About PG PDF

Diunggah oleh

joymotiDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

About PG PDF

Diunggah oleh

joymotiHak Cipta:

Format Tersedia

Maintenance Planning Department

MAINTENANCE BULLETIN

December 2011

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 2 of 44

S Sl l. . N No o. . D De es sc cr ri ip pt ti io on n Page No.

1 Highlights of the Month 3

2 CM (MP)s Column

3 - 5

3 Major Maintenance Jobs Done in the Month

5 -7

4 Compliance of PM Notifications & Orders

7

5 Priority-I Maintenance Activities in the month

8

6 Safety Aspects

8 -9

7 PR/PO/WO Status

9 -10

8 Budgeted vs. Assigned value against Repair & Maintenance

10

9 Financial Position of AF Schemes

10

10 Resources of Maintenance Department

11

11 Mechanical Maint. Mobile Equipment Health Status 11

12 PSV/TSV Calibration Status

11

13 Synopsis-Highlights of the year 2011 12 - 22

14 ANNEXURE- I Status of AMC/ ARC

23 30

15 ANNEXURE- II Status of AF schemes

31 38

16 ANNEXURE- III Status of Live MOC Jobs

39 44

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 3 of 44

Maintenance Bulletin

December 2011

1 1. . H Hi ig gh hl li ig gh ht ts s o of f t th he e M Mo on nt th h: :

1. Number of Priority-I jobs done during the month: 08 nos

2. Number of Accidents/ Incidents of Maintenance Departments during the month: Nil

3. Mr.B.K.Datta, Director (Refineries), BPCL visited Refinery on 21.12.11 during the Synergy Meet hosted by NRL.

4. DM Plant CS-3000 DCS has been inaugurated by Director (Technical) on 2

nd

Dec2011.

2 2. . C CM M ( (M MP P) ) s s C Co ol lu um mn n: :

Topic: Spares Management in Equipment Repair: The

concept of Optimum Replaceable Unit (ORU)

By: P K Baruah, CM (MP)

If your car develops some problem on the way making your vehicle unfit for a long run, obviously you go to

a nearby garage. The mechanic on examining the problem of your car finds that some parts got worn out

and needs immediate replacement. What will happen if the part is not available nearby? You get stuck up

and your whole program gets affected. Then we realize the importance of spares. In the same manner in

industry, a maintenance engineer without spares is like a doctor with no availability of medicine. While

talking of spares of machines and equipments / instruments, the list of important/critical spares must be

known/ available to the engineer and ensure that they are made available.

We can divide the spares mainly in two types:

1) Spare which is a component of the main equipment

2) Sealing component like gasket / gland packing / mechanical seal etc.

While in general, items in serial no. 1 are costlier, items at serial no.2 are low cost items. Items a at serial

no.2 can go bad at any time and hence should be made readily available at all times.

For spare parts of items at serial no.1 i, e parts of the main equipment, concept of Optimum Replaceable

Unit (ORU) is very important to know for maintaining spares availability. Minimum maintenance is the

present day concept in designing of equipments as downtime of equipment is expensive.

Inventory management is a wide subject to deal with to finally ensure minimum down time of equipments

and accordingly manage availability of spares in your place/ware house at optimum cost.

While talking of parts of the machine/ equipment, the concept of Optimum Replaceable unit (ORU) comes

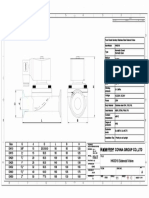

into picture. Consider the case of a simple pressure gauge (instrument). A pointer, dial, bezel, glass cover,

hair spring, movement assembly, gear-pinion, bourdon, link etc. are different parts of the gauge. But is it

required to make available all these parts for repairing a gauge? We need to consider the cost of labor vs.

cost of spares as well as cost of the main equipment/ instrument. The cost of a pressure gauge of lower

accuracy will be hardly around in a some hundreds/ a few thousand at the max. Hence buying of these small

parts will not be cost effective. Hence the whole of the pressure gauge should be considered as an ORU.

However, if there is free time of technician/mechanic usable parts of defective instruments can very well be

utilized for repair.

Maintenance of electronic equipments:

In electronic equipments the following concepts of maintenance exist:

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 4 of 44

1) Card level maintenance

2) Component level maintenance

In earlier days, there was component level maintenance , where the electronic technician repaired the

electronic cards by finding out the defective component of the card using multi meter and replace the

component ( a transistor/ a diode/ capacitor/resistor etc) .

But with present day sophisticated technology instrument / equipments are manufactured with wave

soldering / laser technology and even with better technology; hence the repair of electronic cards at users

end is practically not feasible. More over in case of electronic equipments, the question of reliability is

also an important factor.

Consider a case that your TV has gone bad and you repaired it in nearest TV mechanics shop. Is it

acceptable if almost every two/ three months after your TV goes bad or its performance is not satisfactory?

Obviously not, you will like to either replace the complete card or the TV itself.

Hence in this case the optimum replaceable unit is the card and not the components of the cards.

Repair vs. Reliability:

While defining Optimum Replaceable Unit (ORU), the impact of Reliability vs. Repair is an important

factor. What do we do if the shock absorber of our car goes bad? We replace it with a new one. But

repaired old shock absorbers are also available to buy for use. Although the cost is low for the repaired

shock absorber, the performance and reliability of the same will also be low. Hence in this case the ORU

will be the complete Shock absorber itself. Hence defining the ORU is the job of an experienced

maintenance engineer who will take care of time of repair & its accuracy , reliability and cost.

Advantage of introducing ORU concept in maintaining equipments:

1) Down time will be less.

2) Reliability of maintenance will be better.

3) Over all cost effective.

4) Quality as well accuracy of maintenance will be better.

5) Less number of parts will give better inventory management.

6) Enhanced productivity.

Front side of a simple Pressure Gauge (PG) Behind the dial the Bourdon C PG Behind dial a Spiral Bourdon PG

Front side of a simple Pressure Gauge (PG) Behind the dial the Bourdon C PG Behind dial a Spiral Bourdon PG

Front parts of PG: dial/ pointer /bezel/glass The movement assembly with Sector gear-pinion & hair spring

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 5 of 44

However considering cost of the instrument, repairing cost, reliability of maintenance & accuracy, the ORU

in this case is the complete Pressure Gauge.

Sealing Components:

V Teflon Ring glandpacking Ring & Cut in oblique halves grafoil Graphite Rope Gland packing

gland packing (For high temp)

Gaskets cut from Sheet Gasket Serrated metallic gasket Spiral wound metallic gasket

3 3. . M Ma aj jo or r M Ma ai in nt te en na an nc ce e J Jo ob bs s d do on ne e i in n t th he e m mo on nt th h: :

3.1. Mechanical Maintenance Jobs:

3.1.1. Vessel (Filter) to reduce the phenol content in stripped water going to CRWS pit at SRB

Work Order no: 50016408

Height: 3m

Diameter: 1.5m

Material of Construction: IS-2062 Gr: A

Plate Thickness: 6mm

Service: Reducing of phenol content in stripped water, using activated carbon, going to

CRWS pit at SRB.

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 6 of 44

3.1.2. Reconditioning of Gas Turbine Vertical Air Filters (total 768 nos. filters) of both GTG-1 & GTG-

2 completed.

3.1.3. Utility boiler FD fan turbine AOP no discharge problem rectification.

3.1.4. DAF modified 8 inch outlet line as per MOC completed in ETP.

3.1.5. Installation of new IGV actuator in GT#2.

3.1.6. CWP- A put back into service after complete overhauling.

3.2. Instrumentation Maintenance Jobs:

3.2.1. 04 nos of control valves (34-PV-4210B, 34-PV-1432, 03-FV-1202, 16-PV-1602) servicing done.

3.2.2. All On/off valves (150 nos) of DM plant consisting of Butterfly type and Diaphragm type has been

serviced during this month for proper operation from DCS.

3.2.3. Level Transmitter of HCU ABD has been modified to purge type transmitter with vessel pressure

feedback.

3.2.4. Thermo well 05-TE-4008 has been replaced for cut in the RF of the installed thermo well.

3.2.5. Up gradation of CCU Bagging machine has been completed with new control system by vendor

from M/s Cronos Richardsons.

3.2.6. CCU valve KLC-2101 passing problem rectified by servicing & machining.

3.2.7. New Alarm analysis tool Comparative Effectiveness Analysis Reporting Tool (CART) has been

installed by M/s Yokogawa India Ltd.

3.2.8. MSP Control valve14-LV-2201 passing problem rectified by replacing with an IL make control

valve in place of original MIL valve.

3.2.9. Problem of Dump Valve of slow response has been rectified during plant shut.

3.2.10.Valve error for 05-XCV-2026 attended by taking PSA to 10 beds and rectified.

3.2.11.Commissioning of new WD XRF Sulphur Analyser of QC lab has been completed by the vendor

M/s Volga.

3.2.12. 03 monthly calibration of Refinery & NRMT Gas Detection system has been completed.

3.2.13. Schedule checking (6 monthly) of Refinery Fire Alarm system has been completed.

3.2.14 Hanging problem encountered for HCU DCS console being attended by YIL engineers.

3.3. Electrical Maintenance Jobs:

3.3.1. SS#4: CSS#9 feeder CT control wiring correction done. Simulation completed successfully.CSS#9

feeder charged for Project requirement on 20.12.2011 ACBD by replacing earlier connection

from the 415V ETP PMCC through a control transformer.

3.3.2. 34-PM-AH-207 DC Scanner fan motor of HRSG#1 control circuit checked. 3 nos. of DC power

contactors replaced. Control wiring changed in the Armature side resistors. Complete motor

overhauling also done. Motor drawing high armature current problem rectified.

3.3.3. 23-PM-CF-104, V.T pump motor-1: Junction Box replaced, reglanding, lugging and termination

done. Test run done, DOR checked found OK.

3.3.4. EPABX: AMC visit done by M/s AGCNL & preventive maintenance done as per checklist.

3.3.5. Complete Overhauling of 19 motors completed along with painting.

3.3.6. CSS-8 & CSS-9 of SWBD 203 relay testing job completed. Primary injection and IR Test done in

both the feeders.

3.3.7. 40-PM-101A/B/C in Offsite area: Sand filling job done in cable trance at PH#1 as per ASC point.

3.3.8. MCC-326 in SS#1: 11 nos. Electronic MPR 300 relays installed in spare modules.

3.3.9. 06-PM-RK-01 in CCU: Main Rotary Kiln Motor tripping problem:

- Gate driver card of VFD of the Motor found defective. Replaced the same with new one.

- Cleaning of the VFD done.

3.3.10. Transformer, TR-124in NRMT: Problem: Oil Leakage observed at radiator valves, valves near

Buchholz Relay, other points of the Transformer.

Job done:

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 7 of 44

- Gaskets of all radiator valves (32 nos.) replaced.

- All radiator fins cleaned and painted.

- Gaskets of v/vs near Buchholz Relay, Top & Bottom filter v/vs, bottom sampling v/v

replaced.

- Gaskets of Tap changer, Inspection Cover, HV Terminal Box Top cover replaced.

- Oil leakage from HV & LV bushing rectified.

- TR Oil filtration & top-up done.

- Cleaning of whole Transformer & painting done.

- Marshaling Box Cleaned, painted, proper working of OTI & WTI & wiring checked.

- Simulation at marshaling and with HT feeder done.

- Testing of all rackable relays of LT feeder done.

3.3.11. Providing Emergency Power supply to Emerson PAC#2 situated at CCR, from EPMCC#307A at

SS#1 as per Reference no.: NRL/Elect/MOC/_SS#1/2011/12.

4 4. . C Co om mp pl li ia an nc ce e o of f P PM M N No ot ti if fi ic ca at ti io on ns s & & O Or rd de er rs s: :

NOTIFICATIONS (% completion)

Mechanical Electrical Inst. Civil Total

Priority-I

(Type: M1)

Monthly 50.00 100.00 100.00 NA 87.50

Cumulative 97.62 100.00 100.00 100.00 99.10

Routine Maintenance

(Type: M2)

Monthly 53.30 65.63 90.75 35.38 65.53

Cumulative 89.60 87.42 98.75 75.43 90.49

Shutdown

(Type: M3)

Monthly 0.00 0.00 33.33 0.00 4.35

Cumulative 43.19 83.33 53.19 60.00 50.28

Inspection-Normal Jobs

(Type: M4)

Monthly

Notification not generated since 01.04.2011

Cumulative

Preventive Maintenance

(Type: M5)

Monthly NA NA NA NA NA

Cumulative NA 100.00 NA NA 100.00

Safety

(Type: M6)

Monthly 22.22 100.00 0.00 0.00 20.00

Cumulative 64.91 85.71 66.67 36.84 62.24

Inspection-Shutdown Jobs

(Type: M7)

Monthly

Notification not generated since 01.04.2011

Cumulative

MOC Jobs

(Type: M8)

Monthly 25.00 0.00 0.00 0.00 16.67

Cumulative 36.36 100.00 0.00 0.00 31.58

Condition monitoring

(Type: M9)

Monthly 50.00 100.00 NA NA 66.67

Cumulative 79.25 99.04 NA NA 89.05

ORDERS

Routine Maintenance

(Type: MO01)

Monthly 60.75 51.65 67.50 NA 58.40

Cumulative 74.93 86.35 90.20 NA 82.85

Shutdown Maintenance

(Type: MO02)

Monthly 0.00 100.00 0.00 NA 33.33

Cumulative 75.56 100.00 96.77 NA 92.12

Preventive Maintenance

(Type: MO03)

Monthly 10.63 90.57 94.62 NA 70.67

Cumulative 39.54 98.03 95.00 NA 77.75

Condition based Maintenance

(Type: MO04)

Monthly 100.00 100.00 NA NA 100.00

Cumulative 76.36 90.00 NA NA 85.71

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 8 of 44

5. Priority-I Maintenance Activities in the month:

Notification User

status

System

status

Funct.

Location

Remarks

No. Date Description

Mechanical Maintenance:

10045367 10.12.11 Seal Leakage of

Pump 41- PA-

111B (IFO/ RCO

transfer pump)

APRD NOPR

ORAS

NRL-FMT-

OFS-MEC

The pump was assembled with seal parts.

Notification to close in system.

10045682 25.12.11 04-PA-049 HCU

CBD pump is not

working.

APRD NOPR

ORAS

NRL-FMT-

HCU-MEC

Job completed.

Electrical Maintenance:

10045432 14.12.11 34-PM-410

Turbine FD FAN

LO Pump Motor

checking for trip

problem.

APRD NOCO

ORAS

NRL-UTL-

CPP-ELE

Both side bearing were replaced.

10045583 20.12.11 Attending bearing

problem of 11-

PM-03B (lean

amine transfer

pump).

APRD NOCO NRL-FMT-

SRB-ELE

Both DE and NDE bearings were

replaced. No load test was carried out.

10045709 26.12.11 Garb carne

electrical thruster

problem.

APRD NOCO NRL-FMT-

DCU-ELE

Job completed.

Instrumentation Maintenance:

10045408 12.12.11 Pass-I flow CV

(FV1202A) to be

rectified.

APRD NOCO NRL-FMT-

DCU-INS

Control valve serviced at worshop and

complete trim set replaced.

10045433 14.12.11 PV-1103 stuck up

problem.

APRD NOCO NRL-FMT-

H2U-INS

Job completed.

10045728 27.12.11 34 - PV - 4210B

Control valve

opening problem.

APRD NOCO

ORAS

NRL-UTL-

SGD-INS

Valve servicing done at workshop.

6. Safety Aspects:

6.1. No. of Accidents/ Incidents of Maintenance Departments:

Department Accidents/ Incidents Reported in the Month

Near Miss

(Nos.)

First Aid

(Nos.)

Minor

(Nos.)

Major

(Nos.)

Mechanical

Nil Nil Nil Nil

Electrical

Nil Nil Nil Nil

Instrumentation

Nil Nil Nil Nil

Civil

Nil Nil Nil Nil

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 9 of 44

6.2. Major Pending ESA/ ISA Points of Maintenance:

Sl.

No

Refer

ence

Audit

Observation point Area/

Dept.

Action

by

Status Target

date of

completion

1 ESA

2006/

2009

Provide automatic rim seal

fire detection & suppression

system in large tanks & 70

mtr dia. crude tanks.

Tankage

Area

Mech.

Maint.

MOC/09/ OMS/275. WO: 4300021859

dtd. 04.10.10 placed on HSE Engineers

Pvt. Ltd. Mumbai. Job on progress.

31

st

January

2012

2 -Do- Clean agent flooding system

should be provided in the

Main control room as

specified in OISD STD 116 &

163

Main

Control

Room

Inst.

Maint.

Smoke / Heat detector alarm

system is already installed & functioning

for early warning of fire.

b) For clean agent flooding system, basic

engineering is completed.

AF approved. Spec/ Tender shall be made

ready by Inst Department. Instrumentation

has taken up this matter to discuss with

OISD for any alternate system since its a

critical job and difficult to execute.

CM (Insn) intimated that a joint meeting

with OISD will be conducted in Delhi to

sort out the issue before 31.01.12.

4

th

Qtr 11-12

3 -Do- Flooring below the pump

should be provided with

collection system in order to

collect the spilled oil in case

of any flange leak etc.

NRMT Civil

Maint

Scheme finalized. Under review by Civil

Maint.

4

th

qtr 11-12

4 -Do- Liquid line to LPG gantry as

well as bottling plant should

have ROV at the battery limit

NRMT Inst.

Maint.

PO: 4500009389 dtd. 21.03.11 placed on

Virgo Engineers Ltd. Kolkata, CDD:

28.11.11.

Opportunity

shutdown

5 ISA

2009

In LPG Road loading area the

vent is opened to atmosphere,

steam connection shall be

provided. In sphere vents

connected to flare line.

NRMT Mech.

Maint.

Convention loading arms swivel joint will

be replaced by dry gas coupling to stop

venting in the atmosphere vide

MOC/08/NRMT/240 & AF MK/10013/01

WO: 4300023760 dtd. 11.04.11 (DGC

Assy for loading arm Coupler & Adapter)

Vendor: Woodfield Systems (India) Pvt.

Ltd. Mumbai. Material arrived.

2 nos sample installed. PR 10053550 dtd

12.10.11 raised for remaining 8 nos.

4th qtr 11-

12

6 ISA

2010

Flare area lighting not

adequate.

OM&S Elect.

Maint.

(Notification No. 10038459) Material

arrived at site.

4

th

Qtr 11-12

7 -Do- Two sets of Level Indicators

not available in columns

08-CC-002, 10-CC-01/02, 11-

CC-001/02

SRU Inst.

Maint.

MOC/11/SRB/409. MOC generated,

planned during shutdown.

Opportunity

shutdown

7. PR/ PO Status:

Dept. Status of Purchase Requisition as on 03.01.2012

PR raised in the

Month (Nos.)

PR Commitment in the

month

`

Cumulative PR

in the FY (Nos.)

Cumulative PR Value in

the FY

`

Mech. Maint.

09 (Material)

+ 11 (Service)

35,76,126.35 (Material)

+ 20,303,478.49 (Service)

37 (Service)

+ 84 (Material)

12,62,72,878.29 (Service)

+ 5,06,44,316.68 (Material)

Elect. Maint.

01 (Material)

+ 08 (Service)

1,56,000.00 (Material)

+ 1,39,30,245.72 (Service)

20 (Service)

+ 24 (Material)

29,496,484.89 (Service)

+ 19,976,784.56 (Material)

Inst. Maint.

06 (Material)

+ 03 (Service)

58,54,399.51 (Material) +

50,50,449.92 (Service)

10 (Service)

+ 27 (Material)

13,272,894.99 (Service)

+ 28,102,792.00 (Material)

Civil Maint.

02 (Material) 4,54,272.50 (Material) 11 (Service)

+ 04 (Material)

30,069,088.84 (Service)

+ 23,86,749.40 (Material)

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 10 of 44

8. Budgeted vs. Assigned value against Repair & Maintenance: * *

Revenue Expenditure against Commitment Item Repair & Maintenance

(In Lakhs)

System Item Mechanical Electrical Instrumentation Civil

System Screen

Payment Budget

Budget allocation CFY

3064.99 1195.52 798.45

816.30

Total assigned fund as on

02.01.2012

1346.54 707.95 408.00 448.62

* * Note: Data provided for Fiscal Year 2012

9. Financial Position of AF Schemes:* (As on 03.01.12)

Ongoing Non-plan Capital Expenditure against AF Schemes

(Executor-wise)

(Figs. are in Lakhs)

System Item Total no. of AF

Schemes

Total scheme

Value

Actual Expenditure

up to this month

Committed Value up

to this month

Mechanical

14 1958.50 658.23 699.05

Electrical

06 312.50 37.59 184.40

Instrumentation

06 637.60 359.12 147.45

Civil

04 181.16 14.94 132.07

IHP

02 63.40 22.24 6.11

Total 32

3153.16 1092.12 1169.08

New Non-plan Capital Expenditure against AF Schemes

(Executor-wise)

(Figs. are in Lakhs)

System Item Total no. of AF

Schemes

Total scheme

Value

Actual Expenditure

up to this month

Committed Value up

to this month

Mechanical

13 2736.00 25.53 495.41

Electrical

14 540.89 0.00 287.77

Instrumentation

08 755.35 306.92 156.42

Civil

04 76.96 0.09 53.49

Total 39 4109.20 332.54 993.09

*Note: Refer Annexure II for the details AF schemes financial & physical status

Status of Purchase Orders as on 03.01.2012

Dept.

Monthly WO Status Monthly PO Status Cumulative WO Status

Cumulative PO Status

Released

(Nos.)

WO Value

`

Released

(Nos.)

PO Value

`

Released

(Nos.)

WO Value

`

Release

d (Nos.)

PO Value

`

Mech.

03 80,08,500.00

21 16,837,106.00

44 1,06,958,901.65

137 74,802,742.00

Elect. Nil Nil

02 7,53,000.00

18 32,167,352.82

48 23,897,298.44

Inst.

Nil

Nil

04 11,479,575.65 06

68,33,826.00

55 1,51,373,434.58

Civil

05 Nil 01 Nil 22 1,02,899,312.46

09 92,09,362.00

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 11 of 44

10. Resources of Maintenance Department:

Department Human Resource (No. of Employees) AMC/ARC*

No Mgt. Non-Mgt.

Mech. Maint.

30 66 25

Elect. Maint.

14 29 14

Inst. Maint.

18 20 23

Civil Maint.

4 - 17

MP & IHP

6 - 01

Total 72 115 80

*Note: Refer Annexure- I for detail status of AMC/ARCs

11. Mechanical Maint. Mobile Equipment Health Status:

Equipment Present Status Remarks

100 Te Crane

OK

40 Te Crane

OK

Hydra (Escorts 11 Te)

OK

Hydra (ACE 11 Te)

OK

Hydra (Escorts 10Te)

OK

Tractor (Mahindra)

OK

Tractor (Escorts)

OK

Articulated Boom

OK Used for 03 days in the month of December11.

Mobile Air Compressor (7CFM)

OK

Forklift (Voltas 3 Te)

OK

Forklift (Godrej 3Te )

OK

12. PSV/ TSV Calibration Status:

Units No of PSV/

TSV

Tag Nos./ Calibration date

HCU 04 04-PSV-9305 dtd.06.12.11

04-PSV-1508 dtd.09.12.11

04-PSV-1701 dtd.27.12.11

04-PSV-5304 dtd. 24.12.11

CDU/VDU 01 01-PA-MT-037B dtd. 09.12.11

DCU 01 03-PSV-1312 dtd. 22.12.11

CPP 01 308 A dtd. 31.12.11

MSP 01 16-PSV-1503 dtd. 21.12.11

Total 08 Nos

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 12 of 44

Synopsis

January 2011 to December 2011

1. Highlights of the Year2011:

1.1. The Online Monitoring and Diagnostic system for reliability enhancement of Make Up Gas Compressor

and Off gas Compressor of HCU was inaugurated on 24

th

May2011 at 11:30 am by Managing Director,

Mr.D. Chakravarty.

1.2. NRLs Integrated Access Control system was commissioned and formally inaugurated by MD on 1st

August, 2011.

MD NRL Inaugurating the system MD NRL inaugurating Access Control System

1.3. DMP DCS Conversion job completed and inaugurated by D (T) on 02.12.2011.

DCS in DM Plant Inauguration of DCS in DM Plant

1.4. Environment Display Board at Refinery Main Gate inaugurated by MD, NRL on 28th March2011.

MD NRL, Mr B K Das, inaugurated the Display Board

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 13 of 44

1.5. Calcium silicate insulation job completed by Civil Maintenance.

Calcium silicate insulation job

1.6. Bio Gas Plant inaugurated by MD, NRL on 04.11.11. Use of bio gas at NRL canteen started from same

day.

1.7. Tank Radar Gauge systems for 15 nos. of product tanks commissioned.

1.8. Partial discharge Test & Tan measurement test carried out successfully in GTG-1 & GTG-2

respectively on 28

th

& 29

th

October2011.

1.9. Advanced Process Control (APC) for DCU, HCU completed and in H2U in progress.

1.10. Automatic Fire Rim Seal protection system in Crude tanks 101 C & D on progress.

1.11. Primary & Secondary seal installation completed in 07 nos of Naphtha tanks.

1.12. Dry Gas coupling installation in LPG loading arm completed.

1.13. Painting of overhead flare line completed.

1.14. External painting of Admin Building 75% completed by Civil Maintenance.

Use of massive scaffolding Admin Building external painting

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 14 of 44

1.15. M&I of tanks done by Inspection in 2011: 07 nos as detailed below:

Sl. No Tanks Service

1 41-TT-CR-107A Vacuum Residue

2 41-TT-CR-113B Wet slop

3 41-TT-CR-114C Dry slop

4 44-TT-FR-103A ATF

5 44-TT-FR-103C ATF

6 45-TT-CFR-003B ATF

7 45-TT-FR-004B Naphtha

1.16. Annual Statutory Inspection & Hydro test of following equipments completed & witnessed by state

IBR authority.

1.17. Fire Water damaged piping replaced in 2011: 2586.6 Mtrs.

1.18. Revised PM schedule has been completed in SAP by Maintenance Planning.

1.19. Estimation job for Civil items completed and draft standard SOR for Mechanical items

have been prepared by Maintenance Planning department and forwarded to all concerned for review.

1.20. 12 nos. of Maintenance Bulletins have been prepared by Maintenance Planning.

Sl.

No.

Equipment Inspection Date

1 HRSG-1 07-04-2011 & 08-04-2011

2 HRSG-2 07-09-2011 & 08-09-2011

3 Utility Boiler 27-07-2011 & 28-07-2011

4 CCU (WHRB) boiler 03-02-2011

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 15 of 44

2. Jobs done by Maintenance Planning:

Sl. No. Job Description Remarks

1 Revision of PM schedule in SAP as per revised

equipment criticality list:

Follow up, Receipt & Compilation of revised

criticality list for all units.

Follow up, Receipt & Compilation of revised lists

of PM frequencies from MM & EM by May 11.

Co-ordination with ERP for necessary software

changes

Incorporation in SAP of revised PM schedule by

us.

Received & compiled in March11.

Received & compiled in May11.

ERP blocked all Saturdays on

07.06.11 as required as 1

st

& 3

rd

Saturdays becomes off days.

Completed on 15.06.11.

2 Settlement of completed maintenance orders and

business closing.

Monthly.

3 Tracking of status of different licenses of the refinery.

Generation and circulation of monthly MIS (w.e.f

July11). Maintaining Status of Licenses in web based

license tracking system.

MIS generated: 06 nos

4 Tracking & follow up of status of different

AMC/ARCs of different maintenance departments.

Maintaining Status of AMC/ARCs in web based

contract tracking system.

Updated on monthly basis. MIS

included in Monthly Maintenance

Bulletin.

5 Generation & circulation of MIS on Daily Maintenance

Job plan & status (w.e.f. July11)

143 nos generated.

6 Generation & circulation of MIS on Weekly

Maintenance Notification & Orders.

48 nos generated.

7 Generation & circulation of MIS on Monthly

Maintenance Notification & Orders.

12 nos generated.

8 Generation & circulation of MIS on Lube Oil Stock &

Consumption Status w. e. f 01.04.11.

08 nos generated.

9 Business closing & settlement of Maintenance Orders. Monthly

10 Shutdown Jobs for Refinery Shutdown 2012:

Compilation of jobs, put up for review and

finalization of job list.

Compilation, monitoring of PRs, presentation of

status for review in meetings.

Organizing shut down review meetings,

presentation on preparedness

Coordination with concerned departments &

commercial for shutdown materials & services.

Expediting for procurement & follow up with

vendors

Draft planning of H2U reformer tube replacement

job.

18.03.11 chaired by G(M)

26.04.11 chaired by DGM (Maint)

18.10.11 chaired by CM (MP)

26.11.11 chaired by D(T)

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 16 of 44

Sl. No. Job Description Remarks

11 IHP Jobs:

Bio Gas Pant Installation in NRL. (AF: OP/ 08060) Job completed & successfully

commissioned.

Cetane Improver dosing system installation in PH#3.

(AF: OP/ 11024)

Civil Vessel foundation job &

piping prefabrication job completed.

Balance jobs to be completed after

installation of CI dosing vessel

(under MM scope).

Presentations/ Documents arranged by Maintenance Planning:

1 AF Jobs under GM (Ops):

Compilation of fresh AF proposals and co-

ordination with Corporate Planning for Approval

Tracking of AF jobs, monitoring status,

presentation for periodic review.

Bi-monthly Review.

2 MOC Jobs: Tracking & monitoring progress status of

MOC jobs, presentation for periodic review.

Bi-monthly Review.

3 Coordination for weekly PCMs. Weekly PCM

4 Compilation, Co-ordination for approval of proprietary

items & services as per requirement of user

departments.

As required.

3. Statistics of total jobs done in the year 2011: (As on 09.01.2012)

Departments Total no of

notification

generated

Total no of

notification

completed

% Completion

of maintenance

jobs

Approved M1 Notifications: (Priority-I)

Mechanical 49 48 97.95%

Instrumentation 33 33 100%

Electrical 48 48 100%

Civil 01 01 100%

M2 Notifications: (Malfunction Report)

Mechanical 2922 2701 92.44%

Instrumentation 2134 2117 99.20%

Electrical 653 572 87.60%

Civil 956 772 80.75%

M3 Notifications: (Shutdown)

Mechanical 300 153 51.00%

Instrumentation 121 61 50.41%

Electrical 42 37 88.10%

Civil 30 17 56.67%

M4 Notifications: (Inspection Notification- Normal): No notification has been

issued.

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 17 of 44

Departments Total no of

notification

generated

Total no of

notification

completed

% Completion

of maintenance

jobs

M5 Notifications: (Preventive Maintenance):

Mechanical Nil Nil NA

Instrumentation Nil Nil NA

Electrical 18 12 66.67%

Civil 02 01 50.00%

M7 Notifications: (Inspection Notification- Shutdown): No notification has been

issued.

M8 Notifications: (MOC Job Notification):

Mechanical 11 04 36.36%

Instrumentation 07 01 14.29%

Electrical 04 04 100.00%

Civil 01 Nil 0.00%

M9 Notifications: (Condition Monitoring Notification):

Mechanical 121 97 80.17%

Instrumentation Nil Nil NA

Electrical 130 129 99.23%

Civil Nil Nil NA

MO01 Orders: (Routine Maintenance Orders):

Mechanical 1354 1071 79.10%

Instrumentation 920 828 90.00%

Electrical 706 629 89.10%

MO02 Orders: (Shutdown Maintenance Orders):

Mechanical 61 45 73.77%

Instrumentation 161 152 94.41%

Electrical 04 03 75.00%

MO03 Orders: (Preventive Maintenance Orders):

Mechanical 2076 872 42.00%

Instrumentation 465 464 99.78%

Electrical 3577 3533 98.77%

MO03 Orders: (Condition Based Maintenance Orders):

Mechanical 61 48 78.69%

Instrumentation Nil Nil NA

Electrical 142 130 91.55%

4. HR in Maintenance as on 01.01.2012:

Department Human Resource (No. of Employees) No of AMC/

ARC*

Mgt. Non-Mgt.

Mech. Maint.

29 66 26

Elect. Maint.

14 29 15

Inst. Maint.

18 20 23

Civil Maint.

4 - 16

MP & IHP

6 - 1

Total 71 115 81

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 18 of 44

5. External Training attended in 2011:

Departments Management

Staff

Non-Management

Staff

Mechanical Maintenance 05 out of 29 03 out of 66

Instrumentation Maintenance 12 out of 20 03 out of 22

Civil Maintenance 01 out of 04 NA

Electrical Maintenance 06 out of 14 Nil

Maintenance Planning 02 out of 06 NA

6. Revenue Expenditure (April-Dec11 & Jan -Dec11):

Revenue Expenditure against Commitment Item Repair & Maintenance

(In Lakhs)

System Item Mechanical Electrical Instrumentation Civil

System Screen

Payment Budget

Budget allocation

(CFY)

3064.99 1195.52 798.45 816.30

Total assigned fund

(April11 to Dec11)

1335.27 707.55 411.37 450.05

Total assigned fund

(Jan11 to Dec11)

1690.69 921.84 608.23 634.96

* * Note: Data provided for Fiscal Year 2012

7. Unit Shutdown Summary: (Month- wise)

CDU/VDU

Month NOS. OF SD

Dates/ Timing Idle

hrs

Duration Reason for Shutdown

From To

April'11 1 01.04.11 at

10.00 hrs.

03.04.11 at

11.40 hrs.

52 2 days I/V problem in pump 07A &

07B.

Aug'11 1 14.08.11 at

04.30 hrs.

14.08.11 at

21.00 hrs.

16.5 1 day Total power failure.

Dec'11 1 11.12.11 at

16.53 hrs.

12.12.11 at

13.30 hrs.

20.6 1 day Total power failure.

Total

3 89.1 4 days

DCU

Month NOS. OF SD

Dates/ Timing Idle

hrs

Duration Reason for Shutdown

From To

Jan'11 1 03.01.11 at

17.30 hrs.

09.01.11 at

8.30 hrs

135 6 days SAD job.

May'11 1 12.05.11 at

14.00 hrs.

17.05.11 at

18.00 hrs.

124 6 days SAD job.

Aug'11 1 14.08.11 at

4.30 hrs.

21.08.11 at

23.30 hrs.

187 8 days Total power failure.

Dec'11 2 11.12.11 at

16.53 hrs.

13.12.11 at

14.00 hrs.

45.12 2 days Total power failure.

13.12.11 at

16.10 hrs.

15.12.11 at

5.00 hrs.

36.83 2 days Heater charge pump (03-

PA-10 A/B) lost suction.

Total

5 528 24 days

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 19 of 44

H2U

Month NOS. OF SD

Dates/ Timing Idle

hrs

Duration Reason for Shutdown

From To

Jan'11 1 28.01.11 at

10.30 hrs.

29.01.11 at

14.50 hrs.

28.3 1day HCU was under shut down

for RGC tripping.

July'11 1 20.07.11 at

12.00 hrs

21.07.11 at

16.35 hrs.

28.6 1day Rupture of process pipe.

Aug'11 1 14.08.11 at

4.30 hrs.

15.08.11 at

0.30 hrs.

20 1day Total power failure.

Dec'11 1 11.12.11 at

16.53 hrs

12.12.11 at

19.45 hrs.

26.9 1day Total power failure.

Total

4 104 4 days

HCU

Month NOS. OF SD

Dates/ Timing Idle

hrs

Duration Reason for Shutdown

From To

Jan'11 1 28.01.11 at

10.16 hrs.

30.01.11 at

5.30 hrs.

43.2 2days RGC tripping.

March'11 1 03.03.11 at

0.21 hrs.

03.03.11 at

19.00 hrs.

18.7 1day RGC tripping.

April'11 1 09.04.11 at

1.00 hrs.

12.04.11 at

15.48 hrs.

86.8 3 days RGC maintenance job.

May'11 1 11.05.11 at

3.00 hrs.

12.05.11 at

23.00 hrs.

44.00 2days Due to RGC trip caused by

"Trip Oil Pressure Low"

interlock.

July'11 1 20.07.11 at

11.25 hrs.

22.07.11 at

1.30 hrs.

38.08 2days H2U S/D caused by rupture

of the process piping.

Aug'11 1 14.08.11 at

4.30 hrs.

15.08.11 at

3.55 hrs.

23.42 1day Total power failure.

Sep'11 1 29.09.11 at

9.30 hrs.

30.09.11 at

2.30 hrs.

17.00 1day Leakage of EE-002 t/s inlet

flange.

Dec'11 1 11.12.11 at

16.53 hrs.

13.12.11 at

8.45 hrs.

39.9 2days Total power failure.

Total

8 311 14days

SRU

Month NOS. OF SD

Dates/ Timing Idle

hrs

Duratio

n

Reason for Shutdown

From To

Aug'11 1 14.08.11 at

4.30 hrs.

16.08.11 at

11.30 hrs.

55.0 2days Total power failure.

Dec'11 1 11.12.11 at

16.53 hrs.

14.12.11 at

9.15 hrs.

64.4 3days Total power failure.

Total

2 119.4 5 days

CCU

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 20 of 44

Month NOS. OF SD

Dates/ Timing

Idle

hrs

Duration Reason for Shutdown

From To

Jan'11 1 25.01.11 at

10.00 hrs.

01.02.11 at

6.00 hrs

164.0 7 days Hot spot found on

incinarator shell.

Feb'11 1 01.02.11 at

6.00 hrs.

08.02.10 at

12.22 hrs.

174.4 7 days Hot spot found on

incinarator shell.

May'11 1 21.05.11 at

13.30 hrs.

01.06.11 at

6.00 hrs.

256.5 11 days Cooler exhaust fan problem.

June'11 1 01.06.11 at

6.00 hrs.

03.06.11 at

22.30 hrs.

64.5 3 days Cooler exhaust fan problem.

July'11 1 27.07.11 at

14.30 hrs.

01.08.11at

6.00hrs

87.5 5 days Cooler exhaust fan problem.

Aug'11 1 01.08.11 at

6.00 hrs

15.08.11 at

2.35 hrs.

332.6 14 days Cooler exhaust fan problem

and also total power failure.

Nov'11 1 15.11.11 at

17.00 hrs

19.11.11 at

17.27 hrs.

96.4 4 days Leakage at the firehood

bottom of rotary kiln.

Dec'11 2 11.12.11 at

16.53 hrs.

12.12.11 at

10.15 hrs.

17.4 1 day Total power failure.

19.12.11 at

5.24 hrs.

22.12.11 at

7.45 hrs.

74.4 3days Kiln cooler exhaust fan

NDE bearing problem.

Total

9 1267 55 dys

NHTU

Month NOS. OF SD

Dates/ Timing

Idle

hrs

Duration Reason for Shutdown

From To

Aug'11 1 14.08.11 at

4.30 hrs.

15.08.11 at

12.30 hrs.

32.0 1 day Total power failure.

Dec'11 1 11.12.11 at

16.53 hrs.

13.12.11 at

5.30 hrs.

36.6 2 days Total power failure.

Total

2 68.6 3 days

CRU

Month NOS. OF SD

Dates/ Timing

Idle

hrs

Duration Reason for Shutdown

From To

Aug'11 1 14.08.11 at

4.30 hrs.

16.08.11 at

0.30 hrs.

44.0 2 days Total power failure.

Dec'11 1 11.12.11 at

16.53 hrs.

13.12.11 at

17.00 hrs.

48.1 2 days Total power failure.

Total

2 92.1 4 days

ISOM

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 21 of 44

Month NOS. OF SD

Dates/ Timing

Idle

hrs

Duration Reason for Shutdown

From To

Aug'11 1 14.08.11 at

4.30 hrs.

16.08.11 at

13.00 hrs

44.0 2 days Total power failure.

Dec'11 2 11.12.11 at

16.53 hrs.

14.12.11 at

9.15 hrs.

64.4 3 days Total power failure.

15.12.11 at

20.00 hrs.

29.12.11 at

12.00 hrs.

328.0 13 days Deactivation of 16-RB-001

catalyst.

Total

3 436.4 18days

8. AF Schemes Financial Status as on January2012:

8.1. AF Continuing Schemes Financial Status:

0

200

400

600

800

1000

1200

1400

1600

1800

2000

Mech. Inst. Elect. Civil IHP

Total Budget

Actual

Expenditure

Overall

Commitment

8.2. AF New Schemes Financial Status:

0

500

1000

1500

2000

2500

3000

Mech. Inst. Elect. Civil

Overall Budget

Actual

Expenditure

Overall

Commitment

9. PSV / TSV calibration in the year:

Departments

Cost in

Lakhs

Departments

Cost in

Lakhs

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 22 of 44

Units No of PSV/ TSV

H2U 15

HCU 45

CDU/VDU 14

DCU 30

CPP 52

SRU 14

MSP 17

OM&S 02

NRMT 16

CCU 03

Total 208

10.1. Mechanical Maint. Mobile Equipment Health Status As on Jan2012:

Equipment Present Status

100 Te Crane

OK

40 Te Crane

OK

Hydra (Escorts 11 Te)

OK

Hydra (ACE 11 Te)

OK

Hydra (Escorts 10Te)

OK

Tractor (Mahindra)

OK

Tractor (Escorts)

OK

Articulated Boom

OK

Mobile Air Compressor (7CFM)

OK

Forklift (Voltas 3 Te)

OK

Forklift (Godrej 3Te )

OK

10.2. STATUS EQUIPMENT IN MECHANICAL WORKSHOP: As on Jan2012

Sl. Descriptions PRESENT STATUS

01 Lathe Machine - 03 IN WORKING CONDITION

02 Radial Drilling Machine -01 IN WORKING CONDITION

03 Precision Horizontal Boring Machine 01 IN WORKING CONDITION

04 Surface Grinder -01 IN WORKING CONDITION

05 Universal Milling Machine -01 IN WORKING CONDITION

06 Shaping Machine 01 IN WORKING CONDITION

07 Slotting Machine 01 IN WORKING CONDITION

08 Power Driven Sewing Machine -01 IN WORKING CONDITION

09 Balancing Machine -01 IN WORKING CONDITION

10 Angle Grinding Machine 11 IN WORKING CONDITION

11 Straight Grinding Machine 05 IN WORKING CONDITION

12 Pedestal Grinding Machine - 02 IN WORKING CONDITION

13 Heat Exchanger Tube Sheet Cutting Machine 01 IN WORKING CONDITION

14 Portable Mobile DG Welding Set - 03 IN WORKING CONDITION

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 23 of 44

ANNEXURE- I

S St ta at tu us s o of f A AM MC C/ / A AR RC Cs s a as s o on n 0 03 3. .0 01 1. .1 12 2

C Co on nc ce er rn ns s a ar re e h hi ig gh hl li ig gh ht te ed d w wi it th h p pu ur rp pl le e c co ol lo ou ur r a an nd d b bo ol ld d f fo on nt t i in n t th he e S St ta at tu us s c co ol lu um mn n

Sl WO no. Name of the

Work

Contractor EIC WO value Executed

value

Starting

Date

Cont.

Period

Contract expiry

date / Status

Mechanical:

1 4300022617

dtd.17.12.10

ARC for Heat

Treatment

Work.

Techno

Resources

CM

(MM)

713,979.48 168,600.00

Feb2011 2 Yrs. Feb2013

2 4300018551

dtd.21.12.09

Operation &

Maintenance

of NRL

owned Cranes

& Equipts.

M/s Nishan

Enterprises

CM

(MM)

14,002,570.38 12,430,090.29

08.08.09 6

months

w.e.f.

08.08.

09

Contract

extended up to

07.12.11 or till

lining up of new

contract

whatever

earlier.

3 4300011510

dtd.31.05.08

Periodic

maint. & Up

keepment at

site premises

(522) (Gr-VI).

M/s Ramesh

Das

CM

(MM)

18,64,232.49 1,421,745.45

01.07.08 2 Yrs. Extended to

another 2 years

up to 30.06.12.

4 4300011515

dtd.31.05.08

AMC for Up

keepment of

Mech Field

Office &

CCU Control

Room.

M/s

Tajuddin

Ahmed

CM

(MM)

26,91,057.11 2,091,461.72

01.07.08 2 Yrs.

5 4300012728

dtd.12.09.08

Preventive &

Breakdown

Maint. of

NRL own Fire

Tenders &

Equipments.

M/s

Hanuman

Automobile

CM

(MM)

15,71,179.44 1,302,025.67

01.09.08 2 Yrs Extended up to

11.03.12 or till

lining up of new

contract

whatever

earlier.

6 4300008906

dtd.05.09.07

Contracts for

Machining,

Fabrication,

Welding &

heat exch.

retubing.

M/s Techno

Resource

CM

(MM)

83,05,283.00 74,26, 532.53

01.10.07 2 Yrs New WO placed

as detailed

below:

4300025886

dtd. 28.10.11

ARC for M/c,

Fab, Welding.

M/s Techno

Resource

CM

(MM)

73,23,432.50 Nil H/O by

EIC

2 Yrs Up to 2013

7 4300024721

dtd.01.07.11

AMC for CFR

Octane/

Cetane

CFR

Engines

Services Pvt.

Ltd.

CM

(MM)

5,65,000.00 68,900.00

08.09.11 2 Yrs. 07.09.13

8 4300021387

dtd.24.08.10

AMC contract

service for

Cummins

diesel

engines.

Ramnarayan

Diesel Sales

& Service.

CM

(MM)

8,36,955.00 Nil 25.08.10 2 Yrs 25.08.12

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 24 of 44

Sl WO no. Name of the

Work

Contractor EIC WO value Executed value Starting

Date

Cont.

Period

Contract

expiry date /

Status

Mechanical (Contd.):

9 4300025556

dtd. 21.09.11

Fire Water

Network &

cooling

water U/G

piping.

M/s T.

Borah & Co.

CM

(MM)

10,909,544.43 661,589.70

16.09.11 1 yr. 15.09.12

10 4300018919

dtd 29.01.10

Contract

Service for

Field Valve

Testing &

Maint.

M/s S.S

Electromech

CM

(MM)

41,77,929.35 1,227,284.02

01.02.10 2 Yrs 01.02.12

11 4300013259

dtd.24.10.08

Maint. of

Rotary

Contract.

M/s SCS

Enterprise

CM

(MM)

38,12,236.70 28,89,345.97

01.11.08 2 yrs Extended up to

22.10.11. PR:

PR: 10053418

being refloated.

12

4600004951

dtd.23.04.10

ARC for

mechanical

seal items.

Eagle Seals

& Systems

CM

(MM)

1,02,42,809.22 59,25,042.00 16.03.11 1 yr. 16.03.12

13 4600004871

dtd.15.03.10

ARC for

Mechanical

seal items.

Flowserve

Sanmar Ltd.

CM

(MM)

93,87,764.31 80,52,428.22

15.03.10 1 yr 15.03.11. New

ARC order

issued as

detailed below.

4600007058

dtd. 27.12.11

ARC for

Mechanical

seal items.

Flowserve

Sanmar Ltd.

CM

(MM)

9,600,000.00 42,48,943.00 27.12.11 1 yr 3

months

15.03.13

14 4600004813

dtd.23.02.10

ARC for

bearing items.

Kinjal

Bearing Pvt.

Ltd.

CM

(MM)

8,36,590.00 8,27,030.00

08.03.10 1 Yr CS prepared.

15 4600004812

dtd.23.02.10

ARC for

bearing items.

Bearing

House

CM

(MM)

41,18,195.00 40,30,680.00

08.03.10 1 Yr

16 4300025203

dtd. 16.08.11

Assistance in

Opn & Maint

of CCU.

SCS

Enterprise

CM

(MM)

98,16,019.30 12,25,358.83 16.08.11 1 yr 15.08.12

17 4300016129

dtd.02.07.09

7T grab crane

of DCU coke

yard.

M/S Nishan

Enterprises

CM

(MM)

43,44,650.00 27,86,576.00 01.08.09 2 yrs Extended up to

31.07.12

18 4300025426

dtd. 15.09.11

House

keeping and

Gardening at

CCU Area

Ramen

Kumar

Phukon

M

(CCU)

1,53,574.00 74,555.00 15.09.11 1 yr 14.09.12

19 4300025897

dtd. 31.10.11

AMC Part A:

CDU/ VDU,

H2U, HCU,

SRU, NRMT,

Offsite,

OM&S.

PKM

Erectors

CM

(MM)

91,41,491.00 Nil H/O by

EIC

1 yr. Up to 2012

20 4300025892

dtd. 31.10.11

AMC Part B:

CPP &

Utility, ETP

& RWIP.

North East

Engg. &

Construction

CM

(MM)

88,46,293.00 Nil H/O by

EIC

1 yr Up to 2012

21 4300025898

dtd. 31.10.11

Part C: DCU

Coke

chamber

Operation &

associated

Jobs.

M/s Fokhor

Uddin Ali

Ahmed

CM

(MM)

54,31,037.00 Nil H/O by

EIC

1 yr Up to 2012

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 25 of 44

Sl WO no. Name of the

Work

Contractor EIC WO value Executed value Starting

Date

Cont.

Period

Contract

expiry date /

Status

Mechanical (Contd.):

22 4300006715

dtd.19.02.07

AMC for On-

Line Leak

Sealing Job.

M/s NICCO

Engg.

Service

CM

(MM)

24,60,444.23 24,60,412.96

25.03.09 2 Yrs 26.03.11. New

WO placed as

detailed below:

4300025087

dtd. 12.08.11

AMC for On-

Line Leak

Sealing Job.

Nicco

Engineering

Services

Limited

CM

(MM)

19,99,683.00 Nil H/O by

EIC.

2 Yrs Up to 2013

23 AMC for

Expert

Service of

LPG BP

Carousal

Unit.

CM

(MM)

H/O by

EIC.

2 Yrs New PR:

10052546 dtd.

30.03.11.

Under TEC.

24 4300014886

dtd.10.03.09

Testing of

chain pulley

block,

monorail,

slings, D-

shackles &

EOT/ HOT

crane.

M/s P. K.

Roy

CM

(MM)

18,83,800.00 18,07,200.00

12.03.09 2 yrs. 11.03.11, New

WO placed as

detailed below:

4300025561

dtd. 23.09.11

Testing of

Lifting Tools

& Tackle

Lift.

Bishwajit

Deb

CM

(MM)

12,06,500.00 Nil H/O by

EIC

2 yrs. Up to 2013

25 4300023204

dtd.16.02.11

Repairing of

lining in

tanks/

vessels/ pipe/

headers with

FRP/ PP in

Utility Plant

Area.

Indus Equip

Company

CM

(MM)

42,47,000.00 15,21,197.46 March

11

2 yrs. March13

Total Value (Mechanical)

13,3151949.90 51892068.83

Electrical:

Sl WO no. Name of the

Work

Contractor EIC WO value Executed value Starting

Date

Cont.

Period

Contract

expiry date /

Status

1 4300024401

dtd.10.06.11

AC of Adm.

Building

Blue Star

Ltd.

SM

(EM)

26,27,248.32 4,39,812.00 01.07.11 3 yrs. 30.06.14

2 4300017833

dtd.03.11.09

Telecom

Maint. Ref,

NRMT

B. R.

Construction

SM

(EM)

16,99,232.05 14,36,313.84

01.12.09 2 yrs. 30.11.11, New

PR: 10053888

dtd. 29.11.11

raised.

3 4300020609

dtd.17.06.10

Window/

Split AC

Refinery/

Township.

Ginoria

Trading

SM

(EM)

31,16,435.52 16,71,575.30

17.06.10 2 yrs. 16.06.12

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 26 of 44

Sl WO no. Name of the

Work

Contractor EIC WO value Executed value Starting

Date

Cont.

Period

Contract

expiry date /

Status

Electrical: (Contd.)

4 4300024402

dtd.10.06.11

AMC for

UPS in

Refinery.

Emerson

Network

Power

SM

(EM)

4,70,000.00 4,70,000.00 08.02.11 1 yr. 07.02.12

5 4300019585

dtd.22.03.10

Elevators of

DCU &admin

building.

Otis

Elevator Co.

(I) Ltd.

SM

(EM)

25,42,070.88 12,31,273.44 01.01.10 3 yrs 31.12.12

6 4300022591

dtd.09.12.10

Electrical

system

Nityananda

Borah

SM

(EM)

51,51,293.00 32,03,637.12 01.02.11 2 Yrs. 01.02.13

7 4300021081

dtd.03.08.10

Cable laying

& Misc. elect.

Works.

B. R.

Construction

SM

(EM)

28,18,235.00 20,23,246.99 09.01.10 2 yrs. 08.01.12

8 4300023210

dtd.18.02.11

Garden

maintenance

contract.

D. P.

Traders

SM

(EM)

8,00,138.41 4,45,140.95

01.03.11 1 yr. 01.03.12

9

4300022702

dtd.20.12.10

Emerson

make

Industrial AC

Emerson

Network

Power

(India) Pvt.

SM

(EM)

8,37,600.00 8,37,600.00 07.07.10 1 yr. 06.07.11, New

WO placed as

detailed below:

4300026063

dtd. 14.11.11

Emerson

make

Industrial AC

Emerson

Network

Power

(India) Pvt.

SM

(EM)

21,36,400.00 Nil 07.07.11 2 yrs. 06.07.13

10 4300023540

dtd.21.03.11

O&M of

Central AC of

CCR and

CPP

Blue Star

Ltd.

SM

(EM)

41,47,872.60 16,57,489.85 11.01.11 2 Yrs. 10.01.13

11 4300018918

dtd 29.01.10

Earthing

System,

Ovhd. Line of

Refinery ,

RWI & T/I.

B.R.

Construction

SM

(EM)

10,91,550.00 4,40,028.44 01.08.10 1 yr 31.07.11, New

WO placed as

detailed below:

4300025775

dtd. 17.10.11

AMC for

earth Pit

Maint at

Refinery/

NRMT.

Nityananda

Borah

SM

(EM)

15,69,925.00 Nil H/O by

EIC.

2 yrs. Up to 2013

12 4300022144

dtd.02.11.10

Rate Contract

for LT Motor

Rewinding.

Nirmal

Electric

House

SM

(EM)

18,45,000.00 Nil H/O by

EIC.

2 Yrs. 01.11.13

13 4300022890

dtd.10.01.11

AMC for 2

Nos. Stolway

make HVAC

at NRL Site

Model No.

STAVDFH16

-3FP

Marbco

Trading &

Technical

Services.

SM

(EM)

12,08,600.00 274,984.00

04.04.11 3 Yrs. 03.04.14

14 AMC for

Ductable AC

in NRL

Township

Kalyani Club

SM

(EM)

3 Yrs. PR: 10052614

dtd. 26.03.11

raised. Enquiry

floated.

Total Value (Electrical)

32,061,600.80 14,131,101.90

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 27 of 44

Instrumentation:

Sl WO no. Name of the

Work

Contractor EIC WO value Executed value Starting

Date

Cont.

Period

Contract

expiry date /

Status

1 4300022958

dtd.27.01.11

Inst. Jobs-

CPP & Utility

& Workshop.

M. B.

Enterprises

SM

(IM)

36,67,677.00 12,37,663.00

01.02.11 2 yrs. 31.01.13

2 4300022957

dtd.27.01.11

Inst. Jobs

Refinery

J. Hussain SM

(IM)

38,31,317.00 14,41,998.00 01.02.11 2 yrs. 31.01.13

3 4300013926

dt.16.12.08

Assistance

contract for

Fire Alarm

System.

M/s. M.B.

Enterprise

DM

(Inst.)

9,09,741.30 6,84,624.75

01.01.09 2 yrs. Extended up to

31-12-11. New

PR: 10053579

dtd. 25.11.1,

under TR.

4 4300022875

dtd.07.01.11

Pest &

Rodent

Control

refinery,

NRMT & T/S

Mahanta

Enterprises

SM

(IM)

2,80,000.00 1,07,703.00

03.03.11 2 yrs. 02.03.13

5 4300010963

dt.07-04-08

PA system

supplied by

Laraon

Engineers &

Consultant

Pvt. Ltd.

Laraon

Engineers &

Consultant

Ltd.

DM

(Inst.)

7,60,275.00 4,60,262.50

01.05.08 2 yrs. Extended up to

21.07.12.

6 4300017579

dtd.14.10.09

AMC for X-

ray baggage

Inspection

system.

ECIL

Rapiscan

Ltd.

SM

(IM)

8,42,940.00 5,20,360.00

04.10.09 3 yrs. 03.10.13

7 4300015666

dtd 13.05.09

AMC for lab

gas

Chromatogra

ph.

Thermo

Fisher

Scientific

India

SM

(IM)

8,42,400.00 3,90,250.00 10.08.09 2 yrs. 09.08.12

8 4300010821

dt.26-03-08

Pentex Gas

Detection

system

M/S Pentex

Engg.

Pvt.Ltd.

SM

(IM)

29,64,000.00 28,50,000.00 01.04.08 2 yrs Extended up to

31.12.11.

9 4300017749

dtd.23.10.09

Calibration of

Moisture

analyzer

probes.

GE India

Industrial

Pvt. Ltd.

SM

(IM)

10,24,000.00 4,44,000.00 10.11.09 2 yrs

from

receipt

of 1st

lot of

probes.

09.11.11, Fresh

PR estimate

under

preparation.

10 4300018913

dtd.29.01.10

Calibration of

Master Test

Instruments.

Electronics

Test &

Developmt.

SM

(IM)

8,82,480.00 5,79,760.00 01.03.10 2 yrs. 28.02.12

11 4300014382

dt.03-02-09

ICP

Spectrometer

in QC lab.

M/s Perkin

Elmer India

Pvt. Ltd.,

Kolkata

Mgr.

(Inst.)

2,70,000.00 1,80,000.00 04.02.10 2 yrs.

w.e.f.

1st visit

+1 year

03.02.12

12 4300015425

dtd.27.04.09

H2U PSA

Inlet & outlet

analyzers.

M/s ABB

Ltd.

SM

(IM)

7,50,000.00 5,00,000.00 27.04.09 2 yrs Extended up to

26.04.12

13 4300022098

dtd.20.10.10

Yokogawa

make DCS.

M/s

Yokogawa

India Ltd.

SM

(IM)

69,00,000.00 33,00,000.00 20.10.10 2 Yrs. 19.10.12

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 28 of 44

Sl WO no. Name of the

Work

Contractor EIC WO value Executed value Starting

Date

Cont.

Period

Contract

expiry date /

Status

Instrumentation (Contd.):

14 4300010785

dtd 21/03/08

Mark-V

system.

M/s BHEL

GE Gas

Turbine

Services

SM

(IM)

23,52,500.00 15,37,750.00 06.11.08 2 yrs 05.11.10

(Extension

provision of 1

year).

Correspondenc

e with vendor

is on for

extension of

another 1 year

at same terms

& conditions.

15 4300011987

dtd 21/07/08

Visit of

expert for

PSA Inst.

M/s UOP SM

(IM)

17,72,190.00 6,13,197.15 10.11.08 1 yr 31-12-10, Fresh

PR under

preparation.

16 4300018602

dtd 04.01.10

Weigh bridge

& weigh

scales.

M/s Avery

India Ltd.

SM

(IM)

3,54,000.00 2,39,038.50 04.01.10 3 yrs 03.01.13

17 4300012746

dtd17/09/08

AMC of GE

make GMR

PLCs, Model

: Logic

Master 90-70

M/s GE

Fanuc,

Bangalore

DM

(Inst)

18,00,000.00 10,99,420.00 08.11.08 2 yrs 16-09-10,

Proposal for

extension of

contract up to

30.11.11 under

processing in

Coml. dept.

18 4300012852

dtd23/09/08

Visit of

expert for Air

Compressor

(IR) Inst.

M/s IR

(Ingersoll

Rand India)

DM

(Inst)

9,04,000.00 3,18,729.00 02.06.09

(1st

visit)

2 yrs

from

H/O by

EIC

24.05.11,

PR under

preparation.

19 4300020073

dtd.06.05.10

AAQMS of

NRL.

Chemtrols

Industries

Ltd.

SM

(Inst)

3,60,000.00 90,000.00 05.07.10 3 yrs. 04.07.13

20 4300021384

dtd.23.08.10

Ametek make

Tail Gas

Analyzer.

Chemtrols

Industries

Ltd.

SM

(Inst)

3,52,500.00 2,69,381.00 27.09.10 1 yr. 26.09.11, New

WO placed as

detailed below:

4300025966

dtd. 03.11.11

AMC for

Ametek make

Tail Gas &

Feed gas.

Chemtrols

Industries

Ltd.

Mgr.

(IM)

6,30,000.00 Nil H/O by

EIC

2 yrs. Up to 2013.

21 4300024041

dtd. 10.05.11

Rate contract

for inst. cable

and cable tray

jobs.

Dilip Borah DM

(Inst)

13,53, 426.00 3,71,103.80 01.07.11 2 yrs. 30.06.13

22 4300023319

dtd.23.02.11

AMC for QC

Lab Auto

Titroprocesso

r

Metrohm

(India)

Limited

SM

(Inst)

48,000.00 8,000.00 04.07.11 2 yrs. 03.07.13

23 4300025890

dtd. 29.10.11

AMC for QC

Lab Benzene

GC

PerkinElmer

India Pvt Ltd

CM

(Inst)

2,70,000.00 Nil H/O by

EIC

2 yrs. Up to 2013.

Total Value (Instrumentation)

3,27,68,020.00 1,72,43,241.00

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 29 of 44

Sl WO no. Name of the

Work

Contractor EIC WO value Executed value Starting

Date

Cont.

Period

Contract

expiry date /

Status

Civil:

1 4300015807

dtd.28.05.09

AMC for

water supply.

M/s R.K.

Sharma

SM

(CM)

57,19,292.00 60,86,527.66

26.05.09 2 yrs 27.05.11, New

PR: 10052802

P/bids opened

on 06.12.11.

Forwarded to

Civil on

19.12.11 for

scrutiny of

analysis

submitted by

L1 bidder.

2 4300026368

dtd. 07.12.11

AMC for

building

Tayab Ali Mgr.

(CM)

72,92,322.00 Nil H/O by

EIC.

2 yrs Up to 2013

3 4300018768

dtd.12.01.10

AMC for

Insulation.

Prakashan

Engineering

Mgr.

(CM)

47,72,105.97 41,79,043.09 01.02.10 2 yrs 01.02.12, New

PR: 10053498

dtd. 12.11.11

raised. Floating

note put up on

08.12.11.

4 4300018771

dtd 12.01.10

AMC for

structural.

M/s Dipak

Deka

Mgr

(CM)

28,57,504.08 25,88,533.85 01.03.10 2 yrs 28.02.12

5 4300014050

dtd.22.12.08

Misc.

Civil job.

M/s Prabesh

Barman

SM

(CM)

33,79,337.14 30,62,988.83

22.12.08 2 yrs 22.12.10. New

PR: 10053310

dtd. 13.08.11.

Enquiry to

float.

6 4300024898

dtd.02.08.11

Rate Contract

for misc. civil

jobs.

Dipak

Kumar Deka

Mgr

(CM)

49,91,680.88 3,33,448.48 August

11

2 yrs. Up to

August13

7 4300020740

dtd.02.07.10

AMC for

road.

Prabesh

Barman

Mgr

(CM)

56,05,004.00 43,36,531.40 02.08.10 2 yrs 01.08.12

8 4300019208

dtd.26.02.10

AMC for

drain.

Mridul

Phukan

Mgr

(CM)

16,12,282.02

14,79,262.57

18.02.10 2 yrs 17.02.12

9

4300013908

dtd 11.12.08

Painting Jobs

in Refinery &

NRMT.

M/s Lloyd

Insulations

(India) Ltd.

SM

(CM)

50,59,687.44 34,78,867.86 01.05.09 2 yrs 30.04.11. New

WO placed as

detailed below:

4300024718

dtd.11.07.11

Contract for

painting.

North East

Const. Co.

Mgr

(CM)

43,35,000.00 Nil H/O by

EIC.

2 yrs Up to 2013

10 4300021721

dtd.22.09.10

Weeds

control at un-

graded area at

Refinery Site

M/s Dilip

Borah

Mgr

(CM)

24,64,128.00 11,13,959.81 01.12.10 2 yrs 30.11.12

11 4300011511

dtd.31.05.08

Gr VI: Up

keepment of

Civil Maint.

(NRL/ Old

EIL Site Off.)

Promod

Hazarika

Mgr.

(CM)

16,95,840.00 14,16,317.40 01.07.08 2 yrs.+

2 yrs.

Extended up to

30.06.12.

12 4300016581

dtd.30.07.09

Weeds

Control at

OMS area.

Ranjit

Hazarika

Mgr

(CM)

21,46,486.56 18,11,929.04 20.08.09 2 yrs. 19.08.11.

Contract

expired, new

proposal to be

prepared.

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 30 of 44

Sl WO no. Name of the

Work

Contractor EIC WO value Executed value Starting

Date

Cont.

Period

Contract

expiry date /

Status

Civil: (Contd)

13 4300016582

dtd.30.07.09

Weeds

control at

along Units,

open fields &

Admn. Block.

Dilip Saikia Mgr

(CM)

15,77,367.84 13,01,952.54 17.08.09 2 yrs. 16.08.11.

Contract

expired, new

proposal to be

prepared.

14 4300016580

dtd.30.07.09

Weeds

Control at

Utilities &

Flare area

Dipak

Kumar Deka

Mgr

(CM)

17,61,715.98 14,74,135.69 19.08.09 2 yrs. 18.08.11.

Contract

expired, new

proposal to be

prepared.

15 4300020277

dtd.19.05.10

Concrete

cutting /

demolition

M/s N. T

Industries

Mgr

(CM)

10,85,000.00 6,71,623.00 20.05.10 2 yrs. 19.05.12

16 4300022365

dtd.22.11.10

Supervisory

Assistance at

NRL Site.

M/s Dipak

Kumar Deka

Mgr

(CM)

11,01,273.25 5,82,949.01 01.12.10 2 yrs. 30.11.12

17 4300023906

dtd.28.04.11

Tank painting Tristar

Painting &

Engg. Co.

Mgr

(CM)

15,495,697.00 6,98,511.00 05.08.11 2 yrs 04.08.13

Total Value (Civil)

7,29,51,724.20 3,46,16,581.23

Maintenance Planning & IHP:

1 4300016556

dtd.27.07.09

Data entry &

Xerox

machine

Operation.

M/s Samarjit

Sarmah

SM

(MP &

IHP)

8,20,365.76 7,33,161.13 01.08.09 2 Yrs. Extended up to

31.01.12. New

PR: 10052451

dtd. 14.12.11

raised. Enquiry

floated.

Total Value (MP & IHP)

8,20,365.76 7,33,161.13

Grand Total

2,71,753,660.7 1,18,616,154.10

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 31 of 44

A AN NN NE EX XU UR RE E- - I II I

S St ta at tu us s o of f A AF F s sc ch he em me es s a as s o on n 0 03 3. .0 01 1. .1 12 2

Value INR Lakhs

Continuing Schemes

Sl

No

Proj No. Description Sponsor Tot

Cost

Act

Exp

Comt Present Status

Executor: Mech. Maint

1 OP/ 08024 Lube Oil Test kit. MM 22.50 20.40 0.79 PO: 4500008661 dtd. 09.08.10 (Software & Onsite integrated lube oil tester), M/s

Emerson Process Management: System commissioned.

PO: 4500010197 dtd 11.11.11 (1 TR Split AC), M/s Voltas Ltd., CDD: 10.12.11

2 OP/ 09017 Implementation of Reliability

Centered Maint.

MM 55.00 0.00 55.00 PR: 10044281 dtd 05.08.09 (Installation, implementation & s/w): Under hold.

3 OP/ 10004 Auto fire Detection Rim Seal

Fire Protection in Crude Storage

Floating Roof Tank (04 nos.)

MM 660.00 299.71 78.62 WO: 4300021859 dtd. 04.10.10 placed on HSE Engineers Pvt. Ltd. Mumbai. CDD:

01.04.11: Matl rcvd. Cable laying job completed.

4 OP/ 10010 Double Mechanical Seals in

EFRT & IFRT Tanks.

TS-Egy 100.00 64.29 34.04 WO: 4300022613 dtd. 15.12.10 (Design, engg, testing, supply & installation of

Secondary & Primary Seal for EFRT), M/s Sai Tools Pvt. Ltd.: All material received.

4 out of 7 tanks completed.

5 MK/ 10013 Dry Gas Coupling in Bulk LPG

Loading arms.

MO 25.00 3.72 12.86 WO: 4300023760 dtd. 11.04.11 (Coupler & Adapter) placed on Woodfield Systems

Pvt. Ltd. Mumbai: Material received. 1

st

phase commissioned (in 2 nos. of loading

arms). For 2

nd

phase PR: 10053550 dtd 12.10.11 generated (for remaining 8 nos. of

loading arms): Under TR. Sent to user on 25/11/11

6 CF/ 11001/

03

FW line to east side of road 111

at NRMT.

MM 10.00 5.73 0.59 PR: 10048715 dtd. 02.09.10.

Pipes: Material rcvd.

Gate valve: Material rcvd.

Fittings & Flanges: TR rcvd by Comml on 19/11/11

7 CF/ 11001/

04

Additive dosing pump for GT

Naphtha fuel.

MM 4.00 0.00 2.22 PR: 10052587 dtd 04.10.11 (Metering pump): Offer awaited. Due date 29/12/11

8 OP/ 11004 New Injection Water Pump for

HCU

MM 75.00 0.00 19.27 PO: 4500009607 dtd 31.05.2011, M/s Hiro Nisha Systems Pvt. Ltd., Ahmedabad,

CDD 17.11.2011

_ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _

Maintenance Bulletin December 2011 Page 32 of 44

Sl

No

Proj No. Description Sponsor Tot

Cost

Act

Exp

Comt Present Status

Executor: Mech. Maint (Contd)

9 OP/ 11005 Centralized Oil Mist lubrication

system for rotary equipments of

CDU/VDU

MM 400.00 1.91 237.00 PR: 10048862 dtd. 04.12.10 (Oil mist lubrication & engg, installation/

commissioning): Tender cancelled.

10 OP/ 11008 Interconnection of caustic tanks

of ETP & DM Plant