Pre-Fabricated Concrete

Diunggah oleh

Roy Benedict BautistaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pre-Fabricated Concrete

Diunggah oleh

Roy Benedict BautistaHak Cipta:

Format Tersedia

LECTURE ON PRE-CAST CONCRETE

1

Pre-Cast (also known as Pre-Fab)

Ar. SERGE T. CHUA, Jr. fuap M_Arch CTM Sr MRIAS

Associate Professor II

2

INTRODUCTION INTRODUCTION

The concept of precast (also known as

prefabricated) construction includes

those buildings where the majority of

structural components are standardized

and produced in plants in a location away

from the building, and then transported to

the site for assembly.

HISTORY HISTORY

Ancient Romans Ancient Romans

invented and used concrete extensively

Developed technology of form & mould

making and pouring concrete into these,

shaping the concrete into sizes & shapes

to build their complex network

of aqueducts, culverts, and tunnels.

AQUEDUCTS AQUEDUCTS

refinement of pozzolanas, a natural cement, found in the soil.

cements, sand and gravels- the earliest invention of concrete.

the idea to pour this mixture into molds for building precast blocks

marks the beginning of the idea for precast concrete.

3

To prevent them from stirring up trouble at home, the Roman armies were

often kept busy with engineering projects, . Concrete molds were filled

locally by the tens of thousands at construction sites

Different Forms of Precast Parts:

Corner Pieces, Narrow, Short Or Long Blocks, Etc.

The Individual Blocks May Have Looked Like Quarried Stone, But They

Were The First Uses Of Precast Concrete

4

5

1905 Liverpool, England 1905 Liverpool, England

Pre-cast paneled buildings were

pioneered by England city

engineer -

John Alexander John Alexander Brodie Brodie

the first to develop and perfect

the idea of using precast

concrete forms in modern

architectural design

Genius also had him inventing the

football goal net. The tram stables

at Walton in Liverpool followed in

1906. The idea was not taken up

extensively in Britain. However, it

was adopted all over the world,

particularly in Eastern

Europe and Scandinavia.

John Alexander John Alexander Brodie Brodie

6

Transamerica Pyramid , San Francisco

The Tallest Building To Use Precast Concrete

PRECAST CONCRETE PRODUCTS PRECAST CONCRETE PRODUCTS

1. Structural Members

a. Slabs

b. Beams & Girders

c. Walls

d. Stairs

2. Agricultural

3. Building

4. Sanitary & Stormwater Management

5. Transportation & traffic Related

Products

6. Utility Structures

7. Water & Wastewater Products

POPULAR USES: POPULAR USES:

1. Concrete curtain walls

2. Exterior cladding (exposed

aggregate)

3. Structural walls

4. Ability to precast in three dimensions

allows precast panels to form parts of

mechanical systems

7

8

BUNKERS & SILOS BUNKERS & SILOS

9

BUNKERS & SILOS BUNKERS & SILOS

10

RETAINING WALLS RETAINING WALLS

11

CATCH BASINS CATCH BASINS

12

BOX CULVERTS BOX CULVERTS

13

UTILITY POLES & BASES UTILITY POLES & BASES

14

SEPTIC TANKS SEPTIC TANKS

PRECAST CONCRETE SLAB TYPES: PRECAST CONCRETE SLAB TYPES:

1. (Solid) Flat slab

2. Hollow Core slab

3. Double Tee

4. Single Tee

15

PRECAST SLAB TYPES: PRECAST SLAB TYPES:

1. (Solid) Flat slab

Thicknesses of 0.10m, 0.15 and 0.20;

thinnest @ 0.07 m.

Spans up to 25-0 / 7.62 m

Standard panel width = 4-0 or 1.20 m.

when used on several continuous

spans having widths from 120 to 240

cm. with length up to 11 m

2. Hollow Core slab

Thicknesses of 0.10m, 0.15m,

0.20m,0.25m and 0.30m

Spans up to 40-0 / 12.19 m

Standard panel width = 4-0" / 1.2 m

As lightweight member

made by extrusion in special machine

Thickness ranges from 10 to 20 cm.

Widths from 60 to 120 cm.

As roof

Spans augmented up to 9 m when 5

cm topping is applied to act

monolithically with the hollow planks.

16

17

(Solid) Flat slab

Hollow Core

Hollow Core

17

PRECAST SLABS PRECAST SLABS

3. Single Tee

As Roofing

Spans up to more than

30m.

Flanges of the tee T

constitute the floor or roof

slab.

4. Double Tee

most widely used section

For Longer Span Having

Depth Of 4.00 To 6.50 M

generally used on roof

having a span up to 18 m

applied concrete topping

of at least 5 cm. acts

monolithically with the

precast members.

could be used on floors up

to 15 m span depending

upon the load and

deflection requirements.

Roofs & Floors are made in wide variety of design to suit the different to suit

conditions of span, magnitude of load, fire ratings and appearance.

Single Tee

Double Tee

18

PRECAST BEAMS PRECAST BEAMS ((precast beam shapes depend upon the manner of framing)

19

1. Rectangular (RB)

Typical beam width = 0.30 m and

0.40m

Spans up to 50-0" / 15.240 m

Typical designation = 16RB24 (16 =

width in inches, 24 = depth in

inches)

Where the floor and roof

members are supported on top of

the beam

2. "L" and "IT" (inverted "Tee")

beams (LB and IT)

Ledger beam

designed to reduce the height of

the floor and roof construction.

used to provide bearing

Typically used to support slabs,

walls, masonry, and beams

Typical beam width = 0.30m

Depths of 0.50m, 0.71m, 0.91m,

1.1m, 1.32m, & 1,5m.

3. Single Tee" beams (ST)

Combination beam and slab

Spans up to 120-0" / 36. 58m

Typical width = 8-0" / 2.4m

Typical depths of 36" and 48

4. Double Tee" beams (DT)

Combination beam and slab

Spans up to 100-0" / 30.48m

Typical width = 8-0" / 2.4m

Depths of 12", 18", 24" and 32"

PRECAST RECTANGULAR BEAMS PRECAST RECTANGULAR BEAMS

20

PRECAST L & IT BEAMS PRECAST L & IT BEAMS

21

PRECAST L BEAMS PRECAST L BEAMS

22

PRECAST Ledger & IT BEAMS PRECAST Ledger & IT BEAMS

23

24

PRECAST ST BEAMS PRECAST ST BEAMS

25

PRECAST DT BEAMS PRECAST DT BEAMS

26

PRECAST DT BEAMS PRECAST DT BEAMS

PRECAST IT BEAMS PRECAST IT BEAMS

27

PRECAST COLUMN PRECAST COLUMN

Axial Support

Size ranges from 30 to 60

cm.

Multi storey construction

columns are made

continuous up to four

stories using corbels to

provide bearing for the

beam.

sometimes used directly

to support double tee

floor members without

the use of immediate

member.

28

PRECAST COLUMNS

Dimensions SINGLE TIER WITH CORBELS DOUBLE TIER WITH CORBELS

Width (B): 300 ~ 900 at 50 mm increment 300 ~ 900 at 50 mm increment

Depth (H): 300 ~ 900 at 50 mm increment 300 ~ 900 at 50 mm increment

Height (L): 3.0 m ~14.0 m at 50 mm increment 6.0 m ~14.0 m at 50 mm increment

Wall Panels Wall Panels

Standard widths: 8-0/ 2.4m

Features: Flat or have architectural

features such as window and door

openings, ribs, reveals, textures,

sandwich (insulation built-in),

sculptured, etc.

Designs: depending upon the

Architectural requirements.

Uses: as curtain walls attached to

columns, beams or sometimes on

bearing walls.

improve the thermal insulation of a

panel, glass foam, glass fibers or

expanded plastic is inserted between

the two layers of interconnecting

lightweight concrete adequately

bonded to act as one unit.

The stress on the precast unit made in

the in the factory is greater than

those cast in place due to handling

and erection. Hence, control of

cracking is of great importance.

29

Wall Panel Types Wall Panel Types

1. Flat Panel

2. Vertical Window or Mullion Panel

3. Horizontal Window or Mullion Panel

4. Ribbed Panel

5. Double Tee Panel

6. Spandrel

3.

1.

2. 4. 5.

6.

30

31

31

MODERN DAY USES MODERN DAY USES

Concrete curtain walls

Exterior cladding (may include

exposed aggregate)

Structural walls

Parts of mechanical systems

3-dimensional ability

ATTACHMENT METHODS: ATTACHMENT METHODS:

1. Weld Plates

most common method of

attachment

use of steel weld plates.

embedded plates in the

precast members are used as

welding surfaces for loose

connecting plates or angles

2. Rebar & Grout

with slabs, reinforcing bars are

spliced into slabs and grouted

in place

32

33

DOUBLE WALL PRECAST DOUBLE WALL PRECAST

CONCRETE SANDWICH PANELS CONCRETE SANDWICH PANELS

Advantages

Very rapid speed of erection

Good quality control

Entire building can be

precast - walls, floors, beams,

etc.

Disadvantages

Very heavy members

Camber in beams and slabs

Very small margin for error

Connections may be difficult

Need bracing during on-site

erection of structure

Somewhat limited building

design flexibility

Consists of two wythes of concrete

separated by an insulated void.

Thickness (commonly specified)-

8 inches.

Connection: the two wythes of the

interior and exterior concrete layers

are held together with steel

Height : up to a limit of 12 feet.

a 9-foot clear height preferred for the

quality of look and feel it affords a

building trusses

Uses : multi-family, townhouses,

condominiums, apartments, hotels

and motels, dormitories and schools,

and single-family homes

Qualities: Speed of construction,

durability of finished structure, and

energy-efficiency

34

FLOOR & ROOF SLAB SYSTEM

REMOVABLE STEEL FORM

PERMANENT CONCRETE FORM

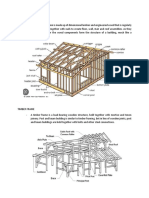

PREFAB SYSTEMS

35

CC--JOIST/PCF/R.C. Slab JOIST/PCF/R.C. Slab

36

PCF Dimensions PCF Dimensions

37

CC--JOIST on Steel I JOIST on Steel I--Beam Beam

38

CC--JOIST on Top of Beam JOIST on Top of Beam

39

40

Pre Pre--Cast Concrete Forms Cast Concrete Forms

41

INSTALLATION GUIDE FOR C INSTALLATION GUIDE FOR C--JOIST/PCF SYSTEM: JOIST/PCF SYSTEM:

1. May be installed or placed manually or with the use of hoisting

equipment.

2. Laid on top of beams (concrete or steel I-beams) on its specified

spacing using a minimum of 4 seating clearance on concrete beams

and at least 3 bearing capacity for steel I-beams.

3. With joists set in its final spacing, PCF(s) are then placed on top of C-

Joists shoulder in between distances, piece by piece from beam

interior face to end of span.

4. Minimum 10 dowel bars spaced @ 0.30 m. to 0.60 m. o. c. with

about L/5 bend development length are required as shear

connectors.

5. 6mm slab temperature reinforcement @ 0.15 m. o. c. b. w., welded

wire fabric or equivalent. Temperature bars are placed d/2 of

specified slab thickness.

6. 50 to 75 cm thick structural concrete slab with minimum compressive

strength of 3,000 psi @ 28 days taken from top line of C-Joist.

7. Shoring: NO shoring is needed for C-Joist 2.50 m. span and below.

Mid-span shoring for spans above 2.50 m. to 5.00 m. and released

ONL after 7 days.

8. Standard installation of utilities as per conventional reinforced

concrete systems.

Anda mungkin juga menyukai

- Prefaricated Structures Unit IIDokumen55 halamanPrefaricated Structures Unit IIvgshankar26Belum ada peringkat

- Why Install A Skillion Roof?: Ridge PitchDokumen2 halamanWhy Install A Skillion Roof?: Ridge PitchTeodoro Miguel Carlos IsraelBelum ada peringkat

- Roofing in SudanDokumen35 halamanRoofing in SudanChitrang JhaBelum ada peringkat

- Lift Slab 2Dokumen8 halamanLift Slab 2mr_sunnydeiBelum ada peringkat

- Roofing ShinglesDokumen10 halamanRoofing Shinglescertainteed 98Belum ada peringkat

- Advantages of Shell Structures PDFDokumen3 halamanAdvantages of Shell Structures PDFNeven Ahmed HassanBelum ada peringkat

- Types of Building TrussDokumen3 halamanTypes of Building Trussrobus0110Belum ada peringkat

- Masonry and Concrete - FinDokumen12 halamanMasonry and Concrete - FinSarah Marie Nueva Sierra100% (1)

- Stone Cladding Fixation 1Dokumen3 halamanStone Cladding Fixation 1wadyspring100% (2)

- Performance SpecificationsDokumen27 halamanPerformance SpecificationsDebbie Jhem DicamBelum ada peringkat

- Footing Design As Per AstmDokumen102 halamanFooting Design As Per AstmZankar R ParikhBelum ada peringkat

- 03930-Concrete Repair-Rev.0 PDFDokumen16 halaman03930-Concrete Repair-Rev.0 PDFMithun UdayanarayanaBelum ada peringkat

- Roof TrussesDokumen19 halamanRoof TrussesShantanuShahBelum ada peringkat

- Concrete BlocksDokumen24 halamanConcrete BlocksMahmood MuftiBelum ada peringkat

- Fort Collins Parking StructureDokumen4 halamanFort Collins Parking Structureunix0123Belum ada peringkat

- Concrete WorksDokumen82 halamanConcrete WorksarnoldalejadoBelum ada peringkat

- Roofing SystemsDokumen13 halamanRoofing SystemsMohamed Hisham100% (1)

- Highrise InformationDokumen59 halamanHighrise InformationNupur BhadraBelum ada peringkat

- Wall Construction Wood Frame in CanadaDokumen146 halamanWall Construction Wood Frame in Canadadsmonteloyolax0% (1)

- Differences Between Galvalume and Galvanized in Metal RoofingDokumen2 halamanDifferences Between Galvalume and Galvanized in Metal RoofingPPM100% (1)

- Cost Estimation - Roofing WorksDokumen2 halamanCost Estimation - Roofing WorksAnjo BalucasBelum ada peringkat

- Tyoes of Steel ConstructionDokumen1 halamanTyoes of Steel ConstructionIshwarya SrikanthBelum ada peringkat

- TBA 09 Detailing of Clay MasonryDokumen42 halamanTBA 09 Detailing of Clay MasonryHenderson CheungBelum ada peringkat

- Micro Concrete - ROOFDokumen4 halamanMicro Concrete - ROOFRajesh ChowhanBelum ada peringkat

- Masonry ManualDokumen114 halamanMasonry Manualdpdqh0Belum ada peringkat

- VMZINC Standing Seam Install Guide 2015 R5 PDFDokumen48 halamanVMZINC Standing Seam Install Guide 2015 R5 PDFAntónio AlmeidaBelum ada peringkat

- 3 Final Plates PDFDokumen48 halaman3 Final Plates PDFAriane Joyze BronzalBelum ada peringkat

- Stone Veneer-Faced Precast Concrete PanelsDokumen28 halamanStone Veneer-Faced Precast Concrete PanelsdantranzBelum ada peringkat

- Retaining Wall DetailDokumen9 halamanRetaining Wall DetailRonald KahoraBelum ada peringkat

- 05 - 12 - 00 - 00 (05120) - Steel FramingDokumen12 halaman05 - 12 - 00 - 00 (05120) - Steel FramingMatthew Ho Choon LimBelum ada peringkat

- Masonry and ConcreteDokumen10 halamanMasonry and ConcreteMelwin MakalintalBelum ada peringkat

- 9 Types of Wood Framing To KnowDokumen19 halaman9 Types of Wood Framing To KnowMarion LauritoBelum ada peringkat

- Canam Steel DeckDokumen168 halamanCanam Steel DeckAnonymous 8hx6hKN3Belum ada peringkat

- Ultra High Rise BuildingsDokumen60 halamanUltra High Rise BuildingsPallav Paban Baruah100% (1)

- Basement InsulationDokumen12 halamanBasement InsulationAdam RossmillerBelum ada peringkat

- Mortarless CMU SystemsDokumen10 halamanMortarless CMU Systemsomisla100% (1)

- Basic Steps For Building A DeckDokumen5 halamanBasic Steps For Building A DeckRi SovannaphumiBelum ada peringkat

- Concrete LintelsDokumen24 halamanConcrete LintelsAmber ChristensenBelum ada peringkat

- Timber CladdingDokumen13 halamanTimber CladdingMegha RajBelum ada peringkat

- Ret Walls DetailsDokumen8 halamanRet Walls DetailstouchyarrowBelum ada peringkat

- Mitek ManualDokumen124 halamanMitek ManualTuroyBelum ada peringkat

- Roofing Fact Sheet-2 Column Format052820final PDFDokumen6 halamanRoofing Fact Sheet-2 Column Format052820final PDFDiego Quiroga CruzBelum ada peringkat

- Framing PDFDokumen5 halamanFraming PDFKenneth Ignacio ArcillaBelum ada peringkat

- Air Leakage Control Materials and TechniquesDokumen15 halamanAir Leakage Control Materials and TechniquesAbubakkar Siddiq100% (2)

- Precast Concrete and Prestressed Concrete: Report Submitted By: Group IiDokumen6 halamanPrecast Concrete and Prestressed Concrete: Report Submitted By: Group IiVaishnavi SikchiBelum ada peringkat

- Reinforcing Steel Design GuideDokumen18 halamanReinforcing Steel Design GuidewillchamBelum ada peringkat

- 21B Brick Masonry Cavity Walls Detailing PDFDokumen15 halaman21B Brick Masonry Cavity Walls Detailing PDFLuísBelum ada peringkat

- Layers of A Floor - Anatomy, and Parts (Illustrated)Dokumen8 halamanLayers of A Floor - Anatomy, and Parts (Illustrated)Melaine A. FranciscoBelum ada peringkat

- How To Prevent Cracks in Buildings: General Measures For Protection of Cracks.Dokumen10 halamanHow To Prevent Cracks in Buildings: General Measures For Protection of Cracks.Cimpureanu FlorinBelum ada peringkat

- Wall and Skylight ConstructionDokumen33 halamanWall and Skylight Constructioncristian santillanBelum ada peringkat

- Building TechnologyDokumen4 halamanBuilding TechnologyDanica LuarezBelum ada peringkat

- Roof CoveringsDokumen25 halamanRoof CoveringsBhanu Pratap SinghBelum ada peringkat

- Pre Cast ConstructionDokumen55 halamanPre Cast ConstructionAmalaBelum ada peringkat

- Waffle Box Building Technology PhilippinesDokumen20 halamanWaffle Box Building Technology PhilippinesRalphGeraldF.LopezBelum ada peringkat

- Post Tensioning in Building StructuresDokumen25 halamanPost Tensioning in Building StructuresBaranitharan ABelum ada peringkat

- Concrete: A Guide To One Hundred AdvantagesDokumen59 halamanConcrete: A Guide To One Hundred Advantageskannanperiyanan100% (4)

- Precast Concrete PDFDokumen36 halamanPrecast Concrete PDFTauwab DanishBelum ada peringkat

- PrecastDokumen35 halamanPrecastalyssa0% (1)

- Footing Systems Part ADokumen16 halamanFooting Systems Part ASixd WaznineBelum ada peringkat

- Prestress ConcreteDokumen135 halamanPrestress ConcreteNishant AgrawalBelum ada peringkat

- Types of Philippines Electrical Socket OutletsDokumen9 halamanTypes of Philippines Electrical Socket OutletsRoy Benedict BautistaBelum ada peringkat

- Thesis PreparationDokumen23 halamanThesis PreparationRoy Benedict BautistaBelum ada peringkat

- Quiet Classrooms - How To Measure Reverberation TimeDokumen3 halamanQuiet Classrooms - How To Measure Reverberation TimeRoy Benedict BautistaBelum ada peringkat

- TCT List 2014 & 2015Dokumen14 halamanTCT List 2014 & 2015Roy Benedict BautistaBelum ada peringkat

- AdU Thesis Format - Archi v2Dokumen49 halamanAdU Thesis Format - Archi v2Roy Benedict Bautista100% (1)

- Guest ListDokumen5 halamanGuest ListRoy Benedict BautistaBelum ada peringkat

- Hicc 100821062618 Phpapp01Dokumen25 halamanHicc 100821062618 Phpapp01Roy Benedict BautistaBelum ada peringkat

- Gothic Architecture FranceDokumen77 halamanGothic Architecture FranceRoy Benedict Bautista100% (1)

- Wedding ChecklistDokumen8 halamanWedding ChecklistRoy Benedict BautistaBelum ada peringkat

- Adamson Arki OJT GuidelinesDokumen11 halamanAdamson Arki OJT GuidelinesRoy Benedict BautistaBelum ada peringkat

- Visual Acuity and Perception: Theory of Architecture 01 - Part 2Dokumen41 halamanVisual Acuity and Perception: Theory of Architecture 01 - Part 2Roy Benedict Bautista100% (1)

- Colored Pencil TechniqueDokumen41 halamanColored Pencil TechniqueRoy Benedict Bautista83% (6)

- The Six Stages of The Church - TheologyDokumen3 halamanThe Six Stages of The Church - TheologyRoy Benedict Bautista100% (4)

- Tree Inventory of Ninoy Aquino Parks & WildlifeDokumen5 halamanTree Inventory of Ninoy Aquino Parks & WildlifeRoy Benedict Bautista100% (1)

- TOA1 Kinesthetic Qualities of SpaceDokumen15 halamanTOA1 Kinesthetic Qualities of SpaceRoy Benedict Bautista33% (9)

- Theory of ArchitectureDokumen12 halamanTheory of ArchitectureRoy Benedict BautistaBelum ada peringkat

- Theory - PerceptionDokumen6 halamanTheory - PerceptionRoy Benedict BautistaBelum ada peringkat

- Historical Context of Ninoy Aquino Parks & WildlifeDokumen1 halamanHistorical Context of Ninoy Aquino Parks & WildlifeRoy Benedict BautistaBelum ada peringkat

- Colored Pencil TechniquesDokumen41 halamanColored Pencil TechniquesRoy Benedict Bautista63% (24)

- Aristotle Metaphysics Lambda Accessed 201111 Classicalk LibraryDokumen19 halamanAristotle Metaphysics Lambda Accessed 201111 Classicalk Librarygijsbo2000Belum ada peringkat

- Medrano, Rene LynnDokumen2 halamanMedrano, Rene LynnRene Lynn Labing-isa Malik-MedranoBelum ada peringkat

- En 1993 09Dokumen160 halamanEn 1993 09Vio ChiBelum ada peringkat

- 4 PDFDokumen81 halaman4 PDFMohammad K. NassouraBelum ada peringkat

- CE-23113-SP-902-R01-00 Asset SpecificationDokumen14 halamanCE-23113-SP-902-R01-00 Asset SpecificationСветлана ФайберBelum ada peringkat

- Chemical Engineering & Processing: Process Intensi Fication: ArticleinfoDokumen9 halamanChemical Engineering & Processing: Process Intensi Fication: Articleinfomiza adlinBelum ada peringkat

- Caroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledDokumen2 halamanCaroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledCaroline BabinBelum ada peringkat

- Manual HobartDokumen39 halamanManual HobartВолодимир БроBelum ada peringkat

- Topic 3 Intellectual RevolutionDokumen20 halamanTopic 3 Intellectual RevolutionOlive April TampipiBelum ada peringkat

- Corrosion Protection PT Tosanda Dwi SapurwaDokumen18 halamanCorrosion Protection PT Tosanda Dwi SapurwaYoga FirmansyahBelum ada peringkat

- Myers Briggs Type Indicator-2Dokumen1 halamanMyers Briggs Type Indicator-2api-261818438Belum ada peringkat

- ISO-50001-JK-WhiteDokumen24 halamanISO-50001-JK-WhiteAgustinusDwiSusantoBelum ada peringkat

- Namagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishDokumen10 halamanNamagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishMonydit santinoBelum ada peringkat

- Brp-Rotax Chassis Approval FormDokumen3 halamanBrp-Rotax Chassis Approval Formdelta compBelum ada peringkat

- Make Yeast StarterDokumen2 halamanMake Yeast StarterAlexandraBelum ada peringkat

- Number CardsDokumen21 halamanNumber CardsCachipún Lab CreativoBelum ada peringkat

- SQL - Day 2: Structured Query LanguageDokumen10 halamanSQL - Day 2: Structured Query LanguageNight KingBelum ada peringkat

- SAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitDokumen61 halamanSAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitARPITA BISWASBelum ada peringkat

- Manitou 1350RDokumen4 halamanManitou 1350RcandlaganBelum ada peringkat

- DA-I Question Bank From Module 1-3 of PHY1701 Course, Winter Semester 2020-21Dokumen6 halamanDA-I Question Bank From Module 1-3 of PHY1701 Course, Winter Semester 2020-21Likith MallipeddiBelum ada peringkat

- CTRLX Automation BrochureDokumen60 halamanCTRLX Automation BrochureNinja do SofáBelum ada peringkat

- Drsent PT Practice Sba OspfDokumen10 halamanDrsent PT Practice Sba OspfEnergyfellowBelum ada peringkat

- 2018-2019 Annual Algebra Course 1 Contest: InstructionsDokumen2 halaman2018-2019 Annual Algebra Course 1 Contest: InstructionsNaresh100% (1)

- Most Dangerous City - Mainstreet/Postmedia PollDokumen35 halamanMost Dangerous City - Mainstreet/Postmedia PollTessa VanderhartBelum ada peringkat

- DAY 3 STRESS Ielts NguyenhuyenDokumen1 halamanDAY 3 STRESS Ielts NguyenhuyenTĩnh HạBelum ada peringkat

- 74 Series Logic ICsDokumen6 halaman74 Series Logic ICsanon-466841Belum ada peringkat

- Solutions of Inverse Geodetic Problem in Navigational Applications PDFDokumen5 halamanSolutions of Inverse Geodetic Problem in Navigational Applications PDFLacci123Belum ada peringkat

- Angle ModulationDokumen26 halamanAngle ModulationAtish RanjanBelum ada peringkat

- Shift Registers NotesDokumen146 halamanShift Registers NotesRajat KumarBelum ada peringkat

- Probability Theory - VaradhanDokumen6 halamanProbability Theory - VaradhanTom HenBelum ada peringkat