Alkali-Silica Reaction in Concrete - From ELKEM

Diunggah oleh

ssi3kJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Alkali-Silica Reaction in Concrete - From ELKEM

Diunggah oleh

ssi3kHak Cipta:

Format Tersedia

Summary

When reactive aggregates

have to be used in construc-

tion,the addition of Elkem

Microsilicais a way of

reducing or eliminating the

expansion caused by alkali-

silica reaction (ASR,also

sometimes called AAR

Alkali Aggregate Reaction) in

concrete. ASR is a process

whereby alkali silicate gel

forms and afterwards

expands on absorption of

water.This expansion may

cause crack formation

throughout the entire volume

of concrete.In recent years

increasing attention has been

given to problems associated

with ASR. This is due to a

number of instances of ASR

attack and the identification

of reactive aggregates in many

countries.

Alkali-silica

reactions

ASR is a reaction between

alkalis,Na

2

O and K

2

O (found

in cement or added to the

concrete),and reactive,

siliceous mineral components

of the aggregates. There has

to be moisture present in the

concrete in order for the

reaction to take place. The

reaction product is an alkali-

silicate gel which on absorp-

tion of water will expand and

generate hydraulic stresses

which may cause cracking.

(Figure 1).

For ASR to take place

requires:

High alkali content of the

concrete,normally

contributed from the

cement,i.e.the cement has

to contain a sufficiently high

level of alkalis.An upper

limit of 3 kg of Na

2

O-

equivalent per m

3

is often

given in the literature as

sufficient to prevent attack.

Access to moisture,mini-

mum 75%RH is required.

Other factors which will

affect the ASR attack

include the amount of

reactive aggregates and the

grain size of the aggregates.

Elkem Microsilica will

suppress ASR as follows:

Elkem Microsilica will bind

free alkalis early,already in

the fresh or plastic

concrete. (Figure 2).

Elkem Microsilica will

reduce the permeability

of the concrete and thus

limit the penetration

of moisture or external

alkalis.

Elkem Microsilica allows a

reduction in the cement

content without affecting

the strength of the

concrete,thus the alkali

contribution from cement

can be reduced.

Elkem Microsilica

CONCRETE

C3-05

Properties

Alkali-Silica Reaction

Water and/ or alkalis

from the

surroundings, e.g.

from road salt

Diffusion of alkalis

in the pore system

from cement and

admixtures.

Reactive

aggregates

Transformation of

reactive aggregates

expansion

Diffusion of water

and alkalis into the

concrete.

Crack

formation

Three-legged

cracks

on the surface.

Cracks parallel

to the surface.

Fig.1 Schematic diagramof ASR attack.Fromreference (1)

C

o

n

c

e

n

t

r

a

t

i

o

n

o

f

K

+

-

i

o

n

s

.

M

o

l

/

l

OPC

OPC + 5% microsilica

OPC + 10% microsilica

OPC + 20% microsilica

Time (days)

Fig.2 Effect of microsilica on the alkali content in cement paste.

Fromreference (4)

C3-05 26.03.01 16:24 Side 1

Conclusions

The use of Elkem Microsilica

will help to suppress ASR

when added at a rate of 5 to

15 %of the cement weight.

(Figure 3).

A prime example of using

microsilica for ASR protection

is Iceland,where the entire

production of cement

contains 7 to

10 %microsilica in order to

reduce the ASR attack caused

by the combination of highly

reactive natural aggregates and

local high alkali cement.

(Figure 4).

Trial mixes to determine the

necessary level of microsilica

addition are recommended.

References

1.Comite Euro-Inter-

national du Beton,

Bulletin dInformation

No.166,24th Plenary

Session of CEB,Rotterdam,

June 1985

2. Asgeirson,Haraldur:

Cement and Concrete

Research,

Vol.16,pp.423-428,1986

3.Olafsson,Hkon,

Thaulow,Niels:

Nordtest Project

173-79,Teknologisk Institut,

Kbenhavn,1981

4.Diamond,Sidney:

Journal of American

Concrete Society,Vol.66,

No.5,1982

5.Spler,Birger (editor):

Betongens

Funksjons-dyktighet,

Rapport No.4;Kjemisk

Pvirkning,NTNF,1986

6.Parker, D.G.:

Report SA854/3C,

prepared for Elkem

Chemicals Ltd,1986

7.Hooton,R.D.:

Influence of Silica Fume

Replacement of Cement on

Physical Properties and

Resistance to Sulfate

Attack,Freezing and

Thawing,and Alkali Silica

Reactivity,ACI Materials

Journal,V.90,

No.2,pp.143-161

Elkem Microsilica

is a registered trademark and belongs to ElkemASA Materials

CONCRETE PROPERTIES JANUARY 2001 C3-05

E

x

p

a

n

s

i

o

n

0

/

0

Limits according to

Icelandic codes.

OPC

OPC + 7.5% microsilica

OPC + 10% microsilica

Age (years)

OPC + 5% microsilica

E

x

p

a

n

s

i

o

n

,

0

/

0

Control

5% Silica Fume

10% Silica Fume

15% Silica Fume

20% Silica Fume

ASTM C 618 Limit

0.020% at 14 Days

Time, days

Fig.3 Expansion of ASTM C 441 Pyrex mortar bars with various silica fume

contents.The alkali content of the control cement was 1.17%Na

2

O

equivalent (adapted fromHooton,1993)

Fig.4 Expansion in mortar prisms with Icelandic standard Portland cement

and Hvalfjord sand.Based on ref.(2)

The information given on this datasheet is based on manyyears of research and field experience and is accurate to the best knowledge of ElkemMaterials.

However, due to the numerous factors that can affect the performance of a concrete,with or without microsilica,

ElkemMaterials offers this information without guarantee and accepts no liabilityfor anydirect or indirect damage fromits use.

If further information or assistance is required,please contact your local representative or the office number given on this datasheet.

ElkemASA Materials

P.O.Box 8126 Vaagsbygd

N-4675 Kristiansand S.

NORWAY

Telephone: +47 38 01 75 00

Telefax: +47 38 01 49 70

e-mail:microsilica.materials@elkem.no

Internet: www.concrete.elkem.com w

w

w

.

f

-

t

r

y

k

k

.

n

o

C3-05 26.03.01 16:24 Side 2

Anda mungkin juga menyukai

- The end of concrete: Pros and cons of an unsuccesful technologyDari EverandThe end of concrete: Pros and cons of an unsuccesful technologyPenilaian: 1 dari 5 bintang1/5 (1)

- Carbon Nanotube Cement Composites - Early Results and Potential ApplicationsDokumen11 halamanCarbon Nanotube Cement Composites - Early Results and Potential ApplicationsChristina ChanBelum ada peringkat

- R&D Advances in Waterglass Sand TechnologiesDokumen5 halamanR&D Advances in Waterglass Sand Technologiesgorane1155Belum ada peringkat

- Elkem Iceland Heat RecoveryDokumen102 halamanElkem Iceland Heat RecoveryLuc MartelBelum ada peringkat

- Ductile Iron NodularityDokumen34 halamanDuctile Iron NodularitykarthikkandaBelum ada peringkat

- Durability of Clay Brick Masonry Walls Reviewed for Salt AttackDokumen18 halamanDurability of Clay Brick Masonry Walls Reviewed for Salt AttackKizito NathanBelum ada peringkat

- Nanosilica Improves Recycled Concrete AggregatesDokumen9 halamanNanosilica Improves Recycled Concrete AggregatesSanjeeva YedavalliBelum ada peringkat

- Novel magnesium phosphate cements with high early strength and antibacterial propertiesDokumen9 halamanNovel magnesium phosphate cements with high early strength and antibacterial propertiesma greBelum ada peringkat

- ARDEX Guide To Waterproofing Liquid Applied MembranesDokumen88 halamanARDEX Guide To Waterproofing Liquid Applied MembranesMoataz MedhatBelum ada peringkat

- Supplementary Cementing Materials Improve Concrete PropertiesDokumen47 halamanSupplementary Cementing Materials Improve Concrete PropertiesOgut Ke'ah100% (1)

- Polymer Impregnated Concrete - Uses, Properties of Polymers in ConcreteDokumen4 halamanPolymer Impregnated Concrete - Uses, Properties of Polymers in ConcretesahilkaushikBelum ada peringkat

- GeopolymerDokumen20 halamanGeopolymerAhmed TahaBelum ada peringkat

- Direct Tensile Test of ConcreteDokumen7 halamanDirect Tensile Test of ConcreteBunkun15100% (1)

- Handbook For The Identification of Alkali-Silica Re Activity in Highway Structures, Revised EditionDokumen25 halamanHandbook For The Identification of Alkali-Silica Re Activity in Highway Structures, Revised EditionTooma DavidBelum ada peringkat

- Chloride Ingress Seminar P 01 6Dokumen357 halamanChloride Ingress Seminar P 01 6cap300050% (2)

- CONCRETE Testing and ProblemsDokumen41 halamanCONCRETE Testing and Problemseunice19970315Belum ada peringkat

- Chloride Ion Diffusion Through Concrete and Test MethodsDokumen30 halamanChloride Ion Diffusion Through Concrete and Test Methodsrekcah ehtBelum ada peringkat

- Aerated Concrete Production Using Various Raw MaterialsDokumen5 halamanAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- Chloride Diffusion Coefficient CalculationDokumen1 halamanChloride Diffusion Coefficient CalculationYash DhabaliaBelum ada peringkat

- Properties of ConcreteDokumen27 halamanProperties of ConcreteEman AgiusBelum ada peringkat

- 201108-Eaf Dust Treatment For High Metal RecoveryDokumen10 halaman201108-Eaf Dust Treatment For High Metal RecoveryAgustine SetiawanBelum ada peringkat

- Micro Silica ConcreteDokumen50 halamanMicro Silica ConcreteShibinMohammedIqbalBelum ada peringkat

- Critical Chloride Content in Reinforced Concrete - Ueli AngstDokumen17 halamanCritical Chloride Content in Reinforced Concrete - Ueli AngstIvan Barrionuevo ABelum ada peringkat

- Microsilica and Nano Silica in Concrete MixturesDokumen25 halamanMicrosilica and Nano Silica in Concrete MixturesSwathi SvBelum ada peringkat

- Tyco UhpDokumen6 halamanTyco UhpalokBelum ada peringkat

- Powder Metallurgy ProcessDokumen9 halamanPowder Metallurgy ProcessYashvir SinghBelum ada peringkat

- ASR PresentationDokumen12 halamanASR PresentationmikecomninosBelum ada peringkat

- Shrinkage of ConcreteDokumen3 halamanShrinkage of Concretegmgoutam550Belum ada peringkat

- Effect of Pozzolanic Additives On Structure and Chemical Durability of ConcreteDokumen8 halamanEffect of Pozzolanic Additives On Structure and Chemical Durability of ConcreteRendotian AnugrahBelum ada peringkat

- Stone Sealer: Navigation SearchDokumen7 halamanStone Sealer: Navigation SearchJulius Mak'OderohBelum ada peringkat

- DURABLE CONCRETE STRUCTURESDokumen28 halamanDURABLE CONCRETE STRUCTURESmanu_696Belum ada peringkat

- A Review Paper On Graphene Modified CementDokumen9 halamanA Review Paper On Graphene Modified CementZunnun Bari PialBelum ada peringkat

- MgO - SiO2 - H2ODokumen12 halamanMgO - SiO2 - H2Oaemp2009100% (1)

- A Review Influence of Refractories On Steel Quality PDFDokumen20 halamanA Review Influence of Refractories On Steel Quality PDFBagas Prasetyawan Adi NugrohoBelum ada peringkat

- Corrosion MechanismsDokumen64 halamanCorrosion MechanismsRahul PandeyBelum ada peringkat

- 9 Standards and Specs - 1Dokumen16 halaman9 Standards and Specs - 1Mutundisavakadzi G-spot LocatorBelum ada peringkat

- How Concrete Has Evolved Over TimeDokumen37 halamanHow Concrete Has Evolved Over TimePradeepLokhandeBelum ada peringkat

- Bolted Conn. With Hot-Dip Galv. Steel Memb.Dokumen14 halamanBolted Conn. With Hot-Dip Galv. Steel Memb.PaulBelum ada peringkat

- Delayed Ettringite Formation in ConcreteDokumen1 halamanDelayed Ettringite Formation in ConcretemakhsmyBelum ada peringkat

- Chloride Resistance of Concrete: Factors and TestsDokumen37 halamanChloride Resistance of Concrete: Factors and TestsCarlos Augusto Sánchez Rondón100% (1)

- FIBRE REINFORCED CONCRETE STRENGTHDokumen11 halamanFIBRE REINFORCED CONCRETE STRENGTHsyedqumbar100% (1)

- Ib 39Dokumen19 halamanIb 39Rup JoshiBelum ada peringkat

- Concrete Block Pavements For RoadsDokumen7 halamanConcrete Block Pavements For RoadsSanjay Garg100% (1)

- Experimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Dokumen6 halamanExperimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Siddhesh Kamat Mhamai100% (2)

- A Study On Durability Properties of Geopolymer Concrete Using Flyash and GgbsDokumen13 halamanA Study On Durability Properties of Geopolymer Concrete Using Flyash and Ggbsbala rajuBelum ada peringkat

- SilicaDokumen29 halamanSilicaClintJanSumalpongBelum ada peringkat

- (BS EN 14487-2 - 2006) - Sprayed Concrete. ExecutionDokumen20 halaman(BS EN 14487-2 - 2006) - Sprayed Concrete. ExecutionAGNIVO RAY0% (1)

- Modelling the tensile behavior of plain concrete under flexural loadingDokumen7 halamanModelling the tensile behavior of plain concrete under flexural loadingAhmad MensaBelum ada peringkat

- Causes and Remedies of Blow Holes in SanDokumen33 halamanCauses and Remedies of Blow Holes in SanNikhil KumarBelum ada peringkat

- Industrial Waste Materials in ConcreteDokumen43 halamanIndustrial Waste Materials in ConcretejohnBelum ada peringkat

- Effect of Cracking On Corrosion of Steel in Concrete PDFDokumen12 halamanEffect of Cracking On Corrosion of Steel in Concrete PDFSteve NolaBelum ada peringkat

- Ceramics 1 MCG2361 2016Dokumen42 halamanCeramics 1 MCG2361 2016Jessica BarhomaBelum ada peringkat

- Portland-Cement Concrete Rheology and Work AbilityDokumen111 halamanPortland-Cement Concrete Rheology and Work AbilityRudiele SchankoskiBelum ada peringkat

- An Overview On The Influence of Various Factors On The Properties of Geopolymer Concrete Derived From Industrial By-ProductsDokumen26 halamanAn Overview On The Influence of Various Factors On The Properties of Geopolymer Concrete Derived From Industrial By-ProductsTaci AlvesBelum ada peringkat

- Effect of Type, Size, and Dosage of Nanosilica and Microsilica On Properties of Cement Paste and MortarDokumen8 halamanEffect of Type, Size, and Dosage of Nanosilica and Microsilica On Properties of Cement Paste and MortarChan NovBelum ada peringkat

- Low Carbon Stabilization and Solidification of Hazardous WastesDari EverandLow Carbon Stabilization and Solidification of Hazardous WastesDaniel C.W. TsangBelum ada peringkat

- 4.durability and Concrete CoverDokumen46 halaman4.durability and Concrete CoverNH PBelum ada peringkat

- Shrinkage Cracks - Causes - Preventive Measures and Repair MethodsDokumen8 halamanShrinkage Cracks - Causes - Preventive Measures and Repair MethodsDaud Hajibhai UnnadpotraBelum ada peringkat

- Installation of Mechanical Interlocking PaversDokumen12 halamanInstallation of Mechanical Interlocking PaversBobby OtienoBelum ada peringkat

- Concreting For Improved Speed and EfficiencyDokumen4 halamanConcreting For Improved Speed and Efficiencyssi3kBelum ada peringkat

- Origin of Mosque of CordobaDokumen150 halamanOrigin of Mosque of Cordobassi3kBelum ada peringkat

- Ceremonial-Urban Dynamic CairoDokumen137 halamanCeremonial-Urban Dynamic Cairossi3kBelum ada peringkat

- Earthquake Design Criteria For SubwaysDokumen10 halamanEarthquake Design Criteria For Subwaysnitinchavan30100% (2)

- Eurocode2 Commentary2008Dokumen168 halamanEurocode2 Commentary2008Claudia MárquezBelum ada peringkat

- Guide To Trench ExcavationsDokumen43 halamanGuide To Trench ExcavationsmlakkissBelum ada peringkat

- Code ExcavationDokumen115 halamanCode ExcavationHerschelSt100% (2)

- Deep Foundation Practice - BarrettesDokumen9 halamanDeep Foundation Practice - Barrettesssi3k100% (1)

- HA and HB Bridge Loading Ex..Dokumen2 halamanHA and HB Bridge Loading Ex..ssi3kBelum ada peringkat

- Strength Development and Prediction of GGBS ConcreteDokumen9 halamanStrength Development and Prediction of GGBS Concretessi3kBelum ada peringkat

- Self Compacting Concrete Offers Design PotentialDokumen4 halamanSelf Compacting Concrete Offers Design Potentialssi3kBelum ada peringkat

- ATS 6 Water Resisting AdmixturesDokumen3 halamanATS 6 Water Resisting Admixturesssi3kBelum ada peringkat

- Ternary Concrete Mixtures With Slag Cement (GGBS)Dokumen2 halamanTernary Concrete Mixtures With Slag Cement (GGBS)ssi3k0% (1)

- Concrete DurabilityDokumen3 halamanConcrete Durabilityssi3kBelum ada peringkat

- Concrete Applications Using GGBSDokumen1 halamanConcrete Applications Using GGBSssi3kBelum ada peringkat

- Ethanol Production Techniques ReviewDokumen14 halamanEthanol Production Techniques ReviewmihaibiancaBelum ada peringkat

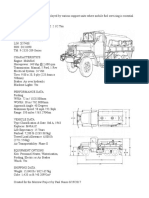

- M49A2CDokumen2 halamanM49A2CArmySGTBelum ada peringkat

- Technology Absorption - AdaptationDokumen5 halamanTechnology Absorption - AdaptationRohit BhandariBelum ada peringkat

- Aerospace Coatings Thermal Insulating EpoxyDokumen13 halamanAerospace Coatings Thermal Insulating EpoxydavidmuttathBelum ada peringkat

- Greenheck CueCube Exhaust Fan Spec SheetDokumen12 halamanGreenheck CueCube Exhaust Fan Spec SheetD2O Yash MathurBelum ada peringkat

- APMRG1 Series: Packaged Air ConditionersDokumen32 halamanAPMRG1 Series: Packaged Air Conditionerszaid jamaluBelum ada peringkat

- Car Park Jet FanDokumen14 halamanCar Park Jet FanYan Aung100% (1)

- Electrolysis PDFDokumen37 halamanElectrolysis PDFHarini SridharanBelum ada peringkat

- COMPOSITE WING OPTIMALIZATION USING FEM ANALYSES SYSTEMS by Miroslav Spišák - Peter MalatinDokumen3 halamanCOMPOSITE WING OPTIMALIZATION USING FEM ANALYSES SYSTEMS by Miroslav Spišák - Peter MalatinVesa RäisänenBelum ada peringkat

- Shell Morlina s2 B 320Dokumen4 halamanShell Morlina s2 B 320Aep HidayatBelum ada peringkat

- Annexure IIIDokumen674 halamanAnnexure IIItakari divisionBelum ada peringkat

- Piping Engineering Man-Hour EstimateDokumen16 halamanPiping Engineering Man-Hour EstimatekamlBelum ada peringkat

- Sodium Chlorate Civilizations EndDokumen3 halamanSodium Chlorate Civilizations EndlunicyBelum ada peringkat

- Lecture 5 CondenserDokumen37 halamanLecture 5 CondenserWalid MohammedBelum ada peringkat

- Section 12 - Welding Consumables - Stainless Steel266 - 27357Dokumen106 halamanSection 12 - Welding Consumables - Stainless Steel266 - 27357getgateclose100% (1)

- Module 4 Introduction To Electrical Conductors Wiring Techniques and Schematic Reading Part1Dokumen10 halamanModule 4 Introduction To Electrical Conductors Wiring Techniques and Schematic Reading Part1Jan Renn ArleBelum ada peringkat

- Sunsai Pharma Equipments Pvt. ltd-1Dokumen2 halamanSunsai Pharma Equipments Pvt. ltd-1Sunsai VasaiBelum ada peringkat

- HarcoLoorDesign Catalog 2012Dokumen188 halamanHarcoLoorDesign Catalog 2012Rozze AngelBelum ada peringkat

- Module Heat - Answer SchemeDokumen27 halamanModule Heat - Answer SchemeCart KartikaBelum ada peringkat

- Air Conditioning Comfort and Cooling Load AnalysisDokumen56 halamanAir Conditioning Comfort and Cooling Load AnalysisNazia ZamanBelum ada peringkat

- Cement Practice QuestionsDokumen2 halamanCement Practice QuestionsSureshKonamBelum ada peringkat

- StoneDokumen17 halamanStoneank25795100% (1)

- Irc 43 2015Dokumen65 halamanIrc 43 2015rajpootsaurabhBelum ada peringkat

- CAESAR II Pipe Stress Analysis GuideDokumen37 halamanCAESAR II Pipe Stress Analysis GuideEko Idris Hutagaol100% (1)

- Welding Quality and Structural Life Enhancement of High Strength Low Alloy Steel S460Dokumen16 halamanWelding Quality and Structural Life Enhancement of High Strength Low Alloy Steel S460Noridzwan Nordin0% (1)

- Center LatheDokumen32 halamanCenter Lathesure516vBelum ada peringkat

- Esquema Inverter FujiDokumen18 halamanEsquema Inverter FujiRicardo Nicolau WerlangBelum ada peringkat

- 3463-Article Text PDF-7221-1-10-20130718Dokumen25 halaman3463-Article Text PDF-7221-1-10-20130718Mátyás DalnokiBelum ada peringkat

- Calculations of Creep and Shrinkage Effects for an Example Bridge with Precast Concrete GirdersDokumen11 halamanCalculations of Creep and Shrinkage Effects for an Example Bridge with Precast Concrete GirdersMahmood MuftiBelum ada peringkat

- CAT6 Modular Plug Installation GuideDokumen2 halamanCAT6 Modular Plug Installation GuideAndrés CisnerosBelum ada peringkat