Air Cooled Condenser - A Dry Cooling Tower

Diunggah oleh

Gmail440 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

253 tayangan6 halamanAn Air Cooled Condenser provides a means of condensing steam without using cooling water, when a lack of water prevents use of a traditional water cooled condenser in a steam power plant.An air cooled condenser is an option for condensing steam if water availability is limited.

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniAn Air Cooled Condenser provides a means of condensing steam without using cooling water, when a lack of water prevents use of a traditional water cooled condenser in a steam power plant.An air cooled condenser is an option for condensing steam if water availability is limited.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

253 tayangan6 halamanAir Cooled Condenser - A Dry Cooling Tower

Diunggah oleh

Gmail44An Air Cooled Condenser provides a means of condensing steam without using cooling water, when a lack of water prevents use of a traditional water cooled condenser in a steam power plant.An air cooled condenser is an option for condensing steam if water availability is limited.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 6

Air Cooled Condensers - A Dry Cooling Tower

Air-cooled condensers, refer as fin-and-tube condensers works on the principle

of air cooled air conditioning system.

While the evaporator is the component in which heat is absorbed, the condenser

is the point of heat rejection in an air conditioning or refrigeration .

The air-cooled condenser uses air to extract the sensible heat and the latent heat

of condensation released by the refrigerant during condensation.

The refrigerant from the compressor enters the condenser as hot super heated

gas and leaves it (usually) as sub cooled liquid to continue the refrigerant cycle.

An Air Cooled Condenser provides a means of condensing steam without using

cooling water, when a lack of water prevents use of a traditional water cooled

condenser in a steam power plant.

An air cooled condenser is an option for condensing steam if water availability is

limited.

Steam Power Plant Rankine Cycle with Air Cooled Condenser,

Types of Air Cooled Condenser : Natural draft and Mechanical draft.

The most common type of air cooled condenser is the mechanical draft, which

has an overall A-frame configuration.

The low pressure steam exhausted from the turbine goes into the air cooled

condenser in the large tube at the top of the A-frame. The steam flows down through

finned tubes that make up the A-frame and is cooled and condensed by air being blown

past the finned tubes by a fan or fans at the bottom.

A plant with an air cooled condenser uses only about 5% as much water as one

with once through cooling or a wet cooling tower.

Description of Air- Cooled Condensers

Air Cooled Condensers are cooled by condenser fans which blow air across the

condenser coil to promote convective heat transfer.

The fans used commonly are axial flow, propeller fans, which are capable of

moving large volumes of air.

Air-cooled condensers are designed for either draw thru' or blow thru' air flow.

a) With draw thru' design, the face velocity across the coil is more uniform and the coil is

more effectively utilized However, the hot discharge air off the condenser coil flows

over the fan and the drive motor, which have to withstand the hot air temperature.

b) In blow thru' designs, the fan and drive motor have ambient air flowing over them. But

the face velocity across the coil is less uniform than in the draw thru' design.

The heat rejection capacity of an air-cooled condenser is proportional to the

condenser temperature difference , which is defined as the difference in saturated

condensing temperature and the air intake dry bulb temperature.

Enhancement of Air Cooled Condenser Performance

The Air Cooled Condenser though having advantage over water cooled condenser

,but have reduced plant efficiency and output in the hotter part of the year.A technique

being investigated for improving plant efficiency and output in hot weather is inlet spray

cooling, that is, spraying water into the air entering the condenser during the hot part of

the year.

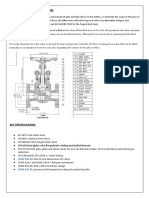

Technical Specification(with reference to McEnergy MONO CU, Air cooled condensing

unit)

Are you ready to have a tour through Air Cooled Condenser,Please click the below link

GEA Dry Cooling - Air Cooled Condenser (ACC)

References:

http://www.geapowercooling.com/opencms/opencms/gpc/en/products/Air_Cooled

_Condensers/

http://www.brighthubengineering.com/power-plants/64903-steam-power-plant-

condenser-cooling-part-three-the-air-cooled-condenser/#imgn_0

http://www.ishrae.in/journals/2001july/article03.html

http://www.mcquay.ru/downloads/pm_mcenergy_mono_cu_en.pdf

Anda mungkin juga menyukai

- Air Cooled CondensersDokumen13 halamanAir Cooled CondensersSyed ShoebBelum ada peringkat

- How Surface Condensers WorkDokumen12 halamanHow Surface Condensers WorkPrabir Kumar Pati100% (1)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ADari EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&APenilaian: 5 dari 5 bintang5/5 (1)

- Air-Cooled Condenser Piping Design RequirementsDokumen3 halamanAir-Cooled Condenser Piping Design RequirementsHoney TiwariBelum ada peringkat

- Introducing Standards for AIR COOLED CONDENSERSDokumen8 halamanIntroducing Standards for AIR COOLED CONDENSERSSyed HafeezBelum ada peringkat

- Air Cooled CondensersDokumen6 halamanAir Cooled CondensersruchiajmerBelum ada peringkat

- Key Parameters For Air Cooled Condenser DesignDokumen12 halamanKey Parameters For Air Cooled Condenser DesignmohantyomBelum ada peringkat

- Air Cooled CondenserDokumen129 halamanAir Cooled CondenserAnonymous 3fTYXaW7W100% (1)

- Air Cooled CondenserDokumen3 halamanAir Cooled CondenserJonathan Buenaobra100% (1)

- Heller System PPT 3 Cooling SystemsDokumen34 halamanHeller System PPT 3 Cooling SystemsShrey DattaBelum ada peringkat

- Boiler NotesDokumen34 halamanBoiler NotesRakesh Singh BhadoriyaBelum ada peringkat

- Vacuum Breaker ValveDokumen2 halamanVacuum Breaker ValveRaghunath YeturiBelum ada peringkat

- Improving Boiler Efficiency by Using Air PreheaterDokumen14 halamanImproving Boiler Efficiency by Using Air PreheaterBudiharyatno Arif PangestuBelum ada peringkat

- Air Cooled Condenser and Non PerformanceDokumen67 halamanAir Cooled Condenser and Non Performanceparthi20065768100% (2)

- WH Vacuum in Steam TurbineDokumen2 halamanWH Vacuum in Steam Turbinemiths_0087Belum ada peringkat

- Air Cooled CondenserDokumen7 halamanAir Cooled Condensermoreds1983Belum ada peringkat

- Performance Evaluation of Air PreheaterDokumen8 halamanPerformance Evaluation of Air PreheaterAndria MatthewsBelum ada peringkat

- 660MW Air Cooled CondenserDokumen26 halaman660MW Air Cooled CondenserRaj_Jai030% (1)

- Once Through and Drum Type Boiler Designs ComparedDokumen3 halamanOnce Through and Drum Type Boiler Designs ComparedagusfaizinBelum ada peringkat

- Air Cooled Heat Exchanger !Dokumen17 halamanAir Cooled Heat Exchanger !RehinaBelum ada peringkat

- Reducing Steam Header PressureDokumen1 halamanReducing Steam Header Pressuresj_scribdBelum ada peringkat

- Maintain STEAM-MATIC FT boiler generatorDokumen3 halamanMaintain STEAM-MATIC FT boiler generatorAppleuk SudarBelum ada peringkat

- LP Turbine Breakable Diaphragm Design and Failure AnalysisDokumen7 halamanLP Turbine Breakable Diaphragm Design and Failure AnalysisAli HassanBelum ada peringkat

- Turbine AccessoriesDokumen22 halamanTurbine Accessoriessrikanth9555Belum ada peringkat

- HRSG StartupDokumen20 halamanHRSG Startupsujiv_sujiv1278100% (1)

- Single and Multistage Steam Jet Ejectors: TorinoDokumen12 halamanSingle and Multistage Steam Jet Ejectors: TorinoSuman SenapatiBelum ada peringkat

- Globe Valve Bs 1873 and Api 602: ASME B16.10Dokumen7 halamanGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILBelum ada peringkat

- Steam Jet EjectorsDokumen4 halamanSteam Jet EjectorsMuhammad Kamal WisyaldinBelum ada peringkat

- Flash Steam SystemDokumen4 halamanFlash Steam SystemAnonymous CX51waIBelum ada peringkat

- Shanghai Boiler Works Co. boiler specificationsDokumen221 halamanShanghai Boiler Works Co. boiler specificationsChandrahas SahuBelum ada peringkat

- HRSG OPERATION AND STARTUPDokumen7 halamanHRSG OPERATION AND STARTUPM Moarraf Naeem100% (1)

- Boiler Operator Exam Preparation Guide pdf-1 PDFDokumen27 halamanBoiler Operator Exam Preparation Guide pdf-1 PDFEmmanuel Jesus Marquez Rea100% (1)

- Applications of Different Types of Steam Traps - TLV - A Steam Specialist Company (United Arab Emirates) PDFDokumen5 halamanApplications of Different Types of Steam Traps - TLV - A Steam Specialist Company (United Arab Emirates) PDFDũng LêBelum ada peringkat

- 023 CepDokumen12 halaman023 Cepjp mishraBelum ada peringkat

- Tubine Bypass SystemDokumen12 halamanTubine Bypass Systemkalyanm203515Belum ada peringkat

- Turbine Auxiliaries - Arrangement of Turbine Auxiliaries - ALL ABOUT POWER PLANTDokumen14 halamanTurbine Auxiliaries - Arrangement of Turbine Auxiliaries - ALL ABOUT POWER PLANTKolahalam RakeshrajuBelum ada peringkat

- Liquid Ring Vacuum Pumps Intial Start Up ProceduresDokumen3 halamanLiquid Ring Vacuum Pumps Intial Start Up ProceduresFA Ay100% (1)

- Positioning of Air Cooled CondensersDokumen9 halamanPositioning of Air Cooled CondensersAlexBelum ada peringkat

- Chapter 15 Condensate SystemDokumen11 halamanChapter 15 Condensate SystemsambhuBelum ada peringkat

- 3 Element Drum Level ControlDokumen3 halaman3 Element Drum Level ControlSriteja JosyulaBelum ada peringkat

- IBR Tutorial for 2nd Class Boiler Engineer ExamDokumen11 halamanIBR Tutorial for 2nd Class Boiler Engineer ExamRavi ShankarBelum ada peringkat

- Presentation On Steam TrapsDokumen18 halamanPresentation On Steam Trapskailash100% (1)

- CondenserDokumen4 halamanCondensermaneeshjha9368100% (1)

- Thermodynamic Analysis of A Steam TurbineDokumen3 halamanThermodynamic Analysis of A Steam TurbinePhil Engel100% (1)

- IAC PAC Power Plant BarhDokumen19 halamanIAC PAC Power Plant BarhMohammad AtaullahBelum ada peringkat

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDokumen224 halamanBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadBelum ada peringkat

- Condensate Cycle SystemDokumen26 halamanCondensate Cycle SystemBhumit Sagathiya100% (2)

- Extraction Condensing Steam Turbine PDFDokumen2 halamanExtraction Condensing Steam Turbine PDFAaronBelum ada peringkat

- Standard For Closed Feedwater HeatersDokumen80 halamanStandard For Closed Feedwater Heatersrenoyabo100% (2)

- Air Cooled Condenser Design, Spec & Operation GuidelineDokumen176 halamanAir Cooled Condenser Design, Spec & Operation GuidelinemohdnazirBelum ada peringkat

- Surging & Blow Out of Loop Seals in A CFBC BoilerDokumen9 halamanSurging & Blow Out of Loop Seals in A CFBC Boilermohamed faragBelum ada peringkat

- Turbine Side PumpsDokumen25 halamanTurbine Side PumpsPrakash Choudhary67% (3)

- Training On Steam CondensersDokumen33 halamanTraining On Steam CondensersMayank GuptaBelum ada peringkat

- (@) Air Conditioning Using Exhaust Gas of AutomobilesDokumen28 halaman(@) Air Conditioning Using Exhaust Gas of AutomobilesJithin JoseBelum ada peringkat

- Cooling Towers: Cold Water BasinDokumen13 halamanCooling Towers: Cold Water BasinmichsantosBelum ada peringkat

- Vapor Compression Refrigeration Cycle ExplainedDokumen16 halamanVapor Compression Refrigeration Cycle ExplainedDiether RigorBelum ada peringkat

- Design and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingDokumen16 halamanDesign and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingSajjad HasanBelum ada peringkat

- Air Cooled Heat Exchnger FormatedDokumen43 halamanAir Cooled Heat Exchnger FormatedMustafa Anwar50% (2)

- Condenser in Power PlantDokumen20 halamanCondenser in Power PlantPrabir Kumar PatiBelum ada peringkat

- Mine ClimateDokumen16 halamanMine ClimateRehal JandialBelum ada peringkat

- Preventive Maintenance Scope-TG and BOPDokumen9 halamanPreventive Maintenance Scope-TG and BOPGmail44Belum ada peringkat

- Coal WasheryDokumen2 halamanCoal WasheryGmail44Belum ada peringkat

- VFD - A Solution To Energy CrisisDokumen4 halamanVFD - A Solution To Energy CrisisGmail44Belum ada peringkat

- Water Treatment - "Let's Water Passes, Not The Trashes"Dokumen8 halamanWater Treatment - "Let's Water Passes, Not The Trashes"Gmail44Belum ada peringkat

- SRK 2002Dokumen68 halamanSRK 2002JOSEBelum ada peringkat

- Tarifa de Precios - Junio 2013: General Catalogue 2013-2014Dokumen114 halamanTarifa de Precios - Junio 2013: General Catalogue 2013-2014Paulo SilvaBelum ada peringkat

- Curriculum For Bachelor of Science in Mechanical EngineeringDokumen13 halamanCurriculum For Bachelor of Science in Mechanical EngineeringCharo GironellaBelum ada peringkat

- Iswara 1.3 S (M) 92-03 Part No ListDokumen13 halamanIswara 1.3 S (M) 92-03 Part No ListNIKODOMEUSBelum ada peringkat

- Server and WSC Architecture Project ProposalDokumen21 halamanServer and WSC Architecture Project ProposalTahaBelum ada peringkat

- World Guide To: Low-Charge AmmoniaDokumen28 halamanWorld Guide To: Low-Charge AmmoniaCarlos Bravo100% (1)

- Mitsubishi Electric - Service Manual 0B378Dokumen36 halamanMitsubishi Electric - Service Manual 0B378jborg100% (1)

- VRF vs VAV Systems Energy ComparisonDokumen12 halamanVRF vs VAV Systems Energy ComparisonJuan Castro PeñaBelum ada peringkat

- PAC 3550 PRO Operating ManualDokumen19 halamanPAC 3550 PRO Operating ManualEnache CristianBelum ada peringkat

- ACMV Design Manual 5 Jan 05 R11Dokumen42 halamanACMV Design Manual 5 Jan 05 R11TienNguyenBelum ada peringkat

- Cre 6-14680 - J.C.M. 1650K & 1850K (ENG)Dokumen54 halamanCre 6-14680 - J.C.M. 1650K & 1850K (ENG)Ricardo Bilbao50% (2)

- HVAC Basics - ADokumen39 halamanHVAC Basics - AAbhik Bhattacharjee100% (1)

- HVAC Designing Training in HyderabadDokumen5 halamanHVAC Designing Training in Hyderabadfuturegen technologiesBelum ada peringkat

- MitsubishiDokumen8 halamanMitsubishiRaheem_ka67% (3)

- Igc 2-1 Work Place Hazards and Risk ControlDokumen142 halamanIgc 2-1 Work Place Hazards and Risk ControlKaren100% (2)

- Sac - WacDokumen4 halamanSac - WacAdyasa ChoudhuryBelum ada peringkat

- 980a1003 PDFDokumen48 halaman980a1003 PDFMichael DavenportBelum ada peringkat

- Traditional Mediterranean Architecture: Troglodyte HouseDokumen5 halamanTraditional Mediterranean Architecture: Troglodyte HousefofiBelum ada peringkat

- Comprensoras Altas GA 250Dokumen122 halamanComprensoras Altas GA 250Rubelinho Poma100% (1)

- New Trends in AcDokumen11 halamanNew Trends in AcNallathambiBelum ada peringkat

- Cat 1Dokumen20 halamanCat 1Shamsul ArefinBelum ada peringkat

- Desiccant Wheels for Air HumidificationDokumen11 halamanDesiccant Wheels for Air HumidificationSelvaraji MuthuBelum ada peringkat

- Outdoor Cabinet Air Conditioner Introduction: Shenzhen Envicool Technology Co., LTDDokumen5 halamanOutdoor Cabinet Air Conditioner Introduction: Shenzhen Envicool Technology Co., LTDGonzalo VegaBelum ada peringkat

- CS-G93KE Service ManualDokumen69 halamanCS-G93KE Service ManualchrsptaBelum ada peringkat

- PDF-fcuk-ctlg Fujitsu 2016-17 Catalogue Product Low-01Dokumen144 halamanPDF-fcuk-ctlg Fujitsu 2016-17 Catalogue Product Low-01Juan FernandezBelum ada peringkat

- Sumitomo Consumables Listing Parts GuideDokumen137 halamanSumitomo Consumables Listing Parts GuidesuriantoBelum ada peringkat

- R Series Air Compressor Operators ManualDokumen44 halamanR Series Air Compressor Operators Manualphalanges1972100% (2)

- Vertiv VRC Self-Contained IT Rack Cooling SystemDokumen8 halamanVertiv VRC Self-Contained IT Rack Cooling SystemnoneBelum ada peringkat

- Dryers, Fans Blowers, PumpsDokumen31 halamanDryers, Fans Blowers, PumpsJay Pee Zey100% (1)

- Split Unit Air Conditioner Technical ManualDokumen36 halamanSplit Unit Air Conditioner Technical ManualHANDOYO RBelum ada peringkat