam Turbine Operation and Maintenance ManualDokumen212 halaman1 汽机运维规程 Steam Turbine Operation and Maintenance ManualMd Suzon MahmudBelum ada peringkat

- Evaluation of Gas Turbine Performance Alternatives For Indonesia PowerDokumen33 halamanEvaluation of Gas Turbine Performance Alternatives For Indonesia PowerMORSHED100% (1)

- Power Systems For The 21st Century - H Gas Turbine Combined Cycles GER3935bDokumen22 halamanPower Systems For The 21st Century - H Gas Turbine Combined Cycles GER3935bLTE002Belum ada peringkat

- BR GT GasturbineDokumen9 halamanBR GT GasturbineVioleta Patriche100% (1)

- performance test procedure 最终提交业主版 - 都利项目性能试验大纲(英文)2014-9-30 PDFDokumen36 halamanperformance test procedure 最终提交业主版 - 都利项目性能试验大纲(英文)2014-9-30 PDFarunrajmech09100% (1)

- SATIP-ME-2002 HRSG Installation Rev 5Dokumen6 halamanSATIP-ME-2002 HRSG Installation Rev 5zhang100% (1)

- DBR 300 MW PDFDokumen78 halamanDBR 300 MW PDFcynaiduBelum ada peringkat

- Turbo Power Services Company ProfileDokumen50 halamanTurbo Power Services Company Profilesomasekharch100% (1)

- 500 MW Turbine Design DataDokumen19 halaman500 MW Turbine Design Datasanjay kumar100% (1)

- HRSG PreservationDokumen4 halamanHRSG PreservationmadusamBelum ada peringkat

- HRSG Design Tutorial - Heat BalanceDokumen3 halamanHRSG Design Tutorial - Heat BalanceRavi KasaudhanBelum ada peringkat

- Pwps Swiftpac BrochureDokumen6 halamanPwps Swiftpac BrochureWilfredo Rojo CastañoBelum ada peringkat

- Heat Recovery Steam Generators PDFDokumen34 halamanHeat Recovery Steam Generators PDFahmed_2211896127100% (1)

- Operation Philosophy of 209HA CCPP BhikkiDokumen34 halamanOperation Philosophy of 209HA CCPP BhikkiMunibBelum ada peringkat

- Nandipur 425MW CCPP Gas Turbine Operation ManualDokumen268 halamanNandipur 425MW CCPP Gas Turbine Operation ManualMuhammad Awais100% (6)

- Breakdown EngineeringDokumen11 halamanBreakdown EngineeringDwi Mulyanti DwimulyantishopBelum ada peringkat

- Combined Cycle PrinciplesDokumen43 halamanCombined Cycle PrinciplesFazalur Rehman Babar100% (1)

- Gas Turbine Manual PDFDokumen721 halamanGas Turbine Manual PDFZakki Afifi100% (2)

- Design of 750 MW Combined Cycle Power Plant: System Design and ConfigurationDokumen21 halamanDesign of 750 MW Combined Cycle Power Plant: System Design and ConfigurationAdrian BundalianBelum ada peringkat

- Duties & Responsibilities of Shift EngineerDokumen35 halamanDuties & Responsibilities of Shift EngineerNaveen ChodagiriBelum ada peringkat

- HRSG Operating ManDokumen49 halamanHRSG Operating ManNicolae Marin100% (1)

- Commissioning of Combined Cycle Power PlantsDokumen30 halamanCommissioning of Combined Cycle Power Plantsa_mohid1780% (5)

- CMI Energy Reference ListDokumen24 halamanCMI Energy Reference Listthanhtbk2000Belum ada peringkat

- Optimizing Duct Burner ReliabilityDokumen10 halamanOptimizing Duct Burner ReliabilityPajooheshBelum ada peringkat

- WPI Combined CycleDokumen2 halamanWPI Combined CycletahirBelum ada peringkat

- Qurayyah Combined Cycle Power Plant - SATDokumen10 halamanQurayyah Combined Cycle Power Plant - SATrenjithv_4100% (1)

- Combined Cycle PowerplantDokumen34 halamanCombined Cycle PowerplantDarrel CamachoBelum ada peringkat

- Back Pressure TurbineDokumen5 halamanBack Pressure Turbinejitendra jhaBelum ada peringkat

- BHEL Gas Turbines - Correction CurvesDokumen27 halamanBHEL Gas Turbines - Correction CurvesRajagopala Sarma Sundar100% (1)

- Product Bulletin No.: TDS-03-16 Release Top Drive Drilling SystemDokumen8 halamanProduct Bulletin No.: TDS-03-16 Release Top Drive Drilling Systemahmedsaid85Belum ada peringkat

- Minimum Critical Spare ListDokumen32 halamanMinimum Critical Spare ListVIBHAVBelum ada peringkat

- Samsung RA20VHSW Service ManualDokumen32 halamanSamsung RA20VHSW Service Manualnuk1doe50% (2)

- 2nd TA Modification Work List Rev1Dokumen71 halaman2nd TA Modification Work List Rev1Vy NguyenBelum ada peringkat

- Eng - Report 10.04.2013Dokumen41 halamanEng - Report 10.04.2013Shivraj GurjarBelum ada peringkat

- Data Sheet Tag 180-Pu-011eDokumen8 halamanData Sheet Tag 180-Pu-011eSarah PerezBelum ada peringkat

- STG Training MaterialDokumen321 halamanSTG Training MaterialMashudi FikriBelum ada peringkat

- Plant Shutdown For Overhaul To Do ListDokumen10 halamanPlant Shutdown For Overhaul To Do ListsprotkarBelum ada peringkat

- Shift Charge Engineer: Rajahmundry, Andhra PradeshDokumen2 halamanShift Charge Engineer: Rajahmundry, Andhra PradeshBv RaoBelum ada peringkat

- GT Startup ActivitiesDokumen1 halamanGT Startup ActivitiesBv RaoBelum ada peringkat

- Data Engineer SkillsDokumen1 halamanData Engineer SkillsBv RaoBelum ada peringkat

- GT Pre Startup Checks: S.no Work Description Status RemarkDokumen2 halamanGT Pre Startup Checks: S.no Work Description Status RemarkBv RaoBelum ada peringkat

- Konaseema OfferDokumen2 halamanKonaseema OfferBv RaoBelum ada peringkat

- Psoriasis Brought On by StressDokumen1 halamanPsoriasis Brought On by StressBv RaoBelum ada peringkat

- What Are Cylindrical Roller Bearings? Types of BearingsDokumen1 halamanWhat Are Cylindrical Roller Bearings? Types of BearingsBv RaoBelum ada peringkat

- Measurement Principle of Helium Leak Test: Tracer GasDokumen3 halamanMeasurement Principle of Helium Leak Test: Tracer GasBv RaoBelum ada peringkat

- Causes of Psoriasis: The Genetic LinkDokumen1 halamanCauses of Psoriasis: The Genetic LinkBv RaoBelum ada peringkat

- What Is Reverse Alignment?: "Moveable"Dokumen2 halamanWhat Is Reverse Alignment?: "Moveable"Bv RaoBelum ada peringkat

- Hot Alignment CalculationDokumen2 halamanHot Alignment CalculationBv RaoBelum ada peringkat

- Soft Foot Checking ProcedureDokumen2 halamanSoft Foot Checking ProcedureBv RaoBelum ada peringkat

- Helium Leak DetectionDokumen3 halamanHelium Leak DetectionBv RaoBelum ada peringkat

- Konaseema Gas Power Limited To The Assi General Manager. Material IndentDokumen2 halamanKonaseema Gas Power Limited To The Assi General Manager. Material IndentBv RaoBelum ada peringkat

- Spread - The Difference Between The Sell Quote and The Buy Quote or The BidDokumen8 halamanSpread - The Difference Between The Sell Quote and The Buy Quote or The BidBv RaoBelum ada peringkat